oSIST prEN 13796-1:2026

(Main)Safety requirements for cableway installations designed to carry persons - Carriers - Part 1: Grips, carrier trucks, on-board brakes, cabins, chairs, carriages, maintenance carriers, tow-hangers

Safety requirements for cableway installations designed to carry persons - Carriers - Part 1: Grips, carrier trucks, on-board brakes, cabins, chairs, carriages, maintenance carriers, tow-hangers

This European Standard specifies the safety requirements applicable to carriers for cableway installations designed to carry persons. It is applicable to the various types of installations and takes into account their environment.

It includes requirements relating to the prevention of accidents and the protection of workers.

It does not apply to installations for the transportation of goods or to inclined lifts.

Sicherheitsanforderungen an Seilbahnen für die Personenbeförderung - Fahrzeuge - Teil 1: Befestigungen am Seil, Laufwerke, Fangbremsen, Kabinen, Sessel, Wagen, Instandhaltungsfahrzeuge, Schleppvorrichtungen

Diese Europäische Norm legt die Sicherheitsanforderungen an Fahrzeuge von Seilbahnen für die Personenbeförderung fest. Dabei werden die verschiedenen Systeme und deren Umgebung berücksichtigt.

Sie enthält Anforderungen an die Unfallverhütung und den Arbeitnehmerschutz unbeschadet der Anwendung nationaler Vorschriften.

Nationale Vorschriften mit bau- oder ordnungsrechtlichem Charakter oder die dem Schutz bestimmter Personengruppen dienen, bleiben unberührt.

Sie ist nicht anwendbar für Seilbahnen des Güterverkehrs noch für Aufzüge.

Prescriptions de sécurité pour les installations à câbles destinées au transport des personnes - Véhicules - Partie 1 : Attaches, chariots, freins embarqués, cabines, sièges, voitures, véhicules de maintenance, agrès

Varnostne zahteve za žičniške naprave za prevoz oseb - Vozila - 1. del: Prižemke, tekala, vrvne zavore, kabine, sedeži, vozički, vozila za vzdrževanje, vlačila

General Information

- Status

- Not Published

- Public Enquiry End Date

- 09-Feb-2026

- Technical Committee

- DTN - Lift and transport appliances

- Current Stage

- 4020 - Public enquire (PE) (Adopted Project)

- Start Date

- 03-Dec-2025

- Due Date

- 22-Apr-2026

Relations

- Effective Date

- 10-May-2023

Overview

prEN 13796-1 is a draft CEN European Standard that specifies safety requirements for cableway installations designed to carry persons, focusing on the vehicle components - collectively called carriers. Titled “Safety requirements for cableway installations designed to carry persons - Carriers - Part 1: Grips, carrier trucks, on-board brakes, cabins, chairs, carriages, maintenance carriers, tow-hangers,” this document applies to different types of passenger cableways and their environments. It addresses accident prevention and worker protection. It does not cover installations for goods transport or inclined lifts.

Key topics and requirements

prEN 13796-1 organizes technical safety content across component types and verification methods. Major topics include:

- General safety principles and scope - application of the standard, hazard factors and safety measures.

- Loads and environmental actions - self-weight, useful load, wind actions, gripping and opening forces, reaction and impact forces, snow/frost effects, damping and torsion moments.

- Design verifications - static checks, fatigue verifications and related mechanical verifications for carriers and components.

- Materials and construction - material selection (steels, welded components), construction principles and production testing.

- Rope and end fixings - haulage rope drum fixings, sockets, grips (fixed and detachable), and specific items such as chapeau de gendarme.

- Vehicle components - carrier trucks for aerial ropeways, funicular chassis, on-board brakes (automatic and manual application and verifications).

- Cabins, chairs and carriages - space envelopes, doors, seating, safety bars, hoods, rescue carriers and carriage doors.

- Maintenance and identification - maintenance carriers, tow-hangers, space envelopes, identification plates, fire prevention and testing requirements.

All above items include prescriptive verification, documentation (plans, certificates, calculations), and production test requirements.

Practical applications and users

This standard is essential for:

- Designers and manufacturers of cabins, chairs, grips, carrier trucks and related components to ensure compliance with European safety expectations.

- Installers and contractors responsible for assembly and commissioning of cableway vehicles.

- Maintenance teams and safety engineers implementing preventive maintenance, inspections and repairs.

- Certification bodies, notified authorities and operators conducting conformity assessment, risk assessment and safety audits.

Using prEN 13796-1 helps reduce mechanical failure risks, improve passenger safety, and ensure consistent documentation and testing practices across cableway equipment.

Related standards

- Part of the EN 13796 series and developed by CEN/TC 242 (Cableway equipment).

- Classified under ICS 45.100 (Cableway equipment).

Keywords: prEN 13796-1, cableway installations, safety requirements, carriers, grips, carrier trucks, on-board brakes, cabins, chairs, maintenance carriers, CEN.

Frequently Asked Questions

oSIST prEN 13796-1:2026 is a draft published by the Slovenian Institute for Standardization (SIST). Its full title is "Safety requirements for cableway installations designed to carry persons - Carriers - Part 1: Grips, carrier trucks, on-board brakes, cabins, chairs, carriages, maintenance carriers, tow-hangers". This standard covers: This European Standard specifies the safety requirements applicable to carriers for cableway installations designed to carry persons. It is applicable to the various types of installations and takes into account their environment. It includes requirements relating to the prevention of accidents and the protection of workers. It does not apply to installations for the transportation of goods or to inclined lifts.

This European Standard specifies the safety requirements applicable to carriers for cableway installations designed to carry persons. It is applicable to the various types of installations and takes into account their environment. It includes requirements relating to the prevention of accidents and the protection of workers. It does not apply to installations for the transportation of goods or to inclined lifts.

oSIST prEN 13796-1:2026 is classified under the following ICS (International Classification for Standards) categories: 45.100 - Cableway equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

oSIST prEN 13796-1:2026 has the following relationships with other standards: It is inter standard links to SIST EN 13796-1:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

oSIST prEN 13796-1:2026 is associated with the following European legislation: EU Directives/Regulations: 2016/424; Standardization Mandates: M/300, M/597. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

oSIST prEN 13796-1:2026 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2026

Varnostne zahteve za žičniške naprave za prevoz oseb - Vozila - 1. del: Prižemke,

tekala, vrvne zavore, kabine, sedeži, vozički, vozila za vzdrževanje, vlačila

Safety requirements for cableway installations designed to carry persons - Carriers - Part

1: Grips, carrier trucks, on-board brakes, cabins, chairs, carriages, maintenance carriers,

tow-hangers

Sicherheitsanforderungen an Seilbahnen für die Personenbeförderung - Fahrzeuge - Teil

1: Befestigungen am Seil, Laufwerke, Fangbremsen, Kabinen, Sessel, Wagen,

Instandhaltungsfahrzeuge, Schleppvorrichtungen

Prescriptions de sécurité pour les installations à câbles destinées au transport des

personnes - Véhicules - Partie 1 : Attaches, chariots, freins embarqués, cabines, sièges,

voitures, véhicules de maintenance, agrès

Ta slovenski standard je istoveten z: prEN 13796-1

ICS:

45.100 Oprema za žičnice Cableway equipment

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

November 2025

ICS 45.100 Will supersede EN 13796-1:2017

English Version

Safety requirements for cableway installations designed to

carry persons - Carriers - Part 1: Grips, carrier trucks, on-

board brakes, cabins, chairs, carriages, maintenance

carriers, tow-hangers

Prescriptions de sécurité pour les installations à câbles Sicherheitsanforderungen an Seilbahnen für die

destinées au transport des personnes - Véhicules - Personenbeförderung - Fahrzeuge - Teil 1:

Partie 1 : Attaches, chariots, freins embarqués, cabines, Befestigungen am Seil, Laufwerke, Fangbremsen,

sièges, voitures, véhicules de maintenance, agrès Kabinen, Sessel, Wagen, Instandhaltungsfahrzeuge,

Schleppvorrichtungen

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 242.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 13796-1:2025 E

worldwide for CEN national Members.

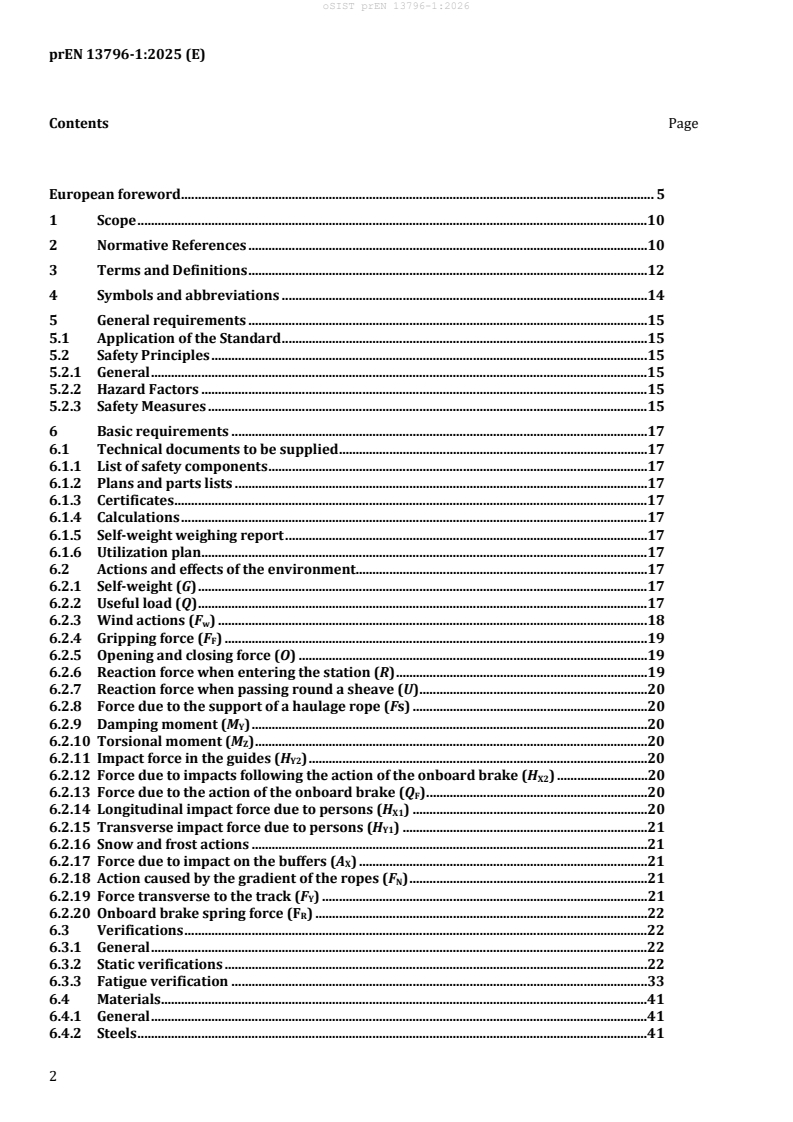

Contents Page

European foreword . 5

1 Scope .10

2 Normative References .10

3 Terms and Definitions .12

4 Symbols and abbreviations .14

5 General requirements .15

5.1 Application of the Standard .15

5.2 Safety Principles .15

5.2.1 General .15

5.2.2 Hazard Factors .15

5.2.3 Safety Measures .15

6 Basic requirements .17

6.1 Technical documents to be supplied .17

6.1.1 List of safety components .17

6.1.2 Plans and parts lists .17

6.1.3 Certificates .17

6.1.4 Calculations .17

6.1.5 Self-weight weighing report .17

6.1.6 Utilization plan .17

6.2 Actions and effects of the environment.17

6.2.1 Self-weight (G) .17

6.2.2 Useful load (Q) .17

6.2.3 Wind actions (F ) .18

w

6.2.4 Gripping force (F ) .19

F

6.2.5 Opening and closing force (O) .19

6.2.6 Reaction force when entering the station (R) .19

6.2.7 Reaction force when passing round a sheave (U) .20

6.2.8 Force due to the support of a haulage rope (Fs) .20

6.2.9 Damping moment (M ) .20

Y

6.2.10 Torsional moment (M ) .20

Z

6.2.11 Impact force in the guides (H ) .20

Y2

6.2.12 Force due to impacts following the action of the onboard brake (H ) .20

X2

6.2.13 Force due to the action of the onboard brake (Q ) .20

F

6.2.14 Longitudinal impact force due to persons (H ) .20

X1

6.2.15 Transverse impact force due to persons (H ) .21

Y1

6.2.16 Snow and frost actions .21

6.2.17 Force due to impact on the buffers (A ) .21

X

6.2.18 Action caused by the gradient of the ropes (F ) .21

N

6.2.19 Force transverse to the track (F ) .21

Y

6.2.20 Onboard brake spring force (F ) .22

R

6.3 Verifications .22

6.3.1 General .22

6.3.2 Static verifications .22

6.3.3 Fatigue verification .33

6.4 Materials .41

6.4.1 General .41

6.4.2 Steels .41

6.4.3 Welded components . 41

6.5 Construction principles . 41

6.6 Production tests . 41

6.7 Fire prevention and firefighting . 42

7 End fixings for ropes and grips . 42

7.1 General . 42

7.2 Haulage rope drum end fixing . 42

7.2.1 General . 42

7.2.2 Haulage rope end clamps on fixing drum . 43

7.2.3 Drum grooves . 43

7.2.4 Coefficients of friction . 43

7.3 Drum fixing of a continuous haulage rope . 43

7.4 Socket end fixings (filled/clamp sockets) . 44

7.4.1 General . 44

7.4.2 Conical bush for filled socket . 44

7.5 Aerial ropeway grips (excluding chapeaux de gendarme) . 44

7.5.1 General . 44

7.5.2 Fixed grips . 48

7.5.3 Detachable grips . 48

7.6 Clamp used as a grip on spliced continuous loops of haulage rope . 49

7.7 Chapeau de gendarme . 51

7.7.1 General . 51

7.7.2 Design requirements . 51

7.7.3 Verifications . 52

7.7.4 Coefficients of friction . 52

7.8 Grips for towing ropes . 53

7.8.1 General . 53

7.8.2 Fixed grips . 53

7.8.3 Detachable bush grips . 54

8 Carrier trucks for aerial ropeways . 54

9 Chassis of funicular railways . 56

10 Onboard brakes . 57

10.1 Automatic application . 57

10.2 Manual application . 57

10.3 Verifications of the brake . 57

11 Cabins, chairs and other carriers of aerial ropeways . 58

11.1 General . 58

11.1.1 Space envelopes . 58

11.1.2 Carrier equipment . 58

11.2 Cabins . 58

11.2.1 General . 58

11.2.2 Cabins for reversible aerial ropeways . 63

11.2.3 Cabin doors . 64

11.3 Rescue carriers . 64

11.4 Chairs . 65

11.4.1 General . 65

11.4.2 Seats, backs and armrests . 65

11.4.3 Safety bars and footrests . 67

11.4.4 Hoods . 68

12 Carriages for funicular railways . 70

12.1 General . 70

12.2 Carriage doors .73

12.2.1 General .73

12.2.2 Doors for carriages with attendant .74

13 Maintenance carriers .75

13.1 General .75

13.2 Space envelopes .76

13.3 Identification plate .76

13.4 Dimensioning of the carrier .76

13.5 Specific provisions for the maintenance and inspection of ropes .76

14 Tow-hanger .77

14.1 General .77

14.2 Rods and springboxes .77

14.3 T-bars and platters .78

Annexe ZA (informative) Relationship between this European Standard and the essential

requirements of Regulation (EU) 2016/424 .79

European foreword

This document (prEN 13796-1:2025) has been prepared by Technical Committee CEN/TC 242 "Safety

requirements for cableway installations designed to carry persons", the secretariat of which is held by

AFNOR.

This document is currently subject to a CEN enquiry.

This document will supersede EN 13796-1:2017.

Compared with the preceding version of EN 13796-1:2017, the main changes are as follows:

— in 5.2.2, a hazard factor was added: in the event of prolonged stoppage, excessive temperature in en-

closed carriers due to weather conditions;

— in 5.2.3, a safety measure was added: modification of enclosed carriers so as to allow their ventila-

tion at least;

— in 6.2.2, a clarification is made between the assumed mass of a person with and without winter

sports equipment (80 and 75 kg);

— in 6.2.3, it is specified to consider the actual wind allowed in operation, with a minimum pressure

that remains fixed at 0,25 kN/m². For chairs without hoods, the determination of the force coeffi-

cient is simplified with a single value set at 1,1;

— in 6.2.9, it is specified that the values of the damping moments shall be verified if there are motorized

actuators present that have an effect on the damping;

— in 6.2.14, the wording is repeated to clarify that the longitudinal impact force is determined on the

basis of the useful load, taking into account the maximum deceleration experienced, regardless of

the carrier capacity, the standard formulae given in this clause setting a minimum value for this

force. It is also specified that the above rules apply to each compartment if the cabin has compart-

ments;

— in 6.2.15, it is specified that if the carrier is divided into compartments, the rules apply to each com-

partment;

— in 6.2.20 (new paragraph), a new force is introduced: onboard brake spring force;

— in 6.3.2.1.3, it is specified that the safety factor of 2 concerns load cases with wind during operation;

— in 6.3.2.5.1, a new load case was added for the static dimensioning of the carrier trucks;

— in 6.3.2.5.3, a new load case was added for cabins that are not protected from the wind when not in

operation;

— in 6.3.2.5.5, the sockets have been removed from the list of grips concerned by the load case men-

tioned, in so far as specific sizing requirements are laid down in clause 7.4 of the carrier standard;

— in 6.3.2.5.6 (new paragraph), a new load case table has been added for the dimensioning of the

onboard brakes of bicable aerial ropeways;

— in 6.3.2.6.1, the safety coefficient has been modified for load case n°2 (wind when not in operation),

in line with the accuracy provided in 6.3.2.1.3;

— in 6.3.2.6.2, the safety coefficient has been increased from 1 to 1,2 for load case no.°7. Indeed, con-

trary to what was indicated in note a below the table for this clause, this is a load case that occurs

several times in the life of a funicular railway, which is therefore not unlikely and there is therefore

no reason to consider a coefficient lower than the minimum coefficient of 6.3.2.1.3;

— in 6.3.2.6.5 (new paragraph), a new load case table has been added for the dimensioning of the

onboard brakes of funicular railways;

— in 6.3.3.2.2, an additional requirement has been formulated for the verification of fatigue by calcula-

tion for carriers for unidirectional monocable aerial ropeways operating more than 4 000 hours per

year;

— in 6.7, standard EN 17064:2018 was introduced, replacing the technical reports CEN/TR 14819 or

EN 45545;

— in 7.2.2.3, details have been provided on the safety coefficients of the end clamps of the haulage rope,

consistent with the provisions of EN 12927:2019;

— paragraph 7.2.4.2 has been deleted, considering that it is not necessary to specify a coefficient of fric-

tion different from those defined in EN 12927:2019;

— paragraph 7.4.1.1 has been amended to refer to the provisions of EN 12927:2019 for the design of

the conical bushes;

— paragraph 7.4.2.3 on the geometry of the conical bushes has been deleted because it was rendered

unnecessary by the modification of 7.4.1.1;

— in 7.4.2.3 (previously 7.4.2.4), the wording was clarified to specify the requirement to withstand the

torsional moment;

— in 7.6 (new paragraph), requirements for clamps used as a grip on spliced continuous loops of haul-

age rope have been introduced;

— in 8.1, details have been provided on the fitting of a suspension for a bicable aerial ropeway on a car-

rier truck in order to guarantee the separation of the functions of stopping the translation of the

axis and of longitudinal damping;

— in 10.3, references to clauses 6.3.2.5.1 and 6.3.2.6.2 (new load case tables) have been added;

— in 11.2.1.1, details have been provided on the stresses considered and the checks to be produced to

verify the strength of the structures and walls of the cabins. In particular, a new dynamic check of

the walls via an impact test has been introduced;

— in 11.2.1.4, the presence of a securing point for wheelchairs has become optional;

— in 11.2.1.7, clarification has been provided, notably, to differentiate between cases of transporting

standing and seated persons. In the case of standing persons, the load may be reduced below 3 500

N/m² under certain conditions;

— in 11.2.1.8, the possibility of dropping below the load of 3 500 N/m² has been introduced, as in

11.2.1.7;

— in 11.2.1.9, the minimum heights of the walls of open cabins have been increased, with different val-

ues depending on the position of the walls;

— in 11.2.1.10, details have been provided on the installation of the windows, consistent with the

changes made to 11.2.1.9;

— in 11.2.1.14 (new paragraph), requirements for ski racks for cabin doors have been added;

— in 11.2.3.1.1, details have been provided on the monitoring of the position and locking of the cabin

doors;

— in 11.2.3.1.4, details have been provided on the minimum passage height of the cabin doors accord-

ing to the capacity of the cabins;

— in 11.2.3.3.2, changes have been made to the locking of the doors, which is no longer possible if a for-

eign object of more than 80 mm is blocking closure (compared with 120 mm previously);

— paragraph 11.4.1.4, which introduced geometric arrangements for chairs, has been moved to clause

11.4.3.4 (new) relating to safety bars;

— in 11.4.2.5, complementary geometric arrangements on the end armrests have been introduced, in

particular to prevent the risk of jamming at the interface with the safety bar;

— in 11.4.2.6 (new paragraph), requirements for chairs whose ends are closed by a side element (e.g.

covered chair) have been added to prevent the risk of jamming at the interface with the safety bar;

— in 11.4.3.4 (new paragraph), the requirements of the previous clause 11.4.1.4 on safety bars have

been repeated and clarified;

— in 11.4.3.5 (new paragraph), additional devices to prevent submarining are now mandatory, so func-

tional and strength requirements have been added for these devices;

— in 11.4.3.6 (new paragraph), exceptions to the previous paragraph have been introduced.

— in 12.1.1, details have been provided on the stresses considered and the checks to be produced to

verify the strength of the structures and walls of the carriages. In particular, a new dynamic check

of the walls via an impact test has been introduced;

— in 12.1.3, a note concerning the transport of persons in wheelchairs has been added;

— in 12.1.8, the minimum heights of the walls of open carriages have been increased, with different val-

ues depending on the position of the walls;

— in 12.1.10, details have been provided on the installation of the windows, consistent with the

changes made to 12.1.8;

— in 12.1.24 (new paragraph), for the transport of standing persons in funicular railway carriages, grip-

ping elements are required, so requirements have been added.

— in 12.2.1.2, details have been provided on the monitoring of the position and locking of the carriage

doors;

— in 12.2.1.2 and 12.2.1.3, details have been provided on the operation of the doors of funicular railway

carriages;

— in 13, clarifications have been made in various paragraphs concerning maintenance carriers in order

to improve the design provisions relating to occupational safety;

— Annex ZA has been updated.

This document has been prepared under a Standardization Request given to CEN by the European

Commission. The Standing Committee of the EFTA States shall then approve these requests for its

Member States.

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this

document.

EN 13796 comprises the following parts under the general title Safety requirements for cableway

installations designed to carry persons — Carriers:

— Part 1: Grips, carrier trucks, onboard brakes, cabins, chairs, carriages, maintenance carriers, tow-

hangers;

— Part 2: Slipping resistance tests for grips;

— Part 3: Fatigue testing.

This European Standard is part of a series of European Standards concerning the safety requirements of

cableway installations designed to carry persons. This series of Standards includes the following parts:

— EN 1907, Safety requirements for cableway installations designed to carry persons — Terminology;

— EN 12929 (all parts), Safety requirements for cableway installations designed to carry persons —

General requirements;

— EN 12930, Safety requirements for cableway installations designed to carry persons — Calculations;

— EN 12927, Safety requirements for cableway installations designed to carry persons — Ropes;

— EN 1908, Safety requirements for cableway installations designed to carry persons — Tensioning

devices;

— EN 13223, Safety requirements for cableway installations designed to carry persons — Drive systems

and other mechanical equipment;

— EN 13796 (all parts), Safety requirements for cableway installations designed to carry persons —

Carriers;

— EN 13243, Safety requirements for cableway installations designed to carry persons — Electrical

equipment other than for drive systems;

— EN 13107, Safety requirements for cableway installations designed to carry persons — Civil

engineering works;

— EN 1709, Safety requirements for cableway installations designed to carry persons — Pre-

commissioning inspection and instructions for maintenance and operational inspection and checks;

— EN 1909, Safety requirements for cableway installations designed to carry persons — Recovery and

evacuation;

— EN 12397, Safety requirements for cableway installations designed to carry persons — Operation;

— EN 12408, Safety requirements for cableway installations designed to carry persons — Quality control;

— EN 17064, Safety requirements for cableway installations designed to carry persons — Prevention and

fight against fire.

Together, these standards govern the design, manufacturing, production, maintenance and operation of

all cableway installations designed to carry persons.

1 Scope

This European Standard specifies the safety requirements applicable to carriers for cableway

installations for passenger transportation. It is applicable to the various types of installations and takes

into account their environment.

It includes requirements relating to the prevention of accidents and the protection of workers, without

affecting the application of national requirements.

National requirements relating to construction law or statutory law, or to the protection of specific

groups of people, shall not be affected.

It does not apply to installations for the transportation of goods or to lifts.

2 Normative References

The following documents, in whole or in part, are referenced in a normative manner in this document

and are essential to its application. For dated references, only the cited edition applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

EN 795:2016, Personal fall protection equipment — Anchor devices

EN 1709:2019, Safety requirements for cableway installations designed to transport persons —

Precommissioning inspection and instructions for maintenance and operational inspection and checks

EN 1907:2017, Safety requirements for cableway installations designed to carry persons — Terminology

EN 1908:2015, Safety requirements of cableway installations designed to carry persons — Tensioning

devices

EN 1909:2017, Safety requirements for cableway installations designed to carry persons — Recovery and

evacuation

EN 1993-1-9:2005, Eurocode 3: Design of steel structures — Part 1-9: Fatigue

EN 1999-1-3:2007, Eurocode 9: Design of aluminium structures — Part 1-3: Structures susceptible to

fatigue

EN 10025-1:2005, Hot rolled products of structural steels - Part 1: General technical delivery conditions

EN 10025-2:2019, Hot rolled products of structural steels - - Part 2: Technical delivery conditions for non-

alloy structural steels

EN 10025-3:2019, Hot rolled products of structural steels - Part 3: Technical delivery conditions for

normalized/normalized rolled weldable fine grain structural steels

EN 10025-4:2019+A1:2022, Hot rolled products of structural steels - Part 4: Technical delivery conditions

for thermomechanical rolled weldable fine grain structural steels

EN 10025-5:2019, Hot rolled products of structural steels - Part 5: Technical delivery conditions for

structural steels with improved atmospheric corrosion resistance

EN 10025-6:2019+A1:2022, Hot rolled products of structural steels - Part 6: Technical delivery conditions

for flat products of high yield strength structural steels in the quenched and tempered condition

EN ISO 683-1:2018, Heat-treated steels, alloy steels and free-cutting steels - Part 1: Non-alloy steels for

quenching and tempering

EN ISO 683-2:2018, Heat-treated steels, alloy steels and free-cutting steels - Part 2: Alloy steels for

quenching and tempering

EN 10204:2004, Metallic products — Types of inspection documents

EN 12397:2017, Safety requirements for cableway installations designed to carry persons — Operation

EN 12408:2004, Safety requirements for cableway installations designed to carry persons — Quality

control

EN 12927:2019, Safety requirements for cableway installations designed to carry persons — Ropes

EN 12929-1:2015+A1:2022, Safety requirements for cableway installations designed to carry persons —

General requirements — Part 1: Requirements for all installations

EN 12929-2:2015+A1:2022, Safety requirements for cableway installations designed to carry persons —

General requirements — Part 2: Additional requirements for reversible bicable aerial ropeways without

carrier truck brakes

EN 12930:2015, Safety requirements for cableway installations designed to carry persons — Calculations

EN 13107:2015, Safety requirements for cableway installations designed to carry persons — Civil

engineering works

EN 13107:2015/AC:2016, (Corrigendum) Safety requirements for cableway installations designed to carry

persons — Civil engineering works

EN 13223:2015+A1:2022, Safety requirements for cableway installations designed to carry persons —

Drive systems and other mechanical equipment

EN 13243:2015, Safety requirements for cableway installations designed to carry persons — Electrical

equipment other than for drive systems

EN 13796-2:2017+A1:2022, Safety requirements for cableway installations designed to carry persons —

Carriers — Part 2: Slipping resistance test for grips

EN 13796-3:2017+A1:2022, Safety requirements for cableway installations designed to carry persons —

Carriers — Part 3: Fatigue testing

EN 17064:2018, Safety requirements for cableway installations designed to carry persons — Prevention

and fight against fire

EN ISO 148-1:2016, Metallic materials — Charpy pendulum impact test — Part 1: Test method (ISO 148-1)

EN ISO 898:2013 (all parts), Mechanical properties of fasteners made of carbon steel and alloy steel

(ISO 898 series)

EN ISO 5817:2023, Welding — Fusion-welded joints in steel, nickel, titanium and their alloys (beam welding

excluded) — Quality levels for imperfections (ISO 5817)

EN ISO 9606-1:2012, Qualification testing of welders — Fusion welding — Part 1: Steels (ISO 9606-1)

EN ISO 9606-2:2004, Qualification test of welders — Fusion welding — Part 2: Aluminium and aluminium

alloys (ISO 9606-2)

3 Terms and Definitions

For the purposes of this document, the terms and definitions given in EN 1907:2017 and the following

apply.

ISO and IEC maintain terminology databases for standardisation, which can be accessed at the following

addresses:

— ISO Online browsing platform: available at http://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

gravitational driving force

F

T

𝐹𝐹 = 𝑚𝑚 ×𝑔𝑔 ×𝑠𝑠𝑠𝑠𝑠𝑠 𝛼𝛼

𝑇𝑇

where

m = mass of the vehicle

-

g = 9,81 m.s ²

α = average incline of the track over the relevant section

Note 1 to this clause: For ropeways, this shall be the average of all angles of the rope (carrying hauling rope or

carrying rope) uphill and downhill from the carrier.

3.2

slipping resistance force

F

characterizes the resistance to slipping provided by a grip.

Note 1 to this clause: A distinction is made between the following slipping resistance forces when they occur:

F calculated slipping resistance force;

theo

Flab slipping resistance force determined experimentally in the laboratory on the rope;

Feff slipping resistance force measured on the rope on the installation.

3.3

pull-off resistance force

F

aus

characterizes the resistance provided by a fixed grip on the rope when a lifting force is exerted normal to

the rope axis in a vertical plane (see Figure 1)

Figure 1 — Pull-off resistance force

3.4

gripping force exerted by the jaws

F

kl

scalar sum of all the normal forces between the surface of the gripping jaws and the surface of the rope.

3.5

funicular railway or aerial ropeway vehicle compartment

passenger compartment, or part of a passenger compartment, whose walls or other delimiting devices

are capable of receiving the impact forces H and H defined in 6.2 exerted by the passengers

X1 Y1

4 Symbols and abbreviations

A reference area for force due to wind [m²]

ref

A force due to impact into buffer [N]

X

d rope diameter (nominal) [mm]

F slipping resistance force [N]

F pull-off resistance force [N]

aus

F slipping resistance force measured on the rope on the installation [N]

eff

F gripping force exerted by the jaws [N]

kl

F slipping resistance force determined experimentally in the laboratory [N]

lab

F calculated slipping resistance force [N]

theo

F force due to the springs of a fixed or detachable grip [N]

F

F action caused by the gradient of the ropes [N]

N

F force exerted by the springs of the onboard brake [N]

R

F force due to the support of a haulage rope [N]

S

F gravitational driving force [N]

T

F wind action [N]

W

F force transverse to the track [N]

Y

G self-weight of the carrier with all its accessories [N]

H longitudinal impact force due to persons [N or

X

N/m]

H transverse impact force due to persons [N or

Y

N/m]

M damping moment [N m]

Y

M torsional moment about the vertical axis [N m]

Z

N number of cycles [-]

O force to open and close a detachable grip [N]

G useful load [N]

Q force due to the action of the onboard brake [N]

F

R reaction force on a carrier when entering the station [N]

S force due to start-up [N]

U reaction force when passing round a sheave [N]

5 General requirements

5.1 Application of the Standard

The requirements of this European Standard apply to all lifts together with those of EN 1709:2019,

EN 1908:2015, EN 1909:2017, EN 12397:2017, EN 12408:2004, EN 12927:2019,

EN 12929:2015+A1:2022, EN 12929-2:2015+A1:2022, EN 12930:2015, EN 13107:2015, EN

13107:2015/AC:2016, EN 13223:2015+A1:2022, EN 13243:2015, EN 13796-2:2017+A1:2022,

EN 13796-3:2017+A1:2022 and EN 17064:2018.

5.2 Safety Principles

5.2.1 General

The safety principles set out in EN 12929-1:2015+A1:2022 apply. In addition, the following hazard

scenarios and safety requirements relative to the scope of this European Standard shall be taken into

account.

5.2.2 Hazard Factors

The following events may lead to hazardous situations that can be avoided or limited by the safety

requirements of this document:

a) overloading of the carrier;

b) exceeding the limits of use permitted by the manufacturer;

c) damage caused by ageing, corrosion, wear, fatigue or deformation;

d) bumps and impacts (between multiple carriers, between carriers and persons, between carriers and

ropes, stations, line structures and external obstacles);

e) derailment and deropement when a carrier passes;

f) derailment or instability of a carrier;

g) failure of the haulage rope or carrying hauling rope where a grip is attached;

h) fault attachments or detachment of a grip;

i) inadequate resistance to slipping and pull-off of a rope grip;

j) faulty door operation (unexpected opening, slamming shut);

k) insufficient protection against persons and any item from the carrier falling;

l) inadequate positioning and difficult access for the maintenance and evacuation personnel;

m) fire;

n) in the event of prolonged stoppage, excessive temperature in enclosed carriers due to weather

conditions.

5.2.3 Safety Measures

The safety measures to be taken to eliminate the hazard scenarios listed in 5.2.2 are the following:

a) checking of the load or limiting the area available to each passenger and systematically informing the

passengers of the maximum authorized load;

b) establishment of an operating manual defining the limits of use;

c) requirements relating to design and manufacture, to the selection of materials, production checks,

type approval tests, pre-commissioning tests and checks during operation;

d) compliance with space envelopes, monitoring of the maximum permissible wind speed in operation,

damping devices on the outside of the carriers;

e) design to enable the free passage of grips in the rope-catchers;

f) requirements relating to the guiding and stability of the carriers;

g) adequate design of the grip to limit the risks of fatigue failure of the haulage rope or carrying hauling

rope;

h) monitoring the attachment and detachment of the carriers, catching a carrier not properly attached

to the rope;

i) monitoring during operation of the gripping force, or of a value representative of this force, of

detachable grips;

j) design of fixed g

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...