SIST EN 17853:2023

(Main)Animal feeding stuff: Methods of sampling and analysis - Determination of intact glucosinolates in feed materials and compound feed by LC-MS/MS

Animal feeding stuff: Methods of sampling and analysis - Determination of intact glucosinolates in feed materials and compound feed by LC-MS/MS

This document specifies a method for the determination of individual intact glucosinolates in feed materials including oilseeds and oilseed products and in compound feeds by high performance liquid chromatography (HPLC) coupled with tandem mass spectrometry (MS/MS).

The method specified in this document has been successfully validated by collaborative trial in the following matrices: rape seed, camelina seed, Brassica oleracea seeds, mixed oilseeds, rape seed flakes, compound feed for bovine, porcine and poultry.

The method is applicable for the quantitative determination of epiprogroitrin, glucoalyssin, glucoarabin, glucobrassicanapin, glucobrassicin, glucocamelinin, glucoerucin, glucoiberin, gluconapin, gluconapoleiferin, gluconasturtiin, glucoraphanin, glucoraphenin, glucotropaeolin, homoglucocamelinin, 4-hydroxyglucobrassicin, 4-methoxyglucobrassicin, neoglucobrassicin, progoitrin, sinalbin and sinigrin.

The concentration ranges tested in the collaborative trial for each individual glucosinolate and for the total glucosinolate content are summarized in Table 1.

[table not represented]

Futtermittel - Probenahme- und Untersuchungsverfahren - Bestimmung von intakten Glucosinolaten in Futtermittel-Ausgangserzeugnissen und Mischfuttermitteln mittels LC-MS/MS

Dieses Dokument legt ein Verfahren zur Bestimmung der einzelnen intakten Glucosinolate in Futtermittel-Ausgangserzeugnissen einschließlich Ölsaaten und Ölsaatenerzeugnissen sowie in Mischfuttermitteln durch Hochleistungsflüssigchromatographie (HPLC) in Verbindung mit Tandem-Massenspektrometrie (MS/MS) fest.

Das in diesem Dokument festgelegte Verfahren wurde im Rahmen eines Ringversuchs mit den folgenden Matrices erfolgreich validiert: Rapssamen, Leindottersamen, Brassica-oleracea-Samen, gemischte Ölsaaten, Rapssamenflocken, Mischfuttermittel für Rinder, Schweine und Geflügel.

Das Verfahren ist anwendbar für die quantitative Bestimmung von Epiprogroitrin, Glucoalyssin, Glucoarabin, Glucobrassicanapin, Glucobrassicin, Glucocamelinin, Glucoerucin, Glucoiberin, Gluconapin, Gluconapoleiferin, Gluconasturtiin, Glucoraphanin, Glucoraphenin, Glucotropaeolin, Homoglucocamelinin, 4-Hydroxyglucobrassicin, 4-Methoxyglucobrassicin, Neoglucobrassicin, Progoitrin, Sinalbin und Sinigrin.

Die im Ringversuch geprüften Konzentrationsbereiche für jedes einzelne Glucosinolat und für den Gesamtgehalt an Glucosinolaten sind in Tabelle 1 zusammengefasst.

[table not represented]

Alimentation animale : Méthodes d’échantillonnage et d’analyse - Dosage des glucosinolates intacts dans les matières premières pour l’alimentation animale et les aliments composés par CLHP MS/MS

Le présent document spécifie une méthode pour le dosage de différents glucosinolates intacts dans les matières premières pour l’alimentation animale incluant les graines oléagineuses et les produits oléagineux et dans les aliments composés pour animaux par chromatographie liquide haute performance (CLHP) couplée à la spectrométrie de masse en tandem (MS/MS).

La méthode spécifiée dans le présent document a été validée par un essai interlaboratoires avec les matrices suivantes : graines de colza, graines de cameline, graines de Brassica oleracea, mélange de graines oléagineuses, flocons de graines de colza, aliments composés pour bovins, porcins et volaille.

La méthode est applicable pour la détermination quantitative de l’épiprogroitrine, la glucoalyssine, la glucoarabine, la glucobrassicanapine, la glucobrassicine, la glucocamélinine, la glucoérucine, la glucoibérine, la gluconapine, la gluconapoléiférine, la gluconasturtiine, la glucoraphanine, la glucoraphénine, la glucotropaéoline, l’homoglucocamélinine, la 4-hydroxyglucobrassicine, la 4-méthoxyglucobrassicine, la néoglucobrassicine, la progoitrine, la sinalbine et la sinigrine.

Les plages de concentration soumises à essai dans le cadre de l’essai interlaboratoires pour déterminer la teneur des différents glucosinolates et des glucosinolates totaux sont présentées dans le Tableau 1.

[Tableau 1]

Krma: metode vzorčenja in analize - Ugotavljanje nepoškodovanih glukozinolatov v sestavinah krme in krmni mešanici z LC-MS/MS

Ta dokument opisuje metodo za določevanje posameznih nepoškodovanih glukozinatov v ogrščici s

tekočinsko kromatografijo visoke ločljivosti (HPLC) v kombinaciji s tandemsko masno spektrometrijo (MS/MS). Progoitrin, glukonapin, glukobrasikanapin, glukobrasicin, nasturtiin, neoglukobrasicin in 4-metoksiglukobrasicin se določajo kvantitativno. Druge glukozinate, kot so 4-hidroksiglukobrasicin, gluknapoliferin in glukoalisin, bo mogoče kvantitativno določiti šele, ko bodo analitični standardi komercialno dostopni.

Ta metoda je bila interno potrjena za semena ogrščice v območju 0,05–60 mmol/kg za posamezne glukozinate.

General Information

- Status

- Published

- Public Enquiry End Date

- 30-Jul-2022

- Publication Date

- 20-Aug-2023

- Technical Committee

- KŽP - Agricultural food products

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 20-Jun-2023

- Due Date

- 25-Aug-2023

- Completion Date

- 21-Aug-2023

Overview

EN 17853:2023 (CEN) - "Animal feeding stuff: Methods of sampling and analysis - Determination of intact glucosinolates in feed materials and compound feed by LC‑MS/MS" - specifies a validated HPLC‑MS/MS procedure for the quantitative determination of intact glucosinolates in feed matrices. The method was validated by a collaborative trial in a range of feed types including rapeseed, camelina seed, Brassica oleracea seeds, mixed oilseeds, rapeseed flakes and compound feeds for bovine, porcine and poultry.

Key procedural points:

- Extraction with methanol:water (70:30, v/v), centrifugation, dilution and filtration.

- Analysis by liquid chromatography coupled to tandem mass spectrometry (LC‑MS/MS / HPLC‑MS/MS).

- Calibration: multi‑level aqueous calibration for oilseeds; calibration in blank feed extract for compound feeds.

- Analytical standards recommended at ≥90 % purity (preferably ≥95 %).

Key Topics

- Scope and validated matrices: method applicability to oilseeds, oilseed products and compound feeds with collaborative trial evidence.

- Target analytes: quantitative determination of individual intact glucosinolates, including (but not limited to) epiprogoitrin, glucoalyssin, glucoarabin, glucobrassicanapin, glucobrassicin, glucocamelinin, glucoerucin, glucoiberin, gluconapin, gluconapoleiferin, gluconasturtiin, glucoraphanin, glucoraphenin, glucotropaeolin, homoglucocamelinin, 4‑hydroxyglucobrassicin, 4‑methoxyglucobrassicin, neoglucobrassicin, progoitrin, sinalbin and sinigrin.

- Performance evidence: collaborative trial concentration ranges were established for individual glucosinolates (examples: epiprogoitrin 0.01–0.93 mmol/kg; sinigrin 0.25–23.7 mmol/kg; sinalbin 0.01–41.1 mmol/kg) and total glucosinolate content tested from 1.48 to 117.3 mmol/kg.

- Quality and reagents: requirements for LC‑MS grade solvents, specified reference materials and quality control procedures.

- Data evaluation: identification, multi‑level quantification, linearity checks and result expression procedures.

Applications

Who uses EN 17853:2023:

- Feed testing laboratories implementing LC‑MS/MS workflows for regulatory or quality control testing.

- Feed manufacturers and oilseed processors monitoring glucosinolate content of raw materials and compound feeds.

- Regulatory authorities and accreditation bodies assessing compliance and analytical method suitability.

- Research groups studying Brassicaceae-derived feed components and their nutritional/toxicological impacts.

Practical value:

- Enables accurate monitoring of undesirable glucosinolates in animal feed.

- Supports risk assessment, formulation decisions and compliance with feed safety requirements.

- Facilitates harmonized, comparable results across laboratories through a standardized, validated LC‑MS/MS protocol.

Related Standards

- EN ISO 3696 - water for analytical laboratory use (referenced for reagent quality).

- EN ISO 9167 - alternative HPLC method for glucosinolates after enzymatic desulfation (related approach using HPLC‑UV).

Frequently Asked Questions

SIST EN 17853:2023 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Animal feeding stuff: Methods of sampling and analysis - Determination of intact glucosinolates in feed materials and compound feed by LC-MS/MS". This standard covers: This document specifies a method for the determination of individual intact glucosinolates in feed materials including oilseeds and oilseed products and in compound feeds by high performance liquid chromatography (HPLC) coupled with tandem mass spectrometry (MS/MS). The method specified in this document has been successfully validated by collaborative trial in the following matrices: rape seed, camelina seed, Brassica oleracea seeds, mixed oilseeds, rape seed flakes, compound feed for bovine, porcine and poultry. The method is applicable for the quantitative determination of epiprogroitrin, glucoalyssin, glucoarabin, glucobrassicanapin, glucobrassicin, glucocamelinin, glucoerucin, glucoiberin, gluconapin, gluconapoleiferin, gluconasturtiin, glucoraphanin, glucoraphenin, glucotropaeolin, homoglucocamelinin, 4-hydroxyglucobrassicin, 4-methoxyglucobrassicin, neoglucobrassicin, progoitrin, sinalbin and sinigrin. The concentration ranges tested in the collaborative trial for each individual glucosinolate and for the total glucosinolate content are summarized in Table 1. [table not represented]

This document specifies a method for the determination of individual intact glucosinolates in feed materials including oilseeds and oilseed products and in compound feeds by high performance liquid chromatography (HPLC) coupled with tandem mass spectrometry (MS/MS). The method specified in this document has been successfully validated by collaborative trial in the following matrices: rape seed, camelina seed, Brassica oleracea seeds, mixed oilseeds, rape seed flakes, compound feed for bovine, porcine and poultry. The method is applicable for the quantitative determination of epiprogroitrin, glucoalyssin, glucoarabin, glucobrassicanapin, glucobrassicin, glucocamelinin, glucoerucin, glucoiberin, gluconapin, gluconapoleiferin, gluconasturtiin, glucoraphanin, glucoraphenin, glucotropaeolin, homoglucocamelinin, 4-hydroxyglucobrassicin, 4-methoxyglucobrassicin, neoglucobrassicin, progoitrin, sinalbin and sinigrin. The concentration ranges tested in the collaborative trial for each individual glucosinolate and for the total glucosinolate content are summarized in Table 1. [table not represented]

SIST EN 17853:2023 is classified under the following ICS (International Classification for Standards) categories: 65.120 - Animal feeding stuffs. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 17853:2023 is associated with the following European legislation: EU Directives/Regulations: 882/2004; Standardization Mandates: M/523. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 17853:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2023

Krma: metode vzorčenja in analize - Ugotavljanje nepoškodovanih glukozinolatov

v sestavinah krme in krmni mešanici z LC-MS/MS

Animal feeding stuff: Methods of sampling and analysis - Determination of intact

glucosinolates in feed materials and compound feed by LC-MS/MS

Futtermittel - Probenahme- und Untersuchungsverfahren - Bestimmung von intakten

Glucosinolaten in Futtermittel-Ausgangserzeugnissen und Mischfuttermitteln mittels LC-

MS/MS

Alimentation animale : Méthodes d’échantillonnage et d’analyse - Dosage des

glucosinolates intacts dans les matières premières pour l’alimentation animale et les

aliments composés par CLHP MS/MS

Ta slovenski standard je istoveten z: EN 17853:2023

ICS:

65.120 Krmila Animal feeding stuffs

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17853

EUROPEAN STANDARD

NORME EUROPÉENNE

April 2023

EUROPÄISCHE NORM

ICS 65.120

English Version

Animal feeding stuff: Methods of sampling and analysis -

Determination of intact glucosinolates in feed materials

and compound feed by LC-MS/MS

Alimentation animale : Méthodes d'échantillonnage et Futtermittel - Probenahme- und

d'analyse - Dosage des glucosinolates intacts dans les Untersuchungsverfahren - Bestimmung von intakten

matières premières pour l'alimentation animale et les Glucosinolaten in Futtermittel-Ausgangserzeugnissen

aliments composés par CLHP MS/MS und Mischfuttermitteln mittels LC-MS/MS

This European Standard was approved by CEN on 3 March 2023.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17853:2023 E

worldwide for CEN national Members.

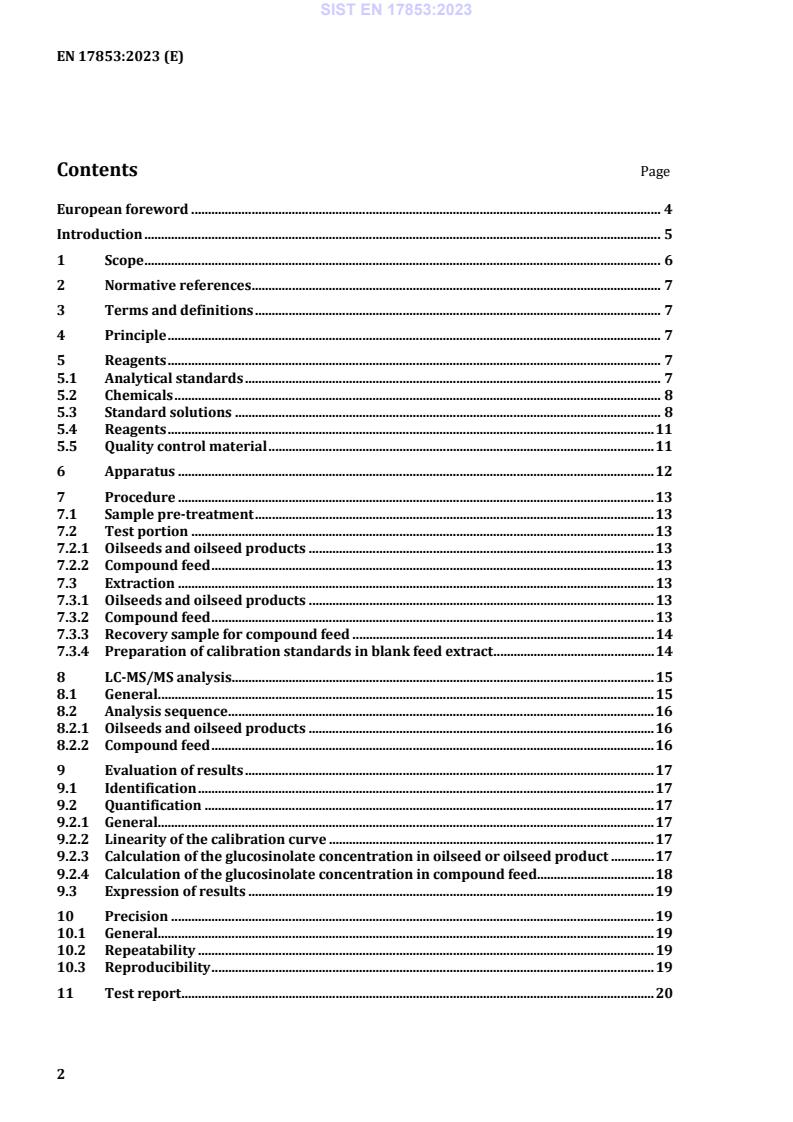

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 7

3 Terms and definitions . 7

4 Principle . 7

5 Reagents . 7

5.1 Analytical standards . 7

5.2 Chemicals . 8

5.3 Standard solutions . 8

5.4 Reagents . 11

5.5 Quality control material . 11

6 Apparatus . 12

7 Procedure . 13

7.1 Sample pre-treatment . 13

7.2 Test portion . 13

7.2.1 Oilseeds and oilseed products . 13

7.2.2 Compound feed . 13

7.3 Extraction . 13

7.3.1 Oilseeds and oilseed products . 13

7.3.2 Compound feed . 13

7.3.3 Recovery sample for compound feed . 14

7.3.4 Preparation of calibration standards in blank feed extract . 14

8 LC-MS/MS analysis . 15

8.1 General. 15

8.2 Analysis sequence . 16

8.2.1 Oilseeds and oilseed products . 16

8.2.2 Compound feed . 16

9 Evaluation of results . 17

9.1 Identification . 17

9.2 Quantification . 17

9.2.1 General. 17

9.2.2 Linearity of the calibration curve . 17

9.2.3 Calculation of the glucosinolate concentration in oilseed or oilseed product . 17

9.2.4 Calculation of the glucosinolate concentration in compound feed. 18

9.3 Expression of results . 19

10 Precision . 19

10.1 General. 19

10.2 Repeatability . 19

10.3 Reproducibility . 19

11 Test report . 20

Annex A (informative) Precision data . 21

Annex B (informative) Example of LC-MS/MS conditions . 45

B.1 General . 45

B.2 Chromatographic conditions . 45

B.3 MS conditions . 46

Annex C (informative) Examples of chromatograms . 48

Annex D (informative) Glucosinolate standards from commercial sources . 50

Bibliography . 52

European foreword

This document (EN 17853:2023) has been prepared by Technical Committee CEN/TC 327 “Animal

feeding stuffs: Methods of sampling and analysis”, the secretariat of which is held by NEN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by October 2023, and conflicting national standards shall

be withdrawn at the latest by October 2023.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document has been prepared under a Standardization Request given to CEN by the European

Commission and the European Free Trade Association.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

Glucosinolates are a group of plant produced secondary metabolites predominantly found in the family

Brassicaceae (mustards and cabbages) ([1], [2], [3]). Many common vegetables such as broccoli, Brussels

sprouts, cabbage and cauliflower, belong to this plant family. At the same time species from the genera

Brassica, Camelina, Crambe, Rhaphanus and Sinapis are agricultural crops used for the production of plant

oils, such as rapeseed oils. The press cake is used as animal feed material. Glucosinolates are considered

undesirable substances in feed [4]. Glucosinolates in rapeseed and rapeseed products can also be

measured after enzymatic desulfation by high-performance liquid chromatography (HPLC) coupled with

UV detection. This method is described in standard EN ISO 9167 [5].

WARNING — This protocol does not purport to address all the safety problems associated with its use.

It is the responsibility of the user of this protocol to establish appropriate safety and health protection

measures and to ensure that regulatory and legal requirements are complied with.

1 Scope

This document specifies a method for the determination of individual intact glucosinolates in feed

materials including oilseeds and oilseed products and in compound feeds by high performance liquid

chromatography (HPLC) coupled with tandem mass spectrometry (MS/MS).

The method specified in this document has been successfully validated by collaborative trial in the

following matrices: rape seed, camelina seed, Brassica oleracea seeds, mixed oilseeds, rape seed flakes,

compound feed for bovine, porcine and poultry.

The method is applicable for the quantitative determination of epiprogroitrin, glucoalyssin, glucoarabin,

glucobrassicanapin, glucobrassicin, glucocamelinin, glucoerucin, glucoiberin, gluconapin,

gluconapoleiferin, gluconasturtiin, glucoraphanin, glucoraphenin, glucotropaeolin, homoglucocamelinin,

4-hydroxyglucobrassicin, 4-methoxyglucobrassicin, neoglucobrassicin, progoitrin, sinalbin and sinigrin.

The concentration ranges tested in the collaborative trial for each individual glucosinolate and for the

total glucosinolate content are summarized in Table 1.

Table 1 — Summary of glucosinolate concentration ranges tested in the collaborative trial

Glucosinolate Number of samples Tested concentration range

with acceptable

mmol/kg

results

Min Max

Epiprogoitrin 7 0,01 0,93

Glucoalyssin 6 0,02 2,10

Glucoarabin 3 0,31 6,15

Glucobrassicanapin 5 0,01 0,38

Glucobrassicin 5 0,02 0,31

Glucocamelinin 3 0,82 16,1

Glucoerucin 3 1,07 15,6

Glucoiberin 3 1,51 18,5

Gluconapin 6 0,23 1,68

Gluconapoleiferin 5 0,01 0,33

Gluconasturtiin 7 0,01 11,0

Glucoraphanin 5 0,01 3,11

Glucoraphenin 1 15,6

Glucotropaeolin 2 0,03 18,3

Homoglucocamelinin 3 0,17 3,23

4-Hydroxyglucobrassicin 6 0,23 7,33

4-Methoxyglucobrassicin 1 0,16

Neoglucobrassicin 5 0,01 0,13

Progoitrin 6 0,62 14,8

Sinalbin 4 0,01 41,1

Sinigrin 3 0,25 23,7

Total content 8 1,48 117,3

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN ISO 3696, Water for analytical laboratory use - Specification and test methods (ISO 3696)

3 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp/ui

4 Principle

Glucosinolates are extracted from the homogenized sample with methanol:water (70:30) (V:V). After

centrifugation, the extracts are diluted, filtered and measured by liquid chromatography coupled to

tandem mass spectrometry (HPLC-MS/MS). In oilseeds and oilseed products individual glucosinolates

are quantified by multi-level calibration using standards in aqueous solution. In compound feeds

individual glucosinolates are quantified by multi-level calibration using standards in blank feed matrix

extract.

5 Reagents

5.1 Analytical standards

Analytical standards should have a demonstrated purity of at least 90 %, preferably of 95 % or higher.

NOTE In this section glucosinolate standards are listed that are currently available from at least one

commercial supplier (see Annex D). Depending on the intended application a selection of the listed glucosinolate

standards can be used.

5.1.1 Epiprogoitrin (2-(S)-hydroxy-3-butenyl glucosinolate) or its potassium salt (CAS 19237-18-4)

5.1.2 Glucoalyssin (5-(methylsulfinyl)pentyl glucosinolate) or its potassium salt (CAS 499-37-6)

5.1.3 Glucoarabin (9-(methylsulfinyl)nonyl glucosinolate) or its potassium salt (CAS 67920-64-3)

5.1.4 Glucobrassicanapin (4-pentenyl glucosinolate) or its potassium salt (CAS 19041-10-2)

5.1.5 Glucobrassicin (3-indolylmethyl glucosinolate) or its potassium salt (CAS 4356-52-9)

5.1.6 Glucocamelinin (10-(methylsulfinyl)decyl glucosinolate) or its potassium salt

(CAS 67884-10-0)

5.1.7 Glucoerucin (4-methoxythiobutyl glucosinolate) or its potassium salt (CAS 21973-56-8)

5.1.8 Glucoiberin (3-methylsulfinylpropyl glucosinolate) or its potassium salt (CAS 554-88-1)

5.1.9 Gluconapin (3-butenyl glucosinolate) or its potassium salt (CAS 19041-09-9)

5.1.10 Gluconapoleiferin (2-(S)-hydroxy-4-pentenyl glucosinolate) or its potassium salt

(CAS 19764-03-5)

Gluconapoleiferin is only available as a 1:1 mixture of 2-S and 2-R isomers. A purity of 50 % is taken for

2S-gluconapoleiferin.

5.1.11 Gluconasturtiin (2-phenylethyl glucosinolate) or its potassium salt (CAS 499-30-9)

5.1.12 Glucoraphanin (4-methylsulfinylbutyl glucosinolate) or its potassium salt (CAS 21414-41-5)

5.1.13 Glucoraphenin (4-methylsulfinylbutenyl glucosinolate) or its potassium salt (CAS 28463-24-3)

5.1.14 Glucotropaeolin (benzyl glucosinolate) or its potassium salt (CAS 499-26-3)

5.1.15 Homoglucocamelinin (11-methylsulfinylundecyl glucosinolate) or its potassium salt

(CAS 186037-18-3)

5.1.16 4-Hydroxyglucobrassicin (4-hydroxy-3-indolylmethyl glucosinolate) or its potassium salt

(CAS 83327-20-2)

5.1.17 4-Methoxyglucobrassicin (4-methoxy-3-indolylmethyl glucosinolate) or its potassium salt

(CAS 83327-21-3)

5.1.18 Neoglucobrassicin (1-methoxy-3-indolylmethyl glucosinolate) or its potassium salt

(CAS 5187-84-8)

5.1.19 Progoitrin (2-(R)-hydroxy-3-butenyl glucosinolate) or its potassium salt (CAS 585-95-5)

5.1.20 Sinalbin (4-hydroxybenzyl glucosinolate) or its potassium salt (CAS 16411-05-5)

5.1.21 Sinigrin (2-propenyl glucosinolate), monohydrate or its potassium salt (CAS 3952-98-5)

5.2 Chemicals

5.2.1 Methanol, LC-MS grade

5.2.2 Acetic acid, 98 % to 100 %, HPLC grade

5.2.3 Water

Water of LC-MS grade, double-distilled or water of grade 1 as specified in EN ISO 3696.

5.3 Standard solutions

5.3.1 General

Accurately weigh (6.1) between 5 mg and 10 mg of each standard (5.1.1-5.1.21) into a separate amber-

coloured glass bottle of 4 ml (6.8). Add a volume of extraction solvent (5.4.1) to produce a solution with

a concentration of 10 µmol/ml. Take into account the weight, the purity and the appearance form of the

standard (see NOTES 1-4). In Table 2 example calculations are given for the preparation of 1 ml stock

solution.

NOTE 1 Glucosinolate standards are typically available as potassium salts. Some glucosinolate standards

additionally contain one molecule of water.

NOTE 2 Most analytical standards of individual glucosinolates are typically obtained in 5 mg and 10 mg

quantities. Since glucosinolates are highly hygroscopic compounds, the solid standard is only used once.

NOTE 3 Depending on the intended application, a selection of the standard solutions listed below can be used.

NOTE 4 The stock standard solutions are stable for 24 months when stored < −18 °C. Methanol:water (70:30)

(V:V) is the preferred solvent because it provides a better stability of glucosinolates than water.

Table 2 — Preparation of stock standard solutions

Glucosinolate Molecular weight Weight standard for 1 ml

potassium form standard solution of 10 µmol/ml

g/mol mg

Epiprogoitrin 427,48 4,2748

Glucoalyssin 489,63 4,8963

Glucoarabin 545,73 5,4573

Glucobrassicanapin 425,51 4,2551

Glucobrassicin 486,26 4,8626

Glucocamelinin 559,76 5,5976

Glucoerucin 459,61 4,5961

Glucoiberin 461,56 4,6156

Gluconapin 411,49 4,1149

Gluconapoleiferin 441,51 4,4151

Gluconasturtiin 461,16 4,6116

Glucoraphanin 475,66 4,7566

Glucoraphenin 473,58 4,7358

Glucotropaeolin 447,52 4,4752

Homoglucocamelinin 573,79 5,7379

4-Hydroxyglucobrassicin 502,56 5,0256

4-Methoxyglucobrassicin 516,59 5,1659

Neoglucobrassicin 516,59 5,1659

Progoitrin 427,49 4,2749

Sinalbin 463,52 4,6352

Sinigrin 397,47 3,9747

5.3.2 Epiprogoitrin (10 µmol/ml)

5.3.3 Glucoalyssin (10 µmol/ml)

5.3.4 Glucoarabin (10 µmol/ml)

5.3.5 Glucobrassicanapin (10 µmol/ml)

5.3.6 Glucobrassicin (10 µmol/ml)

5.3.7 Glucocamelinin (10 µmol/ml)

5.3.8 Glucoerucin (10 µmol/ml)

5.3.9 Glucoiberin (10 µmol/ml)

5.3.10 Gluconapin (10 µmol/ml)

5.3.11 Gluconapoleiferin (10 µmol/ml)

5.3.12 Gluconasturtiin (10 µmol/ml)

5.3.13 Glucoraphanin (10 µmol/ml)

5.3.14 Glucoraphenin (10 µmol/ml)

5.3.15 Glucotropaeolin (10 µmol/ml)

5.3.16 Homoglucocamelinin (10 µmol/ml)

5.3.17 4-Hydroxyglucobrassicin (10 µmol/ml)

5.3.18 4-Methoxyglucobrassicin (10 µmol/ml)

5.3.19 Neoglucobrassicin (10 µmol/ml)

5.3.20 Progoitrin (10 µmol/ml)

5.3.21 Sinalbin (10 µmol/ml)

5.3.22 Sinigrin (10 µmol/ml)

5.3.23 Mixed standard solution (100 nmol/ml)

Pipette (6.12) in a 10 ml volumetric flask (6.11) 100 µl of each stock solution 5.3.2-5.3.22 (10 µmol/ml)

and fill to the mark with extraction solvent (5.4.1).

NOTE 1 Depending on the intended application, a selection of the standard solutions can be used.

NOTE 2 When stored < −18 °C the solution is stable for 1 year. Extraction solvent (methanol:water (70:30) (V:V))

is the preferred solvent because it provides a better stability of glucosinolates than water.

5.3.24 Mixed standard solution (10 nmol/ml)

Pipette (6.12) 2 ml of mixed standard solution 100 nmol/ml (5.3.23) in a 20-ml volumetric flask (6.11)

and fill to the mark with extraction solvent (5.4.1).

NOTE When stored < −18 °C the solution is stable for 1 year. Extraction solvent (methanol:water (70:30) (V:V))

is the preferred solvent because it provides a better stability of glucosinolates than water.

5.3.25 Mixed standard solution (1 nmol/ml)

Pipette (6.12) 500 µl of mixed standard solution 100 nmol/ml (5.3.23) in a 50 ml volumetric flask (6.11)

and fill to the mark with extraction solvent (5.4.1).

NOTE When stored < −18 °C the solution is stable for 1 year. Extraction solvent (methanol:water (70:30) (V:V))

is the preferred solvent because it provides a better stability of glucosinolates than water.

5.3.26 Calibration solutions in aqueous solution

Prepare calibration solutions according to Table 3. Pipette (6.12) directly in HPLC vials (see NOTE).

Table 3 — Preparation of calibration standards in aqueous solution

Code Concentration Mixed standard Mixed standard Mixed standard Water

solution solution solution (5.2.3)

(nmol/ml)

1 nmol/ml 10 nmol/ml 100 nmol/ml µl

(5.3.25) (5.3.24) (5.3.23)

µl µl µl

Cal 1 0 0 0 0 1 000

Cal 2 0,01 10 0 0 990

Cal 3 0,02 20 0 0 980

Cal 4 0,05 50 0 0 950

Cal 5 0,10 0 10 0 990

Cal 6 0,25 0 25 0 975

Cal 7 0,50 0 50 0 950

Cal 8 1,0 0 0 10 990

Cal 9 2,5 0 0 25 975

Cal 10 5,0 0 0 50 950

Calibration standards should be prepared each new day of analysis. It is advised to use all calibration

standards, but at least calibration standards Cal 1,3-8.

NOTE The calibration points required depend on the concentrations expected in the samples (see 7.3), the

dilution factor used (see 7.3) and the dynamic range of the mass spectrometer (see Clause 8).

5.4 Reagents

5.4.1 Extraction solvent: methanol:water (70:30) (V:V)

Mix 700 ml methanol (5.2.1) with 300 ml water (5.2.3). The solvent is stored at room temperature and

can be used for one month.

5.4.2 Mobile phase A: 0,1 % acetic acid in water

Pipette (6.12) 1 ml of acetic acid (5.2.2) in 1 000 ml water (5.2.3). The solvent is stored at room

temperature and can be used for one month.

NOTE The acetic acid concentration can be adjusted in the range of 0,01 % to 0,1 % to optimize the retention

of the analytes on the analytical column.

5.4.3 Mobile phase B: methanol (5.2.1)

5.5 Quality control material

An appropriate material is included in each series and used for quality purposes. This material can be a

reference material , or a material with known natural contamination, or a blank material fortified with

known amounts of the glucosinolates.

ERM®-BC366R Rapeseed, ERM®-BC190R Rapeseed and ERM®-BC367R Rapeseed are examples of suitable

products available commercially. This information is given for the convenience of users of this document and does

not constitute an endorsement by CEN of these products.

6 Apparatus

Usual laboratory equipment and, in particular, the following items.

6.1 Analytical balance with a mass resolution of 0,1 mg or better

6.2 Analytical balance with a mass resolution of 1 mg or better

6.3 (Micro)grinder

6.4 Polypropylene centrifuge tubes 50 ml with screw cap

6.5 Water bath

Capable of maintaining a temperature of 75 °C ± 1 °C.

6.6 Vortex mixer or minishaker

6.7 Vertical or horizontal shaker adjustable

6.8 Amber coloured glass bottle 4 ml size with screw cap

6.9 HPLC autosampler vial glass or polypropylene 1,5 ml

6.10 Centrifuge suitable for use with the 50 ml centrifuge tubes (6.4)

6.11 Volumetric flasks calibrated 10 ml, 20 ml, 50 ml

6.12 Calibrated micrometric pipette(s)

6.13 HPLC system consisting of:

6.13.1 Autosampler thermostated

Capable of maintaining a temperature of 10 °C ± 1 °C.

6.13.2 Binary pump system

Capable of delivering a binary gradient at flow rates appropriate for the analytical column in use with

sufficient accuracy.

6.13.3 Column oven thermostated

Capable of maintaining a temperature of 50 °C ± 1 °C.

6.13.4 Analytical column

Containing C18 reversed phase packing material, capable of the base-line separation of analytes with

identical molecular mass. A C18 stationary phase with charged surface hybrid chemistry has shown to

work well.

6.13.5 Pre-column, optional

Containing the same stationary phase material as the analytical column and with appropriate dimensions.

6.14 Tandem mass spectrometer

Capable of performing multiple selected reaction monitoring in negative mode, with a sufficiently wide

dynamic range, sufficient scan speed and capable of unit mass separation and equipped with a computer-

based data processing system. Any ionization source giving sufficient yield may be employed.

7 Procedure

7.1 Sample pre-treatment

Laboratory samples should be taken and prepared in accordance with European legislation [6] where

applicable or, in any other case with EN ISO 6498.

Homogenize samples in a grinder (6.3) to < 1 mm.

7.2 Test portion

7.2.1 Oilseeds and oilseed products

The amount of homogenized oilseed or oilseed product sample (7.1) examined is 1,00 g ± 0,02 g.

The amount of homogenized oilseed or oilseed product sample may be reduced to 0,50 g ± 0,01 g. The

amount of extraction solvent (7.3.1) shall in that case be reduced accordingly.

7.2.2 Compound feed

The amount of homogenized compound feed sample (7.1) examined is 1,00 g ± 0,02 g.

7.3 Extraction

7.3.1 Oilseeds and oilseed products

Weigh (6.2) a test portion of 1,00 g ± 0,02 g homogenized sample (7.2.1) into a centrifuge tube of 50 ml

(6.4). Add 25 ml extraction solvent (5.4.1), vortex for 10 s (6.6) and place the tube in a water bath at 75 °C

(6.5) (see NOTE 1). Heat the sample for 15 min and then let cool down to room temperature. Place the

tube for 60 min in a shaker rotating at moderate speed (6.7).

Centrifuge the tube for 5 min at 2 000 g at room temperature (6.10). Transfer 5 µl of the supernatant to

a HPLC vial (6.9) and add 995 µl of water and close the vial (see NOTE 2).

NOTE 1 An extraction solvent containing 70 % (volume fraction) methanol gives the best compromise between

analyte stability and extraction efficiency. An extraction solvent with a higher organic content (e.g. 80 % methanol)

increases the stability of the analytes (slow degradation by myrosinase), but also results in a lower extraction

efficiency. An extraction solvent with a lower organic content (e.g. 60 % methanol or 50 % ethanol) results in a

comparable extraction efficiency, but also in a strongly increased myrosinase activity. This can result in partial

degradation of the analytes and in a reduced reproducibility. ISO 9167:2019 describes an alternative extraction

procedure for rapeseed and rapeseed meals using 50 % (volume fraction) ethanol as extraction solvent. This

alternative extraction procedure was not tested in this collaborative trial.

NOTE 2 In specific products concentrations can be present that exceed the working range of the calibration

curve. For these products the extract is further diluted with water to obtain a concentration that falls within the

working range of the calibration curve.

7.3.2 Compound feed

Weigh (6.2) a test portion of 1,00 g ± 0,02 g homogenized sample (7.2.2) into a centrifuge tube of 50 ml

(6.4). Add 25 ml extraction solvent (5.4.1), vortex for 10 s (6.6) and place the tube in a water bath at 75 °C

(6.5). Heat the sample for 15 min and then let cool down to room temperature. Place the tube for 60 min

in a shaker rotating at moderate speed (6.7).

Centrifuge the tube for 5 min at 2 000 g at room temperature (6.10). Transfer 25 µl of the supernatant to

a HPLC vial (6.9) and add 975 µl of water and close the vial.

7.3.3 Recovery sample for compound feed

For preparation of the recovery sample take a representative blank feed sample (see NOTE), preferably

the same that is used for the preparation of the calibration range in blank extract (7.3.4).

Weigh (6.2) a test portion of 1,00 g ± 0,02 g homogenized sample (7.2.2) into a centrifuge tube of 50 ml

(6.4). Add 1,00 ml of mixed standard solution 100 nmol/ml (5.3.22) to the sample. This is equivalent to

0,1 mmol/kg. Vortex for 10 s (6.6).

Add 25 ml extraction solvent (5.4.1), vortex for 10 s (6.6) and place the tube in a water bath at 75 °C (6.5).

Heat the sample for 15 min and then let cool down to room temperature. Place the tube for 60 min in a

shaker rotating at moderate speed (6.7).

Centrifuge the tube for 5 min at 2 000 g at room temperature (6.10). Transfer 25 µl of the supernatant to

a HPLC vial (6.9) and add 975 µl of water and close the vial.

NOTE A blank sample is a sample shown by a preceding analysis not to contain the target analytes in a

concentration above the limit of detection.

7.3.4 Preparation of calibration standards in blank feed extract

For preparation of the calibration curve in matrix take a representative blank feed sample (see NOTE).

Weigh (6.2) a test portion of 1,00 g ± 0,02 g homogenized sample (7.2.2) into a centrifuge tube of 50 ml

(6.4). Add 25 ml extraction solvent (5.4.1), vortex for 10 s (6.6) and place the tube in a water bath at 75 °C

(6.5). Heat the sample for 15 min and then let cool down to room temperature. Place the tube for 60 min

in a shaker rotating at moderate speed (6.7).

Centrifuge the tube for 5 min at 2 000 g at room temperature (6.10). Transfer an aliquot of 1 ml to a new

centrifuge tube of 50 ml (6.4), add 39 ml of water and mix well. This diluted extract is used to prepare

calibration solutions according to Table 4. Pipette (6.12) directly in HPLC vials.

NOTE A blank sample is a sample shown by a preceding analysis not to contain the target analytes in a

concentration above the limit of detection.

Table 4 — Preparation of calibration standards in blank feed extract

Code Concentration Mixed standard Mixed standard Mixed standard Blank feed

solution solution solution extract

nmol/ml

1 nmol/ml 10 nmol/ml 100 nmol/ml (7.3.4)

(5.3.25) (5.3.24) (5.3.23) µl

µl µl µl

Cal 1 0 0 0 0 1 000

Cal 2 0,01 10 0 0 990

Cal 3 0,02 20 0 0 980

Cal 4 0,05 50 0 0 950

Cal 5 0,10 0 10 0 990

Cal 6 0,25 0 25 0 975

Cal 7 0,50 0 50 0 950

Cal 8 1,0 0 0 10 990

Cal 9 2,5 0 0 25 975

Cal 10 5,0 0 0 50 950

8 LC-MS/MS analysis

8.1 General

Chromatographic and mass spectrometric conditions can be chosen freely. The optimal measuring

conditions strongly depend on the instrumentation used. However, some important criteria and

parameters with respect to the chromatographic separation and detection of the analytes are discussed

below.

Analytical columns containing C18 reversed phase packing material can be used for the separation of

analytes. The chosen column dimensions and chromatographic conditions should be appropriate to

obtain base line separation of epimers or isomers with the same molecular mass-to-charge ratio.

Attention should be paid to the more polar glucosinolates, eluting early in the chromatogram. These

analytes are more sensitive to small differences in the composition of the mobile phase resulting in

unstable retention times and distorted peak shapes. A C18 stationary phase with charged surface hybrid

chemistry has shown to work well, providing improved retention and peak shapes.

The injection volume should be optimized for the column dimension and the sensitivity of the mass

spectrometric system. Depending on the sensitivity and linear dynamic range of the mass spectrometric

instrument it can be necessary to dilute the calibration standards and sample extracts by an additional

factor with water.

Mass spectrometric conditions should be appropriate to measure the analytes with sufficient sensitivity

and specificity. Glucosinolates are best analyzed in negative ionization mode. At least two transitions

should be selected and included in the multiple reaction monitoring (MRM) method. In general, the most

intense product ion is the formation of hydrogen sulphate anion (m/z 97). Additional product ions that

are present in the spectra of most glucosinolates are the C H OS anion (m/z 75) and glucose-sulphate

2 3

anion (m/z 259). For several glucosinolates structure specific anions are also formed. See Table B.3 for

detailed information on which other product ions are formed. Preferably, product ions formed by the loss

of water from the de protonated molecular ion should not be selected.

Glucosinolates containing an indole substituent (glucobrassicin and its 4-hydroxy, 4-methoxy and N-

methoxy derivatives) can produce 7-hydroxy and 7-methoxy adducts in the mass spectrometer. The

amount of adducts formed depends on the design of the mass spectrometer and therefore varies

substantially between type or brand of mass spectrometer. The tendency to produce these adducts

diminishes in the order: 4-hydroxyglucobrassicin > 4-

methoxyglucobrassicin > glucobrassicin > > neoglucobrassicin. Adduct formation can result in a

(strongly) reduced sensitivity of the parent molecular ion. It is therefore advised to include the 7-hydroxy

and 7-methoxy adducts in the analytical method. The product ions that are the most sensitive and stable

during the analytical run should be used for quantification.

The instrument should have sufficient sensitivity to detect the analytes at a level of 0,1 mmol/kg in the

oilseed or oilseed product at a level of 0,02 mmol/kg in compound feed with a signal-to-noise ratio of 3

for the weakest selected product ion and signal-to-noise ratio of 10 for the most intense product ion.

The linearity of the mass detector should be verified over the full calibration range before the analysis of

the samples is conducted. Depending on the sensitivity and linear dynamic range of the mass

spectrometric instrument it can be necessary to reduce the injection volume. When this is not possible, it

is advised to dilute the calibration standards and sample extracts by an additional factor with extraction

solvent (5.4.1).

An example of suitable measuring conditions is provided in Annex B and example chromatograms are

given in Annex C.

8.2 Analysis sequence

8.2.1 Oilseeds and oilseed products

An appropriate analysis sequence for oilseeds and oilseed products:

— calibration standard 8 of 1 nmol/ml in water, injected at least three times or until stable

measurement conditions are obtained;

— water;

— calibration standard range in aqueous solution (5.3.26);

— water;

— quality control sample extract (5.5);

— sample extracts (7.3.1);

— water;

— calibration standard range in aqueous solution (5.3.26).

Depending on the number of samples, additional calibration standards may be included in between the

samples.

8.2.2 Compound feed

An appropriate analysis sequence for compound feeds:

— calibration standard 8 of 1 nmol/ml in blank matrix extract, injected at least three times or until

stable measurement conditions are obtained;

— water;

— calibration standard range in blank matrix extract (7.3.4);

— water;

— recovery sample (7.3.3);

— sample extracts (7.3.2);

— water;

— calibration standard range in blank matrix extract (7.3.4).

Depending on the number of samples, additional calibration standards may be included in between the

samples.

9 Evaluation of results

9.1 Identification

The detection and identification of individual glucosinolates in the sample is based on the presence of co-

eluting chromatographic peaks for the transitions measured. Retention time and relative abundance of

the transitions should match with those in the calibration standards. The deviation of the retention time

of the analyte in the sample should not exceed 0,2 min in comparison to the average retention time in the

calibration extracts. The relative intensities of the transitions in the sample should not deviate more than

30 % in comparison to the average of the relative intensities of the transitions in the calibration extracts.

9.2 Quantification

9.2.1 General

For oilseeds and oilseed products quantification is based on multi-level calibration using calibration

standard in aqueous solution (5.3.26). For compound feeds quantification is based on multi-level

calibration using calibration standards in blank matrix extract (7.3.4) (see NOTE 1). The sum area of both

product ions is used for all calculations (see NOTE 2).

NOTE 1 At the conditions described in this document, matrix effects (ion suppression or enhancement) were not

significant for oilseed samples. For compound feed samples matrix effects can be observed.

NOTE 2 Optionally, the area of the quantifier ion only can be used in the calculations of analyte concentration

and recovery.

9.2.2 Linearity of the calibration curve

Plot the sum of the product ion areas for the analyte in the calibration standards in aqueous solution

(5.3.26) or for the calibration standards in matrix extract (7.3.4) as function of the added concentration.

Use weighed least-square linear regression over all data points to estimate slope and intercept of the

calibration lines. Test for linearity of the calibration curves using a suitable test for linearity (e.g. residual

versus fitted-values plot; calculation of correlation coefficient). If the test indicates nonlinearity, identify

its cause and take appropriate measures (e.g. by reduction of the injection volume, by reduction of the

working range of the calibration curve, by using weighted calibration or by dilution of the extracts).

In the residuals versus fitted-values plot, calculated concentrations for individual calibration points

should deviate less than 20 %. The correlation coefficient of the calibration curve should be at least 0,990.

9.2.3 Calculation of the glucosinolate concentration in oilseed or oilseed product

The concentration of the analyte in the oilseed sample is calculated according to Formula (1).

Ab− V

C ×× D

(1)

aW

where

C is the concentration of the analyte in oilseed or oilseed product, in mmol/kg;

A is the sum of the area of the product ions;

b is the intercept of the calibration line (5.3.26);

a is the slope of the calibration line (5.3.26);

V is the volume of extraction solvent added to the sample, in ml;

W is the amount of sample, in g;

D is the dilution factor of the initial extract.

9.2.4 Calculation of the glucosinolate concentration in compound feed

The concentration of the analyte in the compound feed sample is calculated according to Formula (2).

Ab− V 100

C ×××D

(2)

aW R

where

C is the concentration of the analyte in the compound feed, in mmol/kg;

A is the sum of the area of the product ions;

b is the intercept of the calibration line in matrix extract (7.3.4);

a is the slope of the calibration line in matrix extract (7.3.4);

V is the volume of extraction solvent added to the sample, in ml;

W is the amount of sample, in g;

D is the dilution factor of the initial extract;

R is the recovery, in %.

The recovery is calculated according to Formula (3).

Ab−

V

Rec

RD ×× (3)

a W

where

R is the recovery, in %;

A is the sum of the area of the product ions from the analyte in the recovery sample of

Rec

0,1 mmol/kg (7.3.3);

b is the intercept of the calibration line;

a is the slope of the calibration line;

V is the volume of extraction solvent added to the sample, in ml;

=

=

=

W is the amount of sample, in g;

D is the dilution factor of the initial extract;

R is the recovery, in %;

A is the sum of the area of the product ions from the analyte in the recovery sample of

Rec

0,1 mmol/kg (7.3.3);

b is the intercept of the calibration line.

9.3 Expression of results

The concentration obtained is in mmol/kg. Besides the concentration of the individual glucosinolates, the

total concentration of glucosinolates can be reported. The total glucosinolate concentration is the sum of

the quantified individual glucosinolates. Results obtained for oilseeds and oilseed products are not

corrected for recovery. Results obtained for compound feeds are corrected for recovery when the

recovery for the analyte is lower than 90 % or higher than 110 %.

In addition, for sample analysis in the frame of EU directive 2002/32, the final result for reporting needs

to be expressed on the basis of a 12 % moisture content and the concentration needs to be adjusted taking

the actual moisture content of the sample into account [6].

To express the total glucosinolate content as mg/kg allyl isothiocyanate, the concentration in mmol/kg is

multiplied with a factor 99,15.

10 Precision

10.1 General

Precision data were obtained in a collaborative study. Details of the precision of the method are provided

in Annex A. Besides repeatability and r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...