kSIST FprEN IEC 62271-201:2025

(Main)High-voltage switchgear and controlgear - Part 201: AC solid-insulation enclosed switchgear and controlgear for rated voltages above 1 kV and up to and including 52 kV

High-voltage switchgear and controlgear - Part 201: AC solid-insulation enclosed switchgear and controlgear for rated voltages above 1 kV and up to and including 52 kV

Hochspannungs-Schaltgeräte und -Schaltanlagen - Teil 201: Isolierstoffgekapselte Wechselstrom-Schaltanlagen für Bemessungsspannungen über 1 kV bis einschließlich 52 kV

Appareillage à haute tension - Partie 201: Appareillage sous enveloppe isolante solide pour courant alternatif de tensions assignées supérieures à 1 kV et inférieures ou égales à 52 kV

Visokonapetostne stikalne in krmilne naprave - 201. del: Izolacijsko obdane izmenične stikalne in krmilne naprave za napetosti nad 1 kV in do vključno 52 kV

General Information

- Status

- Not Published

- Public Enquiry End Date

- 13-Jun-2024

- Technical Committee

- SKA - Switchgear and control gear

- Current Stage

- 5020 - Formal vote (FV) (Adopted Project)

- Start Date

- 06-Aug-2025

- Due Date

- 24-Sep-2025

- Completion Date

- 06-Aug-2025

Relations

- Effective Date

- 25-Jan-2023

Overview

The kSIST FprEN IEC 62271-201:2025 standard, developed by the CLC and harmonized with IEC 62271-201:2024, covers high-voltage switchgear and controlgear specifically for AC solid-insulation enclosed devices. It applies to equipment with rated voltages above 1 kV and up to 52 kV, focusing on power system safety, performance, and reliability. This standard provides essential guidelines on design, construction, testing, and operational requirements, enabling manufacturers and users to ensure equipment compatibility, safety, and longevity in medium to high voltage electrical systems.

Key Topics

- Scope and Definitions: Establishes terminology for assemblies, parts, operational characteristics, and ratings pertaining to AC solid-insulation enclosed switchgear and controlgear.

- Voltage and Current Ratings: Includes rated voltage, insulation levels, continuous current, short-time withstand currents, and peak withstand current requirements tailored to equipment voltages ranging from 1 kV up to 52 kV.

- Design and Construction Requirements: Covers materials, enclosure specifications, earthing, auxiliary/control circuits, mechanical and electrical operation, insulation, fire safety, electromagnetic compatibility (EMC), and corrosion resistance for solid-insulated high-voltage equipment.

- Testing Procedures:

- Type and Routine Tests such as dielectric withstand, radio interference voltage, continuous current, mechanical operation, pressure tests on gas-filled compartments, and internal arc fault verification.

- Partial Discharge Measurement and humidity tests to ensure insulation integrity and reliability under environmental stress.

- Internal Arc Classification (IAC) testing for safety against internal faults.

- Selection and Application Guidance: Assists in choosing rated values, considering environmental conditions, cable interface compatibility, overload scenarios, and earthing functions.

- Safety and Environmental Impact: Defines procedures to protect personnel from electrical hazards and assesses equipment environmental influence, promoting sustainable electrical infrastructure.

Applications

- Medium and High Voltage Power Distribution: Used in substations, industrial plants, and utilities where reliable switching and controlgear for voltages above 1 kV to 52 kV is required.

- Renewable Energy Integration: Facilitates safe and resilient operations for wind, solar, and other renewable generation connections to grid infrastructure.

- Transportation and Infrastructure: Supports electrical grid components in railway systems, airports, and urban transit requiring secure medium voltage switchgear.

- Oil, Gas, and Petrochemical Facilities: Ensures robust performance and safety in hazardous environments with solid-insulated switchgear designed to reduce fire hazards and improve arc fault management.

- Smart Grid and Automation: Enables advanced control and protection systems with reliable auxiliary and control circuit integration adhering to IEC standards.

Related Standards

- IEC 62271 Series: Including other parts covering conventional air-insulated switchgear, gas-insulated switchgear (GIS), and circuit-breakers for high voltages.

- IEC 60439 / IEC 61439 Series: Standards for low-voltage switchgear and controlgear assemblies.

- IEC 60068: Environmental testing standards referenced for humidity, temperature, and mechanical endurance tests.

- EMC Standards (IEC 61000 Series): Related to electromagnetic compatibility for switchgear auxiliary and control equipment.

- IEC 62271-100: Switchgear for rated voltages above 1 kV to 52 kV with gas-insulated enclosures, complementary to solid-insulated types.

kSIST FprEN IEC 62271-201:2025 represents a critical benchmark for manufacturers, designers, and users of medium voltage AC solid-insulated switchgear and controlgear, ensuring equipment meets modern safety, environmental, and performance criteria under various service conditions. Incorporating this standard enhances system reliability and facilitates international harmonization of electrical infrastructure components.

Frequently Asked Questions

kSIST FprEN IEC 62271-201:2025 is a draft published by the Slovenian Institute for Standardization (SIST). Its full title is "High-voltage switchgear and controlgear - Part 201: AC solid-insulation enclosed switchgear and controlgear for rated voltages above 1 kV and up to and including 52 kV". This standard covers: High-voltage switchgear and controlgear - Part 201: AC solid-insulation enclosed switchgear and controlgear for rated voltages above 1 kV and up to and including 52 kV

High-voltage switchgear and controlgear - Part 201: AC solid-insulation enclosed switchgear and controlgear for rated voltages above 1 kV and up to and including 52 kV

kSIST FprEN IEC 62271-201:2025 is classified under the following ICS (International Classification for Standards) categories: 29.130.10 - High voltage switchgear and controlgear. The ICS classification helps identify the subject area and facilitates finding related standards.

kSIST FprEN IEC 62271-201:2025 has the following relationships with other standards: It is inter standard links to SIST EN 62271-201:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

kSIST FprEN IEC 62271-201:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

oSIST prEN IEC 62271-201:2024

01-junij-2024

Visokonapetostne stikalne in krmilne naprave - 201. del: Izolacijsko obdane

izmenične stikalne in krmilne naprave za napetosti nad 1 kV in do vključno 52 kV

High-voltage switchgear and controlgear - Part 201: AC solid-insulation enclosed

switchgear and controlgear for rated voltages above 1 kV and up to and including 52 kV

Hochspannungs-Schaltgeräte und -Schaltanlagen - Teil 201: Isolierstoffgekapselte

Wechselstrom-Schaltanlagen für Bemessungsspannungen über 1 kV bis einschließlich

52 kV

Appareillage à haute tension - Partie 201: Appareillage sous enveloppe isolante solide

pour courant alternatif de tensions assignées supérieures à 1 kV et inférieures ou égales

à 52 kV

Ta slovenski standard je istoveten z: prEN IEC 62271-201:2024

ICS:

29.130.10 Visokonapetostne stikalne in High voltage switchgear and

krmilne naprave controlgear

oSIST prEN IEC 62271-201:2024 en

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

oSIST prEN IEC 62271-201:2024

oSIST prEN IEC 62271-201:2024

17C/928/CDV

COMMITTEE DRAFT FOR VOTE (CDV)

PROJECT NUMBER:

IEC 62271-201 ED3

DATE OF CIRCULATION: CLOSING DATE FOR VOTING:

2024-03-22 2024-06-14

SUPERSEDES DOCUMENTS:

17C/897/CD, 17C/904/CC

IEC SC 17C : ASSEMBLIES

SECRETARIAT: SECRETARY:

Germany Mr Mark Kuschel

OF INTEREST TO THE FOLLOWING COMMITTEES: PROPOSED HORIZONTAL STANDARD:

TC 17,SC 17A

Other TC/SCs are requested to indicate their interest, if

any, in this CDV to the secretary.

FUNCTIONS CONCERNED:

EMC ENVIRONMENT QUALITY ASSURANCE SAFETY

SUBMITTED FOR CENELEC PARALLEL VOTING NOT SUBMITTED FOR CENELEC PARALLEL VOTING

Attention IEC-CENELEC parallel voting

The attention of IEC National Committees, members of

CENELEC, is drawn to the fact that this Committee Draft

for Vote (CDV) is submitted for parallel voting.

The CENELEC members are invited to vote through the

CENELEC online voting system.

This document is still under study and subject to change. It should not be used for reference purposes.

Recipients of this document are invited to submit, with their comments, notification of any relevant patent rights of

which they are aware and to provide supporting documentation.

Recipients of this document are invited to submit, with their comments, notification of any relevant “In Some

Countries” clauses to be included should this proposal proceed. Recipients are reminded that the CDV stage is the

final stage for submitting ISC clauses. (SEE AC/22/2007 OR NEW GUIDANCE DOC).

TITLE:

High-voltage switchgear and controlgear - Part 201: AC solid-insulation enclosed switchgear and

controlgear for rated voltages above 1 kV and up to and including 52 kV

PROPOSED STABILITY DATE: 2032

NOTE FROM TC/SC OFFICERS:

download this electronic file, to make a copy and to print out the content for the sole purpose of preparing National

Committee positions. You may not copy or "mirror" the file or printed version of the document, or any part of it, for

any other purpose without permission in writing from IEC.

oSIST prEN IEC 62271-201:2024

IEC CDV 62271-201 © IEC 2024 2 17C/928/CDV

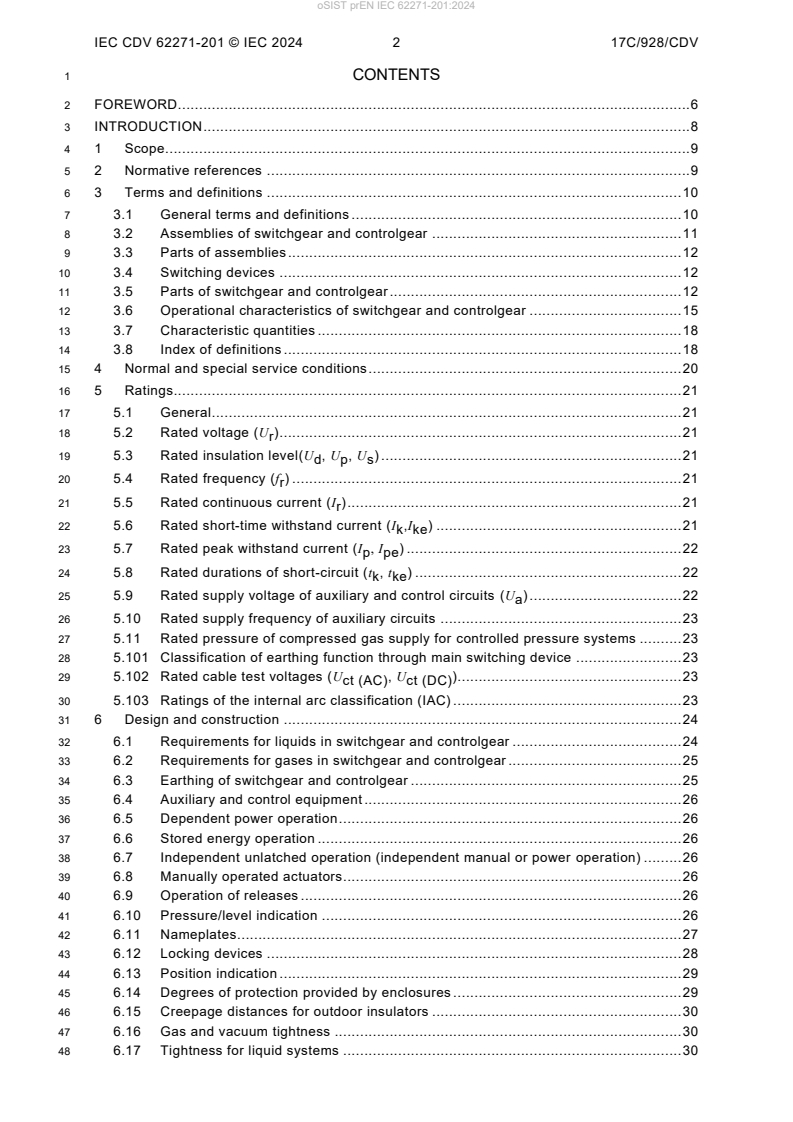

1 CONTENTS

2 FOREWORD. 6

3 INTRODUCTION . 8

4 1 Scope . 9

5 2 Normative references . 9

6 3 Terms and definitions . 10

7 3.1 General terms and definitions . 10

8 3.2 Assemblies of switchgear and controlgear . 11

9 3.3 Parts of assemblies . 12

10 3.4 Switching devices . 12

11 3.5 Parts of switchgear and controlgear . 12

12 3.6 Operational characteristics of switchgear and controlgear . 15

13 3.7 Characteristic quantities . 18

14 3.8 Index of definitions . 18

15 4 Normal and special service conditions . 20

16 5 Ratings . 21

17 5.1 General . 21

18 5.2 Rated voltage (U ) . 21

r

19 5.3 Rated insulation level(U , U , U ) . 21

d p s

20 5.4 Rated frequency (f ) . 21

r

21 5.5 Rated continuous current (I ) . 21

r

22 5.6 Rated short-time withstand current (I ,I ) . 21

k ke

23 5.7 Rated peak withstand current (I , I ) . 22

p pe

24 5.8 Rated durations of short-circuit (t , t ) . 22

k ke

25 5.9 Rated supply voltage of auxiliary and control circuits (U ) . 22

a

26 5.10 Rated supply frequency of auxiliary circuits . 23

27 5.11 Rated pressure of compressed gas supply for controlled pressure systems . 23

28 5.101 Classification of earthing function through main switching device . 23

29 5.102 Rated cable test voltages (U , U ) . 23

ct (AC) ct (DC)

30 5.103 Ratings of the internal arc classification (IAC) . 23

31 6 Design and construction . 24

32 6.1 Requirements for liquids in switchgear and controlgear . 24

33 6.2 Requirements for gases in switchgear and controlgear . 25

34 6.3 Earthing of switchgear and controlgear . 25

35 6.4 Auxiliary and control equipment . 26

36 6.5 Dependent power operation . 26

37 6.6 Stored energy operation . 26

38 6.7 Independent unlatched operation (independent manual or power operation) . 26

39 6.8 Manually operated actuators . 26

40 6.9 Operation of releases . 26

41 6.10 Pressure/level indication . 26

42 6.11 Nameplates . 27

43 6.12 Locking devices . 28

44 6.13 Position indication . 29

45 6.14 Degrees of protection provided by enclosures . 29

46 6.15 Creepage distances for outdoor insulators . 30

47 6.16 Gas and vacuum tightness . 30

48 6.17 Tightness for liquid systems . 30

oSIST prEN IEC 62271-201:2024

IEC CDV 62271-201 © IEC 2024 3 17C/928/CDV

49 6.18 Fire hazard (flammability) . 30

50 6.19 Electromagnetic compatibility (EMC) . 30

51 6.20 X-ray emission . 30

52 6.21 Corrosion . 30

53 6.22 Filling levels for insulation, switching and/or operation . 30

54 6.101 General requirements for assemblies . 30

55 6.102 Solid insulating enclosure . 31

56 6.103 High-voltage compartments . 34

57 6.104 Removable parts . 37

58 6.105 Provisions for dielectric tests on cables . 38

59 6.106 Internal arc fault . 38

60 7 Type tests . 38

61 7.1 General . 38

62 7.2 Dielectric tests . 39

63 7.3 Radio interference voltage (RIV) test . 43

64 7.4 Resistance measurement . 43

65 7.5 Continuous current tests . 44

66 7.6 Short-time withstand current and peak withstand current tests . 46

67 7.7 Verification of the protection . 48

68 7.8 Tightness tests . 48

69 7.9 Electromagnetic compatibility tests (EMC) . 48

70 7.10 Additional tests on auxiliary and control circuits . 48

71 7.11 X-radiation test procedures for vacuum interrupters . 49

72 7.101 Verification of making and breaking capacities . 49

73 7.102 Mechanical operation tests . 50

74 7.103 Pressure withstand test for gas-filled compartments . 52

75 7.104 Tests to verify the protection of persons against dangerous electrical effects . 54

76 7.105 Internal arc test . 55

77 7.106 Thermal stability test . 58

78 7.107 Humidity test . 59

79 8 Routine tests . 59

80 8.1 General . 59

81 8.2 Dielectric test on the main circuit . 59

82 8.3 Tests on auxiliary and control circuits . 60

83 8.4 Measurement of the resistance of the main circuit . 60

84 8.5 Tightness test . 60

85 8.6 Design and visual checks . 60

86 8.101 Partial discharge measurement . 60

87 8.102 Mechanical operation tests . 61

88 8.103 Pressure tests of gas-filled compartments . 61

89 8.104 Tests after erection on site . 61

90 8.105 Measurement of fluid condition after filling on site . 62

91 9 Guide to the selection of switchgear and controlgear (informative) . 62

92 9.1 General . 62

93 9.2 Selection of rated values . 62

94 9.3 Cable-interface considerations . 62

95 9.4 Continuous or temporary overload due to changed service conditions . 63

96 9.5 Environmental aspects . 63

97 9.102 Ratings related to earthing circuits . 67

98 9.103 Internal arc fault . 67

99 9.104 Summary of technical requirements, ratings and optional tests . 71

oSIST prEN IEC 62271-201:2024

IEC CDV 62271-201 © IEC 2024 4 17C/928/CDV

100 10 Information to be given with enquiries, tenders and orders (informative) . 73

101 10.1 General . 73

102 10.2 Information with enquiries and orders . 73

103 10.3 Information with tenders . 74

104 11 Transport, storage, installation, operating instructions and maintenance . 75

105 11.1 General . 75

106 11.2 Conditions during transport, storage and installation . 75

107 11.3 Installation . 75

108 11.4 Operating instructions . 75

109 11.5 Maintenance . 76

110 12 Safety . 76

111 12.101 Procedures . 76

112 12.102 Internal arc aspects . 76

113 13 Influence of the product on the environment . 76

114 Annex A (normative) Internal arc fault – Method to verify the internal arc classification

115 (IAC) . 77

116 A.1 Room simulation . 77

117 A.2 Indicators (for assessing the thermal effects of the gases) . 79

118 A.3 Tolerances for geometrical dimensions of test arrangements . 80

119 A.4 Test parameters . 80

120 A.5 Test procedure . 81

121 Annex B (normative) Partial discharge measurement . 91

122 B.1 General . 91

123 B.2 Application . 91

124 B.3 Test circuits and measuring instruments . 91

125 B.4 Test procedure . 92

126 Annex C (informative) Regional deviations . 97

127 Annex D (normative) Humidity test . 98

128 D.1 General . 98

129 D.2 Test procedure and test conditions . 98

130 D.3 Test criteria and evaluation . 100

131 Annex E (informative) Protection categories . 102

132 E.1 Protection category PA . 102

133 E.2 Protection category PB . 103

134 Annex F (informative) List of symbols and abbreviations used in IEC 62271-201 . 104

135 Annex G (normative) Flowchart categorisation procedure LSC for a given functional

136 unit FU1 with connection compartment . 105

137 Annex H (informative) Pressure coordination chart for gas-filled compartments . 106

139 Bibliography . 107

141 Figure 1 – LSC1 . 66

142 Figure 2 – LSC2 . 66

143 Figure 3 – LSC2 . 66

144 Figure 4 – LSC2 . 66

145 Figure 5 – LSC2A . 66

146 Figure 6 – LSC2B . 66

147 Figure 7 – LSC2B . 67

148 Figure 8 – No LSC assigned . 67

oSIST prEN IEC 62271-201:2024

IEC CDV 62271-201 © IEC 2024 5 17C/928/CDV

149 Figure 9 – No LSC assigned . 67

150 Figure A.1 – Mounting frame for vertical indicators . 84

151 Figure A.2 – Horizontal indicator . 84

152 Figure A.3 – Position of the indicators . 85

153 Figure A.4 – Room simulation and indicator positioning for accessibility A, classified

154 rear side, ceiling above 2 000 mm, functional unit of any height . 86

155 Figure A.5 – Ceiling height stated from the floor or false floor level where the

156 switchgear is actually placed . 87

157 Figure A.6– Indicator positioning in case of protrusion at < 2 000 mm height, at

158 classified side . 88

159 Figure A.7– Indicator positioning in case a bottom exhaust duct belonging to the

160 assembly is defined as a walkable integrated part of the false floor . 89

161 Figure A.8 – Room simulation and indicator positioning for accessibility type A, non-

162 accessible rear side, ceiling at 2 000 mm, so functional unit ≤ 1 800 mm high . 90

163 Figure B.1 – Partial discharge test circuit (three-phase arrangement) . 95

164 Figure B.2 – Partial discharge test circuit (system without earthed neutral) . 96

165 Figure D.1 – Test cycle . 101

166 Figure D.2 – Test chamber . 101

167 Figure E.1 – Possible designs for protection category PA . 102

168 Figure E.2 – Possible designs for protection category PB . 103

169 Figure G.1 – Flowchart categorisation procedure LSC for a given functional unit FU1

170 with connection compartment . 105

171 Figure H.1 – Example of pressure coordination chart . 106

173 Table 1 – Nameplate information . 27

174 Table 2 – Locations, causes and examples of measures to decrease the probability of

175 internal arc faults . 68

176 Table 3 – Single-phase-to-earth arc fault current depending on the network neutral

177 earthing . 71

178 Table 4 – Summary of technical requirements, ratings and optional tests for

179 assemblies . 71

180 Table A.1 – Parameters for internal arc test according to compartment construction . 82

181 Table B.1 – Test circuits and procedures . 93

oSIST prEN IEC 62271-201:2024

IEC CDV 62271-201 © IEC 2024 6 17C/928/CDV

186 INTERNATIONAL ELECTROTECHNICAL COMMISSION

187 ____________

189 HIGH-VOLTAGE SWITCHGEAR AND CONTROLGEAR –

191 Part 201: AC solid-insulation enclosed switchgear

192 and controlgear for rated voltages above 1 kV

193 and up to and including 52 kV

196 FOREWORD

197 1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

198 all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

199 international co-operation on all questions concerning standardization in the electrical and electronic fields. To

200 this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

201 Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

202 Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

203 in the subject dealt with may participate in this preparatory work. International, governmental and non -

204 governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

205 with the International Organization for Standardization (ISO) in accordance with conditions determined by

206 agreement between the two organizations.

207 2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an

208 international consensus of opinion on the relevant subjects since each technical committee has representation

209 from all interested IEC National Committees.

210 3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

211 Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

212 Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

213 misinterpretation by any end user.

214 4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

215 transparently to the maximum extent possible in their national and regional publications. Any divergence

216 between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

217 the latter.

218 5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

219 assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

220 services carried out by independent certification bodies.

221 6) All users should ensure that they have the latest edition of this publication.

222 7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

223 members of its technical committees and IEC National Committees for any personal injury, property damage or

224 other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

225 expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

226 Publications.

227 8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

228 indispensable for the correct application of this publication.

229 9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

230 patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

231 International Standard IEC 62271-201 has been prepared by subcommittee 17C: High-voltage

232 switchgear and controlgear assemblies, of IEC technical committee 17: Switchgear and

233 controlgear.

234 This third edition cancels and replaces second edition, published in 2014. This edition

235 constitutes a technical revision.

236 This edition includes the following significant technical changes with respect to the previous

237 edition:

238 a) aligned with the third edition of IEC 62271-200 (issued in 2021) and its CDV of AMD1, for

239 structure, definitions, classifications, ratings and testing procedures, where appropriate;

240 b) clause numbering aligned with IEC 62271-1:2017, including the adoption of the subclause

241 names of Clause 3;

242 c) in Clause 3 specific definitions are added for; “in service”, “normal operating condition”

243 and “normal use”;

244 d) earthing circuit is more precisely described, including ratings and test requirements;

oSIST prEN IEC 62271-201:2024

IEC CDV 62271-201 © IEC 2024 7 17C/928/CDV

245 e) number of mechanical tests on interlocks is reduced for type testing; forces to apply

246 during type testing are better prescribed (refer to 7.102);

247 f) resistance measuring on main circuit is only needed before continuous current tests (as

248 reference for routine tests) and not anymore needed after this continuous current test.

249 Rationale for this deletion is that this measured resistance does not mean anything; as the

250 temperature rise test was just finished, a new temperature rise test will not give new

251 information;

252 g) IEC 62271-100:2017/AMD2:2018 has been taken into account in 7.101.2;

253 h) IEC 62271-107:2019 and IEC IEEE 62271-37-013:2021 are also considered in 7.101.2;

254 i) LSC category is more precisely described, including an explaining flowchart (Annex G);

255 j) examples not covered by the IAC test are transferred from Clause 6 to 9.103;

256 k) the term “assembly” is defined in Clause 3 and used as synonym for “solid-insulation

257 enclosed switchgear and controlgear” in this document;

258 l) “metallic” is replaced by “metal” where applicable;

259 m) a 1 s rule was introduced for Criterion 4 during IAC tests regarding hot gases versus

260 glowing particles as cause of ignition;

261 n) internal arc tests for switchgear with protrusions are more precisely described in Annex A.

262 The text of this document is based on the following documents:

FDIS Report on voting

17C/594/FDIS 17C/597/RVD

264 Full information on the voting for the approval of this document can be found in the report on

265 voting indicated in the above table.

266 This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

267 This document should be read in conjunction with IEC 62271-1:2017 and its

268 Amendment 1:2021, to which it refers and which is applicable, unless otherwise specified. In

269 order to simplify the indication of corresponding requirements, the same numbering of clauses

270 and subclauses is used as in IEC 62271-1. Amendments to these clauses and subclauses are

271 given under the same numbering, whilst additional subclauses are numbered from 101.

272 The reader's attention is drawn to the fact that Annex C lists all of the “in-some-country” clauses on

273 differing practices of a less permanent nature relating to the subject of this document.

274 A list of all parts in the IEC 62271 series, published under the general title High-voltage

275 switchgear and controlgear, can be found on the IEC website.

276 The committee has decided that the contents of this publication will remain unchanged until

277 the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

278 related to the specific publication. At this date, the publication will be

279 • reconfirmed,

280 • withdrawn,

281 • replaced by a revised edition, or

282 • amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates that it

contains colours which are considered to be useful for the correct understanding of its

contents. Users should therefore print this document using a colour printer.

oSIST prEN IEC 62271-201:2024

IEC CDV 62271-201 © IEC 2024 8 17C/928/CDV

287 INTRODUCTION

288 High-voltage (IEC 60050-601:1985 [1], 601-01-27) switchgear refers to rated voltages above

289 1 kV. However, medium-voltage is commonly used for distribution systems with rated voltages

290 above 1 kV and generally applied up to and including 52 kV; refer to IEC 60050-601:1985 [1] ,

291 601-01-28.

292 Although primarily dedicated to three-phase systems, this document can also be applied to

293 single-phase and two-phase systems.

294 Switchgear and controlgear assemblies having a metal enclosure are covered by

295 IEC 62271-200 [2].

296 Gas-filled medium-voltage designs use to have design pressures below 500 kPa, as

297 mentioned for example in the introduction of EN 50187.

___________

Numbers in square brackets refer to the Bibliography.

oSIST prEN IEC 62271-201:2024

IEC CDV 62271-201 © IEC 2024 9 17C/928/CDV

300 HIGH-VOLTAGE SWITCHGEAR AND CONTROLGEAR –

302 Part 201: AC solid-insulation enclosed switchgear

303 and controlgear for rated voltages above 1 kV

304 and up to and including 52 kV

308 1 Scope

309 This part of IEC 62271 is applicable to prefabricated solid-insulation enclosed switchgear and

310 controlgear assemblies designed for:

311 – alternating current;

312 – rated voltages above 1 kV and up to and including 52 kV;

313 – service frequencies up to and including 60 Hz;

314 – indoor installation;

315 – areas limited to authorized personnel;

316 The assembly can include air-insulated and/or fluid-filled compartments.

317 For components installed in a solid-insulation enclosed switchgear and controlgear, this

318 document supplements or even replaces in some cases, the requirements as stated by the

319 individual product standards.

320 The list of components which may be inside the solid-insulation enclosed switchgear and

321 controlgear is not limited to the ones explicitly cited in this document.

322 2 Normative references

323 The following documents, in whole or in part, are normatively referenced in this document and

324 are indispensable for its application. For dated references, only the edition cited applies. For

325 undated references, the latest edition of the referenced document (including any

326 amendments) applies.

327 IEC 60050 (all parts), International Electrotechnical Vocabulary (IEV) (available at

328 www.electropedia.org)

329 IEC 60060-1:2010, High-voltage test techniques – Part 1: General definitions and test

330 requirements

331 IEC 60270, High-voltage test techniques – Partial discharge measurements

332 IEC 60529:1989, Degrees of protection provided by enclosures (IP Code)

333 IEC 60529:1989/AMD 1:1999

334 IEC 60529:1989/AMD 2:2013

335 IEC 62262:2002, Degrees of protection provided by enclosures for electrical equipment

336 against external mechanical impacts (IK code)

337 IEC 62271-1:2017, High-voltage switchgear and controlgear – Part 1: Common specifications

338 for alternating current switchgear and controlgear

339 IEC 62271-1:2017/AMD1: 2021

340 IEC 62271-100:2021, High-voltage switchgear and controlgear – Part 100: Alternating current

341 circuit-breakers

oSIST prEN IEC 62271-201:2024

IEC CDV 62271-201 © IEC 2024 10 17C/928/CDV

342 IEC 62271-102:2018, High-voltage switchgear and controlgear – Part 102: Alternating current

343 disconnectors and earthing switches

344 IEC 62271-103:2021, High-voltage switchgear and controlgear – Part 103: Alternating current

345 switches for rated voltages above 1 kV up to and including 52 kV

346 IEC 62271-105:2021, High-voltage switchgear and controlgear – Part 105: Alternating current

347 switch-fuse combinations for rated voltages above 1 kV up to and including 52 kV

348 IEC 62271-106:2021, High-voltage switchgear and controlgear – Part 106: Alternating current

349 contactors, contactor-based controllers and motor-starters

350 IEC 62271-107:2019, High-voltage switchgear and controlgear – Part 107: Alternating current

351 fused circuit-switchers for rated voltages above 1 kV up to and including 52 kV

352 IEC/IEEE 62271-37-013:2021, High-voltage switchgear and controlgear – Part 37-013:

353 Alternating current generator circuit-breakers

354 ISO 4126-2, Safety devices for protection against excessive pressure – Part 2: Bursting disc

355 safety devices

356 3 Terms and definitions

357 For the purposes of this document, the terms and definitions given in IEC 62271-1,

358 IEC 60050-151 and IEC 60050-441, and the following apply

359 NOTE The classification system for definitions of IEC 62271-1:2017 is followed. Terms and definitions are

360 referenced and prioritized in the following order:

361 – Clause 3 of this document;

362 – IEC 62271-1:2017;

363 – IEC 60050-441;

364 – IEC 60050-151.

365 ISO and IEC maintain terminological databases for use in standardization at the following

366 addresses:

367 • IEC Electropedia: available at http://www.electropedia.org/

368 • ISO Online browsing platform: available at http://www.iso.org/obp

369 3.1 General terms and definitions

370 The definitions in 3.1 of IEC 62271-1:2017 are applicable, with the following additions:

371 3.1.101

372 ambient air temperature

373 temperature, determined under specified conditions, of the air surrounding

374 the enclosure of an assembly

375 [SOURCE: IEC 60050-441:1984, 441-11-13, modified – "prescribed" has been replaced by

376 "specified", "complete switching device or fuse" by "enclosure of an assembly" and the note

377 has been removed.]

378 3.1.102

379 disruptive discharge

380 phenomenon associated with the failure of insulation under electric stress, in which the

381 discharge completely bridges the insulation under test, reducing the voltage between the

382 electrodes to zero or nearly to zero

oSIST prEN IEC 62271-201:2024

IEC CDV 62271-201 © IEC 2024 11 17C/928/CDV

383 Note 1 to entry: The term applies to discharges in solid, liquid and gaseous dielectrics and to combinations of

384 these.

385 Note 2 to entry: A disruptive discharge in a solid dielectric produces permanent loss of dielectric strength (non -self-

386 restoring insulation); in a liquid or gaseous dielectric, the loss may be only temporary (self -restoring insulation).

387 Note 3 to entry: The term “sparkover” is used when a disruptive discharge occurs in a gaseous or liquid dielectric.

388 The term “flashover” is used when a disruptive discharge occurs over the surface of a solid dielectric in a gaseous

389 or liquid medium. The term “puncture” is used when a disruptive discharge occurs through a solid dielectric

390 3.1.103

391 relative pressure

392 pressure that refers to the local atmospheric pressure

393 Note 1 to entry: When defining a filling level it is in reference to the standard atmospheric pressure of 101,3 kPa, as defined in

394 IEC 62271-1

395 3.1.104

396 segregation

397 arrangement of conductors with earthed metal interposed between them in

398 such a manner that disruptive discharges can only occur to earth

399 Note 1 to entry: A segregation can be established between the conductors as well as between the open contacts

400 of a switching device like a disconnector.

401 Note 2 to entry: This definition does not specify any mechanical protection (IP and IK).

402 [SOURCE: IEC 60050-441:1984, 441-11-11, modified – Notes to entry have been added.]

403 3.1.105

404 in service

405 condition where at least one high voltage part in the assembly is

406 energized

407 3.1.106

408 normal operating condition

409 in service condition with all doors and covers properly closed and secured

410 3.1.107

411 normal use

412 use of the assembly as defined by the manufacturer's instructions

413 reference, corresponding to the conditions and operations in service

414 Note 1 to entry: "normal use" may include maintenance activities within an accessible high -voltage compartment.

415 3.1.108

416 electric shock

417 physiological effect resulting from an electric current through a human or animal body

418 [SOURCE: IEC 60050-195:1998, 195-01-04]

419 3.2 Assemblies of switchgear and controlgear

420 The definitions in 3.2 of IEC 62271-1:2017 are applicable, with the following additions:

421 3.2.101

422 solid-insulation enclosed switchgear and controlgear

423 assembly

424 switchgear and controlgear assemblies with an external solid insulating enclosure and

425 completely assembled, except for external connections

426 Note 1 to entry: This term generally is applicable to high-voltage switchgear and controlgear.

oSIST prEN IEC 62271-201:2024

IEC CDV 62271-201 © IEC 2024 12 17C/928/CDV

427 Note 2 to entry: The external insulation may be supplied with a (semi-)conducting layer.

428 Note 3 to entry: The term "external connections" corresponds to "external conductors (cables or bars) connecting

429 the assembly to the network or an external installation".

430 3.2.102

431 multi-tier design

432 design of an assembly in which the main switching devices of two or more functional units are

433 arranged vertically (one above the other) within a common enclosure.

434 3.3 Parts of assemblies

435 The definitions in 3.3 of IEC 62271-1:2017 are applicable.

436 3.4 Switching devices

437 The definitions in 3.4 of IEC 62271-1:2017 are applicable.

438 3.5 Parts of switchgear and controlgear

439 The definitions in 3.5 of IEC 62271-1:2017 are applicable, with the following additions:

440 3.5.101

441 enclosure

442 part of an assembly providing a specified degree of protection of equipment

443 against external influences and a specified degree of protection against approach to or

444 contact with live parts and against contact with moving parts

445 [SOURCE: IEC 60050-441:1984, 441-13-01]

446 3.5.102

447 solid insulating enclosure

448 part of an assembly providing a specified degree of protection of equipment

449 against external influences and a specified degree of protection against electric shock by

450 limiting the approach to or contact with live parts and against contact with moving parts

451 Note 1 to entry: The main part of the enclosure is of solid insulating material and may have added (semi -)

452 conductive layers.

453 Note 2 to entry: If the resistance of the enclosure of the switchgear and controlgear to the earthing point provided

454 is everywhere less than, or equal to, 100 m, it is identical to the maximum electrical resistance requested by IEC

455 62271-200:2021.

456 [SOURCE: IEC 60050-441:1984, 441-13-01, modified – “electric shock by limiting the” has

457 been added; Notes to entry added.]

458 3.5.103

459 functional unit

460 part of an assembly comprising the main circuits, earthing circuit and

461 auxiliary circuits that contribute to the fulfilment of a single function

462 Note 1 to entry: Functional units can be distinguished according to the function for which they are intended, for

463 example, incoming unit, through which electrical energy is normally fed into the assembly, outgoing unit, through

464 which electrical energy is normally supplied to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...