ISO 14853:2016

(Main)Plastics — Determination of the ultimate anaerobic biodegradation of plastic materials in an aqueous system — Method by measurement of biogas production

Plastics — Determination of the ultimate anaerobic biodegradation of plastic materials in an aqueous system — Method by measurement of biogas production

ISO 14853:2016 specifies a method for the determination of the ultimate anaerobic biodegradability of plastics by anaerobic microorganisms. The conditions described in ISO 14853 do not necessarily correspond to the optimum conditions for the maximum degree of biodegradation to occur. The test calls for exposure of the test material to sludge for a period of up to 90 d, which is longer than the normal sludge retention time (25 to 30 d) in anaerobic digesters, although digesters at industrial sites can have much longer retention times. The method applies to the following materials: - natural and/or synthetic polymers, copolymers or mixtures thereof; - plastic materials which contain additives such as plasticizers, colorants or other compounds; - water-soluble polymers; - materials which, under the test conditions, do not inhibit the microorganisms present in the inoculum. Inhibitory effects can be determined using an inhibition control or by another appropriate method (see e.g. ISO 13641). If the test material is inhibitory to the inoculum, a lower test concentration, another inoculum or a pre-exposed inoculum can be used.

Plastiques — Évaluation de la biodégradabilité anaérobie ultime des matériaux plastiques en milieu aqueux — Méthode par détermination de la production de biogaz

L'ISO 14853:2016 spécifie une méthode pour la détermination de la biodégradabilité anaérobie ultime des plastiques par des micro-organismes anaérobies. Les conditions décrites dans l'ISO 14853:2016 ne correspondent pas nécessairement aux conditions optimales permettant d'obtenir le taux maximal de biodégradation. L'essai exige que le matériau d'essai soit exposé aux boues pendant une période allant jusqu'à 90 j, ce qui est plus long que le temps de rétention normal de la boue (25 j à 30 j) dans les digesteurs anaérobies, bien que les digesteurs sur les sites industriels puissent avoir des temps de rétention beaucoup plus longs. La présente méthode s'applique aux matériaux suivants: - polymères naturels et/ou synthétiques, copolymères ou mélanges de ceux-ci; - matériaux plastiques contenant des additifs, tels que plastifiants, colorants ou autres composés; - polymères hydrosolubles; - matériaux qui, dans les conditions d'essai, n'ont pas d'effet inhibiteur sur les micro-organismes présents dans l'inoculum. Les effets inhibiteurs peuvent être déterminés en utilisant une substance de contrôle de l'effet inhibiteur ou par toute autre méthode appropriée (voir, par exemple, l'ISO 13641). Si le matériau d'essai a un effet inhibiteur vis-à-vis de l'inoculum, il est possible d'utiliser une plus faible concentration, un autre inoculum ou un inoculum pré-exposé.

General Information

- Status

- Published

- Publication Date

- 13-Jul-2016

- Technical Committee

- ISO/TC 61/SC 14 - Environmental aspects

- Drafting Committee

- ISO/TC 61/SC 14/WG 2 - Biodegradability

- Current Stage

- 9020 - International Standard under periodical review

- Start Date

- 15-Jan-2026

- Completion Date

- 15-Jan-2026

Relations

- Effective Date

- 08-Nov-2014

Overview

ISO 14853:2016 - Plastics: Determination of the ultimate anaerobic biodegradation of plastic materials in an aqueous system - Method by measurement of biogas production specifies a laboratory method to quantify the ultimate anaerobic biodegradability (mineralization to CO2, CH4, water and mineral salts plus biomass) of plastic materials. The test exposes plastics to digested sludge inoculum under controlled anaerobic, aqueous conditions and measures biogas production either manometrically (pressure) or volumetrically (gas volume) over a test period normally up to 90 days at 35 ± 2 °C.

Key topics and technical requirements

- Scope of materials: natural/synthetic polymers, copolymers, blends, water‑soluble polymers and plastics containing additives (plasticizers, colorants) provided they do not inhibit the inoculum.

- Test conditions: typical organic carbon load 20–200 mg/L OC in the test suspension; inoculum (washed digested sludge) diluted to 1–3 g/L total solids.

- Measurement methods: biogas quantified by manometric (headspace pressure increase) or volumetric techniques; procedures and apparatus examples are provided in informative annexes.

- Calculations and reporting: procedures for calculating carbon in headspace, inorganic carbon in liquid, theoretical CO2/CH4 production and percentage biodegradation are specified.

- Validity and controls: includes requirements for maintaining anaerobic conditions, detecting inhibition (inhibition control; reference to ISO 13641), and criteria for test validity (lag phase, plateau).

- Documentation: guidance on test duration, sample preparation, inoculum preparation, specific analyses and the required test report contents. Informative annexes include example workflows, biodegradation curves and calculation examples.

Practical applications and users

Who benefits from ISO 14853:2016:

- Test laboratories and QA teams performing standardized biodegradability testing for certification, product claims or regulatory submissions.

- Plastics manufacturers and R&D groups evaluating new polymers, formulations and additives for anaerobic treatability.

- Waste‑management and anaerobic digestion (AD) operators assessing how plastic residues behave in sludge treatment or landfill gas generation.

- Regulators and eco‑label programs needing reproducible data on anaerobic mineralization for policy or labeling decisions.

Practical value:

- Provides a reproducible, internationally recognized method to quantify ultimate anaerobic biodegradation via biogas production, enabling consistent comparisons between materials and processes.

- Helps identify inhibitory effects and informs decisions on material suitability for AD systems or environments prone to anaerobic degradation.

Related standards

- ISO 13641 - referenced for procedures to determine inhibitory effects on inocula.

- ISO 14853:2005 (first edition) - ISO 14853:2016 supersedes and technically revises the earlier edition.

Keywords: ISO 14853:2016, anaerobic biodegradation, plastics, biogas production, anaerobic digestion test, manometric, volumetric, digested sludge, biodegradability testing.

Buy Documents

ISO 14853:2016 - Plastics -- Determination of the ultimate anaerobic biodegradation of plastic materials in an aqueous system -- Method by measurement of biogas production

ISO 14853:2016 - Plastiques -- Évaluation de la biodégradabilité anaérobie ultime des matériaux plastiques en milieu aqueux -- Méthode par détermination de la production de biogaz

Get Certified

Connect with accredited certification bodies for this standard

Smithers Quality Assessments

US management systems and product certification.

DIN CERTCO

DIN Group product certification.

Sponsored listings

Frequently Asked Questions

ISO 14853:2016 is a standard published by the International Organization for Standardization (ISO). Its full title is "Plastics — Determination of the ultimate anaerobic biodegradation of plastic materials in an aqueous system — Method by measurement of biogas production". This standard covers: ISO 14853:2016 specifies a method for the determination of the ultimate anaerobic biodegradability of plastics by anaerobic microorganisms. The conditions described in ISO 14853 do not necessarily correspond to the optimum conditions for the maximum degree of biodegradation to occur. The test calls for exposure of the test material to sludge for a period of up to 90 d, which is longer than the normal sludge retention time (25 to 30 d) in anaerobic digesters, although digesters at industrial sites can have much longer retention times. The method applies to the following materials: - natural and/or synthetic polymers, copolymers or mixtures thereof; - plastic materials which contain additives such as plasticizers, colorants or other compounds; - water-soluble polymers; - materials which, under the test conditions, do not inhibit the microorganisms present in the inoculum. Inhibitory effects can be determined using an inhibition control or by another appropriate method (see e.g. ISO 13641). If the test material is inhibitory to the inoculum, a lower test concentration, another inoculum or a pre-exposed inoculum can be used.

ISO 14853:2016 specifies a method for the determination of the ultimate anaerobic biodegradability of plastics by anaerobic microorganisms. The conditions described in ISO 14853 do not necessarily correspond to the optimum conditions for the maximum degree of biodegradation to occur. The test calls for exposure of the test material to sludge for a period of up to 90 d, which is longer than the normal sludge retention time (25 to 30 d) in anaerobic digesters, although digesters at industrial sites can have much longer retention times. The method applies to the following materials: - natural and/or synthetic polymers, copolymers or mixtures thereof; - plastic materials which contain additives such as plasticizers, colorants or other compounds; - water-soluble polymers; - materials which, under the test conditions, do not inhibit the microorganisms present in the inoculum. Inhibitory effects can be determined using an inhibition control or by another appropriate method (see e.g. ISO 13641). If the test material is inhibitory to the inoculum, a lower test concentration, another inoculum or a pre-exposed inoculum can be used.

ISO 14853:2016 is classified under the following ICS (International Classification for Standards) categories: 83.080.01 - Plastics in general. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 14853:2016 has the following relationships with other standards: It is inter standard links to ISO 14853:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 14853:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 14853

Second edition

2016-07-15

Plastics — Determination of the

ultimate anaerobic biodegradation of

plastic materials in an aqueous system

— Method by measurement of biogas

production

Plastiques — Évaluation de la biodégradabilité anaérobie ultime des

matériaux plastiques en milieu aqueux — Méthode par détermination

de la production de biogaz

Reference number

©

ISO 2016

© ISO 2016, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – All rights reserved

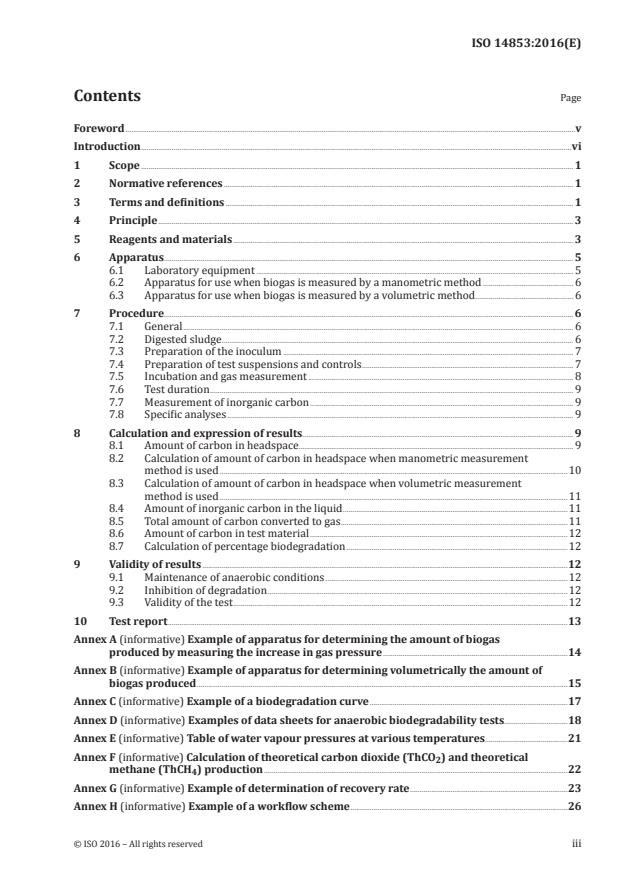

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Principle . 3

5 Reagents and materials . 3

6 Apparatus . 5

6.1 Laboratory equipment . 5

6.2 Apparatus for use when biogas is measured by a manometric method . 6

6.3 Apparatus for use when biogas is measured by a volumetric method . 6

7 Procedure. 6

7.1 General . 6

7.2 Digested sludge . 6

7.3 Preparation of the inoculum . 7

7.4 Preparation of test suspensions and controls . 7

7.5 Incubation and gas measurement . 8

7.6 Test duration . 9

7.7 Measurement of inorganic carbon . 9

7.8 Specific analyses . 9

8 Calculation and expression of results . 9

8.1 Amount of carbon in headspace . 9

8.2 Calculation of amount of carbon in headspace when manometric measurement

method is used .10

8.3 Calculation of amount of carbon in headspace when volumetric measurement

method is used .11

8.4 Amount of inorganic carbon in the liquid .11

8.5 Total amount of carbon converted to gas .11

8.6 Amount of carbon in test material .12

8.7 Calculation of percentage biodegradation .12

9 Validity of results .12

9.1 Maintenance of anaerobic conditions .12

9.2 Inhibition of degradation .12

9.3 Validity of the test .12

10 Test report .13

Annex A (informative) Example of apparatus for determining the amount of biogas

produced by measuring the increase in gas pressure .14

Annex B (informative) Example of apparatus for determining volumetrically the amount of

biogas produced .15

Annex C (informative) Example of a biodegradation curve .17

Annex D (informative) Examples of data sheets for anaerobic biodegradability tests .18

Annex E (informative) Table of water vapour pressures at various temperatures .21

Annex F (informative) Calculation of theoretical carbon dioxide (ThCO ) and theoretical

methane (ThCH ) production .22

Annex G (informative) Example of determination of recovery rate .23

Annex H (informative) Example of a workflow scheme .26

Bibliography .28

iv © ISO 2016 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity assessment,

as well as information about ISO’s adherence to the World Trade Organization (WTO) principles in the

Technical Barriers to Trade (TBT) see the following URL: www.iso.org/iso/foreword.html.

The committee responsible for this document is ISO/TC 61, Plastics, Subcommittee SC 5, Physical-

chemical properties.

This second edition cancels and replaces the first edition (ISO 14853:2005), which has been technically

revised. It also incorporates the Technical Corrigendum ISO 14853:2005/Cor.1:2009.

Introduction

With the increasing use of plastics, their recovery and disposal have become a major issue. As a first

priority, recovery should be promoted. For example, plastic litter, which originates mainly from

consumers, is difficult to recover completely. Additional examples of materials difficult to recover

are found in the disposal of fishing tackle, agricultural mulch films and water-soluble polymers.

These plastic materials tend to leak from closed waste management infrastructures into natural

environments. Biodegradable plastics are now emerging as one of the available options to solve such

environmental issues. Plastic materials, such as products or packaging, which are sent to anaerobic

treatment facilities should be potentially biodegradable. Therefore, it is very important to determine

the potential biodegradability of such materials and to obtain a quantitative measure of their

biodegradability in anaerobic environments.

vi © ISO 2016 – All rights reserved

INTERNATIONAL STANDARD ISO 14853:2016(E)

Plastics — Determination of the ultimate anaerobic

biodegradation of plastic materials in an aqueous system

— Method by measurement of biogas production

WARNING — Sewage and activated sludge may contain potentially pathogenic organisms.

Therefore, appropriate precautions should be taken when handling them. Digesting sewage

sludge produces flammable gases which present fire and explosion risks. Care should be taken

when transporting and storing quantities of digesting sludge. Toxic test chemicals and those

whose properties are not known should be handled with care and in accordance with safety

instructions. The pressure meter and microsyringes should be handled carefully to avoid needle

stick injuries. Contaminated syringe needles should be disposed of in a safe manner.

1 Scope

This International Standard specifies a method for the determination of the ultimate anaerobic

biodegradability of plastics by anaerobic microorganisms. The conditions described in this

International Standard do not necessarily correspond to the optimum conditions for the maximum

degree of biodegradation to occur. The test calls for exposure of the test material to sludge for a period

of up to 90 d, which is longer than the normal sludge retention time (25 to 30 d) in anaerobic digesters,

although digesters at industrial sites can have much longer retention times.

The method applies to the following materials:

— natural and/or synthetic polymers, copolymers or mixtures thereof;

— plastic materials which contain additives such as plasticizers, colorants or other compounds;

— water-soluble polymers;

— materials which, under the test conditions, do not inhibit the microorganisms present in the inoculum.

Inhibitory effects can be determined using an inhibition control or by another appropriate method

(see e.g. ISO 13641). If the test material is inhibitory to the inoculum, a lower test concentration,

another inoculum or a pre-exposed inoculum can be used.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

ultimate anaerobic biodegradation

breakdown of an organic compound by microorganisms in the absence of oxygen to carbon dioxide,

methane, water and mineral salts of any other elements present (mineralization) plus new biomass

3.2

primary anaerobic biodegradation

structural change (transformation) of a chemical compound by microorganisms, resulting in the loss of

a specific property

3.3

digested sludge

mixture of settled sewage and activated sludge which have been incubated in an anaerobic digester at

about 35 °C to reduce the biomass and odour and to improve the dewaterability of the sludge

Note 1 to entry: Digested sludge contains an association of anaerobic fermentative and methanogenic bacteria

producing carbon dioxide and methane.

3.4

concentration of suspended solids in digested sludge

amount of solids obtained by filtration or centrifugation of a known volume of activated sludge and

drying at about 105 °C to constant mass

3.5

dissolved organic carbon

DOC

organic carbon in the water phase which cannot be removed by specified phase separation, for example,

–2

by centrifugation at 40 000 m⋅s for 15 min or by membrane filtration using membranes with pores of

0,2 µm to 0,45 µm diameter

3.6

inorganic carbon

IC

inorganic carbon which is dissolved or dispersed in the aqueous phase of a liquid and is recoverable

from the supernatant liquid after the sludge has been allowed to settle

3.7

total dry solids

amount of solids obtained by taking a known volume of test material or inoculum and drying at about

105 °C to constant mass

3.8

theoretical amount of evolved biogas

Thbiogas

maximum theoretical amount of biogas (CH + CO ) evolved after complete biodegradation of an

4 2

organic material under anaerobic conditions, calculated from the molecular formula and expressed as

millilitres of biogas evolved per milligram of test material under standard conditions

3.9

theoretical amount of evolved carbon dioxide

ThCO

maximum theoretical amount of carbon dioxide evolved after complete oxidation of an organic material,

calculated from the molecular formula and expressed as milligrams of carbon dioxide per milligram of

test material

3.10

theoretical amount of evolved methane

ThCH

maximum theoretical amount of methane evolved after complete reduction of an organic material,

calculated from the molecular formula and expressed as milligrams of methane evolved per milligram

of test material

3.11

lag phase

lag period

time, measured in days, from the start of a test until adaptation and/or selection of the degrading

microorganisms is achieved and the degree of biodegradation of a chemical compound or organic

matter has increased to about 10 % of the maximum level of biodegradation

2 © ISO 2016 – All rights reserved

3.12

plateau phase

time, measured in days, from the end of the biodegradation phase until the end of the test

3.13

biodegradation phase

time, measured in days, from the end of the lag phase of a test until about 90 % of the maximum level of

biodegradation has been reached

3.14

maximum level of biodegradation

degree of biodegradation, measured in percent, of a chemical compound or organic matter in a test,

above which no further biodegradation takes place during the test

4 Principle

The biodegradability of a plastic material is determined using anaerobic conditions in an aqueous

system. Test material with a concentration of 20 mg/l to 200 mg/l organic carbon (OC) is incubated

at (35 ± 2) °C in sealed vessels together with digested sludge for a period normally not exceeding 90 d.

Before use, the digested sludge is washed so that it contains very low amounts of inorganic carbon

(IC) and diluted to 1 g/l to 3 g/l total solids concentration. The increase in headspace pressure or the

volumetric increase (depending on the method used for measuring biogas evolution) in the test vessels

resulting from the production of carbon dioxide (CO ) and methane (CH ) is measured. A considerable

2 4

amount of CO will be dissolved in water or transformed to bicarbonate or carbonate under the

conditions of the test. This inorganic carbon (IC) is measured at the end of the test. The amount of

microbiologically produced biogas carbon is calculated from the net biogas production and the net IC

formation in excess of blank values. The percentage biodegradation is calculated from the total amount

of carbon transformed to biogas and IC and the measured or calculated amount of carbon added as

test material. The course of biodegradation can be followed by making intermediate measurements

of biogas production. As additional information, the primary biodegradability can be determined by

specific analyses at the beginning and end of the test.

This test method is designed to determine the biodegradability of plastic materials under anaerobic

conditions. Optionally, the assessment of the recovery rate may also be of interest (see Annex G).

5 Reagents and materials

5.1 Distilled or deionized water, free of toxic substances, containing less than 2 mg/l of DOC.

5.2 Test medium, prepared using only reagents of recognized analytical grade.

Prepare the test medium to contain the following constituents in the stated amounts:

Anhydrous potassium dihydrogen phosphate KH PO 0,27 g

2 4

Disodium hydrogen phosphate dodecahydrate Na HPO ⋅12H O 1,12 g

2 4 2

Ammonium chloride NH Cl 0,53 g

Calcium chloride dihydrate CaCl ⋅2H O 0,075 g

2 2

Magnesium chloride hexahydrate MgCl ⋅6H O 0,10 g

2 2

Iron (II) chloride tetrahydrate FeCl ⋅4H O 0,02 g

2 2

Resazurin (oxygen indicator) 0,001 g

a

Disodium sulfide nonahydrate Na S⋅9H O 0,1 g

2 2

Stock solution of trace elements (optional) 10 ml

Stock solutions of vitamins (optional) Vitamin solution No. 1 0,5 ml

Anhydrous potassium dihydrogen phosphate KH PO 0,27 g

2 4

Vitamin solution No. 2 0,5 ml

Add water (5.1) (oxygen-free) to 1 l

a

Use freshly prepared sodium sulfide, or wash and dry it before use, to ensure sufficient reductive capacity.

In order to ensure strictly anaerobic conditions, it is recommended that a small amount of sodium dithionite be

added to the medium after it has been prepared until it becomes colourless. Do not use more than 10 mg/l because

higher concentrations may produce inhibitory effects.

Adjust the pH of the medium with dilute mineral acid or alkali, if necessary, to 7 ± 0,2.

To ensure oxygen-free conditions, purge the water with nitrogen for about 20 min immediately before use.

5.3 Trace-element solution (optional).

It is recommended that the test medium be supplemented with the following trace elements to improve

the anaerobic degradation process, especially if low inoculum concentrations are used:

Manganese chloride tetrahydrate MnCl ⋅4H O 0,05 g

2 2

Boric acid H BO 0,005 g

3 3

Zinc chloride ZnCl 0,005 g

Copper (II) chloride CuCl 0,003 g

Disodium molybdate dihydrate Na MoO ⋅2H O 0,001 g

2 4 2

Cobalt chloride hexahydrate CoCl ⋅6H O 0,1 g

2 2

Nickel chloride hexahydrate NiCl ⋅6H O 0,01 g

2 2

Disodium selenite Na SeO 0,005 g

2 3

Disodium tungstate dihydrate Na WO ⋅2H O 0,002 g

2 4 2

Add water (5.1) (oxygen free) to 1 l

Use 10 ml of trace-element solution per litre of test medium.

5.4 Vitamin solutions (optional).

5.4.1 Vitamin solution No. 1

4-Aminobenzoic acid 40 mg

d-Biotin 10 mg

Dissolve in hot water (5.1) 500 ml

Allow to cool and add:

d-Pantothenic acid, calcium salt 50 mg

Pyridoxamine dihydrochloride 150 mg

Thiamine dichloride 100 mg

Filter the solution through a membrane filter (pore size 0,45 µm) that neither adsorbs nor releases

organic carbon in significant amounts, and store in the dark at 4 °C.

Use 0,5 ml of vitamin solution per litre of test medium.

5.4.2 Vitamin solution No. 2

Cyanocobalamin (vitamin B12) 10 mg

Dissolve in water (5.1) 100 ml

4 © ISO 2016 – All rights reserved

Filter the solution through a membrane filter (pore size 0,45 µm) that neither adsorbs nor releases

organic carbon in significant amounts, and store in the dark at 4 °C.

Use 0,5 ml of vitamin solution per litre of test medium.

5.5 Barrier solution.

NaCl 200 g

Dissolve in water (5.1) 1 000 ml

Acidify with citric acid 5 g

Add a pH indicator such as bromophenol blue or methyl orange in order to be able to verify that the

solution remains acid during the test.

5.6 Test material.

The test material is usually added directly as solid to give a concentration of 20 mg/l to 200 mg/l

organic carbon. The test material (plastic) should be used in powdered form, if possible.

The test material should preferably be used in powder form, but it may also be introduced as films,

pieces, fragments or shaped articles. The form and shape of the test material may influence its

biodegradability. Similar shapes should preferably be used if different kinds of plastic material are

to be compared. If the test material is used in the form of a powder, particles of known, narrow size

distribution should be used. A particle-size distribution with the maximum at 250 µm diameter is

recommended. Also, the size of the test equipment used may depend on the form of the test material.

The biodegradability of plastic materials which are not inhibitory to microorganisms can be determined

using concentrations higher than 200 mg/l organic carbon. In this case, ensure that the buffer capacity

and mineral-salt content of the medium are sufficient.

5.7 Reference material.

Use a well-defined anaerobically biodegradable polymer, e.g. poly-β-hydroxybutyrate, cellulose or

poly(ethylene glycol) 400 as a reference material. If possible, the form, size, solubility and concentration

of the reference material should be comparable with that of the test material.

Prepare the reference material in the same way as the test material.

5.8 Inhibition control (optional).

Add both the test material and the reference material to a vessel containing test medium (5.2) to give

the concentrations specified in 5.6 and 5.7, respectively.

6 Apparatus

6.1 Laboratory equipment

Required is usual laboratory equipment, plus the following:

6.1.1 Incubator or water or sand bath, thermostatically controlled at (35 ± 2) °C.

6.1.2 Carbon analyser (optional), suitable for the direct determination of inorganic carbon in the

range 1 mg/l to 200 mg/l IC. Alternatively, the IC in the supernatant may be determined indirectly by

release of the dissolved IC as carbon dioxide that can be measured in the headspace, as described in 7.7.

6.2 Apparatus for use when biogas is measured by a manometric method

6.2.1 Pressure-resistant glass test vessels, nominal size 0,1 l to 1 l, each fitted with a gastight septum

capable of withstanding about 2 000 hPa (for an example, see Annex A). The headspace volume shall be

about 10 % to 30 % of the total volume. If gas is released at regular intervals, about 10 % headspace

volume is adequate, but if gas is released only at the end of the test, 30 % is more appropriate.

From a practical point of view, the use of serum bottles sealed with butyl rubber serum caps and

crimped aluminium rings is recommended.

6.2.2 Pressure-measuring device, e.g. a manometer connected to a suitable syringe needle, with

a gastight three-way valve to facilitate the release of excess pressure. Use and calibrate the device in

accordance with the manufacturer’s instructions.

It is necessary to keep the internal volume of the tubing and the valve as low as possible so that errors

introduced by neglecting the volume of the device are not significant.

6.3 Apparatus for use when biogas is measured by a volumetric method

6.3.1 Glass test vessels (e.g. conical flasks or bottles), nominal size 0,1 l to 1 l, preferably 300 ml for

every 250 ml of medium. If foaming is not expected to occur, a headspace volume of 10 % to 20 % is

recommended. The vessels shall be equipped with a septum for gas sampling (see Annex B) and shall be

connected via gastight tubing to a graduated glass gas-collection tube which is filled with acidified salt

solution (barrier solution 5.5). This graduated glass tube shall be connected to an expansion tank which

can be moved up and down to bring the surface of the acidified solution in the expansion tank to the

same level as that in the gas-collection tube.

7 Procedure

7.1 General

Carry out the following initial operations using techniques which will ensure that the digested sludge

comes into contact with oxygen as little as practicable, e.g. work in a glove-box in an atmosphere of

nitrogen or purge the test vessels with nitrogen.

7.2 Digested sludge

Collect digested sludge from a digester at a sewage treatment plant treating predominantly domestic

sewage. Be sure to collect active sludge. Use wide-necked bottles made of high-density polyethylene or

a similar material which can expand. Glass is not recommended for safety reasons. Fill the bottles to

within 1 cm of the top and seal. After transport to the laboratory, use directly or place in a laboratory-

scale digester. Release excess biogas.

Alternatively, use a laboratory-grown anaerobic sludge as a source of the inoculum.

Consider pre-incubation of the sludge to reduce background gas production and to decrease the

influence of the blanks. Allow the sludge to digest, without the addition of any nutrients or substrates,

at (35 ± 2) °C for up to 7 d.

It has been shown that pre-incubation for about 5 d gives an optimum decrease in gas production by the

blank without an unacceptable increase in either lag period or incubation period during the test. For

test materials which are expected to be poorly biodegradable, consider pre-incubating the sludge with

the test material to get a better adapted inoculum. In such a case, add test material with a concentration

of 5 mg/l to 20 mg/l OC to the digested sludge. Wash the pre-incubated sludge carefully before use.

Indicate in the test report that pre-incubation was carried out.

6 © ISO 2016 – All rights reserved

7.3 Preparation of the inoculum

Wash the sludge just prior to use to reduce the IC content to less than 20 mg/l in the final test suspension.

If the IC has not been sufficiently lowered, wash the sludge an additional two times. Finally, suspend the

sludge in the requisite volume of test medium (5.2) and determine the concentration of total solids (see

3.7). The final concentration of total solids in the test vessels shall be in the range 1 g/l to 3 g/l. Conduct

the above operations in such a way that the sludge has minimal contact with oxygen (e.g. use a nitrogen

atmosphere).

7.4 Preparation of test suspensions and controls

At least three test vessels, F , shall be prepared for the test material, at least three for the blanks,

T

F , and, F , for the positive control (reference material). One or more vessels, F , may optionally be

B P I

prepared for each test material as an inhibition control (see Table 1). The same blanks and controls

can be used for several different test materials which are being tested together. Into all the vessels,

introduce aliquots of the diluted inoculum prepared in 7.3 so that the concentration of total solids is

the same in all the vessels (between 1 g/l and 3 g/l). Add the test material (5.6) and the reference

material (5.7) to the appropriate vessels. The OC concentration in the test suspensions shall normally

be 100 mg/l. In the case of toxic test materials, it may be reduced to 20 mg/l OC or even less if only the

primary biodegradability is to be determined with specific analyses.

NOTE Using lower test concentrations may result in a greater scatter of the test results.

In the case of the blank vessels, add equivalent amounts of oxygen-free water (5.1) instead of the test

material. An extra (replicate) test vessel containing test suspension may also be prepared for analyses,

carried out at the beginning of the test, to determine the pH and, if required, the total solids and IC.

Adjust the pH to 7 ± 0,2, if necessary, with small amounts of dilute mineral acid or alkali. Add the same

amount of neutralizing agent to all the test vessels. If the primary degradability is to be measured,

take a suitable sample from the extra test vessel and measure the test material concentration using

a suitable method. Place magnetic stirrer bars in the vessels if the test suspensions are to be stirred

(optional). Ensure that the total volume of liquid, V , and the volume of the headspace, V , are the same

L H

in all vessels (see 6.2.1). Note V and V (see Clause 8). If necessary, add additional oxygen-free test

L H

medium (5.2). Seal each vessel with a gastight septum and put them into the incubator (6.1.1).

Table 1 — Scheme of test and control assays

Vessel Test material Reference material Inoculum

(biodegradable)

F Test + +

T1

F Test + +

T2

F Test + +

T3

F Blank +

B1

F Blank +

B2

F Blank +

B3

F Positive control + +

P1

F Positive control + +

P2

F Positive control + +

P3

Extra replicate for analysis at

+ +

beginning of test

F Inhibition control (optional) + + +

I

7.5 Incubation and gas measurement

7.5.1 General

Incubation shall take place in sealed vessels at a constant temperature of (35 ± 2) °C, a normal

temperature for an anaerobic digester, in the absence of ox

...

NORME ISO

INTERNATIONALE 14853

Deuxième édition

2016-07-15

Plastiques — Évaluation de la

biodégradabilité anaérobie ultime

des matériaux plastiques en milieu

aqueux — Méthode par détermination

de la production de biogaz

Plastics — Determination of the ultimate anaerobic biodegradation

of plastic materials in an aqueous system — Method by measurement

of biogas production

Numéro de référence

©

ISO 2016

DOCUMENT PROTÉGÉ PAR COPYRIGHT

© ISO 2016, Publié en Suisse

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni utilisée

sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie, l’affichage sur

l’internet ou sur un Intranet, sans autorisation écrite préalable. Les demandes d’autorisation peuvent être adressées à l’ISO à

l’adresse ci-après ou au comité membre de l’ISO dans le pays du demandeur.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – Tous droits réservés

Sommaire Page

Avant-propos .v

Introduction .vi

1 Domaine d’application . 1

2 Références normatives . 1

3 Termes et définitions . 1

4 Principe . 3

5 Réactifs et matériaux . 3

6 Appareillage . 6

6.1 Matériel de laboratoire . 6

6.2 Appareillage à utiliser lorsque le biogaz est mesuré par une méthode manométrique. 6

6.3 Appareillage à utiliser lorsque le biogaz est mesuré par une méthode volumétrique . 7

7 Mode opératoire. 7

7.1 Généralités . 7

7.2 Boue digérée . 7

7.3 Préparation de l’inoculum . 7

7.4 Préparation des suspensions d’essai et des substances de contrôle. 7

7.5 Incubation et mesurage du gaz . 8

7.6 Durée de l’essai . 9

7.7 Mesurage du carbone inorganique .10

7.8 Analyses spécifiques .10

8 Calcul et expression des résultats .10

8.1 Quantité de carbone dans l’espace de tête .10

8.2 Calcul de la quantité de carbone dans l’espace de tête avec une méthode de

mesure manométrique . .11

8.3 Calcul de la quantité de carbone dans l’espace de tête avec une méthode de

mesure volumétrique .11

8.4 Quantité de carbone inorganique dans le liquide .12

8.5 Quantité totale de carbone converti en gaz .12

8.6 Quantité de carbone dans le matériau d’essai .13

8.7 Calcul du pourcentage de biodégradation.13

9 Validité des résultats .13

9.1 Maintien des conditions anaérobies.13

9.2 Inhibition de la dégradation .13

9.3 Validité de l’essai .13

10 Rapport d’essai .14

Annexe A (informative) Exemple d’appareillage pour déterminer la quantité de biogaz

produit en mesurant l’augmentation de la pression du gaz .15

Annexe B (informative) Exemple d’appareillage pour déterminer de manière volumétrique

la quantité de biogaz produit .16

Annexe C (informative) Exemple de courbe de biodégradation .18

Annexe D (informative) Exemples de fiches techniques pour les essais de

biodégradabilité anaérobie .19

Annexe E (informative) Table des pressions de vapeur d’eau à différentes températures .24

Annexe F (informative) Calcul de la production théorique de dioxyde de carbone (ThCO )

et de méthane (ThCH ) .25

Annexe G (informative) Exemple de détermination du taux de récupération .26

Annexe H (informative) Exemple de diagramme de flux .29

Bibliographie .31

iv © ISO 2016 – Tous droits réservés

Avant-propos

L’ISO (Organisation internationale de normalisation) est une fédération mondiale d’organismes

nationaux de normalisation (comités membres de l’ISO). L’élaboration des Normes internationales est

en général confiée aux comités techniques de l’ISO. Chaque comité membre intéressé par une étude

a le droit de faire partie du comité technique créé à cet effet. Les organisations internationales,

gouvernementales et non gouvernementales, en liaison avec l’ISO participent également aux travaux.

L’ISO collabore étroitement avec la Commission électrotechnique internationale (IEC) en ce qui

concerne la normalisation électrotechnique.

Les procédures utilisées pour élaborer le présent document et celles destinées à sa mise à jour sont

décrites dans les Directives ISO/IEC, Partie 1. Il convient, en particulier, de prendre note des différents

critères d’approbation requis pour les différents types de documents ISO. Le présent document a été

rédigé conformément aux règles de rédaction données dans les Directives ISO/IEC, Partie 2 (voir www.

iso.org/directives).

L’attention est appelée sur le fait que certains des éléments du présent document peuvent faire l’objet de

droits de propriété intellectuelle ou de droits analogues. L’ISO ne saurait être tenue pour responsable

de ne pas avoir identifié de tels droits de propriété et averti de leur existence. Les détails concernant

les références aux droits de propriété intellectuelle ou autres droits analogues identifiés lors de

l’élaboration du document sont indiqués dans l’Introduction et/ou dans la liste des déclarations de

brevets reçues par l’ISO (voir www.iso.org/brevets).

Les appellations commerciales éventuellement mentionnées dans le présent document sont données

pour information, par souci de commodité, à l’intention des utilisateurs et ne sauraient constituer un

engagement.

Pour une explication de la signification des termes et expressions spécifiques de l’ISO liés à l’évaluation

de la conformité, ou pour toute information au sujet de l’adhésion de l’ISO aux principes de l’Organisation

mondiale du commerce (OMC) concernant les obstacles techniques au commerce (OTC), voir le lien

suivant: http ://www.iso.org/iso/fr/foreword.html.

Le comité chargé de l’élaboration du présent document est l’ISO/TC 61, Plastiques, sous-comité SC 5,

Propriétés physicochimiques.

Cette deuxième édition annule et remplace la première édition (ISO 14853:2005), qui a fait l’objet d’une

révision technique. Elle intègre également le Corrigendum technique ISO 14853:2005/Cor.1:2009.

Introduction

Les plastiques étant de plus en plus utilisés, leur valorisation et leur élimination sont devenues un enjeu

majeur. Il convient de favoriser en priorité leur valorisation. Par exemple, un déchet plastique, venant

principalement des consommateurs, est difficile à valoriser complètement. Autres exemples de produits

difficiles à valoriser: les articles de pêche, les paillages agricoles et les polymères hydrosolubles. Ces

matériaux plastiques tendent à migrer des infrastructures fermées de gestion des déchets vers le milieu

naturel. Désormais, les plastiques biodégradables apparaissent comme l’une des options possibles

pour résoudre ce genre de problème environnemental. Il convient que les matériaux plastiques, sous

forme de produits ou d’emballages, qui sont envoyés dans les installations de traitement anaérobie

soient potentiellement biodégradables. Il est donc très important de déterminer la biodégradabilité

potentielle de ce type de matériaux et d’obtenir une mesure quantitative de leur biodégradabilité en

milieu anaérobie.

vi © ISO 2016 – Tous droits réservés

NORME INTERNATIONALE ISO 14853:2016(F)

Plastiques — Évaluation de la biodégradabilité anaérobie

ultime des matériaux plastiques en milieu aqueux —

Méthode par détermination de la production de biogaz

AVERTISSEMENT — Les eaux usées et les boues activées peuvent contenir des organismes

potentiellement pathogènes. Il convient donc de prendre les précautions appropriées pour les

manipuler. Les boues d’eaux usées digérées produisent des gaz inflammables qui présentent des

risques d’incendie et d’explosion. Il convient de prendre des précautions lors du transport et

du stockage de grandes quantités de boues digérées. Il convient de manipuler avec précaution

et en respectant les instructions de sécurité les produits chimiques toxiques et ceux dont les

propriétés sont inconnues. Il convient de manipuler avec précaution le pressiomètre et les

microseringues pour éviter les piqûres d’aiguilles. Il convient d’éliminer de manière appropriée

les aiguilles de seringues contaminées.

1 Domaine d’application

La présente Norme internationale spécifie une méthode pour la détermination de la biodégradabilité

anaérobie ultime des plastiques par des micro-organismes anaérobies. Les conditions décrites dans

la présente Norme internationale ne correspondent pas nécessairement aux conditions optimales

permettant d’obtenir le taux maximal de biodégradation. L’essai exige que le matériau d’essai soit exposé

aux boues pendant une période allant jusqu’à 90 j, ce qui est plus long que le temps de rétention normal

de la boue (25 j à 30 j) dans les digesteurs anaérobies, bien que les digesteurs sur les sites industriels

puissent avoir des temps de rétention beaucoup plus longs.

La présente méthode s’applique aux matériaux suivants:

— polymères naturels et/ou synthétiques, copolymères ou mélanges de ceux-ci;

— matériaux plastiques contenant des additifs, tels que plastifiants, colorants ou autres composés;

— polymères hydrosolubles;

— matériaux qui, dans les conditions d’essai, n’ont pas d’effet inhibiteur sur les micro-organismes

présents dans l’inoculum. Les effets inhibiteurs peuvent être déterminés en utilisant une substance

de contrôle de l’effet inhibiteur ou par toute autre méthode appropriée (voir, par exemple, l’ISO 13641).

Si le matériau d’essai a un effet inhibiteur vis-à-vis de l’inoculum, il est possible d’utiliser une plus

faible concentration, un autre inoculum ou un inoculum pré-exposé.

2 Références normatives

Il n’y a pas de références normatives dans le présent document.

3 Termes et définitions

Pour les besoins du présent document, les termes et définitions suivants s’appliquent.

3.1

biodégradation anaérobie ultime

décomposition d’un composé organique par des micro-organismes en l’absence d’oxygène, en dioxyde

de carbone, méthane, eau et sels minéraux de tous les autres éléments présents (minéralisation) et

production d’une nouvelle biomasse

3.2

biodégradation anaérobie primaire

modification structurelle (transformation) d’un composé chimique par des micro-organismes, résultant

en la perte d’une propriété spécifique

3.3

boue digérée

mélange d’eaux usées décantées et de boues activées qui ont été incubées dans un digesteur anaérobie à

environ 35 °C pour réduire la biomasse et l’odeur et pour améliorer la déshydratation de la boue

Note 1 à l’article: Les boues digérées contiennent un ensemble de bactéries fermentatives et méthanogènes

anaérobies qui produisent du dioxyde de carbone et du méthane.

3.4

concentration de la boue digérée en matières solides en suspension

quantité de matières solides obtenue par filtration ou centrifugation d’un volume connu de boue activée

et séchage à environ 105 °C jusqu’à l’obtention d’une masse constante

3.5

carbone organique dissous

COD

carbone organique contenu dans la phase aqueuse, qui ne peut pas être éliminé par une séparation de

–2

phase spécifique, par exemple par centrifugation à 40 000 m⋅s pendant 15 min ou par filtration sur

des membranes ayant des pores de 0,2 µm à 0,45 µm de diamètre

3.6

carbone inorganique

CI

carbone inorganique qui est dissous ou dispersé dans la phase aqueuse d’un liquide et qui est

récupérable dans le liquide surnageant une fois que la boue a décanté

3.7

matières sèches totales

quantité de matières solides obtenue par prélèvement d’un volume connu de matériau d’essai ou

d’inoculum et séchage à environ 105 °C jusqu’à l’obtention d’une masse constante

3.8

quantité théorique de biogaz libéré

Thbiogaz

quantité théorique maximale de biogaz (CH + CO ) libéré après la biodégradation complète d’une

4 2

matière organique dans des conditions anaérobies, calculée d’après la formule moléculaire et exprimée

en millilitres de biogaz libéré par milligramme de matériau d’essai dans les conditions normales

3.9

quantité théorique de dioxyde de carbone libéré

ThCO

quantité théorique maximale de dioxyde de carbone libéré après oxydation complète d’une matière

organique, calculée d’après la formule moléculaire et exprimée en milligrammes de dioxyde de carbone

par milligramme de matériau d’essai

3.10

quantité théorique de méthane libéré

ThCH

quantité théorique maximale de méthane libéré après réduction complète d’une matière organique,

calculée d’après la formule moléculaire et exprimée en milligrammes de méthane libéré par

milligramme de matériau d’essai

2 © ISO 2016 – Tous droits réservés

3.11

phase de latence

période de latence

durée, mesurée en jours, écoulée à partir du début de l’essai jusqu’à l’obtention de l’adaptation

et/ou de la sélection des micro-organismes qui provoquent la dégradation, et jusqu’à ce que le taux de

biodégradation du composé chimique ou de la matière organique ait atteint environ 10 % du niveau

maximal de biodégradation

3.12

phase stationnaire

durée, mesurée en jours, écoulée entre la fin de la phase de biodégradation et la fin de l’essai

3.13

phase de biodégradation

durée, mesurée en jours, depuis la fin de la phase de latence de l’essai jusqu’à ce que l’on ait obtenu

environ 90 % du niveau maximal de biodégradation

3.14

niveau maximal de biodégradation

taux de biodégradation, mesuré en pourcentage, d’un composé chimique ou d’une matière organique

lors d’un essai, au-dessus duquel la biodégradation ne se poursuit pas

4 Principe

La biodégradabilité d’un matériau plastique est déterminée dans des conditions anaérobies en milieu

aqueux. Le matériau d’essai d’une concentration de 20 mg/l à 200 mg/l de carbone organique (CO) est

incubé à (35 ± 2) °C dans des récipients fermés avec la boue digérée pendant une durée ne dépassant

normalement pas 90 j. Avant utilisation, la boue digérée est lavée afin qu’elle contienne de très petites

quantités de carbone inorganique (CI) et elle est diluée à une concentration comprise entre 1 g/l et

3 g/l de matières solides totales. L’augmentation de pression dans l’espace de tête ou l’augmentation

volumétrique (en fonction de la méthode utilisée pour mesurer la libération de biogaz) dans les

récipients d’essai, résultant de la production de dioxyde de carbone (CO ) et de méthane (CH ), est

2 4

mesurée. Une quantité considérable de CO sera dissoute dans l’eau ou transformée en bicarbonate ou

en carbonate dans les conditions de l’essai. Ce carbone inorganique (CI) est mesuré à la fin de l’essai.

La quantité de carbone de biogaz produit de manière microbiologique est calculée à partir de la

production nette de biogaz et de la formation nette de CI dépassant les valeurs du blanc. Le pourcentage

de biodégradation est calculé à partir de la quantité totale de carbone transformé en biogaz et en CI

et de la quantité mesurée ou calculée de carbone ajouté en tant que matériau d’essai. L’évolution de la

biodégradation peut être suivie en réalisant des mesurages intermédiaires de la production de biogaz.

À titre d’informations complémentaires, la biodégradabilité primaire peut être déterminée par des

analyses spécifiques réalisées au début et à la fin de l’essai.

La présente méthode d’essai est conçue pour déterminer la biodégradabilité des matériaux plastiques

dans des conditions anaérobies. À titre facultatif, l’évaluation du taux de récupération peut également

présenter un intérêt (voir l’Annexe G).

5 Réactifs et matériaux

5.1 Eau distillée ou déionisée, exempte de substances toxiques et contenant moins de 2 mg/l de COD.

5.2 Milieu d’essai, préparé uniquement avec des réactifs de qualité analytique reconnue.

Préparer le milieu d’essai en utilisant les constituants suivants dans les quantités indiquées:

Dihydrogénophosphate de potassium anhydre KH PO 0,27 g

2 4

Hydrogénophosphate disodique Na HPO ⋅12H O 1,12 g

2 4 2

dodécahydraté

Chlorure d’ammonium NH Cl 0,53 g

Chlorure de calcium dihydraté CaCl ⋅2H O 0,075 g

2 2

Chlorure de magnésium hexahydraté MgCl ⋅6H O 0,10 g

2 2

Chlorure de fer(II) tétrahydraté FeCl ⋅4H O 0,02 g

2 2

Résazurine (indicateur d’oxygène) 0,001 g

a

Sulfure disodique nonahydraté Na S⋅9H O 0,1 g

2 2

Solution mère d’éléments traces (facultative) 10 ml

Solutions mères de vitamines (facultatives) Solution de vitamines n° 1 0,5 ml

Solution de vitamines n° 2 0,5 ml

Ajouter de l’eau (5.1) (exempte d’oxygène) 1 l

a

Utiliser du sulfure de sodium fraichement préparé ou le laver et le sécher avant utilisation pour

garantir une capacité réductrice suffisante. Pour garantir des conditions strictement anaérobies, il

est recommandé d’ajouter une petite quantité de dithionite de sodium dans le milieu préparé, jusqu’à

ce qu’il devienne incolore. Ne pas utiliser plus de 10 mg/l car des concentrations plus élevées peuvent

produire des effets inhibiteurs.

Ajuster le pH du milieu avec de l’acide ou de la base minéral(e) dilué(e), si nécessaire, à pH 7 ± 0,2.

Pour garantir des conditions exemptes d’oxygène, purger l’eau avec de l’azote pendant environ 20 min

juste avant utilisation.

5.3 Solution d’éléments traces (facultative).

Il est recommandé d’ajouter les éléments traces suivants dans le milieu d’essai pour améliorer le

processus de dégradation anaérobie, en particulier si de faibles concentrations d’inoculum sont

utilisées:

Chlorure de manganèse tétrahydraté MnCl ⋅4H O 0,05 g

2 2

Acide borique H BO 0,005 g

3 3

Chlorure de zinc ZnCl 0,005 g

Chlorure de cuivre(II) CuCl 0,003 g

Molybdate disodique dihydraté Na MoO ⋅2H O 0,001 g

2 4 2

Chlorure de cobalt hexahydraté CoCl ⋅6H O 0,1 g

2 2

Chlorure de nickel hexahydraté NiCl ⋅6H O 0,01 g

2 2

Sélénite disodique Na SeO 0,005 g

2 3

Tungstate disodique dihydraté Na WO ⋅2H O 0,002 g

2 4 2

Ajouter de l’eau (5.1) (exempte d’oxygène) 1 l

4 © ISO 2016 – Tous droits réservés

Utiliser 10 ml de solution d’éléments traces par litre de milieu d’essai.

5.4 Solutions de vitamines (facultatives).

5.4.1 Solution de vitamines n° 1

Acide 4-aminobenzoïque 40 mg

d-biotine 10 mg

Dissoudre dans de l’eau chaude (5.1) 500 ml

Laisser refroidir et ajouter:

Acide d-pantothénique, sel de calcium 50 mg

Dihydrochlorure de pyridoxamine 150 mg

Dichlorure de thiamine 100 mg

Filtrer la solution sur une membrane (ouverture de pore de 0,45 µm) qui n’adsorbe pas et ne libère pas

de carbone organique en quantités significatives, et la conserver dans l’obscurité à 4 °C.

Utiliser 0,5 ml de solution de vitamines par litre de milieu d’essai.

5.4.2 Solution de vitamines n° 2

Cyanocobalamine (vitamine B12) 10 mg

Dissoudre dans de l’eau (5.1) 100 ml

Filtrer la solution sur une membrane (ouverture de pore de 0,45 µm) qui n’adsorbe pas et ne libère pas

de carbone organique en quantités significatives, et la conserver dans l’obscurité à 4 °C.

Utiliser 0,5 ml de solution de vitamines par litre de milieu d’essai.

5.5 Solution barrière.

NaCl 200 g

Dissoudre dans de l’eau (5.1) 1 000 ml

Acidifier avec de l’acide citrique 5 g

Ajouter un indicateur de pH, par exemple du bleu de bromophénol ou de l’orange de méthyle, pour

pouvoir vérifier que la solution reste acide lors de l’essai.

5.6 Matériau d’essai.

Le matériau d’essai est généralement ajouté directement sous forme solide pour donner une

concentration de 20 mg/l à 200 mg/l de carbone organique. Il convient que le matériau d’essai

(plastique) soit utilisé sous forme de poudre, dans la mesure du possible.

Il convient d’utiliser le matériau d’essai de préférence sous forme de poudre; toutefois, ce dernier peut

également être employé sous forme de film, de morceaux, de fragments ou d’articles façonnés. La

consistance et la forme du matériau d’essai peuvent influer sur sa biodégradabilité. Il convient d’utiliser,

de préférence, des formes similaires si l’on doit comparer différents types de matériaux plastiques. Si

le matériau d’essai est utilisé sous forme de poudre, il est recommandé d’utiliser des particules ayant

une distribution granulométrique étroite connue. Une distribution granulométrique avec un diamètre

maximal de 250 µm est recommandée. D’autre part, la forme du matériau d’essai peut également avoir

une influence sur la taille du dispositif d’essai utilisé.

La biodégradabilité des matériaux plastiques qui ne sont pas inhibiteurs de micro-organismes peut

être déterminée à l’aide de concentrations supérieures à 200 mg/l de carbone organique. Dans ce cas,

s’assurer que le pouvoir tampon et la teneur en sels minéraux du milieu sont suffisants.

5.7 Matériau de référence.

Utiliser un polymère biodégradable anaérobie bien défini, par exemple du poly-β-hydroxybutyrate, de

la cellulose ou du poly(éthylène glycol) 400 comme matériau de référence. Si possible, il convient que la

forme, la taille, la solubilité et la concentration du matériau de référence soient comparables à celles du

matériau d’essai.

Préparer le matériau de référence de la même façon que le matériau d’essai.

5.8 Substance de contrôle de l’effet inhibiteur (facultative).

Ajouter à la fois le matériau d’essai et le matériau de référence dans un récipient contenant le milieu

d’essai (5.2) pour obtenir les concentrations spécifiées en 5.6 et 5.7, respectivement.

6 Appareillage

6.1 Matériel de laboratoire

Est nécessaire le matériel courant de laboratoire, et ce qui suit:

6.1.1 Incubateur, bain-marie ou bain de sable, thermostaté à (35 ± 2) °C.

6.1.2 Analyseur de carbone (facultatif), adapté pour la détermination directe du carbone inorganique

dans la plage de 1 mg/l à 200 mg/l de CI. Autrement, le CI présent dans le liquide surnageant peut être

déterminé indirectement par la libération de CI dissous sous forme de dioxyde de carbone qui peut être

mesurée dans l’espace de tête, comme décrit en 7.7.

6.2 Appareillage à utiliser lorsque le biogaz est mesuré par une méthode

manométrique

6.2.1 Récipients d’essai en verre résistants à la pression, d’une taille nominale de 0,1 l à 1 l, munis

d’un septum étanche au gaz capable de résister à environ 2 000 hPa (pour un exemple, voir l’Annexe A).

Le volume de l’espace de tête doit représenter environ 10 % à 30 % du volume total. Si du gaz est libéré

à intervalles réguliers, un volume d’espace de tête d’environ 10 % est adéquat, mais si le gaz est libéré

uniquement à la fin de l’essai, une valeur de 30 % est plus appropriée.

D’un point de vue pratique, l’utilisation de flacons à sérum fermés par des bouchons en caoutchouc

butyle et des anneaux sertis en aluminium est recommandée.

6.2.2 Dispositif de mesure de la pression, par exemple un manomètre raccordé à une aiguille de

seringue adaptée, avec un robinet à trois voies étanche au gaz pour faciliter la libération de la pression en

excès. Utiliser et étalonner ce dispositif conformément aux instructions du fabricant.

Il est nécessaire de faire en sorte que le volume interne du tube et du robinet soit le plus petit possible

pour éviter que les erreurs introduites du fait que le volume du dispositif a été ignoré ne soient pas

significatives.

6 © ISO 2016 – Tous droits réservés

6.3 Appareillage à utiliser lorsque le biogaz est mesuré par une méthode volumétrique

6.3.1 Récipients d’essai en verre (par exemple fioles ou flacons coniques), d’une taille nominale de

0,1 l à 1 l, de préférence de 300 ml pour chaque volume de 250 ml de milieu. Si la formation de mousse

n’est pas prévue, un volume d’espace de tête de 10 % à 20 % est recommandé. Les récipients doivent être

munis d’un septum pour le prélèvement de gaz (voir l’Annexe B) et doivent être raccordés par un tube

étanche au gaz à un tube de collecte de gaz en verre gradué qui est rempli de solution saline acidifiée

(solution barrière 5.5). Ce tube en verre gradué doit être raccordé à un vase d’expansion qui peut être

déplacé vers le haut ou le bas pour amener la surface de la solution acidifiée dans le vase d’expansion au

même niveau que dans le tube de collecte de gaz.

7 Mode opératoire

7.1 Généralités

Réaliser les opérations initiales suivantes en utilisant des techniques qui garantiront que la boue

digérée entre le moins possible en contact avec l’oxygène, par exemple travailler dans une boîte à gants

sous une atmosphère d’azote ou purger les récipients d’essai avec de l’azote.

7.2 Boue digérée

Collecter la boue digérée par le digesteur d’une installation de traitement des eaux usées traitant

principalement des eaux usées domestiques. Veiller à collecter la boue activée. Utiliser des flacons à col

large en polyéthylène haute densité ou en un matériau similaire pouvant se dilater. Le verre n’est pas

recommandé pour des raisons de sécurité. Remplir les flacons jusqu’à 1 cm du haut et les fermer. Après

le transport au laboratoire, les utiliser directement ou les placer dans un digesteur de laboratoire.

Libérer l’excès de biogaz.

Autrement, utiliser une boue anaérobie développée en laboratoire comme source pour l’inoculum.

Étudier la possibilité de pré-incuber la boue pour réduire la production de gaz de fond et l’influence des

blancs. Laisser la boue se digérer, sans ajouter de nutriments ou de substrats, à (35 ± 2) °C pendant une

durée allant jusqu’à 7 j.

Il a été démontré qu’une pré-incubation pendant environ 5 j conduit à une diminution optimale de la

production de gaz par le blanc sans augmentation inacceptable de la période de latence ou de la durée

d’incubation pendant l’essai. Pour les matériaux d’essai qui sont considérés comme peu biodégradables,

envisager une pré-incubation de la boue avec le matériau d’essai pour obtenir un inoculum mieux

adapté. Dans ce cas, ajouter le matériau d’essai à une concentration de 5 mg/l à 20 mg/l de CO à la boue

digérée. Laver soigneusement la boue pré-incubée avant utilisation. Indiquer dans le rapport d’essai

qu’une pré-incubation a été réalisée.

7.3 Préparation de l’inoculum

Laver la boue juste avant de l’utiliser pour réduire la teneur en CI à moins de 20 mg/l dans la suspension

d’essai finale. Si la teneur en CI n’a pas été suffisamment réduite, laver la boue deux autres fois. Pour

finir, mettre la boue en suspension dans le volume requis de milieu d’essai (5.2) et déterminer la

concentration en matières solides totales (voir 3.7). La concentration finale en matières solides totales

dans les récipients d’essai doit être comprise dans la plage de 1 g/l à 3 g/l. Réaliser les opérations ci-

dessus en faisant en sorte que la boue soit le moins possible en contact avec l’oxygène (utiliser par

exemple une atmosphère d’azote).

7.4 Préparation des suspensions d’essai et des substances de contrôle

Préparer au moins trois récipients d’essai F pour le matériau d’essai, au moins trois pour les blancs

T

F et pour le témoin positif F (matériau de référence). Un ou plusieurs récipients supplémentaires F

B P I

peuvent éventuellement être préparés pour chaque matériau d’essai en tant que substance de contrôle

de l’effet inhibiteur (voir le Tableau 1). Les mêmes blancs et substances de contrôle peuvent être utilisés

pour plusieurs matériaux d’essai différents qui sont soumis à l’essai ensemble. Dans tous les récipients,

introduire des parties aliquotes de l’inoculum dilué préparé en 7.3 pour que la concentration en

matières solides totales soit la même dans tous les récipients (entre 1 g/l et 3 g/l). Ajouter le matériau

d’essai (5.6) et le matériau de référence (5.7) dans les récipients appropriés. La concentration en CO

dans les suspensions d’essai doit normalement être de 100 mg/l. Dans le cas de matériaux d’essai

toxiques, elle peut être réduite à 20 mg/l de CO, voire moins, si seule la biodégradabilité primaire doit

être déterminée par des analyses spécifiques.

NOTE L’utilisation de concentrations d’essai plus faibles peut conduire à une plus grande dispersion des

résultats d’essai.

Dans le cas des récipients de blanc, ajouter des quantités équivalentes d’eau exempte d’oxygène (5.1)

à la place du matériau d’essai. Un récipient d’essai supplémentaire (réplicat) contenant la suspension

d’essai peut aussi être préparé pour les analyses réalisées au début de l’essai, afin de déterminer le pH

et, si nécessaire, la concentration en matières solides totales et en CI.

Ajuster le pH à 7 ± 0,2, si nécessaire, avec de petites quantités d’acide ou de base minéral(e) dilué(e).

Ajouter la même quantité d’agent neutralisant dans tous les récipients d’essai. Si la dégradabilité

primaire doit être mesurée, prendre un échantillon adapté dans le récipient d’essai supplémentaire et

mesurer la concentration du matériau d’essai en utilisant une méthode appropriée. Placer des agitateurs

magnétiques dans les récipients si les suspensions d’essai doivent être agitées (facultatif). S’assurer que

le volume total de liquide, V , et le volume d’espace de tête, V , sont les mêmes dans tous les récipients

L H

(voir 6.2.1). Consigner les volumes V et V (voir l’Article 8). Si nécessaire, ajouter davantage de milieu

L H

d’essai exempt d’oxygène (5.2). Fermer les récipients avec un septum étanche au gaz et les placer dans

l’incubateur (6.1.1).

Tableau 1 — Programme d’essai et de contrôle

Matériau de référence

Récipient Matériau d’essai Inoculum

(biodégradable)

F Essai + +

T1

F Essai + +

T2

F Essai + +

T3

F Blanc +

B1

F Blanc +

B2

F Blanc +

B3

F Témoin positif + +

P1

F Témoin positif + +

P2

F Témoin positif + +

P3

Réplicat supplémentaire pour

+ +

l’analyse au début de l’essai

F Substance de contrôle de l’effet

I

+ + +

inhibiteur (facultative)

7.5 Incubation et mesurage du gaz

7.5.1 Généralités

L’incubation doit avoir lieu dans des récipients fermés à une température constante de (35 ± 2) °C, qui

est la température normale pour un digesteur anaérobie, en l’absence d’oxygène, initialement sous une

atmosphère d’azote pur.

8 © ISO 2016 – Tous droits réservés

7.5.2 Mesurage du gaz à l’aide d’un manomètre (voir l’Annexe A)

Incuber les récipients préparés à (35 ± 2) °C pendant environ 1 h pour atteindre l’équilibre, et purger

le gaz en excès dans l’atmosphère, par exemple en agitant chaque récipient l’un après l’autre, en

insérant l’aiguille du manomètre à travers le joint et en ouvrant le robinet jusqu’à ce que le manomètre

indique zéro. Si, à ce stade, ou au moment des mesurages intermédiaires, la pression dans l’espace de

tête est inférieure à la pression atmosphérique, introduire de l’azote gazeux pour rétablir la pression

atmosphérique. Fermer le robinet et poursuivre l’incubation dans l’obscurité, en s’assurant que toutes

les parties des récipients sont maintenues à la température d’incubation.

Observer les récipients après incubation pendant 24 h à 48 h. Rejeter les récipients si leur contenu

présente une coloration rose distincte dans le liquide surnageant. Ce phénomène est dû au changement

de couleur de la résazurine, indiquant la présence d’oxygène. De petites quantités d’oxygène peuvent

être tolérées dans le système, mais des concentrations plus élevées peuvent inhiber l’évolution de la

biodégradation anaérobie.

Mélanger avec précaution le contenu de chaque récipient en l’agitant ou en le secouant pendant quelques

minutes au moins deux ou trois fois par semaine et avant chaque mesurage de la pression. Mesurer

la pression de gaz, par exemple en insérant à travers le septum l’aiguille de la seringue raccordée au

manomètre. Enregistrer la pression en hectopascals.

L’agitation remet l’inoculum en suspension et assure l’équilibre gazeux. Lors du mesurage de la

pression, maintenir le gaz dans l’espace de tête à la température d’incubation. Veiller à éviter que de

l’eau pénètre dans l’aiguille de la seringue. Si cela se produit, sécher les parties humides et utiliser une

nouvelle aiguille.

Mesurer la pression de gaz dans les récipients chaque semaine, en purgeant le gaz en excès dans

l’atmosphère, ou mesurer la pression uniquement à la fin de l’essai pour détecter la quantité totale

de biogaz produit. Il est toutefois vivement recommandé d’effectuer des relevés intermédiaires de la

pression de gaz, car l’augmentation de pression donne une indication sur le moment auquel l’essai peut

être arrêté et elle permet de suivre la cinétique.

7.5.3 Mesurage du gaz à l’aide d’un dispositif volumétrique (voir l’Annexe B)

Le biogaz produit peut être collecté dans un tube en verre gradué séparé de l’atmosphère par une

solution barrière de manière que la pression reste quasiment constante (excepté les variations de

pression atmosphérique) pendant l’essai. Après incubation des récipients préparés à (35 ± 2) °C pendant

environ 1 h, purger le gaz en excès dans l’atmosphère, par exemple en agitant chaque récipient l’un après

l’autre, en insérant l’aiguille d’une seringue à travers le joint du septum et en laissant le gaz s’échapper

jusqu’à ce que la surface de la solution barrière dans le tube en verre gradué atteigne le zéro. S’assurer

que la surface de la solution barrière dans le vase d’expansion est au même niveau que dans le tube de

collecte de gaz. Retirer l’aiguille de la seringue et poursuivre l’incubation dans l’obscurité, en s’assurant

que toutes les parties des récipients sont maintenues à la température d’incubation.

Les relevés du volume de gaz peuvent être effectués directement à partir du tube de collecte de gaz.

Avant d’effectuer un relevé, amener la surface du liquide dans le vase d’expansion au même niveau que la

surface du liquide dans le tube de collecte pour que le volume de gaz soit lu à la pression atmosphérique

(voir l’Annexe B pour les instructions correspondantes). Effectuer un nombre suffisant de mesurages

du volume de gaz, de la pression et de la température (normalement chaque jour) pour déterminer la

vitesse de production de gaz. Des relevés plus fréquents peuvent être exigés lors des premières étapes,

leur fréquence pouvant être réduite par la suite.

7.6 Durée de l’essai

La durée normale de l’essai est de 60 j. L’essai peut être arrêté plus tôt si la courbe de biodégradation

obtenue à partir des mesurages de pression ou de volume a atteint la phase stationnaire (voir 3.12). Si,

à la fin de la période d’incubation normale, la phase stationnaire n’a visiblement pas été atteinte, l’essai

peut être prolongé jusqu’à ce qu’elle le soit. Toutefois, la durée de l’essai ne doit pas dépasser 90 j.

7.7 Mesurage du carbone inorganique

À la fin de l’essai, après le dernier mesurage de la pression de gaz ou l’augmentation du volume de gaz,

laisser la boue décanter, ouvrir chaque récipient et déterminer immédiatement la concentration en

carbone inorganique (CI) (en mg/l) dans le liquide surnageant. Le liquide surnageant ne doit pas être

centrifugé ni filtré à ce stade (voir la Note). Après le mesurage du CI, enregistrer le pH. Réaliser des

mesurages similaires pour les blancs, le matériau de référence et toute substance de contrôle facultative.

Autrement, le CI dans le liquide surnageant peut être déterminé indirectement par la libération de CI

dissous sous forme de dioxyde de carbone qui peut être mesurée dans l’espace de tête. Après le dernier

mesurage de pression de gaz, ajuster la pression dans chacun des récipients d’essai à la pression

atmosphérique. Acidifier le contenu de chaque récipient à environ pH 1 en ajoutant de l’acide minéral

concentré (par exemple 1M de H PO ou 1M de H SO ) à travers le septum des récipients fermés.

3 4 2 4

Incuber les récipients agités à (35 ± 2) °C pendant environ 24 h et mesurer la pression de gaz résultant

du dioxyde de carbone libéré à l’aide d’un pressiomètre.

NOTE La centrifugation ou la filtration conduirait à une perte inacceptable de dioxyde de carbone dissous. Si

l’échantillon de liquide surnageant ne peut pas être analysé immédiatement, il peut être conservé dans un flacon

fermé adapté, sans espace de tête, à environ 4 °C pendant une durée allant jusqu’à 2 j.

Dans certains cas, en particulier si les mêmes blancs et substances de contrôle sont utilisés pour

plusieurs matériaux d’essai différents, étudier la possibilité de mesurer les concentrations en CI

intermédiaires dans les récipients d’essai et de contrôle. Dans ce cas, suivre le mode opératoire ci-après.

Après avoir mesuré la pression de gaz ou l’augmentation du volume sans purger le gaz en excès, prendre

une partie aliquote du liquide surnageant aussi petite que possible en insérant une seringue à travers le

septum sans ouvrir le récipient et déterminer le CI dans l’échantillon. Après avoir prélevé l’échantillon,

le gaz en excès peut être purgé du récipient (voir 7.5).

Noter que même une petite diminution du volume de liquide surnageant (par exemple d’environ 1 %)

peut produire une augmentation significative du volume de l’espace de tête. Corriger la Formule (3) en

8.2 en augmentant V si nécessaire.

H

7.8 Analyses spécifiques

Si la biodégradabilité anaérobie primaire doit être déterminée, réaliser des analyses spécifiques du

matériau d’essai dans le flacon du réplicat (voir 7.4) au début et à la fin de l’essai. Le cas échéant, noter

que le volume de l’espace de tête (V ) et du liquide (V ) seront modifiés et que cela devra être pris en

H L

considération lors du calcul des résultats.

8 Calcul et expression des résultats

8.1 Quantité de carbone dans l’espace de tête

1 mole de méthane et 1 mole de dioxyde de carbone contiennent chacune 12 g de carbone. Calculer la

teneur en carbone d’un volume donné de gaz libéré à l’aide de la Formule (1):

mn=⋅12000 (1)

où

m est la masse de carbone, en milligrammes, dans un volume donné de gaz libéré;

12 000 est la masse atomique relative du carbone, en milligrammes;

n est le nombre de moles de gaz.

10 © ISO 2016 – Tous droits réservés

8.2 Calcul de la quantité de carbone dans l’espace de tête avec une méthode de mesure

manométrique

Calcul

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...