SIST EN 13748-2:2004

(Main)Terrazzo tiles - Part 2: Terrazzo tiles for external use

Terrazzo tiles - Part 2: Terrazzo tiles for external use

This European Standard specifies materials, properties and methods of testing for unreinforced cement-bound terrazzo tiles which are factory made and sold ready to be placed.

The tiles are intended for external use (including roofing applications) in pedestrian areas, e.g. walkways, terraces, commercial centres and swimming-pools.

NOTE This standard applies to ex-factory products and does not take into account the laying of the product.

Terrazzoplatten - Terrazzoplatten für die Anßenverwendung

Die vorliegende Norm legt Materialien, Eigenschaften und Prüfverfahren für unbewehrte zementgebundene Terrazzoplatten fest, die in einer ortsfesten Anlage hergestellt werden und verlegefertig sind. Sie werden entweder einzeln durch Press- und/oder mittels Rüttelverfahren hergestellt oder mittels Rüttelverfahren und/oder Pressverfahren und/oder Vakuumbehandlung in großen Blöcken gefertigt, bevor sie auf ihre endgültige Größe geschnitten werden.

Diese Platten sind für die Anwendung im Freien (einschließlich Dächern) für Flächen, die keine Verkehrsflächen darstellen, vorgesehen.

Platten für die Anwendung in Gebäuden werden in prEN 13748-1 behandelt.

Carreaux de mosaique - Partie 2: Carreaux de mosaique de marbre a usage extérieur

La présente Norme européenne définit les matériaux, les propriétés et les méthodes d'essai relatifs aux carreaux de mosaïque de marbre à liant ciment, non armés, fabriqués en usine et vendus prêts à être posés.

Les carreaux sont prévus pour un usage extérieur (y compris en toiture) dans les zones piétonnières, par exemple allées, terrasses, centres commerciaux et piscines.

NOTE La présente Norme s'applique aux produits à leur sortie d'usine et ne prend pas en compte leur pose.

Teraco plošče - 2. del: Teraco plošče za zunanjo rabo

General Information

- Status

- Published

- Publication Date

- 30-Sep-2004

- Technical Committee

- BBB - Concrete, reinforced concrete and prestressed concrete

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 01-Oct-2004

- Due Date

- 01-Oct-2004

- Completion Date

- 01-Oct-2004

- Directive

- 89/106/EEC - Construction products

Overview

EN 13748-2:2004 is the CEN (European) standard that specifies materials, properties and test methods for unreinforced cement‑bound terrazzo tiles for external use. It covers factory‑made terrazzo tiles-single‑layered or dual‑layered-sold ready to be placed for pedestrian external areas (walkways, terraces, commercial centres, swimming pools and roofing applications). Note: the standard applies to ex‑factory products and does not cover installation/laying.

Keywords: EN 13748-2, terrazzo tiles external use, terrazzo tiles standard, CEN terrazzo.

Key topics and technical requirements

EN 13748-2 defines requirements and test procedures across product design, performance and conformity, including:

- Materials: cement (per EN 197‑1), aggregates, mixing water, admixtures and additions (pigments, fillers, polymers).

- Product types: single‑layered and dual‑layered terrazzo tiles (wear layer + backing).

- Finished product requirements:

- Geometrical tolerances: dimensions, thickness and edge straightness.

- Surface characteristics and appearance: visual and decorative performance for exterior use.

- Mechanical strength: breaking strength and breaking load tests for durability.

- Abrasion resistance: wide‑wheel abrasion and Böhme test methods referenced.

- Slip/skid resistance: unpolished slip resistance value (USRV) method.

- Weathering resistance: resistance to freeze/thaw cycles with de‑icing salts and general outdoor exposure.

- Water absorption and thermal conductivity.

- Fire performance considerations for external applications.

- Physical test methods: detailed procedures for sampling, dimensional checks, flatness, abrasion, slip resistance, water absorption and freeze/thaw testing.

- Conformity & marking: type testing, factory production control (FPC), CE marking and the EU Directive relationship (Annex ZA).

Practical applications and users

EN 13748-2 is essential for stakeholders involved in specification, manufacture, testing and acceptance of external terrazzo tiles:

- Manufacturers - to design, produce and document compliance for external terrazzo tiles.

- Architects & specifiers - to select appropriate products for outdoor pedestrian areas and roofing.

- Contractors & façade/terrace installers - to verify ex‑factory conformity before laying (installation standards are separate).

- Test laboratories & certification bodies - to perform standardized tests (abrasion, USRV, freeze/thaw, water absorption).

- Procurement teams & asset owners - to define performance requirements in tender documents.

Related standards

- EN 13748‑1 - Terrazzo tiles for internal use.

- EN 1339 - Concrete paving flags (contrasts with terrazzo tiles).

- EN 13198 - Decorative products for exterior pedestrian use.

- Reference norms cited (e.g., EN 197‑1 for cement, EN 12620 for aggregates).

EN 13748-2 helps ensure that external terrazzo tiles meet reliable material and performance benchmarks for durability, safety and appearance in outdoor pedestrian environments.

Frequently Asked Questions

SIST EN 13748-2:2004 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Terrazzo tiles - Part 2: Terrazzo tiles for external use". This standard covers: This European Standard specifies materials, properties and methods of testing for unreinforced cement-bound terrazzo tiles which are factory made and sold ready to be placed. The tiles are intended for external use (including roofing applications) in pedestrian areas, e.g. walkways, terraces, commercial centres and swimming-pools. NOTE This standard applies to ex-factory products and does not take into account the laying of the product.

This European Standard specifies materials, properties and methods of testing for unreinforced cement-bound terrazzo tiles which are factory made and sold ready to be placed. The tiles are intended for external use (including roofing applications) in pedestrian areas, e.g. walkways, terraces, commercial centres and swimming-pools. NOTE This standard applies to ex-factory products and does not take into account the laying of the product.

SIST EN 13748-2:2004 is classified under the following ICS (International Classification for Standards) categories: 91.100.30 - Concrete and concrete products. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13748-2:2004 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/119. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase SIST EN 13748-2:2004 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of SIST standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Terrazzo tiles - Part 2: Terrazzo tiles for external useCarreaux de mosaique - Partie 2: Carreaux de mosaique de marbre a usage extérieurTerrazzoplatten - Terrazzoplatten für die Anßenverwendung91.100.30Beton in betonski izdelkiConcrete and concrete productsICS:SIST EN 13748-2:2004en,fr,deTa slovenski standard je istoveten z:EN 13748-2:200401-oktober-2004SIST EN 13748-2:2004SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13748-2

June 2004 ICS 91.100.30

English version

Terrazzo tiles - Part 2: Terrazzo tiles for external use

Carreaux de mosaïque - Partie 2: Carreaux de mosaïque de marbre à usage extérieur

Terrazzoplatten – Teil 2: Terrazzoplatten für die Verwendung im Außenbereich This European Standard was approved by CEN on 1 April 2004.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the Central Secretariat or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2004 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13748-2:2004: E

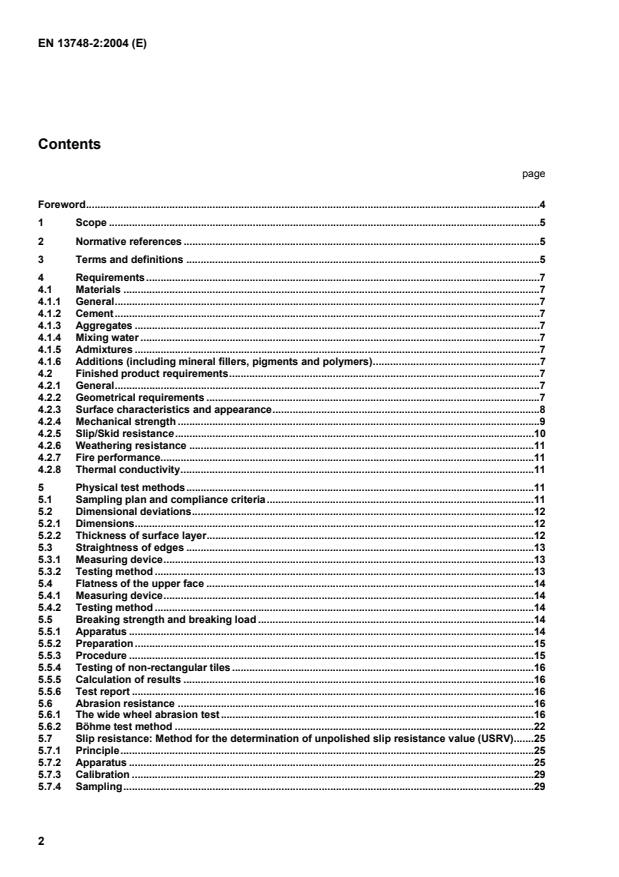

Clauses of this European Standard addressing essential requirements or other provisions of EU Directives.39 ZA.1 Scope and relevant characteristics.39 ZA.2 Procedure for attestation of conformity.40 ZA.2.1 System of attestation of conformity.40 ZA.2.2 EC Declaration of conformity.40 ZA.3 CE marking and labelling.41 Bibliography.43

or alternatively ≤ 26 cm3/50 cm2 measured in accordance with test method described in 5.6.2. 3 H ≤ 23 mm measured in accordance with the test method described in 5.6.1 or alternatively ≤ 20 cm3/50 cm2 measured in accordance with test method described in 5.6.2. 4 I ≤ 20 mm measured in accordance with the test method described in 5.6.1

or alternatively ≤ 18 cm3/50 cm2 measured in accordance with test method described in 5.6.2. 4.2.5 Slip/Skid resistance 4.2.5.1 General Terrazzo tiles for external use have satisfactory slip/skid resistance, provided their whole upper surface has not been ground and/or polished to produce a very smooth surface. If in an exceptional case the unpolished slip/skid resistance value (USRV) is required, the product shall be tested according to 5.7 and the result declared. If the surface of the terrazzo tile contains ridges, grooves or other surface features which prevent testing by pendulum friction equipment, the product is deemed to satisfy the requirements without testing. NOTE The slip/skid resistance value relates to the tiles as manufactured. 4.2.5.2 Durability of slip/skid resistance Under normal conditions of use, terrazzo tiles provide satisfactory slip/skid resistance during the working life of the product, provided they are subjected to normal maintenance that does not modify their initial slipperiness.

Table 5 — Weathering resistance classes Class Marking Water absorption % by mass Mass loss after freeze/thaw test kg/m2 1 A No performance measured No performance measured 2 B ≤ 6 as a mean No performance measured 3 D No performance measured ≤ 1,0 as a mean with no individual value > 1,5 NOTE The National Annex of a country may state the class(es) of weathering resistance required to ensure durability for that country. 4.2.7 Fire performance 4.2.7.1 Reaction to fire Terrazzo tiles for external use are considered to be reaction to fire class A1fl without the need for testing according to EC Decision 96/603/EEC, as amended. 4.2.7.2 External fire performance Terrazzo tiles for external use used as roof covering are deemed to satisfy the requirements for external fire performance without the need for testing according to EC Decision 2000/553/EC. 4.2.8 Thermal conductivity If terrazzo tiles for external use are intended to contribute to the thermal performance of an element, the manufacturer shall declare the thermal conductivity using data given in Table L2 of EN 13369. 5 Physical test methods 5.1 Sampling plan and compliance criteria Table 6 details the sampling and compliance criteria for the testing of each requirement.

Table 6 — Sampling plan and compliance criteria for initial and further type testing Property Requirements Test method Number of tiles Compliance criteria 4.2.2 and 4.2.3 Appearance, dimensions and shape 4.2.2 and 4.2.3 5.2 and 5.3 and 5.4 8* Each tile shall meet the requirements Breaking strength 4.2.4.2 5.5 4 See 4.2.4.2 Breaking load 4.2.4.3 5.5 4 See 4.2.4.3 Abrasion resistance 4.2.4.4 5.6 3 See 4.2.4.4 Slip/skid resistance (only where tested) 4.2.5 5.7 5 The mean of the five tiles shall be declared Weathering resistance 4.2.6 5.8 respectively 5.9 3 See 4.2.6 * These tiles may be used for subsequent tests. 5.2 Dimensional deviations 5.2.1 Dimensions 5.2.1.1 Apparatus A steel rule with an accuracy of 0,5 mm. Callipers with an accuracy of 0,1 mm. 5.2.1.2 Procedure The dimensions shall be measured at 3 points. The maximum and minimum values shall be recorded. 5.2.2 Thickness of surface layer 5.2.2.1 Apparatus Measuring equipment capable of measuring with an accuracy of 0,5 mm. 5.2.2.2 Procedure Take a tile that has been broken. Measure the thickness of the surface layer on the split face at the point where, by visual inspection, the value will be a minimum. Record the measurement to the nearest millimetre. The thickness of the surface layer shall not be measured on the chamfer.

Dimensions in millimetres

Key 1 Depth of channels 5 Minimum thickness upper face 2 Minimum thickness upper face 6 Thickness upper face 3 Thickness upper face 7 Thickness 4 Thickness

Figure 1 — Examples of measurement of the thickness of non-flat surface flags 5.3 Straightness of edges 5.3.1 Measuring device A set of feeler gauges with an accuracy of 0,1 mm. 5.3.2 Testing method The ruler is placed along the edge and the maximum discrepancy i.e. between the edge and the ruler is noted (see Figure 2).

Figure 2 — Measurement of edge straightness 5.4 Flatness of the upper face 5.4.1 Measuring device Measuring equipment with an accuracy of 0,1 mm. 5.4.2 Testing method The maximum convex or concave deviations shall be determined along the two diagonal axes of the upper face (see Figure 3).

Figure 3 — Measurement of upper face flatness 5.5 Breaking strength and breaking load 5.5.1 Apparatus The transverse testing machine shall have a scale with an accuracy of ± 3 % over the range of the anticipated test loads and be capable of increasing the load at specified rates. It shall be constructed in such a way that it can induce 3 point bending into the sample without torsion. The load inducing bar shall be equidistant between the supports. The length of the supports and the load inducing bar shall be at least equal to the width of the sample to be tested (see Figure 4).

KEY F Load Figure 4 — Principle of testing The actual span between the bearers shall be within 0,5 % of the specified span rounded to the nearest millimetre. 5.5.2 Preparation Use whole tiles when their plan shape includes at least two parallel straight edges. In other cases, use sawn samples with the largest possible plan area which includes two parallel straight edges. If necessary, remove any burrs, high spots, etc. Immerse the tiles under water at (20 ± 5) °C for (24 ± 3) h, remove, wipe dry and test immediately. If a face is rough, textured or curved, prepare it by grinding or capping until fully flat. Other methods of preparation may be used for routine testing providing there is a correlation between the results of the two methods, e.g. using unground rough, textured or curved tiles instead of ground tiles. 5.5.3 Procedure The distance between the supports shall be 2/3 of the length of the tile, with an accuracy of ± 0,5 %. Place the sample with its upper face uppermost, symmetrically on the bearers of the testing machine and with its shorter side parallel to the supporting bearers. Depending on the surface profile of the tile any one of the following shall be used at the discretion of the manufacturer: no packing; packing; capping or grinding.

Key 1 Clamping trolley 8 Counterweight 2 Fixing screw 9 Slot 3 Specimen 10 Groove 4 Control valve 11 Abrasive material flow 5 Storage hopper 12 Abrasive collector 6 Flow guidance hopper 13 Wedge 7 Wide abrasion wheel

Figure 5 — Principle of wearing machine The wide abrasion wheel shall be made of steel E360 in accordance with prEN 10083-2. The hardness of the steel shall be between 203 HB and 245 HB. Its diameter shall be (200 ± 1) mm and its width shall be (70 ± 1) mm. It shall be driven to rotate 75 revolutions in (60 ± 3) s.

Key 1 Inclined side 2 Vertical side 6 Flow guidance hopper 9 Slot a, b, c > 10 Figure 6 — Position of slot in the base of the flow guidance hopper The distance of the fall between the slot and the axle of the wide abrasion wheel shall be (100 ± 5) mm and the flow of the abrasive shall be (1 to 5) mm behind the leading edge of the wheel (see Figure 7).

Side view

Plan view Key 3 Specimen 6 Flow guidance hopper 7 Wide abrasion wheel 9 Slot Figure 7 — Position of slot relative to wide abrasion wheel The flow of the abrasive material from the flow guidance hopper shall be at least at a minimum rate of

2,5 l/min onto the wide abrasion wheel. The flow of abrasive shall be constant and the minimum level of the abrasive in the flow guidance hopper shall be 25 mm (see Figure 7). Useful utensils for measuring the results are a magnifying glass, preferably equipped with a light, a steel ruler and a digital caliper.

1) The “Boulonnaise Marble reference is: Lunel demi-clair, thickness: 5 cm, c/passe 2 faces ground with a diamond grit size 100/120, rugotest class N7 (Ra = 1,6 µm) in accordance with EN ISO 4288:1997.

(l1 and l2) of the groove using a ruler (see Figure 8). Then draw a line (A B) in the middle of the groove perpendicular to the centreline of the groove. Position a digital calliper with square tips on the points A and B to the inside edge of the longitudinal limits

(l1 and l2) of the groove and measure and record the dimension to the nearest ± 0,1 mm. Repeat the measurement (10± 1) mm from the ends of the groove (C D) to give three readings. Dimensions in millimetres

Section A – A Face view Key 3 Specimen 10 Groove Figure 8 — Example of a tested specimen showing a groove

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...