SIST EN 13806-3:2025

(Main)Foodstuffs - Determination of trace elements - Part 3: Determination of total mercury in foodstuffs with atomic absorption directly from the foodstuff (elemental mercury analysis)

Foodstuffs - Determination of trace elements - Part 3: Determination of total mercury in foodstuffs with atomic absorption directly from the foodstuff (elemental mercury analysis)

This document specifies a method for the determination of total mercury (Hg) in foodstuffs using direct atomic absorption spectrometry after thermal decomposition in an oxygen or air flow and concentration by amalgam formation. The method is applicable for solid and liquid samples.

This method was tested in a interlaboratory study carried out on seven different materials with a mercury concentration in the range from 0,005 mg/kg to 5,20 mg/kg and successfully validated in this range.

The following foodstuffs were analysed:

— Saithe (dried);

— Celery (dried);

— Wheat noodle powder;

— Wild mushrooms (dried);

— Pig liver (dried);

— Cacao powder;

— Tuna fish (dried).

The lower limit of the method’s applicability varies depending on the food matrix and the water content of the foodstuff. It is a laboratory-specific value and is defined by the laboratory when calculating the limit of quantification (see 9.2).

Lebensmittel - Bestimmung von Elementspuren - Teil 3: Bestimmung des Gesamtquecksilbers in Lebensmitteln durch Atomabsorption direkt aus dem Lebensmittel (Elementare Quecksilberanalyse)

Dieses Dokument legt ein Verfahren zur Bestimmung des Gesamtquecksilbers (Hg) in Lebensmitteln mittels direkter Atomabsorptionsspektrometrie nach thermischer Zersetzung in einem Sauerstoff- oder Luftstrom und Konzentrierung durch Amalgambildung fest. Das Verfahren ist auf feste und flüssige Proben anwendbar.

Dieses Verfahren wurde in einem Ringversuch geprüft, der an sieben verschiedenen Materialien mit einem Quecksilbergehalt im Bereich von 0,005 mg/kg bis 5,20 mg/kg durchgeführt wurde, und wurde für diesen Bereich erfolgreich validiert.

Die folgenden Lebensmittel wurden analysiert:

Seelachs (getrocknet);

(Knollen)-Sellerie (getrocknet);

Weizennudelpulver;

Wildpilze (getrocknet);

Schweineleber (getrocknet);

Kakaopulver;

Thunfisch (getrocknet).

Die untere Grenze der Anwendbarkeit des Verfahrens variiert in Abhängigkeit von der Lebensmittelmatrix und vom Wassergehalt des Lebensmittels. Sie ist laborspezifisch und wird bei der Ermittlung der Bestimmungsgrenze durch das Labor festgelegt (siehe 9.2).

Produits alimentaires - Dosage des éléments traces - Partie 3 : Dosage du mercure total dans les produits alimentaires par absorption atomique directe (analyse du mercure élémentaire)

Le présent document spécifie une méthode pour le dosage du mercure total (Hg) dans les produits alimentaires à l’aide de la spectrométrie d’absorption atomique directe, après décomposition thermique dans un flux d’oxygène ou d’air et concentration par amalgamation. La méthode est applicable aux échantillons solides et liquides.

Cette méthode a été testée dans le cadre d’une étude interlaboratoires réalisée sur sept matériaux différents dans lesquels la concentration du mercure variait entre 0,005 mg/kg et 5,20 mg/kg et a été validée pour ce domaine de concentration.

Les produits alimentaires suivants ont été analysés :

— Lieu noir (séché) ;

— Céleri (séché) ;

— Nouilles de blé en poudre ;

— Champignons sauvages (séchés) ;

— Foie de porc (séché) ;

— Cacao en poudre ;

— Thon (séché).

Le seuil d’applicabilité de la méthode varie en fonction de la matrice alimentaire et de la teneur en eau du produit alimentaire. Il s’agit d’une valeur spécifique au laboratoire, définie par celui-ci lors du calcul de la limite de quantification (voir 9.2).

Živila - Določevanje elementov v sledovih - 3. del: Določevanje celotnega živega srebra v živilih z atomsko absorpcijo neposredno iz živila (elementarna analiza živega srebra)

Ta dokument določa metodo za določevanje celotnega živega srebra (Hg) v živilih z direktno atomsko absorpcijsko spektrometrijo (AAS) po termičnem razkroju v toku kisika ali zraka in koncentriranju s tvorbo amalgama. Ta metoda se uporablja za trdne in tekoče vzorce. Ta metoda je bila preskušena v medlaboratorijski študiji, izvedeni na sedmih različnih materialih s koncentracijo živega srebra v območju od 0,005 mg/kg do 5,20 mg/kg, in uspešno potrjena v tem območju. Analizirana so bila naslednja živila: – trska (posušena); – zelena (posušena); – pšenični rezanci v prahu; – gozdne gobe (posušene); – svinjska jetra (posušena); – kakav v prahu; – tuna (posušena). Spodnja meja uporabnosti metode se razlikuje glede na matrico živila in vsebnost vode v živilu. Gre za laboratorijsko specifično vrednost, ki jo laboratorij določi pri izračunu mejne vrednosti kvantifikacije (glej točko 9.2).

General Information

- Status

- Published

- Public Enquiry End Date

- 10-Sep-2023

- Publication Date

- 03-Apr-2025

- Technical Committee

- KŽP - Agricultural food products

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 03-Apr-2025

- Due Date

- 08-Jun-2025

- Completion Date

- 04-Apr-2025

Relations

- Effective Date

- 01-May-2025

Overview

EN 13806-3:2025 - published by CEN - specifies a validated laboratory method for the determination of total mercury (Hg) in foodstuffs by direct atomic absorption spectrometry (AAS) after thermal decomposition in oxygen/air and concentration by amalgam formation. The procedure applies to both solid and liquid food samples and was validated by an interlaboratory study on seven matrices with Hg levels from 0.005 mg/kg to 5.20 mg/kg.

Key topics and requirements

- Analytical principle: direct thermal decomposition (~700 °C) of weighed sample (no pressure digestion), catalytic gas cleaning, mercury collection on an amalgamator, thermal release and quantification by AAS at 253.7 nm.

- Applicable matrices tested: saithe, celery, wheat noodle powder, wild mushrooms, pig liver, cacao powder, tuna (all dried in the study).

- Performance range: validated for 0.005–5.20 mg/kg; lower limit of applicability depends on matrix and water content and is laboratory-specific (LOQ defined by each lab, see clause 9.2).

- Calibration & reagents: use of stabilized standards (HCl recommended ≈1% in solutions), mercury stock and calibration solutions, fresh preparation of calibration/zero-point solutions; careful control of low-background reagents and water.

- Equipment & cleaning: elemental mercury analyser with appropriate sample carriers (nickel, quartz or ceramic), high-precision balance (0.0001 g readability), and rigorous glassware cleaning per EN 13804 to minimize contamination and adsorption losses.

- Quality control: instrument blanks, calibration checks, measurement cuvettes of different path lengths for extended dynamic range, and statistical performance metrics (precision, reproducibility, trueness) from the interlaboratory study.

- Safety note: method involves hazardous materials and high temperatures; operators must follow lab safety regulations.

Applications and users

Who uses EN 13806-3:2025:

- Food testing laboratories performing routine or regulatory mercury monitoring

- Public health and regulatory authorities assessing Hg compliance in food products

- Laboratories conducting import/export conformity testing and risk assessments

- Food industry QA/QC teams monitoring raw materials (seafood, cocoa, liver, mushrooms, cereals)

- Environmental/analytical labs needing a validated elemental mercury analysis for food matrices

Practical uses:

- Regulatory compliance testing for maximum permitted mercury levels

- Surveillance of seafood and other high-risk foods

- Verification of supplier declarations and batch release testing

- Supporting exposure and dietary risk assessments

Related standards

- EN 13806-1 - AAS cold-vapour technique (complementary method)

- EN 13806-2 - AFS cold-vapour technique (complementary method)

- EN 13804 - General considerations and specific requirements for element and species determination in foodstuffs

Keywords: EN 13806-3:2025, total mercury, foodstuffs, atomic absorption, thermal decomposition, amalgam formation, Hg determination, limit of quantification, elemental mercury analysis.

Frequently Asked Questions

SIST EN 13806-3:2025 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Foodstuffs - Determination of trace elements - Part 3: Determination of total mercury in foodstuffs with atomic absorption directly from the foodstuff (elemental mercury analysis)". This standard covers: This document specifies a method for the determination of total mercury (Hg) in foodstuffs using direct atomic absorption spectrometry after thermal decomposition in an oxygen or air flow and concentration by amalgam formation. The method is applicable for solid and liquid samples. This method was tested in a interlaboratory study carried out on seven different materials with a mercury concentration in the range from 0,005 mg/kg to 5,20 mg/kg and successfully validated in this range. The following foodstuffs were analysed: — Saithe (dried); — Celery (dried); — Wheat noodle powder; — Wild mushrooms (dried); — Pig liver (dried); — Cacao powder; — Tuna fish (dried). The lower limit of the method’s applicability varies depending on the food matrix and the water content of the foodstuff. It is a laboratory-specific value and is defined by the laboratory when calculating the limit of quantification (see 9.2).

This document specifies a method for the determination of total mercury (Hg) in foodstuffs using direct atomic absorption spectrometry after thermal decomposition in an oxygen or air flow and concentration by amalgam formation. The method is applicable for solid and liquid samples. This method was tested in a interlaboratory study carried out on seven different materials with a mercury concentration in the range from 0,005 mg/kg to 5,20 mg/kg and successfully validated in this range. The following foodstuffs were analysed: — Saithe (dried); — Celery (dried); — Wheat noodle powder; — Wild mushrooms (dried); — Pig liver (dried); — Cacao powder; — Tuna fish (dried). The lower limit of the method’s applicability varies depending on the food matrix and the water content of the foodstuff. It is a laboratory-specific value and is defined by the laboratory when calculating the limit of quantification (see 9.2).

SIST EN 13806-3:2025 is classified under the following ICS (International Classification for Standards) categories: 67.050 - General methods of tests and analysis for food products. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13806-3:2025 has the following relationships with other standards: It is inter standard links to SIST EN 13806:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13806-3:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2025

Nadomešča:

SIST EN 13806:2002

Živila - Določevanje elementov v sledovih - 3. del: Določevanje celotnega živega

srebra v živilih z atomsko absorpcijo neposredno iz živila (elementarna analiza

živega srebra)

Foodstuffs - Determination of trace elements - Part 3: Determination of total mercury in

foodstuffs with atomic absorption directly from the foodstuff (elemental mercury analysis)

Lebensmittel - Bestimmung von Elementspuren - Teil 3: Bestimmung des

Gesamtquecksilbers in Lebensmitteln durch Atomabsorption direkt aus dem

Lebensmittel (Elementare Quecksilberanalyse)

Produits alimentaires - Dosage des éléments traces - Partie 3 : Dosage du mercure total

dans les produits alimentaires par absorption atomique directe (analyse du mercure

élémentaire)

Ta slovenski standard je istoveten z: EN 13806-3:2025

ICS:

67.050 Splošne preskusne in General methods of tests and

analizne metode za živilske analysis for food products

proizvode

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13806-3

EUROPEAN STANDARD

NORME EUROPÉENNE

March 2025

EUROPÄISCHE NORM

ICS 67.050 Supersedes EN 13806:2002

English Version

Foodstuffs - Determination of trace elements - Part 3:

Determination of total mercury in foodstuffs with atomic

absorption directly from the foodstuff (elemental mercury

analysis)

Produits alimentaires - Dosage des éléments-traces - Lebensmittel - Bestimmung von Elementspuren - Teil

Partie 3 : Dosage du mercure total dans les produits 3: Bestimmung des Gesamtquecksilbers in

alimentaires par absorption atomique directe (analyse Lebensmitteln durch Atomabsorption direkt aus dem

du mercure élémentaire) Lebensmittel (Elementare Quecksilberanalyse)

This European Standard was approved by CEN on 17 February 2025.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13806-3:2025 E

worldwide for CEN national Members.

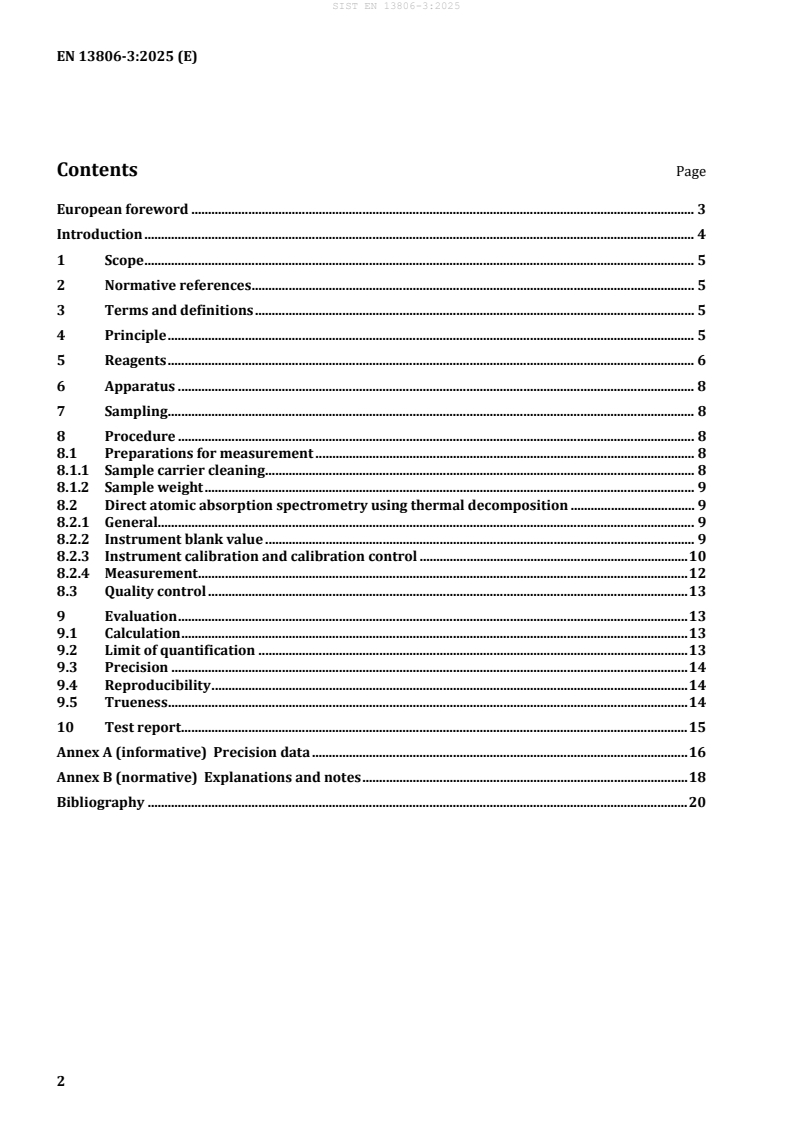

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Principle . 5

5 Reagents . 6

6 Apparatus . 8

7 Sampling . 8

8 Procedure . 8

8.1 Preparations for measurement . 8

8.1.1 Sample carrier cleaning . 8

8.1.2 Sample weight . 9

8.2 Direct atomic absorption spectrometry using thermal decomposition . 9

8.2.1 General. 9

8.2.2 Instrument blank value . 9

8.2.3 Instrument calibration and calibration control . 10

8.2.4 Measurement . 12

8.3 Quality control . 13

9 Evaluation . 13

9.1 Calculation . 13

9.2 Limit of quantification . 13

9.3 Precision . 14

9.4 Reproducibility . 14

9.5 Trueness . 14

10 Test report . 15

Annex A (informative) Precision data . 16

Annex B (normative) Explanations and notes . 18

Bibliography . 20

European foreword

This document (EN 13806-3:2025) has been prepared by Technical Committee CEN/TC 275 “Food

analysis – Horizontal methods”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by September 2025, and conflicting national standards shall

be withdrawn at the latest by September 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 13806:2002.

The main changes compared to the previous edition are listed below:

— the document has been split up into three separate parts: EN 13806-1 covering the AAS-cold-vapour

technique, EN 13806-2 the AFS-cold-vapour technique and EN 13806-3 the solid sample AAS

technique;

— full technical revision to bring the technical realization up to date with the latest technology;

— Stabilization of the digest solution;

— Update of statistical data by new interlaboratory study.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

This document has been developed in parallel with EN 13806-1 [2] and EN 13806-2 [3]. All three

methods were validated in parallel in interlaboratory studies with the same scope. They are statistically

compatible in performances. This allows the users of these documents to employ the most

appropriate/available method depending on the purpose of their studies. The statistical parameters of

these standards are presented in the respective documents.

1 Scope

This document specifies a method for the determination of total mercury (Hg) in foodstuffs using direct

atomic absorption spectrometry after thermal decomposition in an oxygen or air flow and concentration

by amalgam formation. The method is applicable for solid and liquid samples.

This method was tested in a interlaboratory study carried out on seven different materials with a mercury

concentration in the range from 0,005 mg/kg to 5,20 mg/kg and successfully validated in this range.

The following foodstuffs were analysed:

— Saithe (dried);

— Celery (dried);

— Wheat noodle powder;

— Wild mushrooms (dried);

— Pig liver (dried);

— Cacao powder;

— Tuna fish (dried).

The lower limit of the method’s applicability varies depending on the food matrix and the water content

of the foodstuff. It is a laboratory-specific value and is defined by the laboratory when calculating the

limit of quantification (see 9.2).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 13804, Foodstuffs - Determination of elements and their chemical species - General considerations and

specific requirements

3 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

4 Principle

The samples to be analysed are weighed directly - without pressure digestion - into suitable sample

containers and are thermally decomposed in the analyser system in an oxygen atmosphere at approx.

700 °C. The resulting reaction gases are catalytically cleaned together with the mercury vapour, and the

mercury is concentrated on a consecutive amalgamator. Subsequently, the mercury is released as atomic

vapour by fast heating up of the amalgamator, transferred into a system of measurement cuvettes and

quantified by absorption at 253,7 nm.

By the simultaneous use of measurement cuvettes of different lengths, a dynamic measurement range

over several orders of magnitude can be achieved.

The total content of mercury is understood as the content measured using this document. It is indicated

in mg/kg.

WARNING — The use of this method can involve the application of dangerous substances, actions or

equipment. Nevertheless, the method description cannot mention all dangers possibly involved in its

application. Each operator of the method is responsible for taking the appropriate safety precautions and

to respect the corresponding regulations.

5 Reagents

5.1 General

Unless otherwise specified, “solutions” are understood to be aqueous solutions.

The content of mercury in the chemicals and water shall be low enough not to affect the results.

5.2 Hydrochloric acid, ω = 30 % to 37 %, density = approx. 1,15 g/ml.

5.3 Nitric acid, ω = 65 % to 69 %, density = approx. 1,4 g/ml.

5.4 Diluted nitric acid

Nitric acid (5.3) + water, V + V , approx. 1 + 9.

1 2

5.5 Stabilization

The standard, calibration and zero-point solutions are stabilized with hydrochloric acid (5.2). It is

recommended to adjust the hydrochloric acid concentration to approx. ω = 1 % in the solutions.

Alternatively, other stabilizing reagents may be used (for details see the instructions of the instrument

manufacturer or [2]).

5.6 Mercury stock solution, e.g. ϱ = 1 000 mg/l.

The stock solution is commercially available. It is recommended to use certified stock solutions.

5.7 Mercury standard solution

The standard solution is prepared from the stock solution (5.6) by means of dilution (e.g. see Table 1).

For this purpose, fill approx. 5 ml of water into a 20 ml volumetric flask, add the necessary amount of

stabilizing acid (e.g. 0,6 ml hydrochloric acid (5.2)) and mix. After the mixture has cooled down to room

temperature, add the stock solution (5.6) and fill up to the mark with water.

The standard solution is stable for at least one month.

Table 1 — Example for the preparation of Hg standard solution in a 20 ml volumetric flask

Fill up to the

Standard solution Stabilization Initial solution

mark with

[Hg concentration]

water to

200 µl

Standard solution

600 µl hydrochloric acid

20 ml

Hg stock solution

(5.2)

[10 mg/l]

(5.6)

5.8 Mercury calibration solutions and zero-point solution

To produce the examples of calibration solutions and zero-point solution described in Table 2, a 20 ml

volumetric flask is filled with approx. 5 ml of water, the necessary amount of stabilizing acid added

according to Table 2, and mixed. After the mixture has cooled down to room temperature, pipette the

standard solution/calibration solution into the flask and fill up to the mark with water.

Table 2 — Example for the preparation of the Hg calibration solutions and zero-point solution in

20 ml volumetric flasks

Standard Fill up to

Zero-point/ calibration

Stabilization

solution/ the mark

solution

calibration with water

[Hg concentration]

solution to

Zero-point solution 600 µl hydrochloric acid (5.2) - 20 ml

600 µl hydrochloric acid (5.2) 2 000 µl 20 ml

Calibration solution 1

standard

[1 000 µg/l]

solution (5.7)

600 µl hydrochloric acid (5.2) 2 000 µl 20 ml

Calibration solution 2

calibration

[100 µg/l]

solution 1

600 µl hydrochloric acid (5.2) 2 000 µl 20 ml

Calibration solution 3

calibration

[10 µg/l]

solution 2

600 µl hydrochloric acid (5.2) 2 000 µl 20 ml

Calibration solution 4

calibration

[1 µg/l]

solution 3

The mercury calibration solutions and the zero-point solution are used to set up the calibration of the

instrument as specified under 8.2.3.2. For this purpose, they shall be prepared fresh.

NOTE Alternatively, appropriate, certified reference materials can be used for calibration.

5.9 Oxygen or air

The manufacturer’s instructions shall be taken into account, e.g. for the analytical purity.

6 Apparatus

6.1 General

All equipment and labware that come into direct contact with the sample and the solutions used, shall be

carefully pre-treated/cleaned according to EN 13804 to minimize contamination.

For the cleaning of glass and quartz glass equipment the following steps in particular are recommended:

rinsing with tap water, treating with a detergent solution, rinsing again with tap water and immersing

overnight or longer in diluted nitric acid (5.4). Finally, rinse the equipment with high-purity water and

dry them before use. Steam stripping with nitric acid is an effective cleaning method and is used regularly

in element trace analysis.

When preparing solutions, special care shall be taken to avoid contaminations. The volumetric flasks used

for the preparation of the solutions should be made of glass or quartz glass.

Due to the strong adsorption behaviour of mercury on vessel walls it is recommended to always reuse

the same flasks for each concentration of standard and calibration solution. Nevertheless, they shall be

cleaned before each use.

6.2 Elemental mercury analyser

Elemental mercury analyser with instrument control unit and sample containers made of suitable

materials (e.g. nickel, quartz glass or ceramic). The sample containers usually have a capacity of approx.

500 mg of solid sample or 500 µl, 1 000 µl and 1 500 µl of liquids. The instructions in Annex B shall be

observed.

6.3 Analytical balance, readability of at least 0,000 1 g.

For an automated transfer of the sample weights, it is recommended to link the balance to the Hg-

analyser’s control unit (6.2) via a data interface.

7 Sampling

The sampling procedure is not part of the analytical method specified in this document.

Sampling shall be carried out in such a way that there is no loss of or contamination with mercury.

8 Procedure

8.1 Preparations for measurement

8.1.1 Sample carrier cleaning

Mechanically remove any residues adhering to the sample containers. Sample containers made of quartz

glass may be pre-cleaned with diluted nitric acid (5.4) according to EN 13804. Sample containers made

from nickel are only cleaned of adhering residues mechanically.

Subsequently, rinse the sample carriers with water and decontaminate them in a muffle furnace

according to the manufacturers’ instructions, e.g. at approx. 600 °C for at least 15 min. Alternatively, the

sample carriers, without sample weight, could be decontaminated by measuring them in the mercury

analyser by the sample program.

After cleaning, store the sample carriers in a dust-protected place (e.g. in a covered glass petri dish).

Irrespective of the material they are made of, carefully cleaned sample carriers do not show any memory

effects.

8.1.2 Sample weight

The sample prepared according to EN 13804 is weighted directly in the pre-cleaned sample carrier. The

maximum sample quantity depends on the capacity of the sample carrier, the type of sample material and

the expected mercury content (further information under B.2). If the measured absorption value is

outside the calibration range, repeat the analysis with a lower sample weight. With small quantities

attention shall be paid to the homogeneity of the sample and the lowest possible sample weight of the

analytical balance. Solid samples cannot be diluted.

Typical sample weights for sample containers with a volume of approx. 0,5 ml:

Liquid, pasty samples (e.g. milk, 0,1 g to 0,5 g

meat, fruit)

Powdery samples (e.g. flour) 0,05 g to 0,15 g

Samples with high fat content (e.g. 0,05 g to 0,1 g

nuts, margarine)

When analysing samples with high water content, the sample weight may be increased to 0,5 g to 1 g. For

these samples preferably use sample containers with a capacity of 1 ml to 1,5 ml.

NOTE 1 Liquid samples can be applied, for example, to approx. 50 mg of a substrate with low mercury content

(e.g. sea sand, alumina, starch or flour with contents < 0,001 ng of mercury absolute).

Liquid samples should also be weighed in, to prevent insufficient inaccuracies due to sample viscosity

and dosing inaccuracies due to the sample type.

NOTE 2 Samples with high fat content can be coated with a substrate with low mercury content (e.g. sea sand or

alumina with contents < 0,001 ng of mercury absolute), in order to prevent them from squirting in the furnace

during the drying process. Alternatively, furnace programmes with slow heating rates can be used (see 8.2.4,

Table 5).

8.2 Direct atomic absorption spectrometry using thermal decomposition

8.2.1 General

Follow the manufacturer’s instructions with regard to the initial daily operation, stabilizing time and

measurement with the elemental mercury analyser.

8.2.2 Instrument blank value

For solid sample systems the instrument blank value (system blank value originating from measurements

of cleaned sample carriers) is determined every working day, and is deducted from all subsequent

quantifications.

To determine the instrument blank value, measure cleaned sample carriers (8.1.1) in the elemental

mercury analyser. If the absorptions are above a set value, e.g. 0,01, the sample carrier shall be cleaned

again. Discard the blank values measured after switching on and stabilizing the instru

...

SLOVENSKI STANDARD

01-maj-2025

Nadomešča:

SIST EN 13806:2002

Živila - Določevanje elementov v sledovih - 3. del: Določevanje skupnega živega

srebra v živilih z atomsko absorpcijo neposredno iz živila (elementarna analiza

živega srebra)

Foodstuffs - Determination of trace elements - Part 3: Determination of total mercury in

foodstuffs with atomic absorption directly from the foodstuff (elemental mercury analysis)

Lebensmittel - Bestimmung von Elementspuren - Teil 3: Bestimmung des

Gesamtquecksilbers in Lebensmitteln durch Atomabsorption direkt aus dem

Lebensmittel (Elementare Quecksilberanalyse)

Produits alimentaires - Dosage des éléments traces - Partie 3 : Dosage du mercure total

dans les produits alimentaires par absorption atomique directe (analyse du mercure

élémentaire)

Ta slovenski standard je istoveten z: EN 13806-3:2025

ICS:

67.050 Splošne preskusne in General methods of tests and

analizne metode za živilske analysis for food products

proizvode

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13806-3

EUROPEAN STANDARD

NORME EUROPÉENNE

March 2025

EUROPÄISCHE NORM

ICS 67.050 Supersedes EN 13806:2002

English Version

Foodstuffs - Determination of trace elements - Part 3:

Determination of total mercury in foodstuffs with atomic

absorption directly from the foodstuff (elemental mercury

analysis)

Produits alimentaires - Dosage des éléments-traces - Lebensmittel - Bestimmung von Elementspuren - Teil

Partie 3 : Dosage du mercure total dans les produits 3: Bestimmung des Gesamtquecksilbers in

alimentaires par absorption atomique directe (analyse Lebensmitteln durch Atomabsorption direkt aus dem

du mercure élémentaire) Lebensmittel (Elementare Quecksilberanalyse)

This European Standard was approved by CEN on 17 February 2025.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13806-3:2025 E

worldwide for CEN national Members.

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Principle . 5

5 Reagents . 6

6 Apparatus . 8

7 Sampling . 8

8 Procedure . 8

8.1 Preparations for measurement . 8

8.1.1 Sample carrier cleaning . 8

8.1.2 Sample weight . 9

8.2 Direct atomic absorption spectrometry using thermal decomposition . 9

8.2.1 General. 9

8.2.2 Instrument blank value . 9

8.2.3 Instrument calibration and calibration control . 10

8.2.4 Measurement . 12

8.3 Quality control . 13

9 Evaluation . 13

9.1 Calculation . 13

9.2 Limit of quantification . 13

9.3 Precision . 14

9.4 Reproducibility . 14

9.5 Trueness . 14

10 Test report . 15

Annex A (informative) Precision data . 16

Annex B (normative) Explanations and notes . 18

Bibliography . 20

European foreword

This document (EN 13806-3:2025) has been prepared by Technical Committee CEN/TC 275 “Food

analysis – Horizontal methods”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by September 2025, and conflicting national standards shall

be withdrawn at the latest by September 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 13806:2002.

The main changes compared to the previous edition are listed below:

— the document has been split up into three separate parts: EN 13806-1 covering the AAS-cold-vapour

technique, EN 13806-2 the AFS-cold-vapour technique and EN 13806-3 the solid sample AAS

technique;

— full technical revision to bring the technical realization up to date with the latest technology;

— Stabilization of the digest solution;

— Update of statistical data by new interlaboratory study.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

This document has been developed in parallel with EN 13806-1 [2] and EN 13806-2 [3]. All three

methods were validated in parallel in interlaboratory studies with the same scope. They are statistically

compatible in performances. This allows the users of these documents to employ the most

appropriate/available method depending on the purpose of their studies. The statistical parameters of

these standards are presented in the respective documents.

1 Scope

This document specifies a method for the determination of total mercury (Hg) in foodstuffs using direct

atomic absorption spectrometry after thermal decomposition in an oxygen or air flow and concentration

by amalgam formation. The method is applicable for solid and liquid samples.

This method was tested in a interlaboratory study carried out on seven different materials with a mercury

concentration in the range from 0,005 mg/kg to 5,20 mg/kg and successfully validated in this range.

The following foodstuffs were analysed:

— Saithe (dried);

— Celery (dried);

— Wheat noodle powder;

— Wild mushrooms (dried);

— Pig liver (dried);

— Cacao powder;

— Tuna fish (dried).

The lower limit of the method’s applicability varies depending on the food matrix and the water content

of the foodstuff. It is a laboratory-specific value and is defined by the laboratory when calculating the

limit of quantification (see 9.2).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 13804, Foodstuffs - Determination of elements and their chemical species - General considerations and

specific requirements

3 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

4 Principle

The samples to be analysed are weighed directly - without pressure digestion - into suitable sample

containers and are thermally decomposed in the analyser system in an oxygen atmosphere at approx.

700 °C. The resulting reaction gases are catalytically cleaned together with the mercury vapour, and the

mercury is concentrated on a consecutive amalgamator. Subsequently, the mercury is released as atomic

vapour by fast heating up of the amalgamator, transferred into a system of measurement cuvettes and

quantified by absorption at 253,7 nm.

By the simultaneous use of measurement cuvettes of different lengths, a dynamic measurement range

over several orders of magnitude can be achieved.

The total content of mercury is understood as the content measured using this document. It is indicated

in mg/kg.

WARNING — The use of this method can involve the application of dangerous substances, actions or

equipment. Nevertheless, the method description cannot mention all dangers possibly involved in its

application. Each operator of the method is responsible for taking the appropriate safety precautions and

to respect the corresponding regulations.

5 Reagents

5.1 General

Unless otherwise specified, “solutions” are understood to be aqueous solutions.

The content of mercury in the chemicals and water shall be low enough not to affect the results.

5.2 Hydrochloric acid, ω = 30 % to 37 %, density = approx. 1,15 g/ml.

5.3 Nitric acid, ω = 65 % to 69 %, density = approx. 1,4 g/ml.

5.4 Diluted nitric acid

Nitric acid (5.3) + water, V + V , approx. 1 + 9.

1 2

5.5 Stabilization

The standard, calibration and zero-point solutions are stabilized with hydrochloric acid (5.2). It is

recommended to adjust the hydrochloric acid concentration to approx. ω = 1 % in the solutions.

Alternatively, other stabilizing reagents may be used (for details see the instructions of the instrument

manufacturer or [2]).

5.6 Mercury stock solution, e.g. ϱ = 1 000 mg/l.

The stock solution is commercially available. It is recommended to use certified stock solutions.

5.7 Mercury standard solution

The standard solution is prepared from the stock solution (5.6) by means of dilution (e.g. see Table 1).

For this purpose, fill approx. 5 ml of water into a 20 ml volumetric flask, add the necessary amount of

stabilizing acid (e.g. 0,6 ml hydrochloric acid (5.2)) and mix. After the mixture has cooled down to room

temperature, add the stock solution (5.6) and fill up to the mark with water.

The standard solution is stable for at least one month.

Table 1 — Example for the preparation of Hg standard solution in a 20 ml volumetric flask

Fill up to the

Standard solution Stabilization Initial solution

mark with

[Hg concentration]

water to

200 µl

Standard solution

600 µl hydrochloric acid

20 ml

Hg stock solution

(5.2)

[10 mg/l]

(5.6)

5.8 Mercury calibration solutions and zero-point solution

To produce the examples of calibration solutions and zero-point solution described in Table 2, a 20 ml

volumetric flask is filled with approx. 5 ml of water, the necessary amount of stabilizing acid added

according to Table 2, and mixed. After the mixture has cooled down to room temperature, pipette the

standard solution/calibration solution into the flask and fill up to the mark with water.

Table 2 — Example for the preparation of the Hg calibration solutions and zero-point solution in

20 ml volumetric flasks

Standard Fill up to

Zero-point/ calibration

Stabilization

solution/ the mark

solution

calibration with water

[Hg concentration]

solution to

Zero-point solution 600 µl hydrochloric acid (5.2) - 20 ml

600 µl hydrochloric acid (5.2) 2 000 µl 20 ml

Calibration solution 1

standard

[1 000 µg/l]

solution (5.7)

600 µl hydrochloric acid (5.2) 2 000 µl 20 ml

Calibration solution 2

calibration

[100 µg/l]

solution 1

600 µl hydrochloric acid (5.2) 2 000 µl 20 ml

Calibration solution 3

calibration

[10 µg/l]

solution 2

600 µl hydrochloric acid (5.2) 2 000 µl 20 ml

Calibration solution 4

calibration

[1 µg/l]

solution 3

The mercury calibration solutions and the zero-point solution are used to set up the calibration of the

instrument as specified under 8.2.3.2. For this purpose, they shall be prepared fresh.

NOTE Alternatively, appropriate, certified reference materials can be used for calibration.

5.9 Oxygen or air

The manufacturer’s instructions shall be taken into account, e.g. for the analytical purity.

6 Apparatus

6.1 General

All equipment and labware that come into direct contact with the sample and the solutions used, shall be

carefully pre-treated/cleaned according to EN 13804 to minimize contamination.

For the cleaning of glass and quartz glass equipment the following steps in particular are recommended:

rinsing with tap water, treating with a detergent solution, rinsing again with tap water and immersing

overnight or longer in diluted nitric acid (5.4). Finally, rinse the equipment with high-purity water and

dry them before use. Steam stripping with nitric acid is an effective cleaning method and is used regularly

in element trace analysis.

When preparing solutions, special care shall be taken to avoid contaminations. The volumetric flasks used

for the preparation of the solutions should be made of glass or quartz glass.

Due to the strong adsorption behaviour of mercury on vessel walls it is recommended to always reuse

the same flasks for each concentration of standard and calibration solution. Nevertheless, they shall be

cleaned before each use.

6.2 Elemental mercury analyser

Elemental mercury analyser with instrument control unit and sample containers made of suitable

materials (e.g. nickel, quartz glass or ceramic). The sample containers usually have a capacity of approx.

500 mg of solid sample or 500 µl, 1 000 µl and 1 500 µl of liquids. The instructions in Annex B shall be

observed.

6.3 Analytical balance, readability of at least 0,000 1 g.

For an automated transfer of the sample weights, it is recommended to link the balance to the Hg-

analyser’s control unit (6.2) via a data interface.

7 Sampling

The sampling procedure is not part of the analytical method specified in this document.

Sampling shall be carried out in such a way that there is no loss of or contamination with mercury.

8 Procedure

8.1 Preparations for measurement

8.1.1 Sample carrier cleaning

Mechanically remove any residues adhering to the sample containers. Sample containers made of quartz

glass may be pre-cleaned with diluted nitric acid (5.4) according to EN 13804. Sample containers made

from nickel are only cleaned of adhering residues mechanically.

Subsequently, rinse the sample carriers with water and decontaminate them in a muffle furnace

according to the manufacturers’ instructions, e.g. at approx. 600 °C for at least 15 min. Alternatively, the

sample carriers, without sample weight, could be decontaminated by measuring them in the mercury

analyser by the sample program.

After cleaning, store the sample carriers in a dust-protected place (e.g. in a covered glass petri dish).

Irrespective of the material they are made of, carefully cleaned sample carriers do not show any memory

effects.

8.1.2 Sample weight

The sample prepared according to EN 13804 is weighted directly in the pre-cleaned sample carrier. The

maximum sample quantity depends on the capacity of the sample carrier, the type of sample material and

the expected mercury content (further information under B.2). If the measured absorption value is

outside the calibration range, repeat the analysis with a lower sample weight. With small quantities

attention shall be paid to the homogeneity of the sample and the lowest possible sample weight of the

analytical balance. Solid samples cannot be diluted.

Typical sample weights for sample containers with a volume of approx. 0,5 ml:

Liquid, pasty samples (e.g. milk, 0,1 g to 0,5 g

meat, fruit)

Powdery samples (e.g. flour) 0,05 g to 0,15 g

Samples with high fat content (e.g. 0,05 g to 0,1 g

nuts, margarine)

When analysing samples with high water content, the sample weight may be increased to 0,5 g to 1 g. For

these samples preferably use sample containers with a capacity of 1 ml to 1,5 ml.

NOTE 1 Liquid samples can be applied, for example, to approx. 50 mg of a substrate with low mercury content

(e.g. sea sand, alumina, starch or flour with contents < 0,001 ng of mercury absolute).

Liquid samples should also be weighed in, to prevent insufficient inaccuracies due to sample viscosity

and dosing inaccuracies due to the sample type.

NOTE 2 Samples with high fat content can be coated with a substrate with low mercury content (e.g. sea sand or

alumina with contents < 0,001 ng of mercury absolute), in order to prevent them from squirting in the furnace

during the drying process. Alternatively, furnace programmes with slow heating rates can be used (see 8.2.4,

Table 5).

8.2 Direct atomic absorption spectrometry using thermal decomposition

8.2.1 General

Follow the manufacturer’s instructions with regard to the initial daily operation, stabilizing time and

measurement with the elemental mercury analyser.

8.2.2 Instrument blank value

For solid sample systems the instrument blank value (system blank value originating from measurements

of cleaned sample carriers) is determined every working day, and is deducted from all subsequent

quantifications.

To determine the instrument blank value, measure cleaned sample carriers (8.1.1) in the elemental

mercury analyser. If the absorptions are above a set value, e.g. 0,01, the sample carrier shall be cleaned

again. Discard the blank values measured after switching on and stabilizing the instru

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...