ASTM D8366-21

(Specification)Standard Specification for Extruded and Compression Molded Shapes Made from Unfilled Poly(Vinylidene Fluoride) PVDF

Standard Specification for Extruded and Compression Molded Shapes Made from Unfilled Poly(Vinylidene Fluoride) PVDF

SCOPE

1.1 This specification covers the requirements and test methods for the material, dimensions, workmanship, and the properties of extruded sheet, rod and tubular bar manufactured from unfilled PVDF.

1.2 This specification covers the requirements and test methods for the material, dimensions, workmanship, and the properties of extruded and compression molded shapes manufactured from unfilled PVDF.

1.3 The properties included in this specification are those required for shapes made from PVDF polymers. Requirements necessary to identify particular characteristics of the shape are included in Section 5.

1.4 This specification allows for the use of up to 20 % process regrind and reprocessed plastic, total, and of uncontaminated quality.

1.5 The values stated in English Units are to be regarded as the standard in all property and dimensional tables. For reference purposes, SI units are also included.

1.6 The following safety hazards caveat pertains only to the test method or test methods described in this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D8366 −21

Standard Specification for

Extruded and Compression Molded Shapes Made from

1

Unfilled Poly(Vinylidene Fluoride) PVDF

This standard is issued under the fixed designation D8366; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This specification covers the requirements and test

D256 Test Methods for Determining the Izod Pendulum

methods for the material, dimensions, workmanship, and the

Impact Resistance of Plastics

properties of extruded sheet, rod and tubular bar manufactured

D618 Practice for Conditioning Plastics for Testing

from unfilled PVDF.

D638 Test Method for Tensile Properties of Plastics

1.2 This specification covers the requirements and test

D790 Test Methods for Flexural Properties of Unreinforced

methods for the material, dimensions, workmanship, and the

and Reinforced Plastics and Electrical Insulating Materi-

properties of extruded and compression molded shapes manu-

als

factured from unfilled PVDF.

D792 Test Methods for Density and Specific Gravity (Rela-

tive Density) of Plastics by Displacement

1.3 The properties included in this specification are those

D883 Terminology Relating to Plastics

required for shapes made from PVDF polymers. Requirements

D1600 TerminologyforAbbreviatedTermsRelatingtoPlas-

necessary to identify particular characteristics of the shape are

tics

included in Section 5.

D3222 Specification for Unmodified Poly(Vinylidene Fluo-

1.4 This specification allows for the use of up to 20 %

ride) (PVDF) Molding Extrusion and Coating Materials

process regrind and reprocessed plastic, total, and of uncon-

D3418 Test Method for Transition Temperatures and En-

taminated quality.

thalpies of Fusion and Crystallization of Polymers by

Differential Scanning Calorimetry

1.5 The values stated in English Units are to be regarded as

D3835 Test Method for Determination of Properties of

the standard in all property and dimensional tables. For

Polymeric Materials by Means of a Capillary Rheometer

reference purposes, SI units are also included.

D3892 Practice for Packaging/Packing of Plastics

1.6 The following safety hazards caveat pertains only to the

D4000 Classification System for Specifying Plastic Materi-

testmethodortestmethodsdescribedinthisspecification. This

als

standard does not purport to address all of the safety concerns,

D5575 Classification System for Copolymers of Vinylidene

if any, associated with its use. It is the responsibility of the user

Fluoride (VDF) with Other Fluorinated Monomers

of this standard to establish appropriate safety, health, and

environmental practices and determine the applicability of

3. Terminology

regulatory limitations prior to use.

3.1 Definitions:

1.7 This international standard was developed in accor-

3.1.1 For definitions of terms used in this specification and

dance with internationally recognized principles on standard-

associated with plastics issues refer to the terminology con-

ization established in the Decision on Principles for the

tained in Terminology D883.

Development of International Standards, Guides and Recom-

3.2 Definitions of Terms Specific to This Standard:

mendations issued by the World Trade Organization Technical

3.2.1 copolymer, n—a polymer made by the reaction of two

Barriers to Trade (TBT) Committee.

or more different monomers with units of more than one kind.

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

2

and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Materi- For referenced ASTM standards, visit the ASTM website, www.astm.org, or

als. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved April 1, 2021. Published April 2021. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

D8366-21. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8366−21

3.2.2 homopolymer, n—a polymeric molecule in which one 4.2.1 ThePVDFshapeproductcanbecategorizedbyshape,

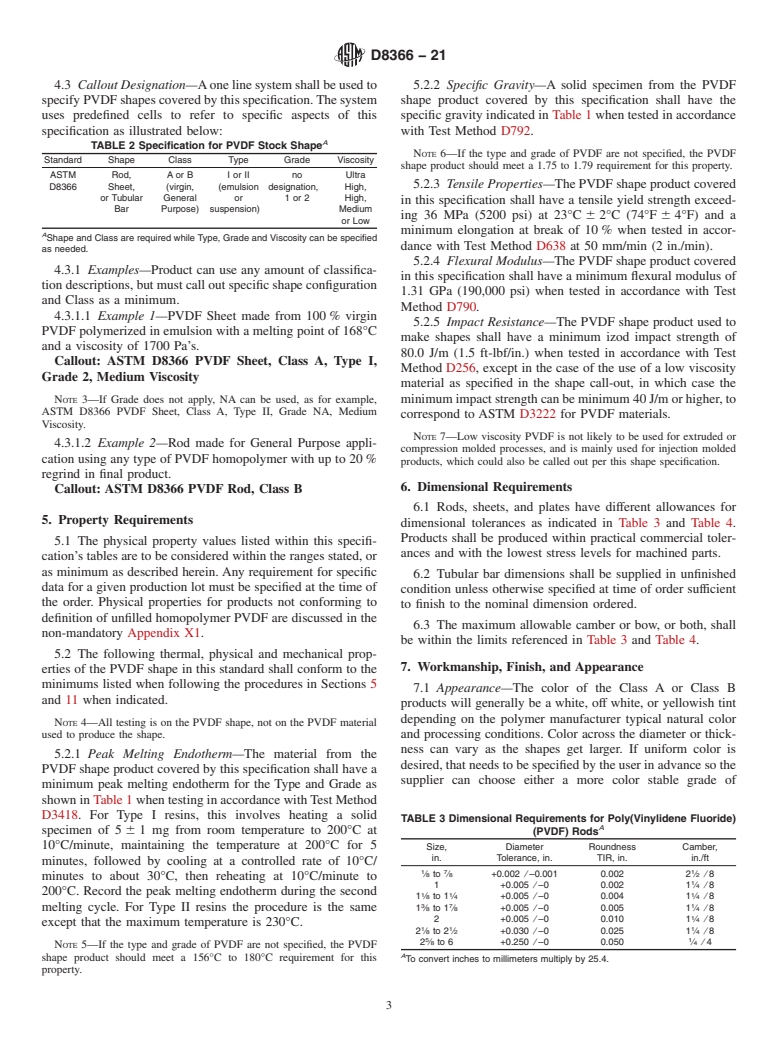

type of chemical repeat unit or monomer is repeated many class, type, grade (if applicable), and viscosity, as listed in

times to produce the final macromolecule. Table1.WhiletheuseofshapeandclasstodescribethePVDF

shape product are mandatory, type, grade and viscosity are

3.2.3 polyvinylidene fluoride (PVDF), n—a semi-crystalline

optional.

polym

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.