ASTM D4096-91(2003)

(Test Method)Standard Test Method for Determination of Total Suspended Particulate Matter in the Atmosphere (High-Volume Sampler Method)

Standard Test Method for Determination of Total Suspended Particulate Matter in the Atmosphere (High-Volume Sampler Method)

SIGNIFICANCE AND USE

The Hi-Vol sampler is commonly used for the collection of the airborne particulate component of the atmosphere. Some physical and chemical parameters of the collected particulate matter are dependent upon the physical characteristics of the collection system and the choice of filter media. A variety of options available for the Hi-Vol sampler give it broad versatility and allow the user to develop information about the size and quantity of airborne particulate material and, using subsequent chemical analytical techniques, information about the chemical properties of the particulate matter.

This test method presents techniques that when uniformly applied, provide measurements suitable for intersite comparisons.

This test method measures the atmosphere presented to the sampler with good precision, but the actual dust levels in the atmosphere can vary widely from one location to another. This means that sampler location may be of paramount importance, and may impose far greater variability of results than any lack of precision in the method of measurement. In particular, localized dust sources may exert a major influence over a very limited area immediately adjacent to such sources. Examples include unpaved streets, vehicle traffic on roadways with a surface film of dust, building demolition and construction activity, or nearby industrial plants with dust emissions. In some cases, dust levels measured close to such sources may be several times the community wide levels exclusive of such localized effects (see Practice D 1357).

SCOPE

1.1 This test method provides for sampling a large volume of atmosphere, 1600 to 2400 m3 [55 000 to 85 000 ft 3], by means of a high flow-rate vacuum pump at a rate of 1.13 to 1.70 m3/min [40 to 60 ft3/min] (1, 2, 3 and 4).

1.2 This flow rate allows suspended particles having diameters of less than 100 m (stokes equivalent diameter) to be collected. However, the collection efficiencies for particles larger than 20 m decreases with increasing particle size and it varies widely with the angle of the wind with respect to the roof ridge of the sampler shelter and with increasing speed (). When glass fiber filters are used, particles within the size range of 100 to 0.1 m diameters or less are ordinarily collected.

1.3 The upper limit of mass loading will be determined by plugging of the filter medium with sample material, which causes a significant decrease in flow rate (see ). For very dusty atmospheres, shorter sampling periods will be necessary. The minimum amount of particulate matter detectable by this method is 3 mg (95 % confidence level). When the sampler is operated at an average flow rate of 1.70 m3/min [60 ft3/min] for 24 h, this is equivalent to 1 to 2 g/m 3 (3).

1.4 The sample that is collected may be subjected to further analyses by a variety of methods for specific constituents.

1.5 Values stated in SI units shall be regarded as the standard. Inch-pound units are shown for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4096–91(Reapproved 2003)

Standard Test Method for

Determination of Total Suspended Particulate Matter in the

Atmosphere (High–Volume Sampler Method)

This standard is issued under the fixed designation D 4096; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method provides for sampling a large volume 2.1 ASTM Standards:

3 3

of atmosphere, 1600 to 2400 m [55 000 to 85 000 ft ], by D 1356 Terminology Relating to Sampling and Analysis of

means of a high flow-rate vacuum pump at a rate of 1.13 to Atmospheres

3 3 2

1.70 m /min [40 to 60 ft /min] (1, 2, 3 and 4). D 3631 Test Methods for Measuring Surface Atmospheric

1.2 This flow rate allows suspended particles having diam- Pressure

eters of less than 100 µm (stokes equivalent diameter) to be E1 Specification forASTM Liquid-in-Glass Thermometers

collected. However, the collection efficiencies for particles 2.2 Other Documents:

larger than 20 µm decreases with increasing particle size and it EPA-600/9-76-005 Quality Assurance Handbook for Air

varies widely with the angle of the wind with respect to the Pollution Measurement Systems, Vol I, Principles (De-

roof ridge of the sampler shelter and with increasing speed (5). cember 1984 Rev.)

When glass fiber filters are used, particles within the size range EPA-600/4-77-027a Quality Assurance Handbook for Air

of 100 to 0.1 µm diameters or less are ordinarily collected. Pollution Measurement Systems, Vol II, Ambient Air

1.3 The upper limit of mass loading will be determined by Specific Methods

plugging of the filter medium with sample material, which

3. Terminology

causes a significant decrease in flow rate (see 6.4). For very

3.1 Definitions—For definitions of other terms used in this

dusty atmospheres, shorter sampling periods will be necessary.

The minimum amount of particulate matter detectable by this test method, refer to Terminology D 1356.

3.2 Descriptions of Terms:

method is 3 mg (95 % confidence level). When the sampler is

3 3

3.2.1 absolute filter—a filter or filter medium of ultra-high

operatedatanaverageflowrateof1.70m /min[60ft /min]for

24 h, this is equivalent to 1 to 2 µg/m (3). collection efficiency for very small particles (submicrometre

size)sothatessentiallyallparticlesofinterestorofconcernare

1.4 The sample that is collected may be subjected to further

analyses by a variety of methods for specific constituents. collected. Commonly, the efficiency is in the region of 99.95 %

or higher for a standard aerosol of 0.3-µm diameter (see

1.5 Values stated in SI units shall be regarded as the

standard. Inch-pound units are shown for information only. Practice D 2986).

3.2.2 Hi-Vol (The High-Volume Air Sampler)—a device for

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the sampling large volumes of an atmosphere, collection of the

contained particulate matter by filtration, and consisting of a

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- high-capacity air mover, a filter to collect suspended particles,

and means for measuring, or controlling, or both, the flow rate.

bility of regulatory limitations prior to use.

3.2.3 primary flow-rate standard—a device or means of

measuring flow rate based on direct primary observations, such

as time and physical dimensions.

1 3

This test method is under the jurisdiction of ASTM Committee D22 on Air For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Quality and is the direct responsibility of Subcommittee D22.03 on Ambient contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Atmospheres and Source Emissions. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved April 10, 2003. Published June 2003. Originally the ASTM website.

e1 4

approved in 1982. Last previous edition approved in 1997 as D 4096 – 91 (1997) . Available from U.S. Environmental Protection Agency, Environmental Moni-

The boldface numbers in parentheses refer to the list of references at the end of toringSystemsLaboratory,QualityAssuranceDivision,ResearchTrianglePark,NC

this practice. 27711. Attn: Distribution Record System.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4096–91 (2003)

3.2.4 secondary flow-rate standard—Aflow-rate-measuring This means that sampler location may be of paramount

device, such as an orifice meter, that has been calibrated importance, and may impose far greater variability of results

against a primary standard. than any lack of precision in the method of measurement. In

3.2.5 spirometer—a displacement gasometer consisting of particular, localized dust sources may exert a major influence

an inverted bell resting upon or sealed by liquid (or other over a very limited area immediately adjacent to such sources.

means) and capable of showing the amount of gas added to or Examples include unpaved streets, vehicle traffic on roadways

withdrawnfromthebellbythedisplacement(riseorfall)ofthe with a surface film of dust, building demolition and construc-

bell. tion activity, or nearby industrial plants with dust emissions. In

3.2.6 working flow-rate standard—a flow rate measuring some cases, dust levels measured close to such sources may be

device, such as an orifice meter, that has been calibrated several times the community wide levels exclusive of such

against a secondary flow-rate standard. The working flow-rate localized effects (see Practice D 1357).

standard is used to calibrate a flow measuring or flow rate

indicating instrument.

6. Interferences

3.2.7 constant flow high-volume sampler—a high volume

6.1 Large extraneous objects, such as insects, may be swept

sampler that is equipped with a constant flow control device.

into the filter and become weighed unnoticed.

6.2 Liquid aerosols, such as oil mists and fog droplets, are

4. Summary of Test Method

retained by the filter. If the amount of liquid so collected is

4.1 This test method describes typical equipment, opera-

sizable, the filter can become wet and its function and mass

tional procedures, and a means of calibration of the equipment

impaired.

using an orifice flowrate meter. (See also Annex A1.)

6.3 Any gaseous or vaporous constituent of the atmosphere

4.2 Air is drawn into a covered housing and through a filter

under test that is reactive with or sorptive upon the filter or its

by means of a high-flow-rate air mover, so that particulate

collected matter will be retained and weighed as particulate

material collects on the filter surface.

matter.

4.3 The amount of particulate matter accumulated on the

6.4 As the filter becomes loaded with collected matter, the

filter over a specified period of time is measured by weighing

sampling rate is reduced. If a significant drop in flow rate

a preweighed filter after exposure.The flow rate of air sampled

occurs, the average of the initial and final flow rate calculated

is measured over the test period. The result is expressed in

in 10.1 will not give an accurate estimate of total flow during

termsofparticulatemasscollected(orloading)perunitvolume

the sampling period. The magnitude of such errors will depend

of air sampled, usually as micrograms per cubic metre (µg/m ).

on the amount of reduction of airflow rate and on the variation

The volume of air sampled is recorded by measurement of the

of the mass concentration of dust with time during the 24-h

device flow rate(s).

sampling period. As an approximate guideline, any sample

4.4 The volume of air sampled is determined by means of a

should be suspect if the final flow rate is less than one half the

flow-rate indicator. The instrument flow-rate indicator is cali-

initial rate. A continuous record of flow rate will indicate the

brated against a reference orifice meter. The latter is a working

occurrence of this problem, or a constant-flow high-volume

standardwhich,inturn,hasbeencalibratedagainstasecondary

sampler may be used to eliminate the problem.

flow meter certified by the U.S. National Institute of Standards

6.5 The possibility of power failure or voltage change

and Technology.

during the test period would lead to an error, depending on the

4.5 Airborne particulate matter retained on the filter may be

extentandtimedurationofsuchfailure.Acontinuousrecordof

examined or analyzed by a variety of methods. Specific

flow rate is desirable.

procedures are not included in this method but are the subject

6.6 Thepassiveloadingofthefilterthatcanoccurifitisleft

of separate standard methods.

in place for any time prior to or following a sampling period

can introduce significant error. For unattended operation, a

5. Significance and Use

sampler equipped with shutters shall be used.

5.1 The Hi-Vol sampler is commonly used for the collection

6.7 If two or more samplers are used at a given location,

of the airborne particulate component of the atmosphere. Some

they should be placed at least2m[6ft] apart so that one

physical and chemical parameters of the collected particulate

sampler will not affect the results of an adjacent sampler.

matter are dependent upon the physical characteristics of the

6.8 Wind tunnel studies have shown significant possible

collection system and the choice of filter media. A variety of

sampling errors as a function of sampler orientation in atmo-

options available for the Hi-Vol sampler give it broad versa-

spheres containing high relative concentrations of large par-

tility and allow the user to develop information about the size

ticles (5).

and quantity of airborne particulate material and, using subse-

6.9 Metal dusts from motors, especially copper, may sig-

quent chemical analytical techniques, information about the

nificantly contaminate samples under some conditions.

chemical properties of the particulate matter.

6.10 Under some conditions, atmospheric SO and NO

2 x

5.2 This test method presents techniques that when uni-

may interfere with the total mass determination (6).

formly applied, provide measurements suitable for intersite

comparisons.

7. Apparatus

5.3 This test method measures the atmosphere presented to

the sampler with good precision, but the actual dust levels in 7.1 The essential features of a typical high-volume sampler

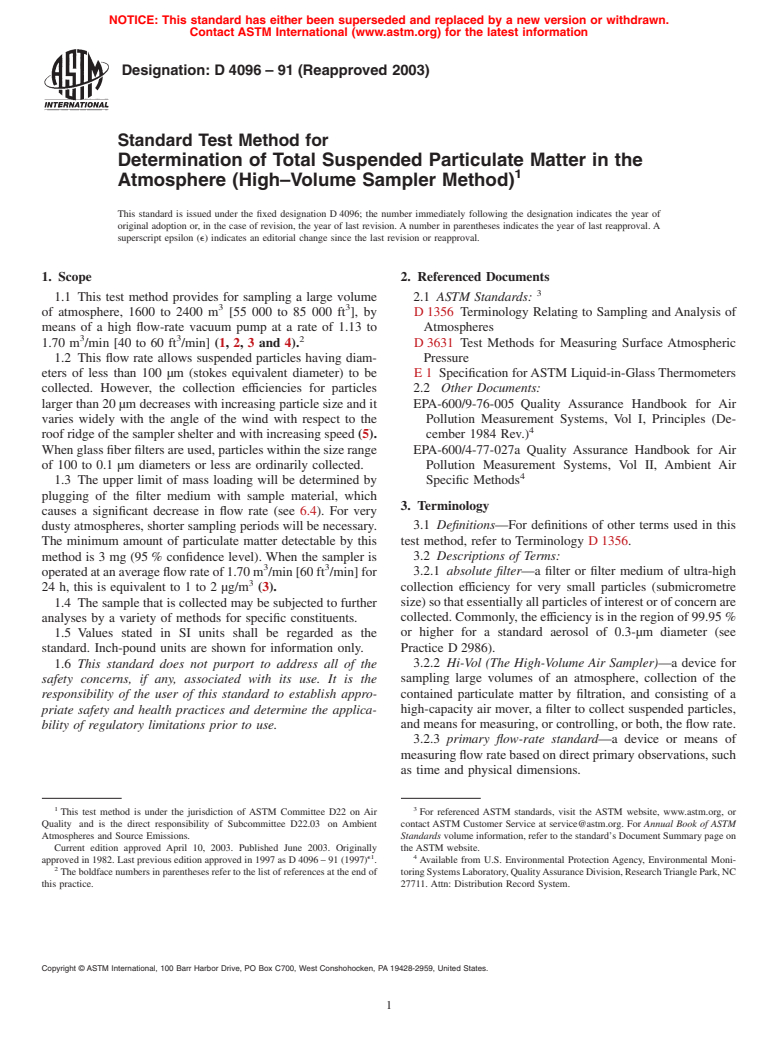

the atmosphere can vary widely from one location to another. are shown in the diagram of Fig. 1 and Fig. 2. It is a compact

D4096–91 (2003)

7.9 Differential Manometer, capable of measuring to 4 kPa

[40 mm Hg].

8. Reagents and Materials

8.1 Filter Medium:

8.1.1 In general, the choice of a filter medium will depend

on the purpose of the test. For any given standard test method

the appropriate medium will be specified. However, it is

important to be aware of certain filter characteristics that can

affect selection and use.

8.1.2 Glass-Fiber Filter Medium—This type is most widely

used for determination of mass loading. Weight stability with

respect to moisture is an attractive feature. High-efficiency or

absolute types are preferred and will collect all airborne

particles of practically every size and description. The follow-

ing characteristics are typical:

Fiber content All-glass-usually mixed sizes

Binder Below 5 % (zero for binderless types)

Thickness Approximately 0.5 mm

Pinholes None

DOP smoke test (Practice 0.05 % penetration, 981 Pa [100 mm of water]

D 2986) at 8.53 m/min [28 ft/min]

NOTE 1—The clearance area between the main housing and the roof at

2 2

its closest point should be 580.5 6 129.0 cm [90 6 20 in. ]. The main

Particulate matter collected on glass-fiber medium can be

housing should be rectangular, with dimensions of about 290 by 360 mm

analyzed for many constituents. If chemical analysis is con-

[11 ⁄2 by 14 in.].

templated binderless filters should be used. It must be borne in

FIG. 1 Assembled Sampler and Shelter

mind, however, that glass is a commercial product generally

containing test-contaminating materials. The high ratio of

unit consisting of a protective housing, an electric motor-

surface area to glass volume permits extraction of such

driven, high-speed, high-volume air mover, a filter holder

contaminants, especially if strong reagents are employed.

capable of supporting a 203 by 254-mm [8 by 10-in.] filter at

8.1.3 Silica Fiber Filters—Where it may be required or

the forward or entrance end, and at the exit end, means for

desirable to use a mineral fiber filter, which may later be

either indicating or controlling the air flow rate, or both, over

extracted by strong reagents, silica fiber filters can be used.

3 3

the range of 1.13 to 1.70 m /min [40 to 60 ft /min]. Designs

Such fibers are usually made by leaching glass fibers with

also exist in which a flow controller is located between the

strong mineral acids followed by washing with deionized

filter and the blower. For unattended operation, a sampler

water. The fibers are rather weak but can be formed into filter

equipped with shutters to protect the filter is required.

sheets using little or no binder. These filters are commercially

7.2 A calibrator kit is required. This contains a working

available (7).

flow-ratestandardofappropriaterangeintheformofanorifice

8.1.4 Cellulose Papers—For some purposes it is desirable

with its own calibration curve. The kit includes also a set of

to collect airborne particles on cellulose fiber filters. Low-ash

five flow-control plates. These kits are available from most

papers are especially useful where the filter is to be destroyed

supply houses that deal in apparatus for air sampling and

by ignition or chemical digestion. However, these papers have

analysis.

higher flow resistance (lower sampling rate) and have been

7.3 A large desiccator or air conditioned room is required

reported to have much poorer collection efficiency than the

for filter conditioning, storage, and weighing. Filters must be

glassfibermedia(8).Furthermore,celluloseisverysensitiveto

stored and conditioned at a temperature of 15 to 27°C and a

moisture conditions and even with very careful conditioning

relative humidity between 0 and 50 %.

before and after sampling it is difficult to make an accurate

7.4 An analytical balance capable of reading to 0.1 mg, and

weighingofthecollectedparticles.Itisusuallynecessarytodo

havingacapacityofatleast5gisnecessary.Itisverydesirable

the weighing with the filter enclosed in a lightweight metal can

to have a weighing chamber of adequate size with a support

with a tight lid.

tha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.