ISO 23409:2011

(Main)Male condoms — Requirements and test methods for condoms made from synthetic materials

Male condoms — Requirements and test methods for condoms made from synthetic materials

ISO 23409:2011 specifies the minimum requirements and the test methods applicable to male condoms produced from synthetic materials or blends of synthetic materials and natural rubber latex which are used for contraceptive purposes and to aid in the prevention of sexually transmitted infections.

Préservatifs masculins — Exigences et méthodes d'essai pour les préservatifs fabriqués en matières synthétiques

General Information

- Status

- Published

- Publication Date

- 02-Feb-2011

- Technical Committee

- ISO/TC 157 - Non-systemic contraceptives and STI barrier prophylactics

- Drafting Committee

- ISO/TC 157 - Non-systemic contraceptives and STI barrier prophylactics

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 03-Dec-2021

- Completion Date

- 14-Feb-2026

Overview

ISO 23409:2011 - "Male condoms - Requirements and test methods for condoms made from synthetic materials" - specifies minimum requirements and test methods for male condoms manufactured from synthetic materials or blends of synthetic materials and natural rubber latex. The standard covers design, preclinical and clinical evaluation, lot-by-lot quality verification, physical performance (bursting, holes, dimensions), biocompatibility, packaging integrity, labelling and shelf-life. It is intended to ensure condoms function effectively for contraception and in helping to prevent sexually transmitted infections (STIs).

Key topics and technical requirements

- Scope and definitions: Clarifies terms such as lot, individual container, expiry date, visible/non-visible holes, shelf-life.

- Design and product claims: Requirements for fit, retention, strength and barrier validation to infectious agents and spermatozoa.

- Preclinical and clinical evaluation: Guidance on laboratory testing and clinical investigations to demonstrate safety and effectiveness before routine lot testing.

- Physical performance tests:

- Bursting volume and pressure testing (annexes describe methods).

- Freedom from holes (water/electrical/bacteriophage methods referenced in annexes).

- Dimensions and thickness measurements (length, width, thickness).

- Biocompatibility: Evaluation of materials and additives to avoid toxicity, sensitization or irritation (referenced ISO 10993 series).

- Sampling and lot release: Lot-by-lot sampling plans and inspection schemes (Annex A/B; ISO 2859-1) for ongoing quality verification.

- Stability and shelf-life: Real-time stability tests, accelerated ageing guidance and determination of expiry date.

- Packaging and labelling: Individual container integrity tests, consumer package labelling and traceability requirements.

- Documentation: Required data sheets and test reports for regulatory compliance and traceability.

Practical applications

- Manufacturer quality systems: design controls, production validation and routine lot release testing.

- Regulatory submissions: evidence for safety, performance and shelf-life in conformity assessments.

- Test laboratories: standardized methods for burst, hole, dimensional, lubricant and packaging integrity testing.

- Procurement and public health programs: product selection criteria and supplier audits for condoms used in family planning and STI prevention.

Who should use ISO 23409:2011

- Condom manufacturers and R&D teams

- Quality assurance / regulatory affairs professionals

- Independent testing laboratories

- Public health procurers and NGOs

- Notified bodies and regulators assessing medical device conformity

Related standards (select)

- ISO 4074 - Natural latex rubber condoms

- ISO 2859-1 - Sampling procedures (AQL)

- ISO 10993 series - Biological evaluation of medical devices

- ISO 13485, ISO 14971 - Quality and risk management for medical devices

- ISO 16037 - Measurement of physical properties for condoms

Keywords: ISO 23409, male condoms, synthetic condoms, test methods, bursting pressure, freedom from holes, shelf-life, sampling plans, biocompatibility, packaging integrity.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

Sponsored listings

Frequently Asked Questions

ISO 23409:2011 is a standard published by the International Organization for Standardization (ISO). Its full title is "Male condoms — Requirements and test methods for condoms made from synthetic materials". This standard covers: ISO 23409:2011 specifies the minimum requirements and the test methods applicable to male condoms produced from synthetic materials or blends of synthetic materials and natural rubber latex which are used for contraceptive purposes and to aid in the prevention of sexually transmitted infections.

ISO 23409:2011 specifies the minimum requirements and the test methods applicable to male condoms produced from synthetic materials or blends of synthetic materials and natural rubber latex which are used for contraceptive purposes and to aid in the prevention of sexually transmitted infections.

ISO 23409:2011 is classified under the following ICS (International Classification for Standards) categories: 11.200 - Birth control. Mechanical contraceptives. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 23409:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 23409

First edition

2011-02-15

Male condoms — Requirements and test

methods for condoms made from

synthetic materials

Préservatifs masculins — Exigences et méthodes d'essai pour les

préservatifs fabriqués en matières synthétiques

Reference number

©

ISO 2011

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2011

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2011 – All rights reserved

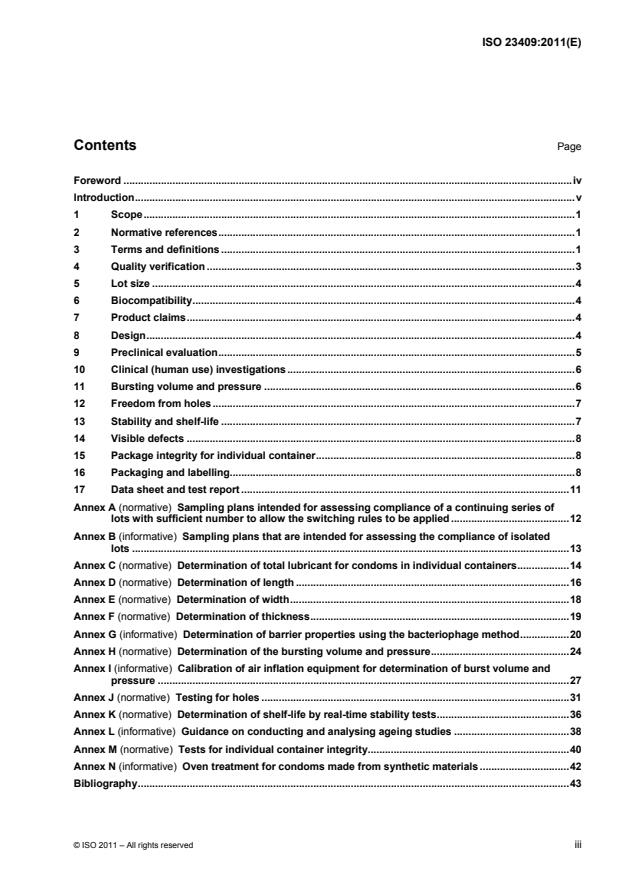

Contents Page

Foreword .iv

Introduction.v

1 Scope.1

2 Normative references.1

3 Terms and definitions .1

4 Quality verification .3

5 Lot size .4

6 Biocompatibility.4

7 Product claims.4

8 Design.4

9 Preclinical evaluation.5

10 Clinical (human use) investigations.6

11 Bursting volume and pressure .6

12 Freedom from holes.7

13 Stability and shelf-life .7

14 Visible defects .8

15 Package integrity for individual container.8

16 Packaging and labelling.8

17 Data sheet and test report .11

Annex A (normative) Sampling plans intended for assessing compliance of a continuing series of

lots with sufficient number to allow the switching rules to be applied .12

Annex B (informative) Sampling plans that are intended for assessing the compliance of isolated

lots .13

Annex C (normative) Determination of total lubricant for condoms in individual containers.14

Annex D (normative) Determination of length .16

Annex E (normative) Determination of width.18

Annex F (normative) Determination of thickness.19

Annex G (informative) Determination of barrier properties using the bacteriophage method.20

Annex H (normative) Determination of the bursting volume and pressure.24

Annex I (informative) Calibration of air inflation equipment for determination of burst volume and

pressure .27

Annex J (normative) Testing for holes .31

Annex K (normative) Determination of shelf-life by real-time stability tests.36

Annex L (informative) Guidance on conducting and analysing ageing studies .38

Annex M (normative) Tests for individual container integrity.40

Annex N (informative) Oven treatment for condoms made from synthetic materials .42

Bibliography.43

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 23409 was prepared by Technical Committee ISO/TC 157, Non-systemic contraceptives and STI barrier

prophylactics.

iv © ISO 2011 – All rights reserved

Introduction

Synthetic condoms can be made from 100 % synthetic materials or a blend of synthetic materials and natural

rubber latex. The material(s) used in synthetic condoms should be validated as constituting a barrier to human

immunodeficiency virus (HIV), to other infectious agents responsible for the transmission of sexually

transmitted infections (STIs), and to spermatozoa. It is essential that the condoms fit the penis properly, remain

on the penis during use, are free from holes and have adequate physical strength so as not to break or tear

during use so that the condoms can be deemed to be effective for contraceptive purposes and in order to help

prevent the transmission of STIs. It is also important that they be correctly packaged so that they are

protected during storage and suitably labelled. All of these issues are addressed in this International Standard.

To be safe, it is essential that the condom and any lubricant, additive, marking materials, dressing, individual

packaging material or powder applied to it neither contain nor liberate substances in amounts that are toxic,

likely to produce allergies (sensitization), locally irritating or otherwise harmful under normal conditions of

storage and use.

Condoms are medical devices. To ensure high quality product, it is essential that condoms be produced under

[4]

a quality management system using design controls. Reference can be made, for example, to ISO 9001 , to

[8] [9]

ISO 14971, and to ISO 13485 . Additional guidance can be found in ISO 16038 .

Condoms are non-sterile medical devices; however, a clean environment is essential to minimize

microbiological contamination of the product during manufacturing and packaging.

Condoms can be of the designs given in the following terms, which are not intended to be exhaustive: smooth,

textured, parallel-sided, non-parallel-sided, plain-ended, reservoir-ended, dry, lubricated, transparent,

translucent, opaque, coloured, preshaped, welded or non-welded.

This International Standard specifies preclinical, clinical, and lot-by-lot physical requirement testing for

condoms made from synthetic materials, including condoms made from a blend of synthetic materials and

natural rubber latex. Application of lot-by-lot testing requirements becomes relevant only after the preclinical and

clinical requirements of this International Standard have been met.

INTERNATIONAL STANDARD ISO 23409:2011(E)

Male condoms — Requirements and test methods for condoms

made from synthetic materials

1 Scope

This International Standard specifies the minimum requirements and the test methods applicable to male

condoms produced from synthetic materials or blends of synthetic materials and natural rubber latex which

are used for contraceptive purposes and to aid in the prevention of sexually transmitted infections.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 2859-1, Sampling procedures for inspection by attributes — Part 1: Sampling schemes indexed by

acceptance quality limit (AQL) for lot-by-lot inspection

ISO 4074, Natural latex rubber condoms — Requirements and test methods

ISO/TR 8550 (all parts), Guidance on the selection and usage of acceptance sampling systems for inspection

of discrete items in lots

ISO 10993-1, Biological evaluation of medical devices — Part 1: Evaluation and testing within a risk

management process

ISO 10993-5, Biological evaluation of medical devices — Part 5: Tests for in vitro cytotoxicity

ISO 10993-10, Biological evaluation of medical devices — Part 10: Tests for irritation and skin sensitization

ISO 14155, Clinical investigation of medical devices for human subjects — Good clinical practice

ISO 14971, Medical devices — Application of risk management to medical devices

ISO 15223 (all parts), Medical devices — Symbols to be used with medical device labels, labelling, and

information to be supplied

ISO 16037, Rubber condoms for clinical trials — Measurement of physical properties

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 2859-1 and the following apply.

3.1

acceptance quality limit

AQL

quality level that is the worst tolerable process average when a continuing series of lots is submitted for

acceptance sampling

[ISO 2859-1:1999, 3.1.26]

3.2

male condom

medical device, intended to cover and to be retained on the penis during sexual activity, used by consumers

for purposes of contraception and prevention of sexually transmitted infections

NOTE If a consumer can responsibly consider a device to be a male condom (due to its shape, packaging, etc.) it is

considered to be a male condom for the purposes of this International Standard.

3.3

consumer package

package, intended for distribution to a consumer, containing one or more individual containers of condoms

3.4

expiry date

date after which a condom is not suitable for use

3.5

identification number

number, or combination of numerals, symbols or letters, used by a manufacturer on consumer packages to

identify uniquely the lot numbers of individual condoms contained in that package, and from which it is

possible to trace those lots through all stages of manufacturing, packaging and distribution

NOTE When the consumer package contains only one type of condom, then the identification number can be the

same as the lot number. However, if the consumer package contains several different types of condoms, e.g. condoms

of different shapes or colours, then the identification number is different from the lot numbers.

3.6

individual container

primary package containing a single condom

3.7

inspection level

relationship between lot size and sample size

NOTE For a description, see ISO 2859-1:1999, 10.1.

3.8

lot

collection of condoms of the same design, colour, shape, size and formulation, manufactured at essentially

the same time, using the same process, raw materials of the same specifications and common equipment,

and packed with the same lubricant and any other additive or dressing in the same type of individual container

3.9

lot number

number, or combination of numerals, symbols or letters, used by the manufacturer to identify a lot of

individually packaged condoms, and from which it is possible to trace that lot through all the stages of

manufacture up to packaging

3.10

lot test

test to assess the conformity of a lot

NOTE A lot test may be limited to include only those parameters that can change from lot to lot.

3.11

non-visible hole

hole in a condom that is not visible under normal or corrected vision, but is detected by a suitable water leak

test or electrical test

NOTE Suitable tests are specified in this International Standard.

2 © ISO 2011 – All rights reserved

3.12

sampling plan

specific plan which indicates the number of units of product from each lot which are to be inspected (sample size

or series of sample sizes) and the associated criteria for determining the acceptability of the lot (acceptance and

rejection numbers)

3.13

shelf-life

period from date of manufacture, during which condoms are required to conform to specified requirements for

burst pressure, burst volume, freedom from holes, and pack integrity

NOTE Suitable requirements are specified in this International Standard.

3.14

synthetic material

any base material other than 100 % natural rubber latex that is used to make condoms

NOTE This term applies to both condoms made from all synthetic materials and to condoms made from synthetic and

latex blends.

3.15

visible hole

hole in the condom that is visible under normal or corrected vision before the condom is filled with water or

electrolyte during testing for freedom from holes

3.16

date of manufacture

date of sheath formation or the date the condoms are packed in their individual containers provided that, in the

latter case, a maximum period of bulk storage is specified and shelf-life studies have been conducted on

condoms that have been subjected to the maximum bulk storage period

3.17

visible defect (other than hole or tear)

broken, missing or severely distorted rim, and permanent creases with adhesion of the film

4 Quality verification

Condoms are mass produced articles manufactured in very large quantities. Inevitably, there is some variation

between individual condoms, and a small portion of condoms in each production run that might not meet the

requirements of this International Standard. Further, the majority of the test methods described in this

International Standard are destructive. For these reasons, the only practicable method of assessing

conformity with this International Standard is by testing a representative sample from a lot or series of lots.

Basic sampling plans are given in ISO 2859-1. Refer to ISO/TR 8550 for guidance on the selection of an

acceptance sampling system, scheme or plan for the inspection of discrete items in a lot. For testing purposes,

sampling shall be conducted by lot number, not by identification number.

When ongoing verification is required of the quality of condoms, it is recommended that, instead of

concentrating solely on evaluation of the final product, the party concerned also directs their attention to the

[3]

manufacturer's quality system. In this connection it should be noted that the ISO 9000 family and in

[8]

particular ISO 13485 cover the provision of an integrated quality system.

Sampling plans shall be selected to provide an acceptable level of consumer protection. Suitable sampling

plans are given in Annexes A and B.

a) Annex A describes sampling plans based on ISO 2859-1 and is most applicable to manufacturers or

purchasers assessing the conformity of a continuing series of lots. The full level of consumer protection

available depends upon the switch to tightened inspection if deterioration in quality is detected. The

switching rules cannot offer their full protection for the first two lots tested, but become progressively more

effective as the number of lots in a series increases. The sampling plans in Annex A are recommended

when five or more lots are being tested.

b) Annex B describes sampling plans, based on ISO 2859-1, that are recommended for the assessment of

isolated lots. The sampling plans in Annex B provide approximately the same level of consumer

protection as those given in Annex A when used with switching rules. It is recommended that these

sampling plans be used for the assessment of fewer than five lots, e.g. in cases of dispute, for referee

purposes, for type testing, for qualification purposes or for short runs of continuous lots.

c) Handling and storage conditions shall be documented before drawing the samples.

It is necessary to know the lot size in order to derive from ISO 2859-1 the number of condoms to be tested.

The lot size varies between manufacturers and is regarded as part of the process and quality controls used by

the manufacturer.

5 Lot size

The maximum individual lot size for production is 500 000.

Otherwise, this International Standard does not specify the size of a lot, but it is possible for a purchaser to do

so as part of the purchasing contract. Purchasers are encouraged to specify a lot size compatible with the

manufacturer's quality management system.

6 Biocompatibility

For any product which is new or which has undergone a significant change to the formulation or

manufacturing process, biocompatibility assessments shall be conducted in accordance with ISO 10993-1.

Testing for cytotoxicity according to ISO 10993-5, irritation according to ISO 10993-10, and sensitization

(delayed contact hypersensitivity) according to ISO 10993-10 shall be conducted. Many synthetic products

that have been established as safe, including condoms and medical gloves, can exhibit a positive cytotoxic

response when tested according to ISO 10993-5. While any cytotoxic effect can be of concern, it is primarily

an indication of potential for in vivo toxicity and a condom cannot necessarily be determined to be unsuitable

for use based solely on cytotoxicity data. The condom together with the any lubricant, additive, dressing

material, or powder applied to it shall be tested. Regulatory bodies might also specify specific local

requirements. Accredited laboratories shall be used for the testing. Regulatory bodies might require the results

to be interpreted by a qualified toxicologist or other suitably qualified expert. The biological assessment report

shall justify that the product is safe under normal conditions of use.

7 Product claims

Condoms meeting the requirements of this International Standard can be used for contraceptive purposes and

help protect against sexually transmitted infections. Manufacturers shall justify any additional claims made for

their products. If a manufacturer makes a claim relating to improved efficacy or safety then the claim shall be

substantiated by clinical investigation. Manufacturers shall make information justifying such claims available to

regulatory bodies, notified bodies, and consumer protection authorities.

8 Design

8.1 Retention mechanism

If a mechanism to retain the condom on the penis or an integral bead is required by the condom design, then

it shall comply with Clause 14.

4 © ISO 2011 – All rights reserved

8.2 Lubrication

If verification is required of the quantity of lubricant in a package, the method given in Annex C shall be used.

The criteria of compliance shall be as agreed between the parties concerned.

The method in Annex C also recovers part of the dressing powder on the condom. An allowance should be

made for this when manufacturers or purchasers specify lubricant levels.

8.3 Dimensions

8.3.1 Length

When tested according to the method given in Annex D, taking 13 condoms from each lot, no individual

measurement shall be below 160 mm.

8.3.2 Width

When tested by the method given in Annex E, measuring at the narrowest part of the condom in the range of

20 mm to 50 mm from the open end, taking 13 condoms from each lot, no measurement of the width shall

deviate from the nominal width stated by the manufacturer by more than ±2 mm.

Where the design of the condom is such that this measurement cannot be made reliably or the narrowest

point within the first 50 mm from the open end of the condom is at the bead, the method of measurement shall

be provided by the manufacturer.

8.3.3 Thickness

If verification is required of the thickness of a condom, the thickness, determined in accordance with the

method given in Annex F, shall be equal to the claimed thickness, subject to a tolerance of:

a) ±0,008 mm for condoms with thickness less than 0,05 mm;

b) ±0,01 mm for condoms with thickness between 0,05 mm and 0,08 mm;

c) ±0,015 mm for condoms with thickness greater than 0,08 mm.

9 Preclinical evaluation

A risk analysis of the product shall be conducted in accordance with ISO 14971. The analysis shall identify

safety and efficacy concerns, and shall address at least the areas where the risks are in excess of those

encountered with natural rubber latex condoms conforming to ISO 4074.

The barrier properties of the condom shall be established by viral penetration studies using simulated use

conditions and a suitable surrogate virus, e.g. bacteriophage phiX 174. Viral penetration properties shall be

compared with those of a latex condom that meets the requirements of ISO 4074. A suitable procedure for

conducting these studies is given in Annex G. The number of test condoms exhibiting leakage of virus

−6

suspension fluid above the detection limit of 2 ¯ 10 ml should not be significantly worse than for the control

latex condom. Appropriate statistical procedures may be used to analyse the results using a 95 % confidence

interval.

Biocompatibility for the finished product and its components shall be established in accordance with the

relevant clauses of ISO 10993-1, ISO 10993-5, and ISO 10993-10. Condoms are a surface device with

repeated contact with mucosa and possibly compromised tissue surfaces. The tests shall indicate whether the

device produces cytotoxicity, sensitization, or mucosal irritation. It is possible for additional testing, e.g. for

[6]

systemic toxicity in accordance with ISO 10993-11 , to be required, depending upon the nature of the

materials used or to meet local regulatory requirements. If there is a likelihood of systemic absorption of any

components or residuals, mutagenicity testing shall be performed. Regulatory bodies can require the results to

be interpreted by a qualified toxicologist or suitably qualified scientist. The biological assessment report shall

justify that the product is safe under normal conditions of use.

All data generated in these investigations shall be available to regulatory authorities on request.

The manufacturer shall obtain, and make available on request from regulatory authorities, toxicity data on all

the additives and residual monomers, residual solvents and known impurities resulting from the manufacture

of the condom. Suitable material safety data sheets are to be supplied as requested for materials used in the

manufacture of products in compliance with this International Standard.

10 Clinical (human use) investigations

The manufacturer shall conduct a randomized controlled clinical investigation comparing the synthetic condom

to a control condom made from natural rubber latex.

a) Clinical investigations in humans shall be conducted in accordance with local regulatory requirements, as

well as ISO 14155.

b) The clinical failure rate (combined slippage and breakage rates) of the synthetic condom shall be non-

inferior to the clinical failure rate of the control condom made from natural rubber latex.

c) In order to demonstrate non-inferiority the upper limit of the one-sided 95 % confidence interval for the

test condom clinical failure rate minus the control condom clinical failure rate shall be less than or equal to

2,5 %.

The limit shall be calculated using a method that accounts for the unique characteristics of data such as:

1) each study participant may contribute data from more than one condom use;

2) very low event rates.

d) For the control condom, the clinical failure rate shall be less than 4,0 %.

e) The control condom shall be made from natural rubber latex and shall conform to ISO 4074.

f) The physical properties of the natural rubber control condom shall be determined in accordance with

ISO 16037.

[10]

NOTE See ISO 29943-1 .

For products in the market prior to the publication of this International Standard, manufacturers may use data

from existing clinical investigations. Information on the studies shall be made available to regulatory and

governmental authorities upon request.

11 Bursting volume and pressure

Manufacturers shall establish appropriate minimum pressure and volume limits for the specific condom based

on the airburst properties of the lot or lots used for the clinical trial. Determine the airburst properties of the lot

or lots used in the clinical study using a sample size of at least 2 000 condoms. If more than one lot was used

in the clinical study then the sample shall be drawn across all the lots, each individual lot being sampled

proportionally to its size. Set the minimum airburst limits at 80 % of the 1,5 percentile values of the airburst

volumes and pressures determined above.

6 © ISO 2011 – All rights reserved

For the purposes of this International Standard, the relevant percentile, x, shall be determined by ranking the

N data values and taking the value of the nth rank, where

Nx 1

n=+

100 2

rounded to the nearest integer (e.g. for N = 2 000, the lower 1,5 percentile is the 31st lowest value).

NOTE 1 Based on data supplied by manufacturers for both synthetic and natural rubber latex condoms, taking 80 % of

the 1,5 percentile values provides an adequate tolerance for the long-term lot-to-lot variability seen in normal manufacture.

For products in the market prior to the publication of this International Standard, manufacturers may use

existing specifications as established by their regulatory bodies for bursting properties, subject to those

specifications being consistent with the above requirements based on a representative sample of the product

tested at the time of the clinical trial. Information regarding the establishment of these values shall be made

available to regulatory and governmental authorities upon request.

[32]

NOTE 2 To ensure that the limits are appropriate, testing can be done by a laboratory accredited to ISO/IEC 17025 ,

by an accreditation body, or organization that is a member of the International Laboratory Accreditation Cooperation.

When tested using the methods given in Annex H, the bursting volumes and bursting pressures shall not be

less than the minimum values specified above. The compliance level shall be an acceptance quality limit

(AQL) of 1,5 for non-conforming condoms. A non-conforming condom is defined as a condom that fails the

requirements for volume, pressure or both, or any condom that exhibits obvious leakage.

12 Freedom from holes

When tested by the methods described in Annex J, the compliance level for each lot, for the sum of condoms

with visible and non-visible holes and tears, shall be an AQL of 0,25.

13 Stability and shelf-life

13.1 General

Manufacturers shall verify that the condoms comply with the requirements of Clauses 11, 12, and 15 until the

end of the shelf-life on the label. Shelf-life claims shall not exceed 5 years.

Data supporting shelf-life claims shall be made available to the appropriate regulatory authorities and direct

purchasers upon request.

Before compliance with this International Standard may be claimed, the manufacturer shall provide evidence

that:

a) a real-time study as described in 13.2 to determine shelf-life has commenced;

b) pending completion of the real-time study, shelf-life claims as described in 13.3 can be substantiated.

13.2 Procedure for determining shelf-life by real-time stability studies

After testing according to Annex K, the condom shall meet the requirements of Clauses 11, 12 and 15.

If the real-time data indicate a shorter shelf-life than that claimed on the basis of accelerated ageing (13.3),

the manufacturer shall notify the relevant regulatory authorities and direct purchasers. The manufacturer shall

change the shelf-life claims for the product to the one based on the real-time study. In no case shall the shelf-

life exceed 5 years.

For condoms placed on the market based on accelerated stability studies, real-time stability studies shall be

completed for the full period of the shelf-life claim.

13.3 Estimating shelf-life based upon accelerated stability studies

Pending the completion of real-time studies, manufacturers shall substantiate the original shelf-life claims.

Accelerated stability studies may be used for this purpose.

Further information on stability studies is provided in Annex L. Data generated from such studies should

support the claim that the condoms fulfil the requirements in Clauses 11, 12, and 15 for the duration of the

+5

shelf-life on the label at 30 °C.

−2

14 Visible defects

For visible defects as described in Annex J (J.2.3.3), the compliance level for each lot shall be an AQL of 0,4.

15 Package integrity for individual container

When an individual container comprising one or more flexible laminated films sealed together is tested in

accordance with Annex M, it shall pass the test. The compliance level for each test shall be an AQL of 2,5. An

AQL of 0,4 shall be applied to individual containers that have visibly open seals.

For other designs of individual containers, the manufacturer shall apply a suitable pack integrity test. The

compliance level for each test shall be an AQL of 2,5. The method given in Annex M may be used with

suitable adjustment to the level of vacuum applied. Details of the test method shall be provided on request.

16 Packaging and labelling

16.1 Packaging

Each condom shall be packed in an individual container. One or more individual containers may be packed in

other packaging such as a consumer package. The individual container, or consumer package or both, shall

protect the condom from environmental damage as is appropriate for the product. If condoms are supplied

directly to consumers in individual containers then the individual container shall be regarded as a consumer

package and shall meet all the labelling requirements.

Any marking medium, such as ink, used on a condom or any part of the package directly in contact with the

condom, shall not have a deleterious effect on the condom or be harmful to the user.

Individual containers and any other packaging shall protect the condom from damage during transport or

storage. Individual containers and any other packaging shall be designed in such a way that the package can

be opened without damaging the condom. The design of the individual container should facilitate easy

opening.

Manufacturers shall ensure that each lot complies with the established specification for packaging.

16.2 Labelling

NOTE National or other regulations relating to labelling, e.g. for latex allergy, which could be more stringent, can

apply.

16.2.1 Symbols

Any symbols used on packaging, information, and marketing materials shall meet the requirements of

ISO 15223.

8 © ISO 2011 – All rights reserved

16.2.2 Individual container

Each individual container shall be indelibly and legibly marked with at least the following information:

a) the identity of the manufacturer or distributor or, if permitted by local regulations, the registered brand or

trade mark;

b) the manufacturer's identifying reference for traceability (e.g. the lot number);

c) the expiry date (year and month) — the format of the year shall be in four digits and the format of the

month shall be in letters or two digits.

If the individual container is distributed outside a consumer pack within Europe then the CE Mark and address

of the manufacturer or European Authorized Representative shall be printed on the individual pack and the

requirements of 16.2.4 shall be met.

16.2.3 Consumer package

16.2.3.1 General. Where products are supplied for distribution in consumer packages, the packages shall

conform to the requirements of 16.2.3.2 and 16.2.3.3.

16.2.3.2 Consumer package exterior. The outside of the consumer package shall bear at least the

following information in at least one of the official languages of the country of destination or as stipulated

differently by that country or the purchaser and the seller:

a) a description of the condom, whether it is contoured or has a reservoir, and if it is coloured or textured;

b) the number of condoms contained in the consumer package;

c) the nominal width of the condom;

d) the name or trade name and address of the manufacturer and/or distributor, depending on national and

regional requirements;

e) the expiry date (year-month or month-year). If a consumer package contains condoms from different lots,

the earliest expiry date shall apply to all condoms;

f) a statement of storage instructions appropriate for the material used;

g) conditions that are impervious to light or other environmental conditions deleterious to the packaging of

the condom;

h) whether the condom is lubricated or dry — when a medicinal ingredient is added, it shall be identified and

its purpose indicated (e.g. spermicidal), and if the condom or lubricant is fragranced or flavoured, this

shall also be stated;

i) the manufacturer's identifying reference for traceability (e.g. the identification number/lot number) — if

different types of condoms, e.g. of different colours, are packaged together in the same consumer

package, the identification number on the consumer package shall allow the manufacturer to identify

uniquely the lot numbers of the individual condoms contained in that package, so that it is possible to

trace those lots through all stages of manufacture up to packaging;

j) a statement indicating the type of synthetic material used, and whether the material contains natural

rubber;

k) a statement indicating that the condom is for single use;

l) the number of this International Standard (ISO 23409:2010);

m) any other applicable warning as required;

n) if necessary, a statement alerting consumers to any potential allergic reactions as a result of product use.

16.2.3.3 Instructions for use. The outside or the inside of the consumer package, or a leaflet contained

within the consumer package, shall bear at least the following instructions for use expressed in simple terms

and in at least one of the official languages of the country of destination, if possible supplemented by pictorial

representation of the major steps involved or as stipulated differently by that country:

a) the need to handle the condom carefully, including removal from the packaging in order to avoid damage

to the condom with fingernails, jewellery, etc.;

b) how and when to put on the condom; mention should be made that the condom should be placed on the

erect penis before any contact occurs between the penis and the partner's body so as to assist in the

prevention of sexually transmitted infections and pregnancy;

c) the need to stop and check if the user feels the condom slipping or tightening excessively on to the penis

because this can lead to breakage;

d) the need to withdraw the penis soon after ejaculation, while holding the condom firmly in place at the

base of the penis;

e) the need, if an additional lubricant is desired, to use the correct type of lubricant which is recommended

for use with the type of condom concerned;

f) the need to consult a doctor or pharmacist about the compatibility of topical medicines that might come in

contact with the condom;

g) advice to seek medical assistance as soon as possible, at least within 72 h should a condom leak or burst

during use;

h) advice that if the individual container is obviously damaged to discard that condom and use a new one

from an undamaged package;

i) instructions on how to dispose of the used condom;

j) a statement that the condom is for single use — if the condom is reused there might be an increased risk

of failure or infection;

k) the number of this International Standard (ISO 23409:2011);

l) the date of issue or the date of the latest revision of the instructions for use.

16.2.4 Condoms not distributed in consumer packages

For condoms that are distributed without a consumer package (e.g. in single foils or strips of foils), it is the

responsibility of the organization distributing the condoms to ensure that adequate information is supplied to

the user in accordance with local regulations. The individual condom containers shall comply with local

labelling requirements. If such condoms are for distribution in Europe, the labelling should be in accordance

[30] [31]

with the European Medical Device Directive 93/42/EEC as modified by 2007/47/EC .

This information may be in the form of leaflets, training sessions, posters, or additional packing added in the

distribution chain. For guidance on the content, see 16.2.3.2 and 16.2.3.3.

16.3 Inspection

For each lot, 13 consumer packages and 13 individual containers shall be inspected for conformity. All

inspected containers shall conform to the requirements of this International Standard.

Under certain conditions, it might be permissible for the manufacturer or distributor to correct faults associated

with packaging and labelling requirements and to resubmit the lot for further conformity testing. Examples

include insertion of missing instruction leaflets or the re-packaging of individual containers into entirely new

complete consumer packages before placing on the market.

10 © ISO 2011 – All rights reserved

If condoms of the same lot are packed into different consumer packages, then at least one consumer package

of each variant should be inspected. The number of packages inspected should not exceed 13, unless the

number of variants exceeds 13.

17 Data sheet and test report

17.1 Data sheet

The manufacturer shall make available to all interested parties a data sheet that contains, for each product

variant, at least the following information:

a) mean nominal dimensions (length, width, thickness);

b) airburst means and values for volume and pressure with limits based on testing according to Clause 11;

c) materials used in the construction of the condom;

d) nominal quantity and type of lubricant;

e) name and address of manufacturer and contractors (if appropriate);

f) reference to the clinical investigation conducted in accordance with Clause 10.

17.2 Test report

The test report shall contain at least the following information:

a) name and address of the test laboratory;

b) name and address of the client;

c) identification of the test report;

d) identification of the sample (sample size, lot number and lot size);

e) origin of the sample, date of the arrival of the sample in the laboratory, and who has taken the sample;

f) a reference to this International Standard (ISO 23409:2011) and the relevant annexes;

g) a listing of the minimum acceptance requirements for each applicable test (dimensions, freedom from

holes, airburst properties, package integrity, visible defects, quantity of lubricant, including measurements

and tolerances);

h) description of all deviations from this International Standard;

i) results according to the relevant annexes;

j) measurement error, if available;

k) date of the test report and the signature and title of the person(s) responsible for the report.

Normally it is recommended that condoms used in testing be destroyed after testing. Sometimes condoms

need to be kept to demonstrate particular problems. Thus it is important that the condoms be marked or

stored in such a way that unintentional use is prevented.

Annex A

(normative)

Sampling plans intended for assessing compliance of a continuing

series of lots with sufficient number to allow the switching rules

to be applied

A.1 Quality verification

When ongoing verification is required of the quality of condoms, it is suggested that, instead of concentrating

solely on evaluation of the final product, the party concerned also directs their attention to the manufacturer's

[3] [8]

quality system. In this connection it should be noted that the ISO 9000 family, and in particular ISO 13485 ,

covers the provision of an integrated quality system.

A.2 Sampling plans and compliance levels

If a party wishes to establis

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...