SIST EN 16423:2013

(Main)Liquefied petroleum gases - Determination of dissolved residue - Gas chromatographic method using liquid, on-column injection

Liquefied petroleum gases - Determination of dissolved residue - Gas chromatographic method using liquid, on-column injection

This European Standard specifies a method for the determination of the dissolved residual matter, also known as evaporation residue, in liquefied petroleum gases (LPG), by gas chromatography in the range of (10 to 600) mg/kg (ppm mass).

This test method quantifies soluble organic compounds (hydrocarbon materials), sometimes called ‘evaporation residue’, which can be present in liquefied petroleum gases and which are substantially less volatile than the LPG product, i.e. with a boiling point between 174 °C and 522 °C (C10 to C40). Higher boiling materials, or materials that adhere permanently to the chromatographic column, will not be detected.

WARNING - This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Flüssiggas - Bestimmung gelöstes Residuals - Gaschromatografisches Prüfverfahren mit benützung von flüssigem, on-column Injektion

Diese Europäische Norm legt ein Bestimmungsverfahren für gelöste Rückstände, auch Abdampfrückstand genannt, in Flüssiggas (LPG) fest, und zwar durch Gaschromatographie im Bereich von (10 bis 600) mg/kg (ppm Masse).

Dieses Prüfverfahren bestimmt quantitativ lösliche organische Verbindungen (Kohlenwasserstoffe), manchmal „Abdampfrückstand“ genannt, die in Flüssiggas vorhanden sein können und erheblich weniger flüchtig sind als das LPG-Produkt, d. h. mit einem Siedepunkt zwischen 174 °C und 522 °C (C10 bis C40). Noch höher siedende Verbindungen oder Stoffe, die permanent auf der chromatographischen Säule haften bleiben, werden nicht erfasst.

WARNUNG — Diese Europäische Norm gibt nicht vor, alle mit ihrer Anwendung verbundenen Sicherheitsprobleme anzusprechen. Der Anwender dieser Europäischen Norm ist dafür verantwortlich, vorher angemessene Maßnahmen im Hinblick auf Sicherheit und Gesundheit zu ergreifen und die Anwendbarkeit einschränkender Vorschriften zu ermitteln.

Gaz de pétrole liquéfié - Détermination des résidus dissous - Méthode par chromatographie en phase gazeuse avec injection liquide sur colonne

La présente Norme européenne spécifie une méthode pour la détermination des matières résiduelles dissoutes, également appelées résidu d’évaporation, dans les gaz de pétrole liquéfiés (GPL). Cette méthode fait appel à la chromatographie en phase gazeuse et est applicable pour des teneurs comprises entre 10 mg/kg et 600 mg/kg.

La présente méthode d’essai quantifie les composés organiques solubles (hydrocarbures), quelquefois appelés ‘résidu d’évaporation’, qui peuvent être présents dans les gaz de pétrole liquéfiés et qui sont considérablement moins volatils que les constituants du GPL, c.-à-d. ayant un intervalle de distillation compris entre 174 °C et 522 °C (C10 à C40). Les produits ayant un point d’ébullition plus élevé ou adhérant de manière permanente sur la colonne chromatographique ne sont pas détectés.

AVERTISSEMENT - La présente norme européenne n'est pas censée aborder tous les problèmes de sécurité concernés par sa mise en oeuvre. Il est de la responsabilité de l'utilisateur de consulter et d'établir des règles de sécurité et d'hygiène appropriées et de déterminer l'applicabilité des restrictions réglementaires avant utilisation.

Utekočinjeni naftni plini - Določevanje raztopljenega ostanka - Metoda plinske kromatografije z injiciranjem tekočine v kolono

Ta evropski standard določa metodo za določanje raztopljenih ostankov, znanih tudi kot ostankov izhlapevanja pri utekočinjenih naftnih plinih (LPG) s plinsko kromatografijo v območju od (10 do 600) mg / kg (ppm mase). S to metodo merimo topne organske spojine (ogljikovodikove materiale), ki jih včasih imenujemo »ostanki izhlapevanja«, ki so lahko prisotni pri utekočinjenih naftnih plinih in so z vreliščem med 174 °C in 522 °C (C10 do C40) bistveno manj hlapljivi kot utekočinjeni naftni plini. Materialov z višjim vreliščem ali materialov, ki se trajno primejo kromatografske kolone, ni mogoče zaznati.

General Information

- Status

- Published

- Public Enquiry End Date

- 09-Jul-2012

- Publication Date

- 06-Nov-2013

- Technical Committee

- NAD - Petroleum products, lubricants and related products

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 04-Nov-2013

- Due Date

- 09-Jan-2014

- Completion Date

- 07-Nov-2013

Overview

EN 16423:2013 - "Liquefied petroleum gases - Determination of dissolved residue - Gas chromatographic method using liquid, on-column injection" is a CEN standard that defines a gas chromatographic (GC) procedure for measuring dissolved residue (aka evaporation residue) in liquefied petroleum gases (LPG). The method quantifies soluble organic hydrocarbon contaminants in the range 10 to 600 mg/kg (ppm mass) and targets compounds with boiling points approximately 174 °C to 522 °C (C10 to C40). The standard explains required instrumentation, calibration, test procedure and safety measures, and notes limitations where higher‑boiling materials or species that stick to the column are not detected.

Key topics and requirements

- Measurement scope: Dissolved organic residues in LPG, reported as total residue between C10–C40 (10–600 mg/kg).

- Analytical principle: Liquid, on‑column injection of LPG in the liquid phase using a high pressure liquefied gas injector; separation by capillary GC with a flame ionisation detector (FID).

- Essential apparatus: GC fitted with a Large Volume Cold On Column Injector (LVOCI), solvent vent, retention gap, retaining pre‑column, analytical column (polydimethylsiloxane stationary phase), column coupler/splitter, pressure station and high‑pressure injector.

- Calibration and standards: Uses mineral oil calibration mixtures (certified mineral oil in LPG or mineral oil in pentane) and n‑alkane retention standards (e.g., C10 and C40) for retention time referencing and quantification.

- Procedure outline: Pressurise LPG sample cylinder (typical 2 500 kPa), flush injector, introduce a controlled aliquot to the Cool On Column inlet, vent light components, switch pre‑column to analytical column and run temperature program to separate and quantify residue.

- Limitations and quality control: Higher boiling fractions or compounds that adhere permanently to the column are not quantified. EN 16423 includes sections on calibration, precision, repeatability/reproducibility and quality control (annexes for validation, FID linearity, and additional analyses).

Applications and users

- Who uses it: Industrial and independent petrochemical laboratories, LPG producers, distributors, pipeline and terminal operators, quality control teams, and regulatory/inspection bodies.

- Practical uses:

- Routine quality control of LPG against product specifications (e.g., EN 589).

- Investigating contamination events during production, transport or storage by providing quantitative residue levels and contaminant fingerprint (boiling‑point range).

- Method replacement where greater sensitivity and speed are required compared to manual evaporation/gravimetric methods.

- Safety note: The standard warns about LPG fire and freezing hazards; users must implement appropriate safety/ventilation, grounding and waste handling.

Related standards

- EN 589 (Automotive fuels - LPG - Requirements and test methods) - referenced for context and product limits.

- EN ISO 4257 (Sampling of LPG) and EN ISO 8973 (density/vapour pressure calculations) - normative references used in the procedure.

Keywords: EN 16423:2013, liquefied petroleum gases, LPG, dissolved residue, evaporation residue, gas chromatography, liquid on‑column injection, LVOCI, FID, C10–C40.

Frequently Asked Questions

SIST EN 16423:2013 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Liquefied petroleum gases - Determination of dissolved residue - Gas chromatographic method using liquid, on-column injection". This standard covers: This European Standard specifies a method for the determination of the dissolved residual matter, also known as evaporation residue, in liquefied petroleum gases (LPG), by gas chromatography in the range of (10 to 600) mg/kg (ppm mass). This test method quantifies soluble organic compounds (hydrocarbon materials), sometimes called ‘evaporation residue’, which can be present in liquefied petroleum gases and which are substantially less volatile than the LPG product, i.e. with a boiling point between 174 °C and 522 °C (C10 to C40). Higher boiling materials, or materials that adhere permanently to the chromatographic column, will not be detected. WARNING - This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

This European Standard specifies a method for the determination of the dissolved residual matter, also known as evaporation residue, in liquefied petroleum gases (LPG), by gas chromatography in the range of (10 to 600) mg/kg (ppm mass). This test method quantifies soluble organic compounds (hydrocarbon materials), sometimes called ‘evaporation residue’, which can be present in liquefied petroleum gases and which are substantially less volatile than the LPG product, i.e. with a boiling point between 174 °C and 522 °C (C10 to C40). Higher boiling materials, or materials that adhere permanently to the chromatographic column, will not be detected. WARNING - This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

SIST EN 16423:2013 is classified under the following ICS (International Classification for Standards) categories: 75.160.30 - Gaseous fuels. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 16423:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Flüssiggas - Bestimmung gelöstes Residuals - Gaschromatografisches Prüfverfahren mit benützung von flüssigem, on-column InjektionGaz de pétrole liquéfié - Détermination des résidus dissous - Méthode par chromatographie en phase gazeuse avec injection liquide sur colonneLiquefied petroleum gases - Determination of dissolved residue - Gas chromatographic method using liquid, on-column injection75.160.30Plinska gorivaGaseous fuelsICS:Ta slovenski standard je istoveten z:EN 16423:2013SIST EN 16423:2013en,de01-december-2013SIST EN 16423:2013SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16423

October 2013 ICS 75.160.20 English Version

Liquefied petroleum gases - Determination of dissolved residue -Gas chromatographic method using liquid, on-column injection Gaz de pétrole liquéfié - Détermination des résidus dissous - Méthode par chromatographie en phase gazeuse avec injection liquide on-column

Flüssiggas - Bestimmung gelöster Rückstände - Gaschromatographisches Prüfverfahren durch Direkteinspritzung von Flüssigkeit auf die Säule This European Standard was approved by CEN on 31 August 2013.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2013 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 16423:2013: ESIST EN 16423:2013

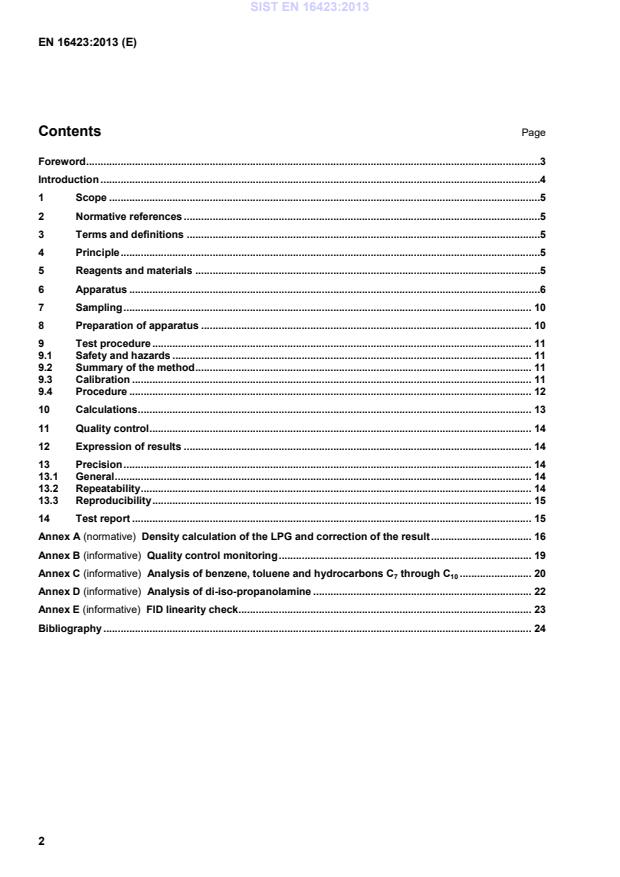

Density calculation of the LPG and correction of the result . 16 Annex B (informative)

Quality control monitoring . 19 Annex C (informative)

Analysis of benzene, toluene and hydrocarbons C7 through C10 . 20 Annex D (informative)

Analysis of di-iso-propanolamine . 22 Annex E (informative)

FID linearity check. 23 Bibliography . 24

This standard has been developed as a potential replacement of the commonly used methods, as this method of determination: − is quicker and much more sensitive than manual methods, such as ASTM D2158 [1] or EN 15471 [2], which are based on evaporation of (large) sample volumes followed by visual or gravimetric estimation of residue content; − provides enhanced sensitivity in measurements of heavier (evaporation) residues compared to EN 15470 [3], with a quantification limit of 10 mg/kg total residue; − gives both quantitative results and information about contaminant composition such as boiling point range and fingerprint, which can be very useful in tracing the source of a particular contaminant.

This test method quantifies soluble organic compounds (hydrocarbon materials), sometimes called ‘evaporation residue’, which can be present in liquefied petroleum gases and which are substantially less volatile than the LPG product, i.e. with a boiling point between 174 °C and 522 °C (C10 to C40). Higher boiling materials, or materials that adhere permanently to the chromatographic column, will not be detected.

WARNING — This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 589, Automotive fuels — LPG — Requirements and test methods EN ISO 4257, Liquefied petroleum gases — Method of sampling (ISO 4257)

EN ISO 8973:1999, Liquefied petroleum gases — Calculation method for density and vapour pressure (ISO 8973:1997) ISO 1998-1, Petroleum industry — Terminology — Part 1: Raw materials and products 3 Terms and definitions For the purposes of this document, the terms and definitions given in EN 589, ISO 1998-1, and the following apply. 3.1

high pressure liquefied gas injector sample introduction device which injects liquefied gas samples under pressure and at room temperature directly onto the chromatographic column thereby maintaining the sample in liquid phase during the injection process 3.2 pressure station device that supplies high pressure inert gas to a suitable sample cylinder and therefore maintains sample in the liquid phase during the injection procedure 4 Principle A small quantity of LPG is directly transferred in liquid phase from the sample cylinder on to a GC column using a high pressure liquefied gas injector. The mixture is then analysed by capillary gas chromatography and the dissolved residue content is quantified by the external standard method. 5 Reagents and materials IMPORTANT — Standards that are prepared in pentane, normally liquid at room temperature, shall be stored under refrigeration and transferred to sample cylinders prior to use. Alternatively, they can be stored in air tight cylinders.

One of the following mixtures shall be selected for calibration: 5.1.1 Mineral oil in LPG calibration mixture, certified calibration mixture with about 50 mg/kg mineral oil in LPG. 5.1.2 Mineral oil in pentane calibration mixture. Prepare a calibration standard of mineral oil in pentane. Record the exact weighed value to the nearest mg of mineral oil and calculate the concentration in mg/kg. The concentration of the mineral oil shall be close to the expected concentration of the contamination in the LPG sample. 5.1.3 Mineral oil or local hydrocarbon fraction, boiling point range approximately C10 to C40.

Alternatively, a well characterised local hydrocarbon fraction, within the range C10 to C40, can be used to provide quantitative and qualitative comparison to the contaminant in the sample. Care should be taken to ensure no significant fraction falls outside the C10 to C40 range. 5.2 Validation standard, mineral oil in pentane. Prepare a validation standard of mineral oil in pentane. Record the exact weighed value to the nearest mg of mineral oil and calculate the concentration in mg/kg. The concentration of the mineral oil shall be close to the expected concentration of the contamination in the LPG sample.

5.3 n-Alkane retention time standard, mixture containing at least C10 and C40 in a concentration of (nominally) 5 mg/l each, dissolved in pentane or heptane. 5.4 Solvent, GC grade pentane. 6 Apparatus NOTE Successfully used columns and conditions are given in Table 1. 6.1 Gas chromatograph, equipped with a Large Volume Cold on Column Injector (LVOCI), linear temperature programmable column oven, and a flame ionisation detector (FID), with data acquisition and processing system. For checking the linearity of the FID one may use Annex E. 6.2 Solvent vent, controlled to allow venting the major part of the matrix. 6.3 Retention gap, uncoated stainless steel capillary.

6.4 Retaining pre-column, a column with a polydimethylsiloxane stationary phase. 6.5 Analytical column, a column with a polydimethylsiloxane stationary phase. 6.6 Column coupler, coupling device suitable for leak free coupling of the retention gap to the retaining pre-column.

See Figure 1 for a schematic overview of the couplings inside the GC oven and the couplings to the solvent vent valve. SIST EN 16423:2013

Analytical column: HP-1, 30 m, 0,32 mm, 0,25 µm Pressure station Sample flow: 2 ml/min Nitrogen pressure: 2 500 kPa Nitrogen purge pressure: 500 kPa Liquefied gas injector Injection: 25 ms

1) Sulfinert ® is a stainless steel treatment system from Restek Co., 110 Benner Circle, Bellefonte, PA 16823, USA. This information is given for the convenience of users of this European Standard and does not constitute an endorsement by CEN of the product named. Equivalent products may be used if they can be shown to lead to the same results.

See Figure 1 for a schematic overview of the couplings inside the GC oven and the couplings to the solvent vent valve.

Key A solvent vent valve B cool on-column inlet C detector D column splitter E retention gap F retaining pre-column G analytical column Figure 1 — Column overview SIST EN 16423:2013

Key A electrical attachment B solenoid on C valve spring D spray tip E pressurised fuel injection F injector casing G plunger Figure 2 — High pressure valve SIST EN 16423:2013

Key A sample cylinder B sample line in C injection device D cool on column inlet E gas chromatograph F sample line out G rotometer H vaporiser I waste systemFigure 3 — Typical configuration of the pressure station 7 Sampling Unless otherwise specified in the commodity specification, samples shall be taken as described in EN ISO 4257 and/or in accordance with the requirements of national regulations for the sampling of the product under test. 8 Preparation of apparatus CAUTION —Take all the necessary safety measures and, in particular, earth the equipment in order to eliminate the risks associated with static electricity. 8.1 Gas chromatograph: install and verify performance in accordance with the manufacturer’s instructions. Typical operating conditions are shown in Table 1. 8.2 Pressure station: install in accordance with the manufacturer’s instructions. Purge sample and check carefully for leaks. Connect the outlet to a waste system. 8.3 High pressure liquefied gas injector: install in accordance with the manufacturer’s instructions.

8.4 Column configuration: install the columns as shown in Figure 1, using low dead volume connections, and check for leaks. SIST EN 16423:2013

b) The injection system is flushed with LPG in liquid phase at room temperature. The end of the injection purge line is connected to a heated vaporiser which vaporises the LPG before transporting it to a waste disposal system. c) After flushing, the injection device is routed to the GC injector port and LPG (25 ms activation time equivalent to 30 µl) is introduced via a high pressure valve and needle which is inserted into the Cool On Column inlet.

d) The gas chromatograph is equipped with a solvent vent which routes most of the LPG light components out of the analytical system and leaves behind the components of interest.

e) The dissolved residue to be determined is retained on the pre-column. f) After venting, the light ends, the flow from the pre-column is switched to the analytical column and a temperature program is started. g) Dissolved residue contaminants are separated and identified based on differences in boiling point temperature. h) Total residue is quantified using area summation of component

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...