SIST EN 12227:2011

(Main)Playpens for domestic use - Safety requirements and test methods

Playpens for domestic use - Safety requirements and test methods

This European Standard specifies the safety requirements and test methods for playpens and folding playpens for domestic use, for a child with a body weight up to 15 kg.

If a playpen has several functions or can be converted into another function, it shall comply with the relevant standards.

Kinderlaufställe für den Wohnbereich - Sicherheitstechnische Anforderungen und Prüfungen

Diese Europäische Norm legt die sicherheitstechnischen Anforderungen und Prüfungen für Kinderlaufställe und klappbare Kinderlaufställe für den Wohnbereich fest, die für Kinder mit einem Körpergewicht bis zu 15 kg bemessen sind.

Falls ein Kinderlaufstall mehrere Anwendungsmöglichkeiten hat oder für eine andere Anwendung umgebaut werden kann, muss er mit den jeweils zutreffenden Normen übereinstimmen.

Parcs à usage domestique - Exigences de sécurité et méthodes d'essai

La présente Norme européenne spécifie les exigences de sécurité et les méthodes d’essai des parcs et parcs pliants à usage domestique, pour un enfant dont le poids n’excède pas 15 kg.

Si un parc remplit plusieurs fonctions ou peut être converti, il doit être conforme aux normes applicables.

Stajice za domačo uporabo - Varnostne zahteve in preskusne metode

Ta evropski standard določa varnostne zahteve in preskusne metode za stajice in zložljive stajice za domačo uporabo, za otroka s težo do 15 kg. Če ima stajica več funkcij ali se lahko pretvori v drugo funkcijo, mora biti skladna z ustreznimi standardi.

General Information

- Status

- Published

- Public Enquiry End Date

- 19-Jun-2008

- Publication Date

- 13-Jan-2011

- Technical Committee

- POH - Furniture

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 13-Jan-2011

- Due Date

- 20-Mar-2011

- Completion Date

- 14-Jan-2011

Relations

- Effective Date

- 01-Feb-2011

- Effective Date

- 01-Feb-2011

Overview

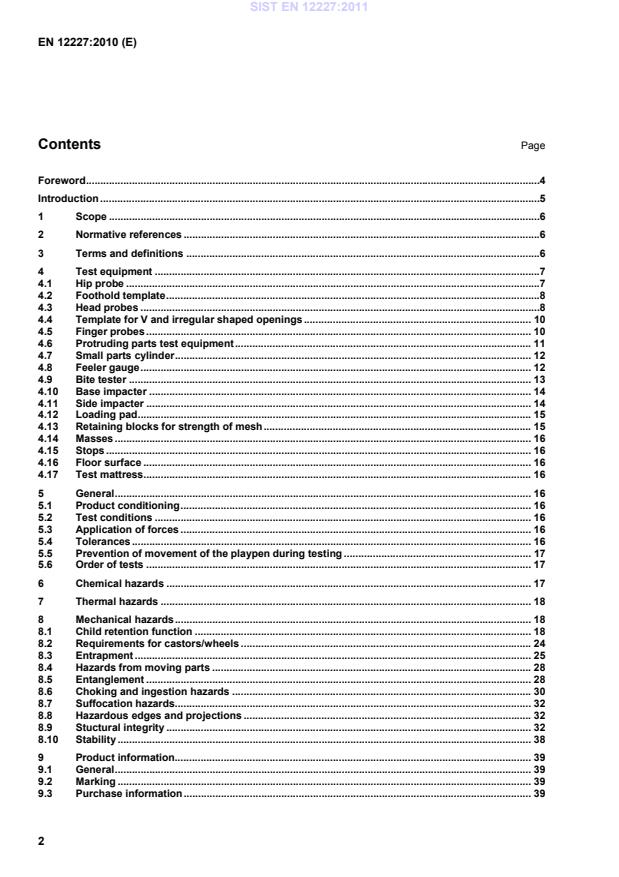

EN 12227:2010 - published by CEN - defines safety requirements and test methods for playpens and folding playpens for domestic use. It applies to products intended to retain a child with a body weight up to 15 kg. The standard covers mechanical, thermal and chemical hazards and specifies detailed test equipment and procedures to verify compliance. If a playpen has multiple functions or converts to another product, it must also meet the relevant standards for those functions.

Key topics and technical requirements

- Scope and definitions: clear definitions for playpen types (e.g., folding playpen), barrier, base and accessible parts.

- Test equipment: prescribes representative test probes and rigs such as hip probes, head probes (small and large), foothold templates, finger probes, bite tester, small-parts cylinder, impacters and ball-chain/spherical-mass devices.

- Mechanical hazards: requirements for child retention, structural integrity, stability, strength of mesh and protection from hazardous edges, projections and detachable components.

- Entrapment & entanglement: tests and templates to assess V-shaped or irregular openings, footholds, moving parts and entanglement risks.

- Choking, ingestion and suffocation: small-parts cylinder tests, tests for mattress/bedclothes interactions and breathable surfaces.

- Castors and wheels: specific requirements and tests for locking, retention and braking to prevent unintended movement.

- Thermal and chemical hazards: references to flammability and migration of elements; product materials must meet relevant toy/textile safety requirements.

- Product information & marking: required instructions, markings, purchase information and test reporting format to support safe use.

Practical applications - who uses EN 12227:2010

- Manufacturers and product designers - to design playpens that meet European safety expectations and to select compliant materials and components.

- Test laboratories and conformity assessors - to perform prescribed tests (impact, entrapment, small parts, stability) and prepare test reports.

- Retailers and purchasing teams - to verify supplier declarations and ensure products include required markings and instructions.

- Regulators and safety authorities - to reference a harmonized European benchmark for market surveillance.

- Safety consultants and child-safety advocates - to evaluate product risk and recommend safer designs.

Related standards

Normative references included in EN 12227:2010 (examples):

- EN 71-1 / EN 71-2 / EN 71-3 (Safety of toys - mechanical/flammability/migration)

- EN 1103 (textile burning behaviour)

- EN ISO 2439 and ISO 7619-2 (material hardness/indentation)

EN 12227:2010 is essential for ensuring playpens meet harmonized safety and test-method requirements across CEN member states, improving child safety and providing a clear compliance pathway for businesses.

Frequently Asked Questions

SIST EN 12227:2011 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Playpens for domestic use - Safety requirements and test methods". This standard covers: This European Standard specifies the safety requirements and test methods for playpens and folding playpens for domestic use, for a child with a body weight up to 15 kg. If a playpen has several functions or can be converted into another function, it shall comply with the relevant standards.

This European Standard specifies the safety requirements and test methods for playpens and folding playpens for domestic use, for a child with a body weight up to 15 kg. If a playpen has several functions or can be converted into another function, it shall comply with the relevant standards.

SIST EN 12227:2011 is classified under the following ICS (International Classification for Standards) categories: 97.140 - Furniture. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 12227:2011 has the following relationships with other standards: It is inter standard links to SIST EN 12227-1:2001, SIST EN 12227-2:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 12227:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Kinderlaufställe für den Wohnbereich - Sicherheitstechnische Anforderungen und PrüfungenParcs à usage domestique - Exigences de sécurité et méthodes d'essaiPlaypens for domestic use - Safety requirements and test methods97.140PohištvoFurnitureICS:Ta slovenski standard je istoveten z:EN 12227:2010SIST EN 12227:2011en,fr,de01-februar-2011SIST EN 12227:2011SLOVENSKI

STANDARDSIST EN 12227-2:2001SIST EN 12227-1:20011DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 12227

August 2010 ICS 97.190 Supersedes EN 12227-1:1999, EN 12227-2:1999English Version

Playpens for domestic use - Safety requirements and test methods

Parcs à usage domestique - Exigences de sécurité et méthodes d'essai

Kinderlaufställe für den Wohnbereich - Sicherheitstechnische Anforderungen und Prüfungen This European Standard was approved by CEN on 19 July 2010.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2010 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 12227:2010: ESIST EN 12227:2011

Rationales for inclusion of requirements for domestic playpens . 41A.1General . 41A.2Chemical hazards . 41A.3Thermal hazards . 41A.3.1Flammability . 41A.3.2Flash effect . 41A.4Mechanical hazards . 41A.4.1General . 41A.4.2Child retention function . 42A.4.3Entrapment hazards . 42A.4.4Hazards from moving parts . 43A.4.5Entanglement . 43A.4.6Detachable components . 43A.4.7Hazardous edges and projections . 44A.4.8Structural integrity . 44A.4.9Stability . 44Annex B (informative)

Examples for the design of safe edges and corners . 45Bibliography . 47 SIST EN 12227:2011

Part 1: Mechanical and physical properties EN 71-2, Safety of toys

Part 2: Flammability EN 71-3, Safety of toys

Part 3: Migration of certain elements EN 1103, Textiles

Fabrics for apparel

Detailed procedure to determine the burning behaviour EN ISO 2439:2008, Flexible cellular polymeric materials

Determination of hardness (indentation technique) (ISO 2439:2008) ISO 7619-2, Rubber, vulcanized or thermoplastic — Determination of indentation hardness — Part 2: IRHD pocket meter method 3 Terms and definitions For the purposes of this document, the following terms and definitions apply. 3.1 playpen enclosure comprising barrier and integral base intended to retain a child whilst allowing it space in which to play 3.2 folding playpen playpen which can be folded or dismantled without the use of a tool for transportation or storage 3.3 grab handle part attached to the playpen to assist the child within the playpen to attain and maintain a standing position 3.4 barrier structure which forms the outer perimeter of the playpen, which may be continuous or comprise several components 3.5 base structure forming the floor of the playpen to support the child SIST EN 12227:2011

Key 1 Hip probe 2 Handle 3 Diameter NOTE Tolerances on dimensions: −5,0065mm −5,00105mm (30 ± 5) mm (200 ± 5) mm All other dimensions as per general tolerances (see 5.4). Figure 1 — Hip probe with handle SIST EN 12227:2011

Key 1 Triangular cells plotted on a 5 mm × 5 mm grid Figure 2 — Template for foothold test (example of left hand template) Two templates are required to provide a left and right hand template. The markings shown in Figure 2 are on the bottom face of each template to avoid parallax errors. 4.3 Head probes 4.3.1 Small head probe The small head probe, representing a child aged three months to six months, shall be made from plastics or other hard, smooth material with the dimensions given in Figure 3.

Key a = mm1015,00− b = mm1375,00− c = 119 mm d = (45 ± 5) mm 1 Small head probe 2 Handle Figure 3 — Small head probe with handle 4.3.2 Large head probe The large head probe shall be made from plastics or other hard, smooth material with the dimensions given in Figure 4. Dimensions in millimetres

Key a = ()mm2235,00+ 1 Large head probe 2 Handle Figure 4 — Large head probe with handle SIST EN 12227:2011

Key 1 B portion 2 A portion Figure 5 — V and irregular shaped openings template 4.5 Finger probes Probes made from plastics or other hard, smooth material of diameters 7 mm and 12 mm with a full hemispherical end that can be mounted on a force-measuring device, see Figure 6. Probe for assessing mesh made from plastics or other hard, smooth material as shown in Figure 7. SIST EN 12227:2011

Key 1 R3,5 or R6 2 Line scribed around circumference showing depth of penetration 3 Ø ()01,07− mm or Ø ()1,0012 mm Figure 6 — 7 mm and 12 mm diameter probes

Dimensions in millimetres

Figure 7 — 7 mm diameter probe for mesh 4.6 Protruding parts test equipment 4.6.1 Ball chain loop and spherical mass This comprises a ball chain loop attached to a spherical mass, see Figure 8.

Key 1 Ball chain loop (4.6.2) 2 Common fixing point at the spherical mass 3 Spherical mass (4.6.3) Figure 8 — Loop and mass SIST EN 12227:2011

Figure 9 — Ball chain 4.6.3 Spherical mass A smooth spherical mass of (2,5 ± 0,5) kg and 115 mm diameter. 4.7 Small parts cylinder Cylinder, having the main dimensions given in Figure 10. Dimensions in millimetres

Figure 10 — Small parts cylinder 4.8 Feeler gauge Feeler gauge with the dimensions given in Figure 11. SIST EN 12227:2011

side view

top view

Figure 11 — Feeler gauge 4.9 Bite tester The bite tester, see Figure 12, consists of two sets of teeth, see Figure 13, made from H13 high chrome tool steel or equivalent and hardened to 45-50 Rockwell C. There are two teeth at the top and two at the bottom of the bite tester, positioned so that the vertical centre line of one pair of teeth is (1 ± 0,1) mm in front of the centre line of the other set of teeth. In the fully closed position the teeth shall overlap each other by (1 ± 0,1) mm. The outer most corners of the teeth shall have a radius of (0,3 ± 0,1) mm. The teeth shall be mounted so as to pivot about a point (50 ± 1) mm from the rear most pair of teeth and positioned so that when closed the centre lines of the two pairs of teeth are parallel to each other. The bite tester shall be equipped with a stop to prevent the distance between the teeth from exceeding (28 ± 1) mm when fully opened. The closing force of the teeth shall be set at (50 ± 5) N. The bite tester shall be provided with a guide to prevent items entering further into the fully opened jaws by more than (17 ± 1) mm. The bite tester shall be equipped with a means whereby a force of (50 ± 5) N may be applied along its centre line in a direction tending to pull the teeth off the sample. Dimensions in millimetres

Key 1 Position of guide 2 Pivot point Figure 12 — Bite tester SIST EN 12227:2011

Figure 13 — Test teeth 4.10 Base impacter An impacter with a total mass of 10 kg made of hardwood or equivalent material, with the dimensions given in Figure 14. The impacter shall be guided so that it is kept upright and always falls on the impact point. Dimensions in millimetres

Key SR Spherical radius Figure 14 — Base impacter 4.11 Side impacter A pendulum with a cylindrical head made of steel with the dimensions given in Figure 15. The head of the pendulum shall be surrounded by a 10 mm thick layer of rubber of hardness 76 IRHD to 78 IRHD in accordance with ISO 7619-2. The total mass shall be 2 kg. SIST EN 12227:2011

Key 1 Pivot point 2

Centre of gravity 3

Rubber 76 to 78 IRHD Figure 15 — Side impacter 4.12 Loading pad A rigid cylinder of 100 mm diameter having a smooth hard surface and rounded edges with a radius of 12 mm. 4.13 Retaining blocks for strength of mesh Two retaining blocks made of a rigid material with a support surface for the playpen rim of 100 mm × 100 mm and a radius of 5 mm on the edges.

Mass of 15 kg and cross section of 100 mm × 100 mm. 4.14.2

Mass of 20 kg distributed evenly over an area of 150 mm × 150 mm.

4.15 Stops Stops which prevent the article from sliding but not tilting, not higher than 12 mm except in cases where the design of the item necessitates the use of higher stops, in which case the lowest that will prevent the item from sliding shall be used. 4.16 Floor surface Horizontal, rigid and flat surface. 4.17 Test mattress A PUR foam sheet with a thickness of 60 mm, a bulk density of (35 ± 2) kg/m3 and an indentation hardness index of (170 ± 20) N in accordance with A 40 of EN ISO 2439:2008 and being at least 400 mm × 800 mm in area but not larger than the mattress base of the playpen under test. The test mattress shall have a cotton cover with a mass per unit area of 100 g/m2 to 120 g/m2. 5 General 5.1 Product conditioning Before testing, any fabrics used shall be cleaned or washed and dried twice in accordance with the manufacturer's instructions. 5.2 Test conditions The tests shall be carried out in ambient conditions of 15 °C to 25 °C. The tests are designed to be applied to playpens that are fully assembled and ready for use. If of a knock-down type, the playpen shall be assembled according to the manufacturer's instructions. If the playpen can be assembled or combined in different ways, the most onerous combinations shall be used for each test.

Knock-down fittings shall be tightened before testing. Further re-tightening shall not take place unless this is specifically required by the manufacturer. 5.3 Application of forces The forces in the static load tests shall be applied sufficiently slowly to ensure that negligible dynamic force is applied. The forces in durability tests shall be applied at a rate to ensure that excessive heating does not occur. 5.4 Tolerances Unless otherwise stated, the following tolerances apply: a) Forces:

± 5 % of the nominal force; SIST EN 12227:2011

± 0,5 % of the nominal mass; c) Dimensions:

± 1,0 mm of the nominal dimension; d) Angles:

± 2° of the nominal angle; e) Positioning of loading pads: ± 5 mm; f) Duration of forces:

1) (2 ± 1) s for durability tests; 2) (10 ± 2) s for static load tests. The tests are described in terms of the application of forces. Masses can however be used. The relationship 10 N = 1 kg may be used for this purpose. Unless otherwise specified, the test forces may be applied by any suitable device which does not adversely affect the results. 5.5 Prevention of movement of the playpen during testing If the playpen tends to slide or roll during the tests specified in Clause 8, it shall be restrained by stops (4.15). 5.6 Order of tests Unless otherwise stated the tests shall be carried out on the same playpen in the order listed in this standard. 6 Chemical hazards See rationale in A.2. The migration of synthetic or natural elements from coatings of paint, varnish, lacquer, polymer and similar coatings on exterior surfaces shall comply with the following amounts: a) Antimony: 60 mg/kg; b) Arsenic:

25 mg/kg; c) Barium:

1 000 mg/kg; d) Cadmium: 75 mg/kg; e) Chromium: 60 mg/kg; f) Lead:

90 mg/kg; g) Mercury:

60 mg/kg; h) Selenium: 500 mg/kg. These limits shall be verified in accordance with the test method given in EN 71-3. Where a surface is coated with a multi-layer of paint or similar coating, the test sample shall not include the base material. SIST EN 12227:2011

Figure 16 — Example of measurement between footholds and/or top of barriers with its base in its lowest position With the base in its highest position the minimum vertical distance between the upper surface of the playpen base and any part of the upper surface of the barrier shall be at least 300 mm when measured in accordance with 8.1.2.2.9. The rationale is given in A.4.2.2. 8.1.2.2 Determination of a foothold 8.1.2.2.1 Continuous structure A foothold exists on a continuous structure if four triangles marked on the template are completely obscured by the structure being checked. These four triangles shall have at least one side in common with another of the triangles, see Figure 17.

Key 1 This shaded area denotes one triangle; four shaded areas denotes four obscured triangles Figure 17 — Examples of obscured triangles indicating a foothold on a continuous structure 8.1.2.2.2 Non-continuous structure A foothold exists on a non-continuous structure if two or more triangles marked on the template are completely obscured between the edge of the template and the bold lines of the template by the structure being checked. The two or more triangles on either side of the template shall have at least one side in common with each other, see Figure 18.

Key 1

This shaded area denotes one triangle Figure 18 — Example of obscured triangles on a foothold on a non-continuous structure 8.1.2.2.3 Wire, thin structures and similar parts A foothold exists on a wire, thin structure and similar part if it projects across the bold lines on the template, see Figure 19. SIST EN 12227:2011

Key

Denotes a wire, thin structure or similar part Figure 19 — Example of a foothold on a wire, thin structure and similar part 8.1.2.2.4 Footholds on a continuous structure at an angle less than 55°°°° Using either the left or right hand template, place the template with its marked face on any continuous structure inclined at an angle of less than 55° to the horizontal. Orientate either template, see Figure 2, to check whether any four triangles are obscured indicating a foothold; see Figure 20 for examples. 8.1.2.2.5 Footholds on a non-continuous structure at an angle of less than 55° Using either the left or right hand template, place the template with its marked face on any non-continuous structure inclined at an angle of less than 55° to the horizontal. Orientate either template, see Figure 2, to check whether two or more triangles are obscured between the edges of the template and the bold lines on the template indicating a foothold; see Figure 21 for examples. 8.1.2.2.6 Footholds on wire, thin structures or similar parts at an angle less than 55° Using either the left or right hand template, place the template with its marked face on any wire, thin structure or similar parts at an angle less than 55° to the horizontal. Check whether the wire, thin structure or similar part has a line of contact extending between the two bold lines marked along the template; see Figure 22 for examples. 8.1.2.2.7 Footholds on an intersecting or adjacent structure where the second structure prevents slipping Using either the left or right hand template, place the template with its marked face on any structure, thin structure or similar parts between 55° and 80° to the horizontal where there is also a supporting structure. Orientate either template, see Figure 2, to check whether any four triangles are obscured indicating a foothold; see Figure 23 for examples. 8.1.2.2.8 Footholds on rigid components covered by flexible materials Where flexible materials or fabrics are covering rigid components, the template is pushed against the flexible material or fabric with a horizontal force of up to 30 N acting along the longitudinal axis of the template. Orientate either the left hand or the right hand template, see Figure 2, to check whether any four triangles are obscured by the rigid components indicating a foothold. SIST EN 12227:2011

Figure 20 — Examples of footholds on a continuous structure at an angle less than 55°

Figure 21 — Examples of footholds on a non-continuous structure at an angle less than 55° SIST EN 12227:2011

Figure 22 — Example of footholds on thin structures, on wire, or similar parts at an angle less than 55°

Figure 23 — Example of footholds on intersecting or adjacent structures where the second structure prevents slipping 8.1.2.2.9 Measurement of vertical height of barrier Measure the vertical distance between the upper surface of the base, without applying any load to the base, and any part of the upper surface of the barrier. Apply a force of 300 N, positioned as described in 8.9.6.2, to the upper surface of the barrier and measure the height of the barrier under load. 8.1.2.2.10 Measurement between any foothold and the upper surface of barrier Measure the distance between any foothold and any part of the upper surface of the barrier. SIST EN 12227:2011

8.1.3.2 Test method Apply the hip probe, see 4.1, with a force in the longitudinal axis of the probe in any direction with a force up to 30 N into any opening accessible from inside the playpen. 8.1.4 Security of folding mechanisms 8.1.4.1 Requirements To avoid the hazards due to unintentional release or operation by a child, one of the following conditions shall be fulfilled before and after testing in accordance with 8.1.4.2: a) all locking mechanisms require a minimum force of 50 N; or b) folding is only possible when two independent locking mechanisms are operated simultaneously; or c) there are two or more automatically engaging locking mechanisms that cannot be released by one single action; or

d) folding of the playpen requires two consecutive actions, the first of which shall be maintained while the second is carried out, where the weight of the child acts to prevent folding, the removal of the child can be considered as one action; or e) have two locking mechanisms separated by a distance of at least 850 mm and requiring to be operated simultaneously. Playpens that fold towards the inside shall be equipped with at least two locking mechanisms. See rationale in A.4.2.4. 8.1.4.2 Test methods With the playpen assembled for use in accordance with the manufacturer's instructions unfold and fold the playpen 300 times. 8.2 Requirements for castors/wheels Castors/wheels shall not be fitted except in the following configuration, either: a) two or more castors/wheels and at least two other support points; or b) at least four castors/wheels, of which at least two can be locked. SIST EN 12227:2011

Completely bound openings that allow the large head probe to pass completely through shall comply with the requirement for partially bound, V and irregular shaped openings when tested in accordance with 8.3.2.2.2. Partially bound, V and irregular shaped openings shall be constructed so that: a) portion B of the template (see 4.4) does not enter the opening when tested in accordance with 8.3.2.2.2; or b) the apex of portion A of the template contacts the base of the opening when tested in accordance with 8.3.2.2.2. The following requirements do not apply to playpens that have mesh or fabric sides/ends and a rigid leg or support system, when the lowest part of the opening is less than 100 mm from the floor. The area under the playpen base is excluded from these requirements. 8.3.2.2 Test methods 8.3.2.2.1 Completely bound openings Press the small head probe specified in 4.3.1 with the highest force possible up to 30 N into completely bound openings. If the small head probe passes completely through the opening, then the large head probe specified in 4.3.2 shall pass completely through the completely bound opening with a force of up to 5 N. If completely bound openings contain V or irregular shaped openings, they should be assessed in accordance with 8.3.2.2.2. 8.3.2.2.2 Partially bound, V and irregular shaped openings Position the B portion of the V and irregular shaped openings template specified in 4.4 between and perpendicular to the boundaries of the opening, as shown in Figure 24 or Figure 25 as appropriate. If the full thickness of the template cannot be inserted there is no hazard, but if it can be inserted there is a hazard, see Figures 24 and 25. If the V and irregular shaped openings template can be inserted to a depth greater than the thickness of the template (45 mm), apply the A portion of the V and irregular shaped openings template, so that its centre line is in line with the centre line of the opening. Ensure that the plane of the test template is parallel and applied in line with the opening, as shown in Figure 26. Insert the V and irregular shaped openings template along the centre line of the opening until its motion is arrested by contact with the boundaries of the opening. If the V and irregular shaped openings template touches the bottom of the opening there is no hazard, but if the sides of the template touch the sides of the opening there is a hazard, see Figure 26. SIST EN 12227:2011

Key 1 is not a hazard 2 is not a hazard 3 is a hazard 4 is a hazard Figure 24 — Method of insertion of portion B

Key 1 is not a hazard 2 is a hazard Figure 25 — Method of insertion of portion B SIST EN 12227:2011

Key 1 is not a hazard 2 is a hazard Figure 26 — Method of insertion of portion A

8.3.3 Finger entrapment 8.3.3.1 Requirements There shall be no openings between 7 mm and 12 mm unless the depth of penetration is less than 10 mm when tested in accordance with 8.3.3.2. Playpens that do not permit a child's hand to reach through the barrier shall have the exterior of the playpen, from 300 mm below the rim, excluded from this requirement. Playpens that permit a child's hand to reach through the barrier shall have the underside of the base only excluded from this requirement. There shall be no openings in mesh or flexible materials that allow the finger probe for mesh (Figure 7) to penetrate to the 7 mm diameter section. The rationale is given in A.4.3.2. 8.3.3.2 Test method Check whether the 7 mm probe (see Figure 6), with an applied force of up to 30 N, enters 10 mm or more into any accessible opening in any possible orientation. If the 7 mm probe enters 10 mm or more, then the 12 mm probe (see Figure 6) shall also enter 10 mm or more with an applied force of up to 5 N. Check whether the finger probe for mesh (see Figure 7), with an applied force of up to 30 N, penetrates openings in mesh and flexible materials to the 7 mm diameter section. SIST EN 12227:2011

The rationale is given in A.4.5.2. SIST EN 12227:2011

The rationale is given in A.4.5.3. 8.5.2.2 Test method The length of a cord, ribbon or similar part is measured from the fixing point on the article to the free end of the cord, ribbon or part used as a tie while a 25 N tensile force is applied. The peripheral dimension of a loop shall be measured while a 25 N tensile force is applied. 8.5.3 Protruding parts 8.5.3.1 Requirements When tested in accordance with 8.5.3.2, the ball chain loop and spherical mass shall not be supported by any protruding part accessible from inside the playpen. Parts of the playpen barrier more than 1 400 mm above the playpen base are considered not accessible. The rationale is given in A.4.5.4. 8.5.3.2 Test methods Place the base of the playpen in its lowest position. Hold the spherical mass of the test equipment (see 4.6) in one hand and with the other hand create an open loop in the ball chain. Place the ball chain loop over any potential protruding part accessible from the inside of the playpen. Lower the weight until either the ball chain loop gets caught and the weight hangs freely from the protruding part, see Figure 27, or the ball chain loop slides over the protruding part.

Repeat the test for a total of three times. If during any of the three tests the loop and mass is supported by a protruding part, this is considered to be a failure.

Figure 27 — Retention of loop and mass SIST EN 12227:2011

The rationale is given in A.4.6.2. 8.6.1.3 Test methods 8.6.1.3.1 Assessment of child's ability to grip components A component is considered to be able to be gripped by a child if it can grip the component between its thumb and forefinger or between its teeth. Where it is difficult to assess whether a child can grip a component, it shall be possible to insert the feeler gauge specified in 4.8 for a least 2 mm using a force of (10 ± 1) N between the component and the underlying layer of the component or the playpen. 8.6.1.3.2 Torque test Apply a torque gradually to the component within a period of 5 s in a clockwise direction until either a rotation of 180° from the original position has been attained; or a torque of 0,34 Nm is reached. The maximum rotation or required torque shall be applied for 10 s. The component shall then be allowed to return to a relaxed condition and the procedure repeated in an anticlockwise direction.

Where projections, components or assemblies are rigidly mounted on an accessible rod or shaft designed to rotate together with the projections, components or assemblies, during the test, the rod or shaft shall be clamped to prevent rotation. If a component which is attached by a screw thread that becomes loosened during application of the required torque, the torque shall continue to be applied until the required torque is exceeded or the component disassembles or it becomes apparent that the component will not disassemble. When using clamps and test equipment care shall be taken not to damage the attachment mechanism or body of the component. Check whether any component or part of a component that is removed during the test fits wholly within the small parts cylinder specified in 4.7. 8.6.1.3.3 Tensile test The tensile test shall be carried out on the same components as the torque test. SIST EN 12227:2011

Fasten the component in a tensile testing machine and apply a tensile force of up to 90 N to the component to be tested. Apply the force gradually within a period of 5 s and maintain for 10 s. Check whether the component or any part of a component that is removed during the test fits wholly within the small parts cylinder specified in 4.7. 8.6.2 Playpen rim 8.6.2.1 Requirements No filling shall be detached from the playpen rim when tested in accordance with 8.6.2.2. The rationale is given in A.4.6.3. 8.6.2.2 Test method The test procedure comprises two stages:

Stage 1) Pinch the materials of the inside face of the playpen rim between finger and thumb and attach the bite tester, specified in 4.9 so as to "bite” the smallest amount of materials possible to allow contact with all four teeth and apply a pulling fo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...