SIST EN 13814-2:2019+A1:2024

(Main + Amendment)Safety of amusement rides and amusement devices - Part 2: Operation, maintenance and use

Safety of amusement rides and amusement devices - Part 2: Operation, maintenance and use

This document specifies the minimum requirements necessary to ensure the safe maintenance, operation, inspection and testing of amusement ride and amusement devices which are intended to be installed both repeatedly without degradation or loss of integrity, and temporarily or permanently in fairgrounds and amusement parks or any other locations.

Grandstands, construction site installations, scaffolding, removable agricultural structures, simple coin operated children's amusement devices, carrying up to three children, and recreational devices like waterslides or summer toboggan runs, playground equipment, rope courses, climbing wall, inflatable, trampolines, swimming pool equipment (this list is not exhaustive) are not covered by this document.

In terms of workers’ health and safety, national regulations apply.

Sicherheit von Fahrgeschäften und Vergnügungseinrichtungen - Teil 2: Betrieb, Instandhaltung und Gebrauch

Dieses Dokument legt grundlegende Anforderungen fest, um die sichere Wartung, den sicheren Betrieb, die sichere Inspektion und Prüfung von Fahrgeschäften und Vergnügungsanlagen, die sowohl zu einem wieder¬holten Aufbau ohne Substanzverlust als auch vorübergehend oder dauerhaft auf Veranstaltungsplätzen, in Vergnügungsparks oder anderen Örtlichkeiten vorgesehen sind, sicherzustellen.

Feste Tribünen, Bau und andere Gerüste sowie entfernbare landwirtschaftliche Konstruktionen und einfache münzbetriebene Vergnügungsanlagen für Kinder, die bis zu drei Kinder tragen sowie Sport und Freizeitanlagen, wie Wasserrutschen oder Sommerrodelbahnen, Spielplatzgeräte, Seilgärten, Kletterwände, Hüpfburgen, Trampoline, Schwimmbadgeräte (diese Liste ist nicht vollständig) sind nicht Gegenstand dieses Dokumentes.

Für Belange des Arbeits- und Gesundheitsschutzes gelten nationale Vorschriften.

Sécurité des manèges et des dispositifs de divertissement - Partie 2 : Installation, maintenance et exploitation

Le présent document spécifie les exigences minimales requises pour assurer la sécurité de la maintenance, de l’exploitation, du contrôle et des essais des manèges et dispositifs de divertissement destinés à être installés de manière répétitive sans dégradation ni perte d’intégrité, que ce soit provisoirement ou définitivement, dans des fêtes foraines, des parcs d’attractions ou d’autres emplacements.

Les tribunes, les installations des chantiers de construction, les échafaudages et les structures agricoles amovibles, les dispositifs de divertissement pour enfants actionnés par un simple jeton ne transportant pas plus de trois enfants, ainsi que les dispositifs de divertissement comme les toboggans aquatiques ou les pistes de luge d’été, les équipements pour aires de jeux, les parcours accrobranches, les murs d’escalade, les équipements gonflables, les trampolines, les équipements de piscine (cette liste n’est pas exhaustive) ne sont pas couverts par le présent document.

En matière de santé et de sécurité des ouvriers, les réglementations nationales s’appliquent.

Varnost naprav in opreme v zabaviščnih parkih - 2. del: Delovanje, vzdrževanje in uporaba (vključno z dopolnilom A1)

Ta dokument določa minimalne zahteve, ki so potrebne za zagotavljanje varnega vzdrževanja, delovanja, nadzorovanja in preskušanja naprav ter opreme v zabaviščnih parkih, ki je namenjena tako za večkratno nameščanje brez degradacije ali izgube celovitosti kot tudi za začasno ali stalno nameščanje v zabaviščih in zabaviščnih parkih ali na kateri koli drugi lokaciji.

Tribune, gradbiščne konstrukcije, odri, odstranljive kmetijske konstrukcije, preproste naprave na kovance v zabaviščnih parkih, ki so namenjene za največ tri otroke, in rekreacijske naprave, kot so vodni tobogani ali poletna sankališča, oprema otroških igrišč, vrvni plezalni parki, plezalne stene, napihljiva igrala, trampolini in oprema bazenov (ta seznam ni popoln), niso zajeti v tem dokumentu.

V zvezi z zdravjem in varnostjo delavcev veljajo nacionalni predpisi.

General Information

- Status

- Published

- Publication Date

- 12-Aug-2024

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 05-Aug-2024

- Due Date

- 10-Oct-2024

- Completion Date

- 13-Aug-2024

Relations

- Effective Date

- 22-May-2024

- Effective Date

- 22-May-2024

Overview

EN 13814-2:2019+A1:2024 is the CEN European standard that sets minimum requirements for the safe operation, maintenance, inspection and testing of amusement rides and amusement devices. It applies to devices intended for repeated installation (without loss of integrity) and temporary or permanent use in fairgrounds, amusement parks or other locations. This edition includes Amendment 1 (2024) and supersedes EN 13814-2:2019. National adoption is required under CEN rules.

The standard complements Part 1 (design & manufacture) and Part 3 (inspection requirements) of EN 13814 and interacts with national regulations for workers’ health and safety and licensing.

Key Topics and Requirements

- Scope & exclusions: clarifies devices covered and lists excluded equipment (e.g., grandstands, scaffolding, simple coin-operated children’s devices carrying up to three children, waterslides, playground equipment, trampolines).

- Standard documentation: required documentation, logbooks and records to support safe operation and maintenance.

- Roles & responsibilities: duties for the controller, operator, attendant, competent persons and inspection bodies.

- Staff competence & training: selection, training, qualification and experience requirements for personnel involved in operation, servicing and supervision.

- Assembly, disassembly & care: procedures for correct installation, dismantling and ongoing care of equipment.

- Trial operations & checks: pre-opening tests, commissioning and verification before public use.

- Operation & supervision: safe-running procedures, attendant tasks and operator responsibilities during normal operation.

- Servicing, repair & modification: definitions for routine maintenance, major modifications and record keeping.

- Independent inspection & reporting: in-service inspections, reporting requirements and documentation for inspection bodies.

- Emergency planning: evacuation, escape routes and fire considerations for incident response.

- Annexes: guidance on training, operation permits, testing and inspection intervals (informative).

Applications and Users

This standard is used to:

- Develop operational procedures, maintenance schedules and safety management systems for rides and devices.

- Prepare technical documentation and operation permits for licensing bodies.

- Train and assess operators, attendants and maintenance staff.

- Guide inspection bodies performing initial and in-service inspections and audits.

- Support owners, controllers and concessionaires to meet EU and national safety expectations.

Typical users: ride controllers/owners, park operators, maintenance teams, designers referencing Part 1, inspection bodies, licensing authorities and safety auditors.

Related Standards

- EN 13814-1:2019 (Design and manufacture)

- EN 13814-3:2019 (Inspection requirements)

- EN 12385 (Steel wire ropes)

- EN 60947-3; EN ISO 2307; EN ISO 9554; EN ISO 13857

Keywords: EN 13814-2:2019+A1:2024, amusement rides, amusement devices, operation, maintenance, inspection, CEN, safety, operator training.

Frequently Asked Questions

SIST EN 13814-2:2019+A1:2024 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Safety of amusement rides and amusement devices - Part 2: Operation, maintenance and use". This standard covers: This document specifies the minimum requirements necessary to ensure the safe maintenance, operation, inspection and testing of amusement ride and amusement devices which are intended to be installed both repeatedly without degradation or loss of integrity, and temporarily or permanently in fairgrounds and amusement parks or any other locations. Grandstands, construction site installations, scaffolding, removable agricultural structures, simple coin operated children's amusement devices, carrying up to three children, and recreational devices like waterslides or summer toboggan runs, playground equipment, rope courses, climbing wall, inflatable, trampolines, swimming pool equipment (this list is not exhaustive) are not covered by this document. In terms of workers’ health and safety, national regulations apply.

This document specifies the minimum requirements necessary to ensure the safe maintenance, operation, inspection and testing of amusement ride and amusement devices which are intended to be installed both repeatedly without degradation or loss of integrity, and temporarily or permanently in fairgrounds and amusement parks or any other locations. Grandstands, construction site installations, scaffolding, removable agricultural structures, simple coin operated children's amusement devices, carrying up to three children, and recreational devices like waterslides or summer toboggan runs, playground equipment, rope courses, climbing wall, inflatable, trampolines, swimming pool equipment (this list is not exhaustive) are not covered by this document. In terms of workers’ health and safety, national regulations apply.

SIST EN 13814-2:2019+A1:2024 is classified under the following ICS (International Classification for Standards) categories: 97.200.40 - Playgrounds. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13814-2:2019+A1:2024 has the following relationships with other standards: It is inter standard links to SIST EN 13814-2:2019, SIST EN 13814-2:2019/oprA1:2023. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13814-2:2019+A1:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2024

Varnost naprav in opreme v zabaviščnih parkih - 2. del: Delovanje, vzdrževanje in

uporaba (vključno z dopolnilom A1)

Safety of amusement rides and amusement devices - Part 2: Operation, maintenance

and use

Sicherheit von Fahrgeschäften und Vergnügungseinrichtungen - Teil 2: Betrieb,

Instandhaltung und Gebrauch

Sécurité des manèges et des dispositifs de divertissement - Partie 2 : Installation,

maintenance et exploitation

Ta slovenski standard je istoveten z: EN 13814-2:2019+A1:2024

ICS:

97.200.40 Igrišča Playgrounds

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13814-2:2019+A1

EUROPEAN STANDARD

NORME EUROPÉENNE

July 2024

EUROPÄISCHE NORM

ICS 97.200.40 Supersedes EN 13814-2:2019

English Version

Safety of amusement rides and amusement devices -

Part 2: Operation, maintenance and use

Sécurité des manèges et des dispositifs de Sicherheit von Fahrgeschäften und

divertissement - Partie 2 : Installation, maintenance et Vergnügungseinrichtungen - Teil 2: Betrieb,

exploitation Instandhaltung und Gebrauch

This European Standard was approved by CEN on 13 May 2018 and includes Amendment 1 approved by CEN on 7 June 2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATIO N

EUROPÄISCHES KOMITEE FÜR NORMUN G

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13814-2:2019+A1:2024 E

worldwide for CEN national Members.

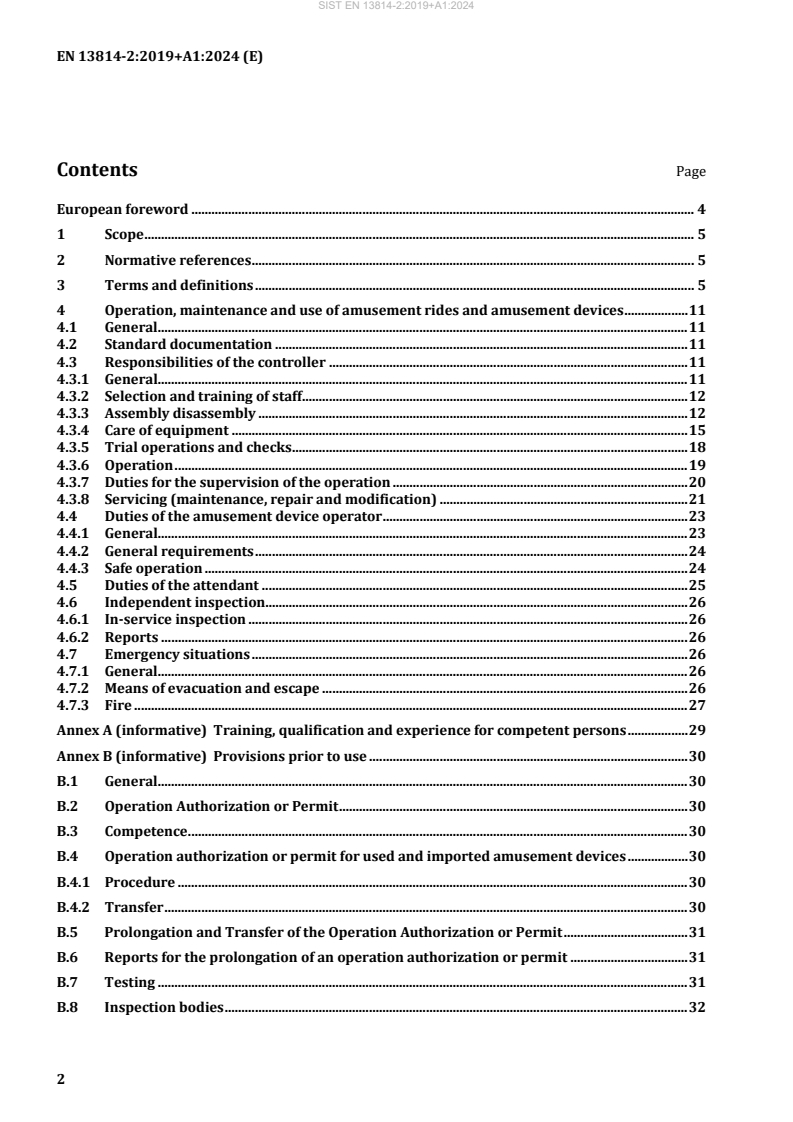

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Operation, maintenance and use of amusement rides and amusement devices . 11

4.1 General. 11

4.2 Standard documentation . 11

4.3 Responsibilities of the controller . 11

4.3.1 General. 11

4.3.2 Selection and training of staff . 12

4.3.3 Assembly disassembly . 12

4.3.4 Care of equipment . 15

4.3.5 Trial operations and checks . 18

4.3.6 Operation . 19

4.3.7 Duties for the supervision of the operation . 20

4.3.8 Servicing (maintenance, repair and modification) . 21

4.4 Duties of the amusement device operator . 23

4.4.1 General. 23

4.4.2 General requirements . 24

4.4.3 Safe operation . 24

4.5 Duties of the attendant . 25

4.6 Independent inspection. 26

4.6.1 In-service inspection . 26

4.6.2 Reports . 26

4.7 Emergency situations . 26

4.7.1 General. 26

4.7.2 Means of evacuation and escape . 26

4.7.3 Fire . 27

Annex A (informative) Training, qualification and experience for competent persons . 29

Annex B (informative) Provisions prior to use . 30

B.1 General. 30

B.2 Operation Authorization or Permit . 30

B.3 Competence . 30

B.4 Operation authorization or permit for used and imported amusement devices . 30

B.4.1 Procedure . 30

B.4.2 Transfer . 30

B.5 Prolongation and Transfer of the Operation Authorization or Permit . 31

B.6 Reports for the prolongation of an operation authorization or permit . 31

B.7 Testing . 31

B.8 Inspection bodies . 32

B.9 Installation Examination . 32

B.10 Examples of examination intervals used by member states' regulations . 32

B.10.1 General . 32

B.10.2 Germany . 32

B.10.3 United Kingdom . 36

B.10.4 Netherlands . 36

B.10.5 Italy . 36

Bibliography . 37

European foreword

This document (EN 13814-2:2019+A1:2024) has been prepared by Technical Committee

CEN/TC 152 “Fairground and amusement park machinery and structures – Safety”, the secretariat of

which is held by UNI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by January 2025, and conflicting national standards shall

be withdrawn at the latest by July 2027.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document includes Amendment 1 approved by CEN on 7 June 2024.

This document !supersedes EN 13814-2:2019".

The start and finish of text introduced or altered by amendment is indicated in the text by tags !".

EN 13814 consists of the following parts, under the general title Safety of amusement rides and

amusement devices:

— Part 1: Design and manufacture

— Part 2: Operation, maintenance and use

— Part 3: Requirements for inspection during design, manufacture, operation and use

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta,

Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and the United Kingdom.

1 Scope

This document specifies the minimum requirements necessary to ensure the safe maintenance,

operation, inspection and testing of amusement ride and amusement devices which are intended to be

installed both repeatedly without degradation or loss of integrity, and temporarily or permanently in

fairgrounds and amusement parks or any other locations.

Grandstands, construction site installations, scaffolding, removable agricultural structures, simple coin

operated children's amusement devices, carrying up to three children, and recreational devices like

waterslides or summer toboggan runs, playground equipment, rope courses, climbing wall, inflatable,

trampolines, swimming pool equipment (this list is not exhaustive) are not covered by this document.

In terms of workers’ health and safety, national regulations apply.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 12385 (all parts), Steel wire ropes — Safety

EN 13814-1:2019, Safety of amusement rides and amusement devices — Part 1: Design and Manufacture

EN 13814-3:2019, Safety of amusement rides and amusement devices — Part 3: Requirements for

inspection during design, manufacture, operation and use

EN 60947-3, Low-voltage switchgear and controlgear - Part 3: Switches, disconnectors, switch-

disconnectors and fuse-combination units (IEC 60947-3)

EN ISO 2307, Fibre ropes - Determination of certain physical and mechanical properties (ISO 2307)

EN ISO 9554, Fibre ropes - General specifications (ISO 9554)

EN ISO 13857, Safety of machinery - Safety distances to prevent hazard zones being reached by upper and

lower limbs (ISO 13857)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

amusement device

arrangement of equipment that produces the desired effect of amusement or entertainment when the

passenger (3.28) moves through it or on it primarily by his or her own action, or any other system that

is not covered by the term amusement ride (3.2)

3.2

amusement ride

equipment that is designed to entertain the passengers (3.28) during motion including the consequence

of biomechanical effect

Note 1 to entry: In this standard, the word amusement device is used to refer to an amusement device (3.1) or

amusement ride (3.2).

3.3

attendant

trained person appointed to work under the supervision of an operator (3.27), to assist in the operation

of an amusement device (3.1) available for use by the public

3.4

barrier

device intended to prevent the user from falling and from passing beneath

3.5

closed restraint

closed restraint position in which the restraint (3.37) is intended to remain during the operation of the

device in order to restrain the passenger (3.28)

3.6

competent person

person who can demonstrate that he has acquired through training, qualifications or experience, or a

combination of these, the knowledge and skills enabling that person to perform a specified task

3.7

controller

ride controller

person or organisation having overall control of an amusement device (3.1). This may be either an

individual or corporate body owning an amusement device (3.1) or the concessionaire or lessee who has

been granted control of the amusement device, by the owner, for a specified period

3.8

design review

document detailing the review of all the applicable design documents, to determine the suitability for

use of an amusement device

3.9

design risk assessment

DRA

document, produced by the designer (3.10) as a tool for safe design, within the agreed scope of supply

3.10

designer

engineer

person or body that is responsible for the design of an amusement device (or modifications thereof),

including, but not limited to establishing and describing the configuration of the amusement device,

conducting appropriate risk assessment(s), establishing strength (including fatigue strength), designing

and specifying electrical/electronic control systems, defining the acceptable quality level for

production, defining inspection criteria and including the publication of the necessary documentation

3.11

amusement device log

book and/or electronic data file containing all the necessary information about the use and history of

any amusement device

3.12

fail safe

characteristic of a system, component or device the failure of which maintains a safe state

3.13

fence

structure designed to restrict or prevent movement across a boundary without changing elevation

3.14

gate

section of fence (3.13) or barrier (3.4) that may be opened to provide access or egress

3.15

guardrail

rail intended to prevent a user from falling

3.16

guest

person that may interact with an amusement device

3.17

handrail

rail intended to assist the user to balance

3.18

initial approval

design and calculation review, verification, examinations and tests executed by the inspection

body (3.19) before a ride is first made available for public use

3.19

inspection body

organisation capable of carrying out examination, tests and approval of amusement devices

3.20

latching restraint

restraint (3.37) which is held secure against opening except by intentional action of the

passenger (3.28), operator (3.27), or other means. This can include restraints (3.37) (e.g. drop bars) held

in place by gravity, detents or other means

3.21

licensing body

national authority or body legally authorised to issue a permit for operation of an amusement device

and related documents

3.22

locking restraint

restraint (3.37) which is held secure against opening except by intentional action of the operator (3.27)

or other means not accessible by the passenger (3.28)

3.23

machinery component

component which form part of an assembly in which at least one component moves (excluding

vibration and deformation)

3.24

major modification

safety-related alteration to the hardware or software of an amusement device (3.1), including the

introduction of a new safety-related component (3.41) or the substitution of a safety-related

component (3.41), which results in a deviation from the current design specification

3.25

manufacturer

individual or commercial entity who is responsible for designing and manufacturing a product with the

view to placing it on the market under their own name

Note 1 to entry: Any commercial entity that either places a product on the market under their own name or

trademark or modifies a product in such a way that compliance with applicable requirements maybe affected

should be considered to be the manufacturer and should assume the obligations of the manufacturer.

3.26

operation and use risk assessment

OURA

document, produced by the controller (3.7), that details all of the considered risks inherent during all

modes of an amusement device operation and the means taken to mitigate against them

Note 1 to entry: This term is explained in details in EN 13814-1:2019, 5.1.2.2.

3.27

operator

trained person appointed by the controller (3.7) to be in charge of the operation of an amusement

device (3.1) when it is intended to be available for the public

3.28

passenger

patron

person using an amusement device

3.29

passenger containment

components (e.g. seating, footwells, handrails (3.17) and passenger restraints) designed to prevent

passengers (3.28) from moving outside a predetermined area on a ride either as a result of the ride

forces or the behaviour of the passenger (3.28)

3.30

passenger reach envelope

physical space where a passenger (3.28) can reach during a ride cycle while properly positioned, as

defined by the ride analysis, in the amusement ride (3.2) or amusement device (3.1) and limited only by

the vehicle, seat geometry, and restraint system

3.31

passenger unit

PU

part or parts of an amusement ride (3.2) in or on which the passenger (3.28) is intended to ride

3.32

permit

authorisation to operate an amusement device in a particular member state granted by the legally

authorised body after successful approval and/or examination

3.33

platform

horizontal or inclined surface raised above the level of an adjacent area

Note 1 to entry: See EN 13814-1:2019, 5.1.3.2 for maximum slope of platform.

3.34

reasonably foreseeable misuse

use of a machine in a way not intended by the designer (3.10), but which can result from readily

predictable human behaviour

Note 1 to entry: EN 13814-1:2019, Annex F (Guest Behaviour) gives a non-exhaustive list of human behaviours.

[SOURCE: EN ISO 12100:2010, 3.24, modified — Note 1 to entry has been added.]

3.35

redundancy

application of more than one device or system, or part of a device or system, with the objective of

ensuring that in the event of one failing to perform its function another will perform that function

3.36

repair

restoration of components or assemblies to an acceptable condition

3.37

restraint

system, device, or characteristic that is intended to inhibit or restrict the body movement and/or keep

the body position to tolerate accelerations of the passenger(s) (3.28) while on the amusement ride (3.2)

or amusement device (3.1)

3.38

safe stop

stop of an amusement ride (3.2) in a safe way and in a final safe stable position

3.39

safety envelope

theoretical or actual physical space that may be encroached by any part of a passenger (3.28) of an

amusement ride during the ride cycle

Note 1 to entry: This is the passenger reach envelope (3.30) plus a suitable margin as defined

in EN 13814-1:2019, Annex H.

3.40

safety-related control system

SRCS

assembly of components that may be electronic, electric, electro-mechanical, hydraulic, pneumatic or

mechanical combined to monitor and control an amusement device so as to reduce risks to guests (3.16)

3.41

safety-related part or component

part or component of an amusement device (3.1) on which the safety of the passengers (3.28) is

dependent as identified in the design risk assessment (3.9) and/or the operation and use risk

assessment (3.26)

3.42

service

replacement or replenishment and check on the condition of components, including fluids which are

designated to be replaced or replenished at specified intervals

3.43

sideshow

booth or similar enclosed structure containing, shows, activities or games for the entertainment of the

public, where the guest (3.16) is not carried in any way by the structure

3.44

spectator

person in the vicinity of an amusement device (3.1). Typically defined as a person watching the

operation of the amusement device or waiting to gain access to the use the amusement device

3.45

structural component

calculated load bearing part which has not been classified as machinery components (3.23) by the

designer (3.10)

3.46

sustained acceleration

accelerations with duration greater than or equal to 200 ms

3.47

temporarily installed amusement device

amusement device which is designed to be installed and uninstalled, the installation period of which

shall not exceed more than 3 months

3.48

thorough examination

procedures and investigations necessary for the inspection body (3.19) to decide whether the

amusement device (3.1) can continue to be operated safely, or whether it requires defects to be

remedied immediately or within a specified time

3.49

trial run

proving run of an amusement device (3.1) during which no passengers (3.28) are carried

4 Operation, maintenance and use of amusement rides and amusement devices

4.1 General

This standard is concerned with installing, assembling and disassembling, operating, handling,

maintaining, repairing, modifying and inspecting amusement devices and is addressed to controllers,

operators, attendants and inspection bodies.

4.2 Standard documentation

! The documents, which shall be prepared for all amusement devices, are:

— official technical dossier (see EN 13814-1:2019, 5.8) inclusive DRA;

— manuals (see EN 13814-1:2019, 5.5.1);

— amusement device log (see EN 13814-1:2019, 5.7 and Annex E);

— OURA (see EN 13814-1:2019, 5.1.2.3);

— operating procedures from the controller (based on OURA to cover also residual risks; see

EN 13814-1:2019, Figure 6)"."

4.3 Responsibilities of the controller

4.3.1 General

The controller or nominated delegate(s) shall:

— ensure that the required documentation accompanies the amusement device when being bought,

sold or otherwise transferred or supplied;

— select and train operators and attendants;

— assemble, and disassemble safely;

— ensure safe operation in full compliance with all laws, prescriptions and regulations issued by local

and national authorities;

— service, maintain, repair and modify safely;

— where required, ensure that only amusement devices which have a valid operational permit and are

examined and tested by appropriately independent inspection bodies, are operated;

— maintain, keep available and update as required the Operating Manual and Amusement Device Log,

as well as creating necessary reports;

— ensure that where operators do not have a clear view of all loading or unloading points, devise a

clear system of signals for checking with attendants that it is safe to start. Make sure every person

using the system is instructed how to use it and display a copy of the signal code in appropriate

positions;

— ensure that emergency procedures are established, well documented and regularly practiced;

— provide full instructions on the control or communications system.

The ride controller can delegate any part of his duties, but remains responsible in law.

4.3.2 Selection and training of staff

Obtaining suitable and competent staff involves selection, training, testing of knowledge and

understanding, monitoring, auditing and keeping records. The controller shall select people able to put

the safety of the public first, to follow procedures conscientiously and having the maturity and authority

to give confidence to the public.

Adequate training shall be provided to all employees and training records kept. Training shall be

appropriate to the risks and given in a way that those being trained can understand.

The operator and attendants of amusement devices shall demonstrate competency in the operation of

amusement devices according to the manual(s).

No operators or attendants of the amusement device shall be younger than required by national

standards or law in the country of use.

Operators and attendants depending on their duties, shall be provided with suitable and sufficient

information and training in the working of their amusement devices, covering:

— systems of work for safe operation, including speed limits and any other specific safety measures;

— procedures for reporting breakdown, defects or unusual occurrences;

— loading and unloading procedures;

— passenger restrictions such as height and weight limits, medical conditions, limited accessibility

(guest behaviour);

— control of waiting and viewing areas;

— use and operation of passenger containment and passenger restraint systems including the

checking of restraint closure;

— controlled/emergency stop procedures;

— emergency procedures, including passenger evacuation.

4.3.3 Assembly disassembly

4.3.3.1 Siting of amusement devices

4.3.3.1.1 General

Amusement devices shall be sited and assembled in accordance with manufacturer’s instruction and

applicable national requirements.

4.3.3.1.2 Standard conditions for the siting of amusement rides and amusement devices

The ride controller or his representative shall ensure that an amusement device is only sited on ground

which is suitable for this purpose in accordance with the manual(s). For example ensure that the

ground:

— can safely bear the load of the amusement device. For existing structures e.g. buildings or piers, a

detailed inspection and calculation shall be carried out in order to establish permissible loads;

— is sufficiently flat, even and stable for the attraction to be assembled and used on safely, in

accordance with the amusement device log and manual.

The ground shall be checked at regular intervals after assembly, to confirm that there is no

deterioration in its load bearing capacity, especially during adverse weather conditions. Drainage shall

be considered.

The controller shall establish the position of underground services or overhead lines which may

present hazards during the assembly or operation of the amusement device, taking advice as necessary

from the appropriate authority. Where these could be a source of danger to persons employed or to

members of the public, all reasonably practicable precautions shall be taken to prevent such danger,

either by the provision of adequate and suitably placed barriers or otherwise.

Care shall be taken to ensure that underground services are not struck when poles or pegs are placed in

the ground or when excavation is undertaken. Service location techniques shall be employed before any

such work is commenced, unless it has been confirmed beforehand that there are no services present.

When positioning amusement devices, controllers shall apply the following principles.

a) The proximity to other fixed or mobile structures or services shall be in accordance with the

requirements of EN 13814-1:2019.

b) There shall be sufficient clearance between adjacent amusement devices, buildings or other

occupied areas to minimize the risk of fire spread.

c) Consideration shall be given to any possibility of uplift caused by wind.

d) They shall be arranged so that the public have safe access to each amusement device entrance, and

safe egress at exit points, so that there are no bottle necks which could cause overcrowding in an

emergency.

e) Sufficient clearance shall be provided between amusement devices on main access routes, so as to

provide access for emergency service vehicles, and provide access to fixed fire hydrants even when

the public may be being evacuated.

f) Where rides cross over or pass through each other, as a minimum the clearance envelopes for each

ride (see EN 13814-1:2019) shall apply. The controllers shall ensure that safety envelopes for both

passengers and spectators are not compromised. For coin-operated children's rides, spacing may

vary providing the safety envelopes are not thereby compromised.

g) The OURA will need to consider whether protection is required to prevent falling objects hitting

passengers or spectators.

NOTE There can be local regulations that define the minimum distance between amusement devices and

other structures, objects, services etc.

4.3.3.2 Transportation, assembly and disassembly

When amusement devices are transported, assembled or disassembled on site they shall be under the

direct supervision of the controller and/or competent delegate(s).

4.3.3.3 Ground packing, stability and anchors

4.3.3.3.1 General

All necessary measures shall be taken during assembly to ensure that the amusement device will be

stable when in use.

No amusement device shall be assembled on sloping or uneven ground, unless suitable packing has

been incorporated which allows the amusement device to be used safely.

The amusement device shall be level where necessary and have its load adequately distributed and

firmly supported. Its stability shall be checked frequently.

The number of packing pieces used shall be kept to a minimum. The height of the packing material shall

be kept to a minimum and the packing itself shall be stable.

All packing materials incorporated shall be sound and suitable for the purpose, chosen and located in

accordance with the manual(s), so as to prevent slipping and sinking, or dislodgement.

Packing shall be placed directly beneath the load points of the amusement device. If this cannot be

achieved a suitable supporting structure shall be formed which effectively transmits the load of the

amusement device safely through the packing to the ground. Dynamic loads can lead to the loosening of

packing and anchorage; consequently, repeated checks of the packing and anchors are essential.

If an attraction is equipped with props to support the structure, these props shall be used in accordance

with the manufacturer’s instructions.

Hydraulic jacks shall not be used to support an amusement device during operation, unless they are

designed and approved for the purpose.

4.3.3.3.2 Public safety

Members of the public shall not be admitted into areas where an amusement device is being assembled

or disassembled.

The controller and/or competent delegate(s) shall, where necessary, provide means to prevent

members of the public entering work areas e.g. with fences and/or warnings.

4.3.3.3.3 Working method

A safe system of work, which as a minimum takes into account the manufacturer’s manual(s) shall be

followed during these operations. Controllers shall make themselves familiar with, and follow the

official requirements of local and national authorities.

Amusement devices shall be moved so as to minimize the risk of damage to safety-related components

and all loads shall be properly secured during transit.

Where there is a risk of temporary instability or overstressing in the device during assembly or

dismantling, the precautions specified by the designer, manufacturer, and/or supplier, shall be

followed. This may require e.g. the use of temporary guys, stays, supports and fixings to prevent danger

through collapse of any part of the amusement device

Temporary provisions for access and working during assembly and disassembly operations shall be

safe, including sufficient and suitable lighting to allow work to be conducted in a safe and proper

manner.

Unauthorized access shall be prevented through openings in platforms and through any gaps within the

amusement device, which are only intended for access when the amusement device is not in motion or

use. Such openings or gaps shall be provided with covers, be securely fixed in position or equipped with

barriers and access doors, which are securely fastened.

Before reassembly, all components as specified in the manual(s) shall be cleaned, carefully examined

for signs of wear, deformation or other damage, confirming fitness for purpose or otherwise repaired or

replaced.

They shall be properly lubricated in accordance with the manual(s). Replacements and repairs of

safety-related components shall be noted in the Amusement Device Log.

Fastening and securing components shall be used in accordance with manufacturer's instructions and

correctly adjusted, or replaced if necessary.

Upon completion of assembly, all components that are important to the safety of the amusement device,

shall be checked to ensure that they have been properly installed in accordance with the manufacturer’s

manual(s).

All structural members needed to ensure the stability and safety of an amusement device shall be used

and correctly fitted. Where it is a design requirement, the whole assembly shall be securely anchored to

ensure that it is stable.

Where rail tracks form part of the amusement device, they shall be properly laid and aligned, according

to the manual(s).

4.3.4 Care of equipment

4.3.4.1 General

All equipment shall be maintained in accordance with manufacturer’s manual(s) and / or general

engineering practices.

4.3.4.2 Mechanical equipment

At the intervals as stated in the manual(s), safety-related components shall be checked to ensure that

they are within the limits stated in the manual. Parts requiring replacement shall be consistent with the

design specification.

Controllers shall have procedures to ensure that safety-related components are:

— individually identifiable by design and quality;

— traceable as per the location(s) on the amusement device;

— not interchangeable such that parts cannot be used in incorrect positions – for example, two pins

may look identical but have different material properties;

— stored so as to prevent deterioration and contamination;

— cleaned and lubricated as required by the manual before being incorporated into the amusement

device;

— carefully assembled so that they are not damaged, in particular:

1) assembled using fastenings and fixings correctly used and adjusted, in accordance with the

manual(s);

2) all pins shall be provided with their secondary retention system (such as safety locknuts and

washers, split pins or castellated nuts with split pins, etc.) as defined in the manual(s). Split-

pins shall be spread effectively;

3) “R” clips shall be of the right size, in good condition, of the right material and fitted correctly;

4) self-locking nuts shall not be used more than the maximum number of times specified in the

manual(s);

5) close attention shall also be paid to bolted joints by using tightening torques, dimensions and

classes of bolt in accordance with the requirements of the manual(s); torque wrenches shall be

used as required;

6) components having a specified operational life shall be checked to verify their operational life

is not expired, checked in accordance with manual(s) and replaced when necessary.

If there is repeated, unexpected or unusual damage to safety-related components, the manufacturer or

designer and the inspection body shall be informed and advice of these parties sought.

When lifting equipment is used for the assembly of components, the manufacturer's instructions shall

be followed so as not to adopt unsuitable lifting methods which might cause damage and subsequent

danger during operation.

Steel wire ropes for erection and dismantling shall be used in accordance with EN 12385 series.

Synthetic fibre ropes for erection and dismantling shall be used in accordance with EN ISO 2307

and/or EN ISO 9554.

NOTE Lifting equipment, whether integral to the amusement device or not, and depending on their function,

can be subject to specific local regulations, including inspection and testing.

4.3.4.3 Hydraulic and pneumatic equipment

The Controller shall ensure that pressure systems are operating within the limits set in the manual(s) as

supplied by the manufacturer.

The pressure system shall also be examined in accordance with the written scheme of inspection.

Leakage shall be kept to a minimum, contained where possible, and not create risks. For further

information refer to EN ISO 4413 and EN ISO 4414.

Equipment subject to compliance to the Pressure Equipment Directive or other nationally applicable

legislation should meet those requirements. Compliance with EN 13445 series can be used to

demonstrate compliance with the Pressure Equipment Directive.

4.3.4.4 Electrical equipment

4.3.4.4.1 Isolation and access

All electrical cabinets or enclosures shall be properly locked to prevent unauthorised access.

Amusement devices shall be provided with means to disconnect (isolate) the supply to all live

conductors and shall have a means permitting it to be locked in the off (isolated) position

(e.g. by padlocks). Suitable means of disconnection are listed in EN 60204-1.

When used for achieving isolation, the disconnecting device shall have a means permitting it to be

locked in the off (isolated) position (e.g. by padlocks).

Devices used for isolation shall have a visible gap or a position indicator that conforms

with EN 60947-3.

4.3.4.4.2 Inspection

See EN 13814-3:2019, 4.3.3.

4.3.4.4.3 Operating control equipment

All operating controls shall be:

— clearly visible to the operator;

— easily distinguishable from each other;

— readily accessible to the operator;

— easy to operate;

— clearly marked to show the function and mode of operation. All markings shall be permanent and

readable. Written markings shall be in a suitable language(s).

The operators working position shall:

— be safe (and have safe access);

— be designed with ergonomic considerations;

— have adequate lighting;

— give, where possible, an unobstructed view of all areas of operation. If it is not the case, other

means of surveillance shall be implemented (e.g. mirrors, surveillance cameras);

— take into account environmental aspects (e.g. temperature, vibration and noise).

The design shall take account of any need for the operator and operators to communicate, between

themselves and where necessary with the public e.g.:

— visibly;

— by phone/ intercom;

— public address;

— through the ride control system (such as 2-button operating systems).

4.3.4.4.4 Control equipment operated by passengers

Controls equipment intended to be operated by passengers shall:

— be clearly marked, in a language agreed with the controller, to show their functions;

— be accessible to all passengers within the designated size limits;

— not present a risk to passengers through their positioning or use;

— not be foreseeably capable of causing injury to passengers either directly (e.g. by trapping hands or

fingers, electric shock, etc) or by causing any controlled device to malfunction or operate

inappropriately;

— only be operable by passengers when it is safe for them to do so;

— never override an operator selected control input where it would be unsafe to do so;

— be able to be muted or over-ridden by the operator if necessary.

Controls equipment located in public areas and accessible to the general public should be tamper-proof

where necessary to prevent misuse.

The OURA shall take into account the risks related to anticipated failure of controls equipment or

misuse as well as the possibility of operator error shall not cause significant risk from such events.

Where an amusement device has remote areas or areas obscured from the view of the operator, means

of observing and communicating with passengers, as required by risk assessment, shall be provided at

the control station.

NOTE Assisted views can be provided by means such as the use of closed-circuit television, mirrors or

additional operators.

4.3.5 Trial operations and checks

4.3.5.1 Putting into use after assembly

After assembly the Controller, shall ensure that the amusement device is checked by a competent

person to ensure the assembly is in accordance with the manufacturer’s manual(s).

A similar check routine shall be carried out where an amusement device has been i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...