SIST EN 17683:2023

(Main)Animal feeding stuffs - Methods of sampling and analysis - Determination of pyrrolizidine alkaloids in animal feeding stuff by LC-MS/MS

Animal feeding stuffs - Methods of sampling and analysis - Determination of pyrrolizidine alkaloids in animal feeding stuff by LC-MS/MS

This document specifies a method for the quantitative determination of pyrrolizidine alkaloids (PA) in the concentration ranges shown in Table 1 in complete and supplementary feed and in forages by liquid chromatography tandem mass spectrometry (LC-MS/MS) after solid phase extraction (SPE) clean-up.

Table 1 - Summary of concentration ranges per PA tested in the collaborative trial

NOTE 1 A second method was part of the method validation collaborative main trial. For this method PA-N-Oxides are reduced by adding zinc powder to the extract of the feed material. The following steps correspond to the first and main method. Quantitative results for each PA except the otonecine type PA senkirkine represent the sum of the free PA base and its corresponding N-oxide.

NOTE 2 Due to insufficient numbers of data for some analyte-matrix combinations statistical evaluation was not valid for standardization. Received data indicated the methods applicability in experienced laboratories with appropriate quality assurance measures. Therefore, the method description is included as an informative annex (Annex D).

Futtermittel - Probenahme- und Untersuchungsverfahren - Bestimmung von Pyrrolizidinalkaloiden in Futtermitteln mittels LC-MS/MS

Dieses Dokument legt ein Verfahren zur quantitativen Bestimmung von Pyrrolizidinalkaloiden (PA) in den in Tabelle 1 angegebenen Konzentrationsbereichen in Allein- und Ergänzungsfuttermitteln sowie in Grünfutter mittels Flüssigchromatographie mit Massenspektrometrie-Kopplung (LC MS/MS) nach Aufreinigung durch Festphasenextraktion (SPE, en: solid phase extraction) fest.

Tabelle 1 - Zusammenfassung der im Ringversuch geprüften Konzentrationsbereiche je PA

ANMERKUNG 1 Ein zweites Verfahren war Teil des Haupt-Ringversuchs zur Verfahrensvalidierung. Bei diesem Verfahren werden PA N Oxide durch Zugabe von Zinkpulver zum Extrakt des Futtermittels reduziert. Die folgenden Schritte entsprechen dem ersten und wichtigsten Verfahren. Die quantitativen Ergebnisse für jedes PA mit Ausnahme des PA vom Otonecin-Typ Senkirkin stellen die Summe der freien PA-Base und ihres entsprechenden N Oxids dar.

ANMERKUNG 2 Aufgrund einer unzureichenden Anzahl von Daten für einige Analyt-Matrix-Kombinationen war die statistische Auswertung für die Normung nicht gültig. Die erhaltenen Daten weisen auf die Anwendbarkeit des Verfahrens in erfahrenen Laboren mit entsprechenden Qualitätssicherungsmaßnahmen hin. Daher ist die Verfahrensbeschreibung als informativer Anhang (Anhang D) beigefügt.

Alimentation animale - Méthodes d’échantillonnage et d’analyse - Dosage des alcaloïdes pyrrolizidiniques dans l'alimentation animale par CL-SM/SM

Le présent document spécifie une méthode de dosage des alcaloïdes pyrrolizidiniques (AP) dans les gammes de concentrations indiquées dans le Tableau 1 dans les aliments composés pour animaux complets et complémentaires ainsi que dans les fourrages, par chromatographie liquide couplée à une spectrométrie de masse en tandem (CL-SM/SM) après purification par extraction en phase solide (SPE).

Tableau 1 - Résumé des gammes de concentrations par AP soumis à essai lors de l’essai interlaboratoires

NOTE 1 Une seconde méthode faisait partie de l’essai interlaboratoires principal de validation de la méthode. Pour cette méthode, les N-oxydes d‘AP sont réduits en ajoutant de la poudre de zinc à l’extrait d’aliment composé pour animaux. Les étapes suivantes correspondent à la première et principale méthode. Les résultats quantitatifs pour chaque AP, excepté l’AP senkirkine de type otonécine, représentent la somme de la base libre d’AP et de son N-oxyde correspondant.

NOTE 2 En raison du nombre insuffisant de données pour certaines combinaisons analyte-matrice, l’évaluation statistique n’était pas valide pour la normalisation. Les données reçues ont indiqué l’applicabilité des méthodes au sein de laboratoires expérimentés avec des mesures d’assurance qualité appropriées. Par conséquent, la description de la méthode est incluse à titre d’annexe informative (Annexe D).

Krma - Metode vzorčenja in analize - Določanje pirolizidinskih alkaloidov v krmi z LCMS/MS

Ta dokument opisuje metodo za kvantitativno določevanje pirolizidinskih alkaloidov (PA) v polnovredni in dopolnilni krmi s tandemsko masno spektrometrijo s tekočinsko kromatografijo (LC-MS/MS) po izpiranju z ekstrakcijo na trdni fazi (SPE).

Ta metoda je bila uspešno potrjena v primerjalnem preskusu za matrice s polnovredno krmo za konje, dopolnilno krmo za konje, dopolnilno krmo za glodavce, seno, lucerno in travno silažo. Potrditev je bila izvedena za pirolizidinske alkaloide (PA) in vrednosti koncentracije, navedene v tabeli 1. Dokazano je bilo, da izomerna para pirolizidinskih alkaloidov sineciverin in senecionin ter senecivernin-N-oksid in senecionin-N-oksid, ni mogoče določiti posamezno zaradi neustreznega kromatografskega ločevanja. Vseeno pa so bile vsote posameznih pirolizidinskih alkaloidov izomernih parov kvantificirane z ustrezno stopnjo ponovljivosti. Upoštevati je treba sočasno eluacijo drugih izomerov pirolizidinskih alkaloidov, ki niso zajeti v metodo. Seznam izomerov s potencialno sočasno eluacijo je podan v dodatku E.

Čeprav je kalibracijsko območje protokola metode določeno od 10 μg/kg do 300 μg/kg, so rezultati primerjalne študije pokazali, da redčenje ekstraktov vzorcev z ekstrakti slepih vzorcev omogoča kvantitativno določanje koncentracij, ki presegajo kalibracijsko območje. Zadovoljiva ponovljivost je vila dosežena pri kvantificiranju do 1428 μg/kg za posamezen pirolizidinski alkaloid in do 887 μg/kg za vsoto izomernih parov.

OPOMBA 1: Druga metoda je bila del primerjalnega glavnega preskusa potrjevanja metode. Pri tej metodi so bili PA-N-oksidi zmanjšani z dodajanjem cinkovega prahu ekstraktu krmnega material. Spodnji koraki ustrezajo prvi in glavni metodi. Kvantitativni rezultati za vsak pirolizidinski alkaloid razen pirolizidinskega alkaloida senkirkin vrste otenocin predstavljajo vsoto proste baze pirolizidinskih alkaloidov in njen ustrezen N-oksid.

OPOMBA 2: Zaradi nezadostnega števila podatkov za nekatere kombinacije analita in matrike statistična ocena za standardizacijo ni bila veljavna. Pridobljeni rezultati so kazali uporabnost metod v izkušenih laboratorijih z ustrezno kakovostjo ukrepov za zagotavljanje kakovosti. Za to je opis metode vključen kot informativni dodatek (dodatek D).

General Information

- Status

- Published

- Public Enquiry End Date

- 14-Sep-2021

- Publication Date

- 05-Apr-2023

- Technical Committee

- KŽP - Agricultural food products

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 30-Mar-2023

- Due Date

- 04-Jun-2023

- Completion Date

- 06-Apr-2023

Overview

SIST EN 17683:2023 specifies a validated laboratory method for the quantitative determination of pyrrolizidine alkaloids (PA) in animal feeding stuffs and forages using LC‑MS/MS after solid phase extraction (SPE) clean‑up. The standard covers PA concentration ranges tested in the collaborative trial (see Table 1), applicable to complete and supplementary feeds and to forages such as hay, alfalfa and grass silage. The method was developed and validated within CEN/TC 327 and includes procedural details from sampling and extraction to chromatographic separation and mass spectrometric detection.

Key topics and technical requirements

- Target analytes: Multiple PAs and corresponding N‑oxides (list of standards included), with quantification generally representing the sum of PA base + N‑oxide except for otonecine type senkirkine.

- Validated matrices: Complete feed for horses, supplementary feed (horses, rodents), hay, alfalfa, grass silage (collaborative trial validation).

- Sample preparation: Test portion (2 g) extraction by sonication in aqueous sulphuric acid, centrifugation and SPE clean‑up (C18 reversed phase).

- Chromatography & detection: RP‑HPLC separation with a binary gradient and detection by triple‑stage quadrupole LC‑MS/MS; quantification via matrix matched calibration (MMS).

- Calibration & range: Protocol calibration range specified from 10 µg/kg to 300 µg/kg; validated results indicate acceptable quantification after extract dilution up to ~1 428 µg/kg for individual PA and ~887 µg/kg for isomer sums.

- Isomeric limitations: Certain isomeric pairs (e.g., senecivernine/senecionine) cannot be fully chromatographically resolved individually - sums are reported.

- Quality & safety: Includes precision data, performance criteria, and warnings about hazardous reagents and operations.

- Annexes: Informative annexes provide precision data (A), example LC‑MS/MS conditions and chromatograms (B, C), alternative reduction method for N‑oxides using zinc (Annex D), and a list of potentially co‑eluting PA isomers (Annex E).

Practical applications and who uses this standard

- Laboratories performing feed safety testing for regulators and industry (official control laboratories, commercial testing labs).

- Quality assurance teams in the animal feed industry implementing contaminant monitoring for hay, silage and compound feeds.

- Research institutions studying plant toxins, PA contamination routes, and toxicology.

- Regulatory authorities and risk assessors referencing validated methods for enforcement and surveillance programs across the EU.

Practical benefits include standardized sample processing, improved inter‑laboratory comparability using matrix matched calibration, and guidance on handling PA‑N‑oxides and co‑eluting isomers.

Related standards and references

- EN ISO 3696 - Water for analytical laboratory use (referenced normative document).

- Commission Regulation (EU) 2020/2040 - lists of potentially co‑eluting PA isomers (informative context cited in the standard).

Keywords: pyrrolizidine alkaloids, PA, LC‑MS/MS, animal feeding stuffs, feed testing, solid phase extraction, matrix matched calibration, feed safety, SEN17683.

Frequently Asked Questions

SIST EN 17683:2023 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Animal feeding stuffs - Methods of sampling and analysis - Determination of pyrrolizidine alkaloids in animal feeding stuff by LC-MS/MS". This standard covers: This document specifies a method for the quantitative determination of pyrrolizidine alkaloids (PA) in the concentration ranges shown in Table 1 in complete and supplementary feed and in forages by liquid chromatography tandem mass spectrometry (LC-MS/MS) after solid phase extraction (SPE) clean-up. Table 1 - Summary of concentration ranges per PA tested in the collaborative trial NOTE 1 A second method was part of the method validation collaborative main trial. For this method PA-N-Oxides are reduced by adding zinc powder to the extract of the feed material. The following steps correspond to the first and main method. Quantitative results for each PA except the otonecine type PA senkirkine represent the sum of the free PA base and its corresponding N-oxide. NOTE 2 Due to insufficient numbers of data for some analyte-matrix combinations statistical evaluation was not valid for standardization. Received data indicated the methods applicability in experienced laboratories with appropriate quality assurance measures. Therefore, the method description is included as an informative annex (Annex D).

This document specifies a method for the quantitative determination of pyrrolizidine alkaloids (PA) in the concentration ranges shown in Table 1 in complete and supplementary feed and in forages by liquid chromatography tandem mass spectrometry (LC-MS/MS) after solid phase extraction (SPE) clean-up. Table 1 - Summary of concentration ranges per PA tested in the collaborative trial NOTE 1 A second method was part of the method validation collaborative main trial. For this method PA-N-Oxides are reduced by adding zinc powder to the extract of the feed material. The following steps correspond to the first and main method. Quantitative results for each PA except the otonecine type PA senkirkine represent the sum of the free PA base and its corresponding N-oxide. NOTE 2 Due to insufficient numbers of data for some analyte-matrix combinations statistical evaluation was not valid for standardization. Received data indicated the methods applicability in experienced laboratories with appropriate quality assurance measures. Therefore, the method description is included as an informative annex (Annex D).

SIST EN 17683:2023 is classified under the following ICS (International Classification for Standards) categories: 65.120 - Animal feeding stuffs. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 17683:2023 is associated with the following European legislation: EU Directives/Regulations: 882/2004; Standardization Mandates: M/523. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 17683:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2023

Krma - Metode vzorčenja in analize - Določanje pirolizidinskih alkaloidov v krmi z

LCMS/MS

Animal feeding stuffs - Methods of sampling and analysis - Determination of pyrrolizidine

alkaloids in animal feeding stuff by LC-MS/MS

Futtermittel - Probenahme- und Untersuchungsverfahren - Bestimmung von

Pyrrolizidinalkaloiden in Futtermitteln mittels LC-MS/MS

Alimentation animale - Méthodes d’échantillonnage et d’analyse - Dosage des alcaloïdes

pyrrolizidiniques dans l'alimentation animale par CL-SM/SM

Ta slovenski standard je istoveten z: EN 17683:2023

ICS:

65.120 Krmila Animal feeding stuffs

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17683

EUROPEAN STANDARD

NORME EUROPÉENNE

March 2023

EUROPÄISCHE NORM

ICS 65.120

English Version

Animal feeding stuffs - Methods of sampling and analysis -

Determination of pyrrolizidine alkaloids in animal feeding

stuff by LC-MS/MS

Alimentation animale - Méthodes d'échantillonnage et Futtermittel - Probenahme- und

d'analyse - Dosage des alcaloïdes pyrrolizidiniques Untersuchungsverfahren - Bestimmung von

dans l'alimentation animale par CL-SM/SM Pyrrolizidinalkaloiden in Futtermitteln mittels LC-

MS/MS

This European Standard was approved by CEN on 17 January 2023.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17683:2023 E

worldwide for CEN national Members.

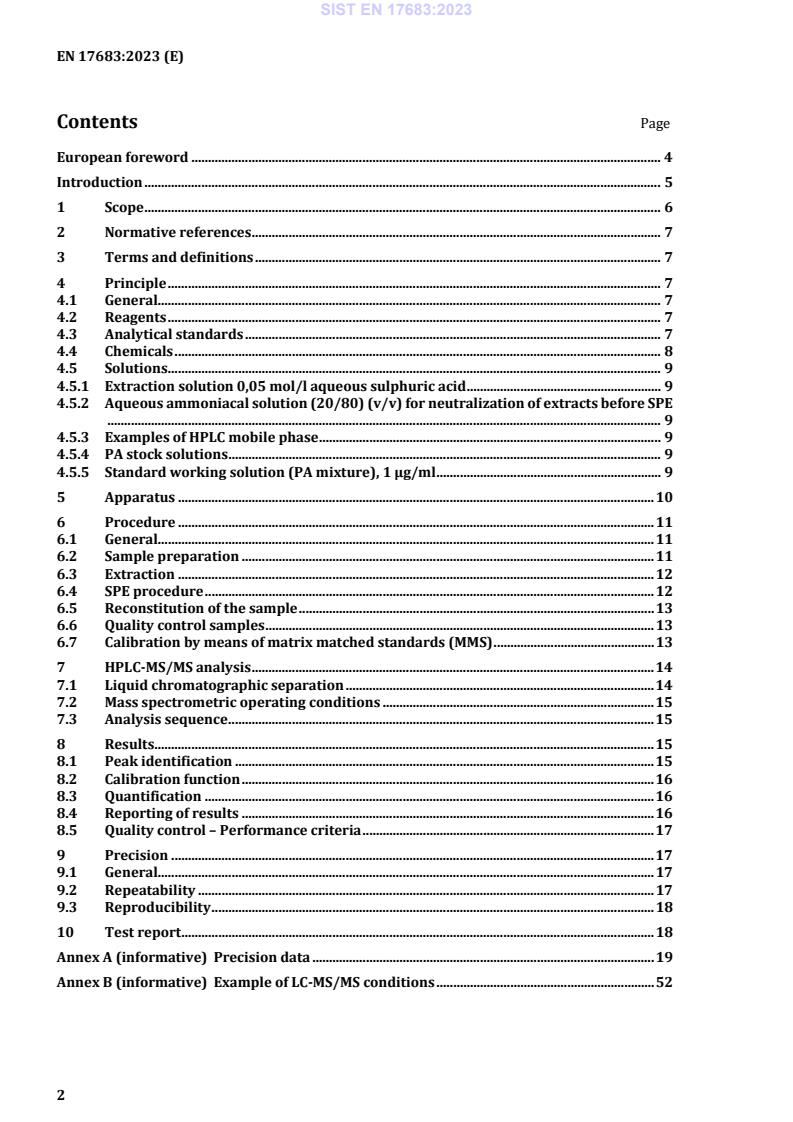

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 7

3 Terms and definitions . 7

4 Principle . 7

4.1 General. 7

4.2 Reagents . 7

4.3 Analytical standards . 7

4.4 Chemicals . 8

4.5 Solutions . 9

4.5.1 Extraction solution 0,05 mol/l aqueous sulphuric acid . 9

4.5.2 Aqueous ammoniacal solution (20/80) (v/v) for neutralization of extracts before SPE

..................................................................................................................................................................... 9

4.5.3 Examples of HPLC mobile phase . 9

4.5.4 PA stock solutions . 9

4.5.5 Standard working solution (PA mixture), 1 µg/ml . 9

5 Apparatus . 10

6 Procedure . 11

6.1 General. 11

6.2 Sample preparation . 11

6.3 Extraction . 12

6.4 SPE procedure . 12

6.5 Reconstitution of the sample . 13

6.6 Quality control samples . 13

6.7 Calibration by means of matrix matched standards (MMS) . 13

7 HPLC-MS/MS analysis . 14

7.1 Liquid chromatographic separation . 14

7.2 Mass spectrometric operating conditions . 15

7.3 Analysis sequence . 15

8 Results . 15

8.1 Peak identification . 15

8.2 Calibration function . 16

8.3 Quantification . 16

8.4 Reporting of results . 16

8.5 Quality control – Performance criteria . 17

9 Precision . 17

9.1 General. 17

9.2 Repeatability . 17

9.3 Reproducibility . 18

10 Test report . 18

Annex A (informative) Precision data . 19

Annex B (informative) Example of LC-MS/MS conditions . 52

Annex C (informative) Example LC-MS/MS chromatogram of a pyrrolizidine alkaloid

mixture . 55

Annex D (informative) Method protocol for the determination of pyrrolizidine alkaloids in

animal feeding stuff by LC-MS/MS after reduction of N-oxides using metallic zinc . 56

Annex E (informative) List of potentially co-eluting pyrrolizidine alkaloid (PA) isomers . 66

Bibliography . 67

European foreword

This document (EN 17683:2023) has been prepared by Technical Committee CEN/TC 327 “Animal

feeding stuffs: Methods of sampling and analysis”, the secretariat of which is held by NEN.

This European Standard shall be given the status of a national standard, either by publication of

an identical text or by endorsement, at the latest by September 2023, and conflicting national standards

shall be withdrawn at the latest by September 2023.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document has been prepared under a Standardization Request given to CEN by the European

Commission and the European Free Trade Association.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

Pyrrolizidine alkaloids (PA) are secondary metabolites of flowering plants. Ingestion of high doses results

in acute liver damage. In animal studies some PA have proven to be genotoxic carcinogens. Therefore, PA

are undesired substances in food and feed [1], [2]. Poisoning in animals has been reported with known

outbreaks attributed to Heliotropium, Trichodesma, Senecio, and Crotalaria species. In general, grazing

animals will avoid PA-bearing plants. However, if weedy crops are used for the production of hay, silage

or other plant derived feed materials the animals can no longer exercise discrimination when feeding

because the toxins survive storage processes and are completely intermixed with the feed. Therefore,

analytical methods for the control of PA levels in animal feed are needed [1], [2]. This document describes

methods of sampling and analysis for the determination of pyrrolizidine alkaloids in animal feeding stuff

by LC-MS/MS.

The method has been successfully validated in a collaborative trial for the matrices complete feed for

horses, supplementary feed for horses, supplementary feed for rodents, hay, alfalfa and grass silage.

Validation was carried out for the PA and concentrations ranges as described in Clause 1. It was

demonstrated that the PA isomeric pairs senecivernine and senecionine as well as senecivernine-N-oxide

and senecionine-N-oxide cannot be determined individually due to insufficient chromatographic

separation. However, the sums of the individual PA of the isomeric pairs were quantified with sufficient

reproducibility. Co-elution of other PA-isomers not included in the scope of the method need to be taken

into account. A list of potentially co-eluting isomers is presented in Commission Regulation (EU)

2020/2040 [3].

Although the calibration range of the method protocol is specified from 10 µg/kg to 300 µg/kg, the results

of the collaborative study showed, that the dilution of sample extracts with blank sample extracts enables

for the quantitation of concentrations exceeding the calibration range. Satisfactory reproducibility was

achieved when quantifying up to 1 428 µg/kg for individual PA and up to 887 µg/kg for the sum of

isomeric pairs.

WARNING — The use of this protocol involves hazardous materials, operations and equipment. This

protocol does not purport to address all the safety problems associated with its use. It is the responsibility

of the user of this protocol to establish appropriate health and safety practices and determine the

compatibility with regulatory limitations prior to use.

1 Scope

This document specifies a method for the quantitative determination of pyrrolizidine alkaloids (PA) in

the concentration ranges shown in Table 1 in complete and supplementary feed and in forages by liquid

chromatography tandem mass spectrometry (LC-MS/MS) after solid phase extraction (SPE) clean-up.

Table 1 — Summary of concentration ranges per PA tested in the collaborative trial

a

Tested pyrrolizidine alkaloid (PA) Abbreviation Tested concentration range

(µg/kg)

From To

Echimidine Em 20 435

Echimidine-N-oxide EmN 5 30

Erucifoline Er 20 245

Erucifoline-N-oxide ErN 20 370

Europine Eu 15 330

Europine-N-oxide EuN 25 285

Heliotrine Hn 25 280

Heliotrine-N-oxide HnN 25 245

Jacobine Jb 20 230

Jacobine-N-oxide JbN 20 215

Lasiocarpine Lc 20 350

Lasiocarpine-N-oxide LcN 5 250

Intermedine Im 25 560

Intermedine-N-oxide ImN 5 395

Lycopsamine La 25 500

Lycopsamine-N-oxide LaN 20 280

Monocrotaline Mc 20 360

Monocrotaline-N-oxide McN 20 365

Retrorsine Re 250 375

Retrorsine-N-oxide ReN 5 285

b

Senecionine Sc 25 205

b

Senecionine-N-oxide ScN 5 300

b

Senecivernine Sv 20 205

b

Senecivernine-N-oxide SvN 5 165

Senkirkine Sk 20 275

Seneciphylline Sp 25 225

Seneciphylline-N-oxide SpN 5 225

Trichodesmine Td 5 250

Intermedine + Lycopsamine Im+La 50 890

Intermedine-N-oxide + Lycopsamine-N-oxide ImN+LaN 5 645

Senecivernine + Senecionine Sv+Sc 30 280

Senecivernine-N-oxide + Senecionine-N-ide SvN+ScN 10 380

a

Rounded figures

b

Individual PA of the isomeric pairs Sv+Sc and SvN+ScN were not evaluated statistically due to insufficient

chromatographic separation.

NOTE 1 A second method was part of the method validation collaborative main trial. For this method PA-N-

Oxides are reduced by adding zinc powder to the extract of the feed material. The following steps correspond to the

first and main method. Quantitative results for each PA except the otonecine type PA senkirkine represent the sum

of the free PA base and its corresponding N-oxide.

NOTE 2 Due to insufficient numbers of data for some analyte-matrix combinations statistical evaluation was not

valid for standardization. Received data indicated the methods applicability in experienced laboratories with

appropriate quality assurance measures. Therefore, the method description is included as an informative annex

(Annex D).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN ISO 3696, Water for analytical laboratory use - Specification and test methods (ISO 3696)

3 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

4 Principle

4.1 General

A test portion of 2 g feed material is sonicated twice in aqueous sulphuric acid solution for PA extraction.

After centrifugation, an aliquot of the supernatant is purified by solid phase extraction (SPE) using

reversed phase (C18) material. PA are released from the cartridge using methanol. Subsequently, the

eluate is evaporated to dryness and reconstituted in methanol/water (initial HPLC conditions).

For chromatographic separation, an RP-HPLC column is used with a binary gradient. Analytes are

detected by triple stage quadrupole mass spectrometry. Quantification of PA is accomplished by means

of matrix matched calibration.

4.2 Reagents

All chemicals should at least be of pro-analysis quality or higher. References to products or vendors are

just for general information and do not imply that other products or producers with the same or similar

characteristics are ruled out.

If not specified elsewise, use only reagents of analytical grade and solvents suitable for HPLC-MS/MS.

4.3 Analytical standards

4.3.1 Senecionine (Sc), CAS-Nr.: 130-01-8

4.3.2 Senecionine-N-oxide (ScN), CAS-Nr.: 13268-67-2

4.3.3 Seneciphylline (Sp), CAS-Nr.: 480-81-9

4.3.4 Seneciphylline-N-oxide (SpN), CAS-Nr.: 38710-26-8

4.3.5 Monocrotaline (Mc), CAS-Nr.: 315-22-0

4.3.6 Monocrotaline-N-oxide (McN), CAS-Nr.: 35337-98-5

4.3.7 Retrorsine (Re), CAS-Nr.: 480-54-6

4.3.8 Heliotrine (Hn), CAS-Nr.: 303-33-3

4.3.9 Heliotrine-N-oxide (HnN), CAS-Nr.: 6209-65-0

4.3.10 Trichodesmine (Td), CAS-Nr.: 548-90-3

4.3.11 Retrorsine-N-oxide (ReN), CAS-Nr.: 15503-86-3

4.3.12 Echimidine (Em), CAS-Nr.: 520-68-3

4.3.13 Echimidine-N-oxide (EmN), CAS-Nr.: 41093-89-4

4.3.14 Intermedine (Im), CAS-Nr.: 10285-06-0

4.3.15 Intermedin-N-oxide (ImN), CAS-Nr.: 95462-14-9

4.3.16 Lycopsamine (La), CAS-Nr.: 10285-07-1

4.3.17 Lycopsamine-N-oxide (LaN), CAS-Nr.: 95462-15-0

4.3.18 Erucifoline (Er), CAS-Nr.: 40158-95-0

4.3.19 Erucifoline-N-oxide (ErN), CAS-Nr.: 123864-94-8

4.3.20 Senecivernine (Sv), CAS-Nr.: 72755-25-0

4.3.21 Senecivernine-N-oxide (SvN), CAS-Nr.: 101687-28-9

4.3.22 Jacobine (Jb), CAS-Nr.: 6870-67-3

4.3.23 Jacobine-N-oxide (JbN), CAS-Nr.: 38710-25-7

4.3.24 Lasiocarpine (Lc), CAS-Nr.: 303-34-4

4.3.25 Lasiocarpine-N-oxide (LcN), CAS-Nr.: 127-30-0

4.3.26 Europine (Eu) as europine hydrochloride, CAS-Nr.: 570-19-4

4.3.27 Europine-N-oxide (EuN), CAS-Nr.: 65582-53-8

4.3.28 Senkirkine (Sk), CAS-Nr.: 2318-18-5

4.4 Chemicals

4.4.1 Formic acid (HCOOH) 98 to 100 %

4.4.2 Methanol (MeOH) in LC-MS quality

4.4.3 Sulphuric acid (H SO ) 98 %

2 4

4.4.4 Ammonia (NH ) 32 %

4.4.5 Ammonium formate (NH COOH) in LC-MS quality

4.4.6 Acetonitrile (CH CN) in LC-MS quality

4.4.7 Water (H O) in LC-MS quality, double-distilled or water of grade 1 as defined in EN ISO 3696

4.5 Solutions

4.5.1 Extraction solution 0,05 mol/l aqueous sulphuric acid

Prepare a 0,05 mol/l solution of aqueous sulphuric acid. Make up 2,665 ml of sulphuric acid (H SO )

2 4

(4.4.3) to 1 l with water (4.4.7). The extraction solution can be used for 1 month when stored at room

temperature.

4.5.2 Aqueous ammoniacal solution (20/80) (v/v) for neutralization of extracts before SPE

Dilute a volume fraction of 20 % ammonia 32 % (4.4.4) with a volume fraction of 80 % water (4.4.7). The

solution shall be prepared every working day.

EXAMPLE Mix 5 ml of ammonia 32 % with 20 ml of water (4.4.7).

4.5.3 Examples of HPLC mobile phase

• Eluent A 5 mmol/l ammonium formate in water with 0,1 % formic acid:

Weigh 315 mg ammonium formate (4.4.5) and dissolve in 5 ml of water (4.4.7) in a 1 000 ml

volumetric flask, add 1 ml of formic acid (4.4.1) and make up to 1 l with water (4.4.7). The solution

can be used for 1 month when stored at room temperature.

• Eluent B 5 mmol/l ammonium formate in methanol with 0,1 % formic acid::

Weigh 315 mg ammonium formate (4.4.5) and dissolve in 5 ml of water (4.4.7) in a 1 000 ml

volumetric flask, add 1 ml of formic acid (4.4.1) and make up to 1 l with methanol (4.4.2). The

solution can be used for 3 months when stored at room temperature.

4.5.4 PA stock solutions

To create a stock solution, weigh 1 mg to 10 mg (depending on the amount available per unit purchased)

of a pyrrolizidine alkaloid standard in a 10 ml volumetric flask using an analytical balance (5.2) and make

up to 10 ml with a suitable organic solvent like methanol or acetonitrile. The resulting concentration of

the stock solution is 0,1 mg/ml to 1 mg/ml. Stock solutions are stable for at least 2 years when

stored below −18 °C.

If the available analytical balance does not provide sufficient accuracy, higher quantities shall be weighed.

NOTE Instructions of standard providers can indicate suitable solvents for the preparation of stock solutions

but are not mandatory to be used.

4.5.5 Standard working solution (PA mixture), 1 µg/ml

Transfer respective volumes each PA stock solution between 0,1 mg/ml to 1 mg/ml (4.5.4) using an

appropriate device (5.1) into a volumetric flask (5.12) and make up with acetonitrile (4.4.6), to achieve a

concentration of 1 µg/ml for each PA contained in the mixture. Long term stability tests proved

acetonitrile to be the most suitable solvent, but is not mandatory to be used. The PA mixture is stable for

at least 2 years when stored below −18 °C.

If no baseline separation can be achieved for an isomeric pair (intermedine(-N-oxide) and lycopsamine

(-N-oxide); senecivernine(-N-oxide) and senecionine(-N-oxide)), the sum concentration of both PA can

be calculated via the calibration of one of them. The composition of the standard mix shall be prepared

accordingly by including only one isomer of the pair. In case of baseline separation of the isomeric pairs

all pa analytical standards including 4.3.20 and 4.3.21 should be included in the PA mixture.

5 Apparatus

Use laboratory equipment and, in particular, the following elements.

NOTE References to products, instruments or vendors are just for general information and do not imply that

other products or producers with the same or similar characteristics are ruled out.

5.1 Various piston pipettes and multiple dispenser and respective tips

5.2 Analytical balance, capable of weighing to 0,1 mg accuracy

5.3 Compartment drier

5.4 Centrifugal mill with 0,5 mm sieve

5.5 Centrifuge for 50 ml centrifuge tubes, capable of at least 5 000 g

5.6 Laboratory shaker

5.7 Overhead shaker

5.8 Evaporation station with or without vacuum support

5.9 Ultrasonic bath

5.10 Centrifuge tubes 50 ml

5.11 Test tubes 15 ml

5.12 Volumetric flasks, 10 ml and 20 ml

5.13 Folded filters

5.14 SPE cartridges: C18, 500 mg sorbent material

® 1

NOTE Supelco Discovery DSC18 500 mg/6 ml is an example of a suitable product available commercially .

5.15 pH indicator strips

5.16 SPE vacuum chamber

5.17 Membrane filter 0,2 µm or 0,45 µm

Centrifugal filters should have > 0,5 ml capacity and contain modified nylon membrane. Other filtering

tools can be used as well.

1 ®

Supelco Discovery is an example of a suitable product available commercially. This information is given for the

convenience of users of this document and does not constitute an endorsement by CEN of this product.

5.18 HPLC vials 2 ml

5.19 Glass inserts, 250 µl conic for HPLC vials

5.20 Chromatographic column

C18 reversed phase packing material applicable at acidic pH-conditions (pH 2-3), capable of baseline

separation of analytes with identical molecular mass, separation of isomeric pairs is desirable. Other

stationary phases (for example biphenyl phases) or mobile phases (for example with basic pH) can be

used if comparable or better baseline separation of isomers is achieved.

5.21 LC-MS/MS system

Capable of performing multiple selected reaction monitoring in positive ionization mode, with a

sufficiently wide dynamic range and capable of unit mass separation and equipped with a computer-

based data processing system. Any ionization source giving sufficient yield may be employed. Exemplarily

instrument configuration and measuring conditions are shown in Annex B.

6 Procedure

6.1 General

Animal feed is a complex matrix containing a wide range of ingredients in varying amounts leading to

variable and sample dependent matrix effects (suppression/enhancement). For this reason, a

quantification of the analytes shall be accomplished by matrix-matched calibration.

Comparison of matrix effects of different feed materials has shown that there might be a difference in

signal suppression of around 50 % depending on the analyte-matrix combination. As usually a variety of

feed materials can be analysed in one sequence, a representative mix of blank feed materials can be used

(e.g. 75 % different types of grass, like hay and silage, and legumes and 25 % cereals). If the sequence

contains only samples of one specific feed material, a blank matrix as similar as possible to the sample

matrix should be used for matrix-matched calibration.

Samples exceeding the calibration range can be diluted using blank sample extract. Recovery shall be

checked with every series of samples proving the required range of recovery. Recovery correction is

carried out if recovery is outside of 90 % to 110 % according to EURL-MP’s Guidance document on

performance criteria for the analysis of mycotoxins and plant toxins in food and feed [4]

6.2 Sample preparation

To determine the PA concentration that is representative for the entire sample, the sample material

should meet the following characteristics: uniform particle size and a homogenous distribution.

Therefore, an appropriate portion of the sample material is ground to a particle size of 0,5 mm (5.4) and

homogenized for example using an overhead shaker (5.7).

Prior to grinding fresh feed samples (for example silage or grass) are dried at 40 °C to 45 °C at

atmospheric pressure for approximately 18 h in a drying oven (5.3). Frozen samples are defrosted at

room temperature before drying.

Dry samples are mixed with dry ice (ratio 2:1) and the mixture is allowed to stand for 10 min before

grinding to a particle size of 0,5 mm using an ultra-centrifugal mill (5.4). The ground material is

homogenized by shaking for example using an overhead shaker (5.7) for 1 h.

NOTE Grinding with dry ice has proven to obtain excellent grinding results due to shear forces and porosity of

the frozen sample material.

If the test material cannot be ground to a particle size of 0,5 mm or smaller without generation of heat,

increasing the weighed sample amount to at least 10 g is also possible to enhance the results

representativeness for the sample. In order to keep a constant ratio of sample amount to extraction

volume, the used volume of extraction solution (4.5.1) needs to be increased accordingly.

Laboratories shall prove that the performance of their homogenization procedure used is sufficient.

6.3 Extraction

Weigh 2,0 g ± 0,1 g of the homogenized sample into a centrifuge tube (5.10).

1) Extraction step 1: Add 20 ml of the extraction solution (4.5.1) to the sample and mix (5.6) to wet

the sample material completely before extraction by ultra-sonication (5.9) for 15 min at ambient

temperature.

NOTE 1 Extraction can be accomplished by other techniques than ultra-sonication (e.g. using an over-head

shaker), if sufficient extraction efficiency was shown during in-house validation.

2) Centrifugation: Centrifuge the tube for 10 min ± 2 min at approximately 3800 g (5.5). Transfer the

supernatant (extract 1) into a clean centrifuge tube (5.10) and use the sediment for the second

extraction step.

3) Extraction step 2: Add 20 ml of extraction solution (4.5.1) to the sediment. Shake the centrifuge tube

vigorously to distribute the sample (the sample can also be stirred if necessary) and extract again by

ultra-sonication for 15 min at ambient temperature.

NOTE 2 Extraction can be accomplished by other techniques than ultra-sonication (e.g. using an over-head

shaker), if sufficient extraction efficiency was shown during in-house validation.

4) Centrifugation: Centrifuge the tube for 10 min ± 2 min at approximately 3800 g (see 5.5) and

combine the supernatant (extract 2) with extract 1.

5) Neutralization: Adjust the pH of the combined extracts to pH 7 using the neutralization solution

(4.5.2). Check the pH value using indicator strips. Usually, about 500 µl to 1 000 µl of the solution is

required.

6) Filtration: Pass the complete neutralized extract through a filter (e.g. folded filters see 5.13) or

centrifuge alternatively. Use an aliquot of the filtered supernatant for SPE. Repeat the filtration step

in case of larger quantities of remaining particles in the solution. Thereby, blockage of SPE cartridges

can be avoided.

6.4 SPE procedure

If SPE cartridges other than proposed under 5.14 are used, solvent volumes for conditioning, sample

loading, washing and eluting have to be adapted. Depending on the solid phase material, it might be

necessary to protect the stationary from running dry until the washing step.

1) Conditioning step 1: Load 5 ml of methanol (4.4.2) onto the SPE cartridge (5.14) and let it pass

through under normal pressure.

2) Conditioning step 2: Load 5 ml of water (4.4.7) onto the SPE cartridge (5.14) and let it pass through

under normal pressure.

3) Sample load: Load 10 ml of the sample extract (combined supernatants from 6.3) onto the SPE

cartridge (5.14) and let it pass through without letting the cartridge run dry.

4) Washing step: Wash the SPE cartridge (5.14) 2 × 5 ml of water.

5) Drying of cartridges: Dry the SPE cartridges (5.14) by applying vacuum for 5 - 10 min (use the

vacuum chamber (5.15).

6) Elution of PA: Elute the analytes from the SPE cartridges (see 5.14) using 2 × 5 ml methanol (see

4.4.2) into a clean test tube (5.11). The eluate is dried under a nitrogen stream at 50 °C ± 5 °C (5.8),

or according to the recommendations for the evaporation equipment used.

6.5 Reconstitution of the sample

Dissolve the residue in 1 ml of methanol/water (5/95, v/v) by shaking (5.7).

Filter the reconstituted sample extracts through a 0,2 to 0,45 µm membrane filter (5.17). When using

centrifugal filters, 500 µl of the sample are centrifuged at 20 000 g for 10 min ± 3 min. Transfer 200 µl of

the filtrate into an HPLC vial (5.18) with a glass insert (5.19).

6.6 Quality control samples

In every sample batch, recovery as a sum of extraction efficiency, clean-up and LC-MS/MS detection shall

be checked. Preferably, a reference material or well characterized positive samples should be used. If no

reference material is available, recovery can be determined by spiking a representative feed material (see

6.1) that is free from PA. Spiking procedure (example):

EXAMPLE Spike 2 g of the blank feed material with PA working solution (4.5.5), vortex or mix by hand

vigorously and leave open for 1 h to allow the solvent to evaporate. Analyse the spiked sample alongside with the

unknown samples.

NOTE Addition of 50 µl of PA working solution (4.5.5) were used in the method validation study and worked

well.

6.7 Calibration by means of matrix matched standards (MMS)

For the correction of matrix effects, a matrix matched calibration is used. In order to obtain the same

matrix strength in the MMS and the samples, blank feed shall be processed as described in Clause 6 to

receive blank matrix extract. Afterwards, MMS are prepared by mixing different volumes of the standard

working solution with the blank matrix extract. The volume of matrix extract should account for at least

80 % in each MMS solution. Low concentration calibration levels can be prepared by diluting higher MMS

levels with blank feed extract. Table 2 shows an exemplary scheme for the preparation of MMS.

Samples containing PA at a concentration exceeding the highest calibration level should be diluted using

blank feed extract to obtain PA levels in the calibration range.

Table 2 — Example for the preparation of matrix matched calibration solutions

Final PA Final PA Aliquot taken Aliquot Aliquot

No. of

concentration concentration from Volume taken from

calibration

in calibration in feed blank feed

level

solution material extract

ng/ml µg/kg µl μl

1 5 10 MMS_4 20 180

2 10 20 MMS_4 40 160

3 25 50 Standard 5 195

working

solution(1 µg/ml)

4 50 100 Standard 10 190

working

solution(1 µg/ml)

5 75 150 Standard 15 185

working

solution(1 µg/ml)

6 100 200 Standard 20 180

working

solution(1 µg/ml)

7 125 250 Standard 25 175

working

solution(1 µg/ml)

8 150 300 Standard 30 170

working

solution(1 µg/ml)

7 HPLC-MS/MS analysis

7.1 Liquid chromatographic separation

The measurements can be carried out with different high-performance liquid chromatographs (HPLC)

(5.21) and separation columns (5.20). The chromatographic conditions can be chosen freely. The

acceptable minimum retention time is twice the retention time for the dead volume of the column.

Analytes that cannot be distinguished by means of mass spectrometry should be separated

chromatographically. If no baseline separation can be achieved for PA isomers, the sum concentration of

PA can be determined via the calibration of one representative PA. The composition of the standard mix

shall be prepared accordingly by including only one of the co-eluting isomers.

Co-elution of PA-isomers is well-known and can also include PA which are not in the scope of this method.

Annex E provides a list of a PA that can be present in unknown samples and could co-elute with the 28 PA

included in the collaborative trial. This list is based on Commission Regulation (EU) 2020/2040 of 11

December 2020 amending Regulation (EC) No 1881/2006 as regards maximum levels of pyrrolizidine

alkaloids in certain foodstuffs [3].

The conditions listed in Annex A using a C 18 column (5.20) and the mobile phase described in 4.5.3 have

shown to be suitable. However, they are shown exemplarily.

7.2 Mass spectrometric operating conditions

The measurements can be carried out with MS/MS devices (5.21) of different manufacturers. In Annex A

the device-specific settings of one measurement system are given as an example. Mass spectrometric

(MS) conditions should be optimized in the laboratory by means of pure standards to provide analyte

signals with sufficient sensitivity and selectivity.

At least two transitions from the precursor to characteristic product ions should be selected to be

included in the selected reaction monitoring (SRM) method. Preferably, the protonated molecular parent

ion mass should be selected as precursor mass and the product ions should be specific for the compound.

Preferably, product ions that are formed by the loss of water from the protonated molecular ion should

not be selected. Each chromatographic peak should be composed of at least 10 MS data points.

7.3 Analysis sequence

For quantitative analysis, the following criteria are specified.

Injection: Standards, and if desired all samples, are injected in duplicate in order to assess

repeatability of MS detection and to check for possible response drift during the sequence.

The response drift serves as a quality control parameter (see 8.5).

Sequence: The following order of analysis should be defined in a sequence:

1) Solvent Blank;

2) Matrix matched standards, 1st injection;

3) Solvent blank;

4) Samples including quality control (QC), 1st injection;

5) Solvent blank;

6) Matrix matched standards, 2nd injection;

7) Solvent blank (optional);

8) Samples including QC, 2nd injection (optional).

8 Results

8.1 Peak identification

The qualitative detection is carried out by comparison of the retention time and relative abundance of

the measured transitions (at least 2 per analyte, see SANTE/12089/2016 [5]) in the sample with those

of the calibration standards. The maximum deviation of the retention time of the analyte in the sample

and the calibration standards should be ± 0,1 min. The peak area ratios of the analyte's quantifier and

qualifier transitions in the sample should be in a range of ± 30 % of the respective ratios in the calibration

standards according to internally accepted guidelines (e.g. SANTE/12089/2016 [5]). However, results of

the collaborative trial demonstrated that for co-eluting isomeric pairs the deviation of the ion ratios can

be higher than ± 30 %.

8.2 Calibration function

For the determination of the calibration function, the peak areas received for the calibration levels (at

least 3 to 5) are plotted against the respective concentrations. An appropriate approach should be used

to calculate the calibration function for each analyte. Suitable calibration according to the Guidance

document on analytical quality control and method validation procedures for pesticides residues and

analysis in food and feed SANTE/12682/2019 [6] and the EURL-MP guidance document [4] are linear or

quadratic, with or without weighing or forcing through the function through zero.

8.3 Quantification

The quantitative determination is performed according to the method of the matrix matched standard by

integration of the peak areas in relation to the calibration function by means of Formula (1).

Depending on the structure of the analysis sequence (see Clause 7.3), bracketed calibration with one set

of samples or two independent sets of matrix matched standards and samples can be applied for analyte

quantification.

For bracketed calibration the mean calibration function of the two data sets of matrix matched standards

is used to quantify the analytes in the bracketed samples (one injection of samples). If the samples have

been injected twice (no bracketing) analyte concentrations are calculated for the two injections of the

samples individually and subsequently used to calculate the mean value.

V

yb− 1

extract

cF=β×= × × × V (1)

S sample

am V

weight SPE

where

c is the concentration of individual analytes in the sample, in µg/kg;

S

ß is the analyte concentration in ng/ml in the sample extract;

F is the conversion factor from ng/ml to µg/kg;

y is the peak area of the target analyte;

a is the slope of the calibration function (calculated for b = 0, see 8.2);

b is the intercept of the calibration function (b = 0, if the function is forced through 'zero');

is the volume of extraction solution in ml;

Vextract

m is the sample weight in g;

weight

V is the volume of the extract applied for SPE in ml;

SPE

V is the final volume of the sample solution for LC-MS/MS analysis in ml.

sample

8.4 Reporting of results

The results are reported in µg/kg with two significant decimals. To convert the concentration in the

sample solution in ng/ml to the concentration in the feed sample in µg/kg a factor of 2 is used according

to the sample preparation procedure described in Clause 6.

Recovery correction is carried out if recovery is outside of 90 % to 110 % according to EURL-MP's

Guidance document on performance criteria for the analysis of mycotoxins and plant toxins in food and

feed [4].

8.5 Quality control – Performance criteria

Recovery control (see 6.6) using a spiked sample or well characterized positive sample shall be checked

in every sample batch. Tolerable ranges of recovery can be e.g. 70 % to 120 % according to the EURL-

MP's Guidance document on performance criteria for the analysis of mycotoxins and plant toxins in food

and feed [4] (under development) and Annex II (section 4) of Commission Regulation Commission

Regulation (EC) No 401/2006 [5]. In some cases, a lower recovery can be accepted, if it is within the range

of the mean recovery ± 2 × RSD from initial method validation or ongoing recovery results according to

the guidance document on pesticide residues analysis [6]. Recoveries outside the acceptable range

require appropriate measures, e.g. re-analysis of the sample batch.

The quality of the calibration function should also be monitored. The deviation of the back-calculated

concentrations of the calibration standards from the true concentrations using the calibration equation

used should not be more than ± 20 % [6]. If elimination of individual deviating calibration levels is

possible regarding an appropriate number of calibration levels, analyte concentrations within the

adapted calibration range can still be quantified. Otherwise the sample batch should be re-analysed.

Changes in sensitivity during one sequence shall be checked for by means of the slopes of the 1st and 2nd

calibration curve. The relative deviation of both slopes should not exceed 30 % (if the higher slope is set

as 100 %) according to SANTE/12682/2019 [6]. If the response drift is higher than 30 %, re-analysis of

the sequence is required unless no positive samples for the respective analyte are concerned.

9 Precision

9.1 General

Precision data were obtained in a collaborative study. Results on the precision of this method are

provided in detail in Annex A. Besides repeatability and reproducibility also the functional relationships

between the measured concentration of analytes and the obtained repeatability and reproducibility are

shown.

9.2 Repeatability

The absolute difference between two single test results on identical test materials by one operator using

the same apparatus within the shortest feasible time interval will exceed the repeatability limit r in not

more than 5 % of the cases. It can be calculated from the repeatability standard deviation s as:

r

r=2,8 xs

r

(2)

where

r is the repeatability limit;

s is the repeatability standard deviation.

r

9.3 Reproducibility

The absolute difference between two single test results on identical test materials reported by two

laboratories will exceed the reproducibility limit R in not more than 5 % of the cases.

R=2,8 x

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...