ASTM A914/A914M-16

(Specification)Standard Specification for Steel Bars Subject to Restricted End-Quench Hardenability Requirements

Standard Specification for Steel Bars Subject to Restricted End-Quench Hardenability Requirements

ABSTRACT

This specification covers hot-worked alloy and carbon-boron steels designed to attain restricted depth of hardening in the end-quench test. These steel compositions are identified by the suffix letter “RH” added to the conventional grade number. The steel shall be made by one or more of the following primary processes: open-hearth, basic-oxygen, or electric furnace. The primary melting may incorporate separate degassing or ladle refining and may be followed by secondary melting using electroslag remelting or vacuum arc remelting. Where secondary melting is employed, the heat shall be defined as all the ingots remelted from a single primary heat. Immediately after hot working, the bars shall be allowed to cool when necessary to a temperature below the critical range under suitable conditions, to prevent injury by too rapid cooling. The steel shall have an austenitic grain size of five to eight. The grain structure shall be considered satisfactory when a minimum of 70% of the rated grains are within the specified size limits. Hardenability values specified are based on fine-grain steels and are not applicable to coarse-grain steel. All forged and rolled hardenability test specimens must be normalized prior to testing. Cast specimens need not be normalized.

SCOPE

1.1 This specification covers hot-worked alloy and carbon-boron steels designed to attain restricted depth of hardening in the end-quench test. These steel compositions are identified by the suffix letter “RH” added to the conventional grade number.

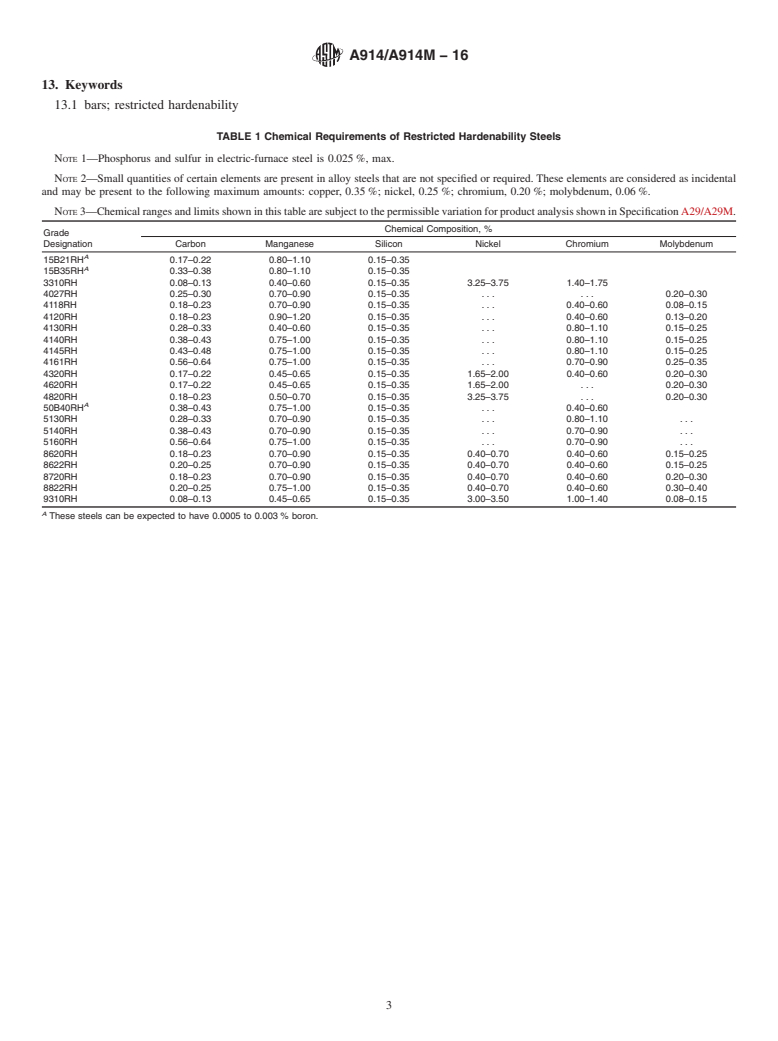

1.2 In general, steels with restricted hardenability (RH steels) will exhibit a hardness range not greater than 5 HRC at the initial position on the end-quench hardenability bar and not greater than 65 % of the hardness range for standard H-band steels (Specification A304) in the inflection region. Generally the restricted hardenability band follows the middle of the corresponding standard H-band. An example of the RH band compared with the H band is given for Grade 4140 in Fig. 1.

1.2.1 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This specification is expressed in both inch-pound units and SI units. However, the material will be supplied to inch-pound units unless the purchase order specifies the “M” specification designation.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A914/A914M −16

Standard Specification for

Steel Bars Subject to Restricted End-Quench Hardenability

1

Requirements

This standard is issued under the fixed designationA914/A914M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope* 2.2 SAE Standards:

J 406 Methods of Determining Hardenability of Steels

1.1 This specification covers hot-worked alloy and carbon-

J 1268 Hardenability Bands for Carbon and Alloy H Steels

boron steels designed to attain restricted depth of hardening in

J 1868 Restricted Hardenability Bands for Selected Alloy

the end-quench test. These steel compositions are identified by

Steels

the suffix letter “RH” added to the conventional grade number.

1.2 In general, steels with restricted hardenability (RH

3. Terminology

steels) will exhibit a hardness range not greater than 5 HRC at

3.1 Definitions of Terms Specific to This Standard:

the initial position on the end-quench hardenability bar and not

3.1.1 hardenability—the relative ability of a steel to harden

greater than 65 % of the hardness range for standard H-band

under heat treatment becomes apparent in the degree to which

steels (Specification A304) in the inflection region. Generally

the material hardens when quenched at different cooling rates.

the restricted hardenability band follows the middle of the

3.1.1.1 Discussion—Hardenability is measured

corresponding standard H-band. An example of the RH band

quantitatively, usually by noting the extent or depth of hard-

compared with the H band is given for Grade 4140 in Fig. 1.

ening of a standard size and shape test specimen in a

1.2.1 ThevaluesstatedineitherSIunitsorinch-poundunits

standardized quench. In the end-quench test the depth of

are to be regarded separately as standard. The values stated in

hardening is the distance along the specimen from the

each system may not be exact equivalents; therefore, each

quenched end to a given hardness.

system shall be used independently of the other. Combining

values from the two systems may result in non-conformance

4. Ordering Information

with the standard.

4.1 Orders for material under this specification should

1.3 This specification is expressed in both inch-pound units

include the following information, in proper sequence:

and SI units. However, the material will be supplied to

4.1.1 Quantity (weight),

inch-pound units unless the purchase order specifies the “M”

4.1.2 Name of material (alloy or carbon-boron steel),

specification designation.

4.1.3 Cross-sectional shape,

4.1.4 Size,

2. Referenced Documents

4.1.5 Length,

2

2.1 ASTM Standards:

4.1.6 Grade,

A29/A29M SpecificationforGeneralRequirementsforSteel

4.1.7 End-quenched hardenability (see Section 9),

Bars, Carbon and Alloy, Hot-Wrought

4.1.8 Report of heat analysis, if desired (see Section 7),

A255 Test Methods for Determining Hardenability of Steel

4.1.9 Special straightness, if required,

A304 Specification for Carbon andAlloy Steel Bars Subject

4.1.10 ASTM designation and date of issue, and

to End-Quench Hardenability Requirements

4.1.11 End use or special requirements.

E112 Test Methods for Determining Average Grain Size

NOTE 1—A typical ordering description is as follows: 10 000 lb, alloy

bars, round, 4.0-in. diameter by 10 ft, Grade 4140RH, heat analysis

1

required,completehardenabilitydatarequired,ASTMAXXX,[AXXXM]

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee dated _____ worm gear.

A01.15 on Bars.

4.2 The purchaser shall specify the desired grade, including

Current edition approved Dec. 1, 2016. Published December 2016. Originally

the suffix letters “RH,” in accordance with Table 1.

approved in 1992. Last previous edition approved in 2011 as A914/

A914M - 92(2011). DOI: 10.1520/A0914_A0914M-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from SAE International (SAE), 400 Commonwealth Dr.,Warrendale,

the ASTM website. PA 15096, http://www.sae.org.

*A Summary of Changes section appears at the end of this standard

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

1

---------------------- Page: 1 ----------------------

A914/A914M−16

4.3 Band limits are shown graphically and as tabulations in Where secondary melting is employed, the heat shall be

Figs. 2-23, inclusive. For specification purposes, one

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A914/A914M − 92 (Reapproved 2011) A914/A914M − 16

Standard Specification for

Steel Bars Subject to Restricted End-Quench Hardenability

1

Requirements

This standard is issued under the fixed designation A914/A914M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This specification covers hot-worked alloy and carbon-boron steels designed to attain restricted depth of hardening in the

end-quench test. These steel compositions are identified by the suffix letter “RH” added to the conventional grade number.

1.2 In general, steels with restricted hardenability (RH steels) will exhibit a hardness range not greater than 5 HRC at the initial

position on the end-quench hardenability bar and not greater than 65 % of the hardness range for standard H-band steels

(Specification A304) in the inflection region. Generally the restricted hardenability band follows the middle of the corresponding

standard H-band. An example of the RH band compared with the H band is given for Grade 4140 in Fig. 1.

1.2.1 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 This specification is expressed in both inch-pound units and SI units. However, the material will be supplied to inch-pound

units unless the purchase order specifies the “M” specification designation.

2. Referenced Documents

2

2.1 ASTM Standards:

A29/A29M Specification for General Requirements for Steel Bars, Carbon and Alloy, Hot-Wrought

A255 Test Methods for Determining Hardenability of Steel

A304 Specification for Carbon and Alloy Steel Bars Subject to End-Quench Hardenability Requirements

E112 Test Methods for Determining Average Grain Size

3

2.2 SAE Standards:

J 406 Methods of Determining Hardenability of Steels

J 1268 Hardenability Bands for Carbon and Alloy H Steels

J 1868 Restricted Hardenability Bands for Selected Alloy Steels

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 hardenability—the relative ability of a steel to harden under heat treatment becomes apparent in the degree to which the

material hardens when quenched at different cooling rates.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.15

on Bars.

Current edition approved April 1, 2011Dec. 1, 2016. Published June 2011December 2016. Originally approved in 1992. Last previous edition approved in 20052011 as

A914/A914M - 92(2005).(2011). DOI: 10.1520/A0914_A0914M-92R11.10.1520/A0914_A0914M-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from SAE International (SAE), 400 Commonwealth Dr., Warrendale, PA 15096-0001,15096, http://www.sae.org.

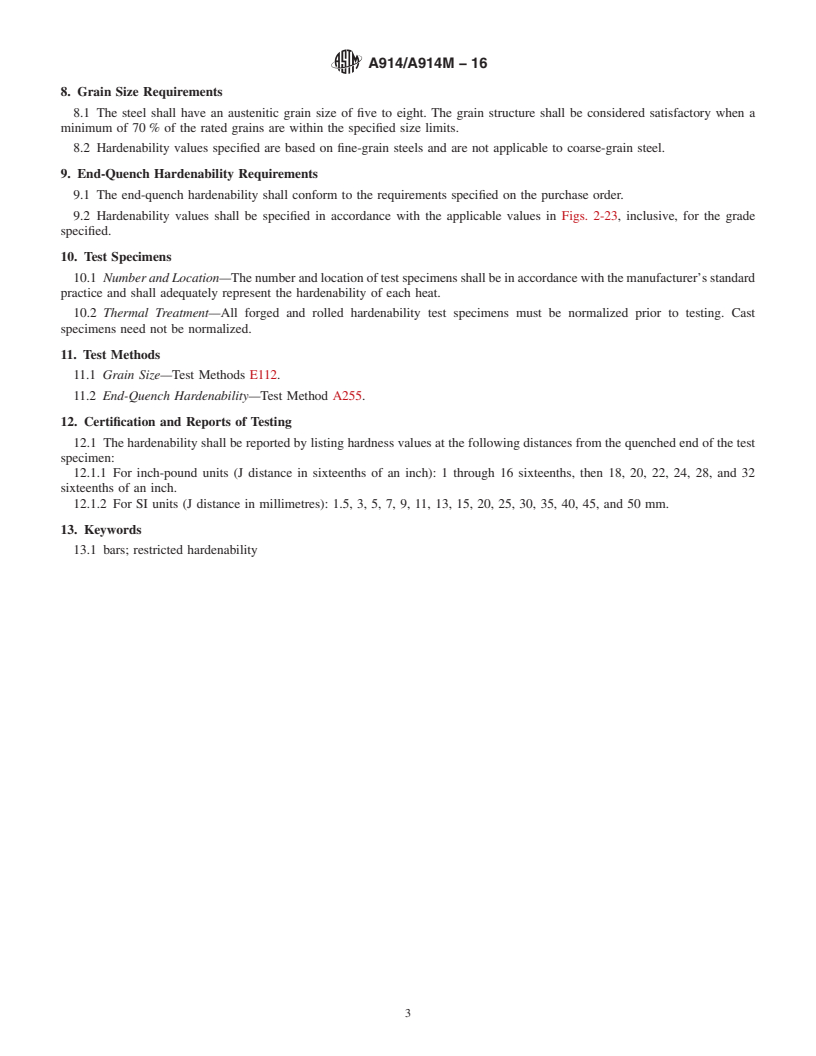

3.1.1.1 Discussion—

Hardenability is measured quantitatively, usually by noting the extent or depth of hardening of a standard size and shape test

specimen in a standardized quench. In the end-quench test the depth of hardening is the distance along the specimen from the

quenched end to a given hardness.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A914/A914M − 16

4. Ordering Information

4.1 Orders for material under this specification should include the following information, in proper sequence:

4.1.1 Quantity (weight),

4.1.2 Name of material (alloy or carbon-boron steel),

4.1.3 Cross-sectional shape,

4.1.4 Size,

4.1.5 Length,

4.1.6 Grade,

4.1.7 End-quenched hardenability (see Section 9),

4.1.8 Report of heat analysis, if desired (see Section 7),

4.1.9 Special straightness, if required,

4.1.10 ASTM designation and date of issue, and

4.1.11 End use or special requirements.

NOTE 1—A typical ordering description is as follows: 10 000 lb, alloy bars, round, 4.0-in. di

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.