ISO/IEC 17594:2004

(Main)Information technology — Cases for 120 mm and 80 mm DVD-RAM disks

Information technology — Cases for 120 mm and 80 mm DVD-RAM disks

ISO/IEC 17594:2004 specifies the characteristics of a case for use with the 120 mm and 80 mm DVD-RAM disks specified in ISO/IEC 17592. ISO/IEC 17594:2004 specifies nine related, but different implementations of this case. ISO/IEC 17594:2004 specifies: the environments in which the cases are to be operated and stored; the dimensional and mechanical characteristics of the case, so as to provide mechanical interchangeability between data processing systems. ISO/IEC 17594:2004 provides for mechanical interchange between optical disk drives. Together with ISO/IEC 17592 for 120 mm (4,7 Gbytes per side) and 80 mm (1,46 Gbytes per side) DVD-RAM disks and a standard for volume and file structure, it provides for full data interchange between data processing systems.

Technologies de l'information — Coffrets pour disques DVD-RAM de 120 mm et 80 mm

General Information

- Status

- Published

- Publication Date

- 11-Jul-2004

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 21-Aug-2020

- Completion Date

- 12-Feb-2026

Overview

ISO/IEC 17594:2004 - Information technology - Cases for 120 mm and 80 mm DVD‑RAM disks - defines the physical and mechanical characteristics of cases (cartridges) used with DVD‑RAM optical media. The standard covers nine case implementations (Types 1–9) for 120 mm (4.7 Gbytes per side) and 80 mm (1.46 Gbytes per side) DVD‑RAM disks and specifies environments, dimensional tolerances and mechanical interfaces to ensure mechanical interchangeability between data processing systems and optical disk drives.

Key topics and technical requirements

- Case types and general description: Nine related but different case implementations with drawings and type-specific features.

- Environments: Test, operating, storage and transportation conditions under which cases must perform.

- Dimensional characteristics: Detailed overall dimensions, location and alignment holes, reference surfaces, insertion slots, gripper slots, label areas and identification marks for each case type.

- Mechanical characteristics: Requirements for material, mass, edge distortion, compliance and shutter opening force to ensure reliable handling and drive compatibility.

- Interface features: Spindle and head windows, capture cylinder dimensions, inner case dimensions and paths for shutter openers to enable standard mechanical interchange between drives and cartridges.

- Operational elements: Write‑inhibit/write‑protect holes, sensor holes and sensing areas, mis‑insertion protection slots and disk orientation guidance for one‑ and two‑sided disks.

- Safety and durability: Temperature shock, flammability and basic safety requirements to support long‑term storage and transport.

Applications and practical value

- Ensures interoperability between DVD‑RAM media, cartridges and optical drives across manufacturers.

- Guides manufacturers of optical media, cartridges and drive mechanisms in producing compatible hardware.

- Supports system integrators, archival storage providers and IT procurement teams who need assured mechanical interchange and reliable handling.

- Used by quality assurance, test engineers and design teams to define tolerances, test conditions and acceptance criteria for cases and cartridge‑style packaging.

- Useful for preserving media integrity in supply chains, archives and automated media libraries where consistent mechanical interface and labeling is required.

Who should use this standard

- Optical media and cartridge manufacturers

- Optical drive designers and OEMs

- Test laboratories and QA teams

- Data center, archival and media library administrators

- Procurement and compliance officers specifying media handling and interchangeability

Related standards

- ISO/IEC 17592 - DVD‑RAM disk characteristics (referenced by ISO/IEC 17594).

- Standards for volume and file structure (referenced for full data interchange).

Keywords: ISO/IEC 17594:2004, DVD‑RAM cases, 120 mm DVD‑RAM, 80 mm DVD‑RAM, optical disk cartridge, dimensional characteristics, mechanical interchangeability, shutter, write‑protect, sensor holes, spindle.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

NYCE

Mexican standards and certification body.

Sponsored listings

Frequently Asked Questions

ISO/IEC 17594:2004 is a standard published by the International Organization for Standardization (ISO). Its full title is "Information technology — Cases for 120 mm and 80 mm DVD-RAM disks". This standard covers: ISO/IEC 17594:2004 specifies the characteristics of a case for use with the 120 mm and 80 mm DVD-RAM disks specified in ISO/IEC 17592. ISO/IEC 17594:2004 specifies nine related, but different implementations of this case. ISO/IEC 17594:2004 specifies: the environments in which the cases are to be operated and stored; the dimensional and mechanical characteristics of the case, so as to provide mechanical interchangeability between data processing systems. ISO/IEC 17594:2004 provides for mechanical interchange between optical disk drives. Together with ISO/IEC 17592 for 120 mm (4,7 Gbytes per side) and 80 mm (1,46 Gbytes per side) DVD-RAM disks and a standard for volume and file structure, it provides for full data interchange between data processing systems.

ISO/IEC 17594:2004 specifies the characteristics of a case for use with the 120 mm and 80 mm DVD-RAM disks specified in ISO/IEC 17592. ISO/IEC 17594:2004 specifies nine related, but different implementations of this case. ISO/IEC 17594:2004 specifies: the environments in which the cases are to be operated and stored; the dimensional and mechanical characteristics of the case, so as to provide mechanical interchangeability between data processing systems. ISO/IEC 17594:2004 provides for mechanical interchange between optical disk drives. Together with ISO/IEC 17592 for 120 mm (4,7 Gbytes per side) and 80 mm (1,46 Gbytes per side) DVD-RAM disks and a standard for volume and file structure, it provides for full data interchange between data processing systems.

ISO/IEC 17594:2004 is classified under the following ICS (International Classification for Standards) categories: 35.220.30 - Optical storage devices. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/IEC 17594:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO/IEC

STANDARD 17594

First edition

2004-07-15

Information technology — Cases for

120 mm and 80 mm DVD-RAM disks

Technologies de l'information — Coffrets pour disques DVD-RAM de

120 mm et 80 mm

Reference number

©

ISO/IEC 2004

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO/IEC 2004

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO/IEC 2004 – All rights reserved

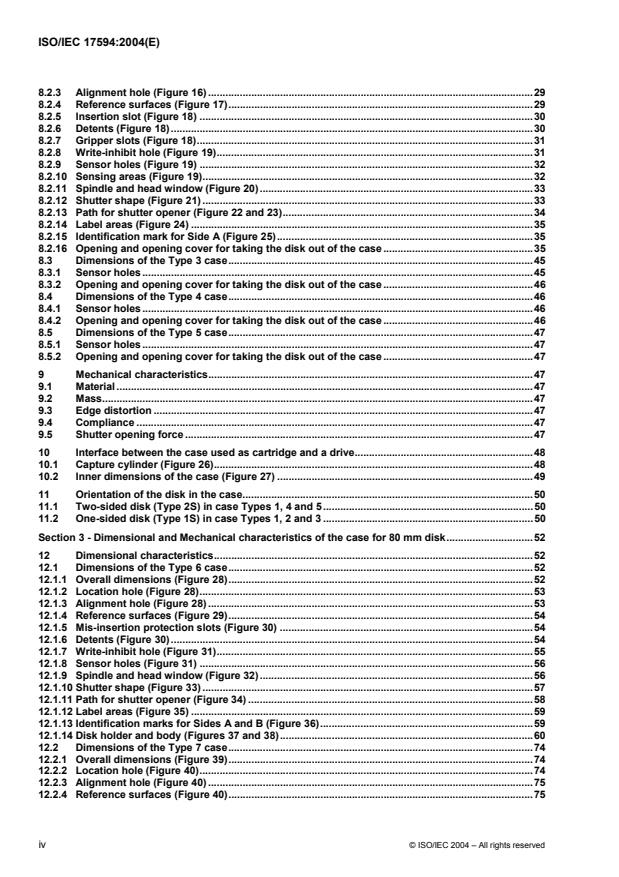

Contents Page

Section 1 - General. 1

1 Scope. 1

2 Conformance . 1

3 Normative references . 2

4 Definitions. 2

5 Conventions and notations. 2

5.1 Representation of numbers . 2

5.2 Names. 2

6 General description of the case . 2

6.1 General description of the Type 1 case (Figure 1) . 2

6.2 General description of the Type 2 case (Figure 2) . 2

6.3 General description of the Type 3 case (Figure 2) . 3

6.4 General description of the Type 4 case (Figure 3) . 4

6.5 General description of the Type 5 case (Figure 3) . 4

6.6 General description of the Type 6 case (Figure 4) . 5

6.7 General description of the Type 7 case (Figure 5) . 5

6.8 General description of the Type 8 case (Figure 4) . 6

6.9 General description of the Type 9 case (Figure 5) . 6

7 General requirements . 7

7.1 Environments . 7

7.1.1 Test environment . 7

7.1.2 Operating environment. 7

7.1.3 Storage environment . 8

7.1.4 Transportation. 8

7.2 Temperature shock . 8

7.3 Safety requirement. 8

7.4 Flammability . 8

Section 2 - Dimensional and mechanical characteristics of the case for 120 mm disks . 9

8 Dimensional characteristics . 9

8.1 Dimensions of the Type 1 case . 9

8.1.1 Overall dimensions (Figure 6) . 9

8.1.2 Location hole (Figure 6) . 10

8.1.3 Alignment hole (Figure 6). 10

8.1.4 Reference surfaces (Figure 7) . 11

8.1.5 Insertion slots (Figure 8) . 11

8.1.6 Detents (Figure 8). 12

8.1.7 Gripper slots (Figure 8) . 12

8.1.8 Write-inhibit hole (Figure 9) . 13

8.1.9 Sensor holes (Figure 9) . 13

8.1.10 Sensing areas (Figure 9) . 14

8.1.11 Spindle and head window (Figure 10). 14

8.1.12 Shutter shape (Figure 11). 15

8.1.13 Path for shutter opener (Figures 12 and 13) . 15

8.1.14 Label areas (Figure 14). 16

8.1.15 Identification marks for Sides A and B (Figure 15) . 16

8.2 Dimensions of the Type 2 case . 28

8.2.1 Overall dimensions (Figure 16) . 28

8.2.2 Location hole (Figure 16) . 29

© ISO/IEC 2004 – All rights reserved iii

8.2.3 Alignment hole (Figure 16) .29

8.2.4 Reference surfaces (Figure 17).29

8.2.5 Insertion slot (Figure 18) .30

8.2.6 Detents (Figure 18).30

8.2.7 Gripper slots (Figure 18).31

8.2.8 Write-inhibit hole (Figure 19).31

8.2.9 Sensor holes (Figure 19) .32

8.2.10 Sensing areas (Figure 19).32

8.2.11 Spindle and head window (Figure 20).33

8.2.12 Shutter shape (Figure 21) .33

8.2.13 Path for shutter opener (Figure 22 and 23).34

8.2.14 Label areas (Figure 24) .35

8.2.15 Identification mark for Side A (Figure 25).35

8.2.16 Opening and opening cover for taking the disk out of the case .35

8.3 Dimensions of the Type 3 case.45

8.3.1 Sensor holes .45

8.3.2 Opening and opening cover for taking the disk out of the case .46

8.4 Dimensions of the Type 4 case.46

8.4.1 Sensor holes .46

8.4.2 Opening and opening cover for taking the disk out of the case .46

8.5 Dimensions of the Type 5 case.47

8.5.1 Sensor holes .47

8.5.2 Opening and opening cover for taking the disk out of the case .47

9 Mechanical characteristics.47

9.1 Material .47

9.2 Mass.47

9.3 Edge distortion .47

9.4 Compliance .47

9.5 Shutter opening force .47

10 Interface between the case used as cartridge and a drive.48

10.1 Capture cylinder (Figure 26).48

10.2 Inner dimensions of the case (Figure 27) .49

11 Orientation of the disk in the case.50

11.1 Two-sided disk (Type 2S) in case Types 1, 4 and 5.50

11.2 One-sided disk (Type 1S) in case Types 1, 2 and 3 .50

Section 3 - Dimensional and Mechanical characteristics of the case for 80 mm disk.52

12 Dimensional characteristics.52

12.1 Dimensions of the Type 6 case.52

12.1.1 Overall dimensions (Figure 28).52

12.1.2 Location hole (Figure 28).53

12.1.3 Alignment hole (Figure 28) .53

12.1.4 Reference surfaces (Figure 29).54

12.1.5 Mis-insertion protection slots (Figure 30) .54

12.1.6 Detents (Figure 30).54

12.1.7 Write-inhibit hole (Figure 31).55

12.1.8 Sensor holes (Figure 31) .56

12.1.9 Spindle and head window (Figure 32).56

12.1.10 Shutter shape (Figure 33) .57

12.1.11 Path for shutter opener (Figure 34) .58

12.1.12 Label areas (Figure 35) .59

12.1.13 Identification marks for Sides A and B (Figure 36).59

12.1.14 Disk holder and body (Figures 37 and 38).60

12.2 Dimensions of the Type 7 case.74

12.2.1 Overall dimensions (Figure 39).74

12.2.2 Location hole (Figure 40).74

12.2.3 Alignment hole (Figure 40) .75

12.2.4 Reference surfaces (Figure 40).75

iv © ISO/IEC 2004 – All rights reserved

12.2.5 Mis-insertion protection slots (Figure 41) . 76

12.2.6 Detents (Figure 41). 76

12.2.7 Write-inhibit hole (Figure 42) . 77

12.2.8 Sensor holes (Figure 42) . 77

12.2.9 Spindle and head window (Figure 43). 78

12.2.10 Shutter shape (Figure 44). 79

12.2.11 Path for shutter opener (Figure 45). 80

12.2.12 Label areas (Figure 46). 81

12.2.13 Identification marks for Sides A and B (Figure 47) . 81

12.2.14 Disk holder and body (Figure 48) . 82

12.3 Dimensions of the Type 8 case . 96

12.3.1 Sensor holes. 96

12.3.2 Disk holder and body. 96

12.4 Dimensions of the Type 9 case . 96

12.4.1 Sensor holes. 96

12.4.2 Disk holder and body. 97

13 Mechanical characteristics . 97

13.1 Material. 97

13.2 Mass . 97

13.3 Edge distortion. 97

13.4 Compliance. 97

13.5 Shutter opening force. 97

14 Interface between the case used as cartridge and a drive . 97

14.1 Capture cylinder (Figure 50) . 97

14.2 Inner dimensions of the case (Figure 51). 97

15 Orientation of the disk in the case . 98

15.1 Two-sided disk (Type 2S) in case Types 6 and 8. 98

15.2 One-sided disk (Type 1S) in case Types 7 and 9. 98

Annex A (normative) Position of the case for 120 mm disk relative to the Reference Planes. 101

Annex B (normative) Edge distortion test of the case for 120 mm disk. 102

Annex C (normative) Compliance test of the case for 120 mm disk. 104

Annex D (normative) Position of the case for 80 mm disk relative to the Reference Planes. 106

Annex E (normative) Edge distortion test of the case for 80 mm disk . 107

Annex F (normative) Compliance test of the case for 80 mm disk . 109

Annex G (normative) Shutter opening force test of the case for 80 mm disk. 111

Annex H (informative) Examples of an opening cover for a Type 2 case, a Type 3 case, a Type 4

case or a Type 5 case . 112

Annex J (informative) Connection between disk holder and body of the case for 80 mm disk. 114

Annex K (informative) Transportation . 115

© ISO/IEC 2004 – All rights reserved v

Foreword

ISO (the International Organization for Standardization) and IEC (the International Electrotechnical

Commission) form the specialized system for worldwide standardization. National bodies that are members of

ISO or IEC participate in the development of International Standards through technical committees

established by the respective organization to deal with particular fields of technical activity. ISO and IEC

technical committees collaborate in fields of mutual interest. Other international organizations, governmental

and non-governmental, in liaison with ISO and IEC, also take part in the work. In the field of information

technology, ISO and IEC have established a joint technical committee, ISO/IEC JTC 1.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of the joint technical committee is to prepare International Standards. Draft International

Standards adopted by the joint technical committee are circulated to national bodies for voting. Publication as

an International Standard requires approval by at least 75 % of the national bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO and IEC shall not be held responsible for identifying any or all such patent rights.

ISO/IEC 17594 was prepared by Ecma International (as ECMA-331) and was adopted, under a special “fast-

track procedure”, by Joint Technical Committee ISO/IEC JTC 1, Information technology, in parallel with its

approval by national bodies of ISO and IEC.

vi © ISO/IEC 2004 – All rights reserved

INTERNATIONAL STANDARD ISO/IEC 17594:2004(E)

Information technology — Cases for 120 mm and 80 mm

DVD-RAM disks

Section 1 - General

1 Scope

This International Standard specifies the characteristics of a case for use with the 120 mm and 80 mm DVD-

RAM disks specified in International Standard ISO/IEC 17592. The present International Standard specifies

nine related , but different implementations of this case, viz.

Type 1 A case for a one-sided (Type 1S) or a two-sided (Type 2S) 120 mm DVD-RAM disk such that the

disk cannot be removed from the case. This case is reversible.

Type 2 A case for a one-sided (Type 1S) 120 mm DVD-RAM disk such that the disk may be removed from

the case. This case is not reversible.

Type 3 A case into which a one-sided (Type 1S) or a two-sided (Type 2S) 120 mm DVD-RAM disk may be

inserted, then used as a cartridge. This case is not reversible.

Type 4 A case for a two-sided (Type 2S) 120 mm DVD-RAM disk such that the disk may be removed from

the case. This case is reversible.

Type 5 A case into which a one-sided (Type 1S) or a two-sided (Type 2S) 120 mm DVD-RAM disk may be

inserted, then used as a cartridge. This case is reversible.

Type 6 A case for a two-sided (Type 2S) 80 mm DVD-RAM disk such that the disk may be removed from

the case. This case is reversible.

Type 7 A case for a one-sided (Type 1S) 80 mm DVD-RAM disk such that the disk may be removed from

the case. This case is not reversible.

Type 8 A case into which a two-sided (Type 2S) 80 mm DVD-RAM disk may be inserted, then used as a

cartridge. This case is reversible.

Type 9 A case into which a one-sided (Type 1S) 80 mm DVD-RAM disk may be inserted, then used as a

cartridge. This case is not reversible.

This International Standard specifies

− the environments in which the cases are to be operated and stored;

− the dimensional and mechanical characteristics of the case, so as to provide mechanical

interchangeability between data processing systems;

This International Standard provides for mechanical interchange between optical disk drives. Together with

International Standard ISO/IEC 17592 for 120 mm (4,7 Gbytes per side) and 80 mm (1,46 Gbytes per side)

DVD-RAM disks and a standard for volume and file structure, it provides for full data interchange between

data processing systems.

2 Conformance

A claim of conformance with this International Standard shall specify the Type implemented. A case shall be in

conformance with this International Standard if it meets the mandatory requirements specified herein for its

Type.

© ISO/IEC 2004 – All rights reserved 1

3 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO/IEC 17592:2004, Information technology — 120 mm (4,7 Gbytes per side) and 80 mm (1,46 Gbytes per

side) DVD Rewritable Disk (DVD-RAM)

ECMA-287:2002, Safety of electronic equipment

4 Definitions

For the purpose of this International Standard the following definitions apply:

4.1

cartridge

a device consisting of a case containing a rewritable disk

4.2

case

the housing for an optical disk, that protects the disk and facilitates disk interchange

5 Conventions and notations

5.1 Representation of numbers

A measured value is rounded off to the least significant digit of the corresponding specified value. For

instance, it implies that a specified value of 1,26 with a positive tolerance of + 0,01 and a negative tolerance of

- 0,02 allows a range of measured values from 1,235 to 1,275.

5.2 Names

The names of entities, e.g. specific sides, etc. are given a capital initial.

6 General description of the case

6.1 General description of the Type 1 case (Figure 1)

The case is a rigid protective container of rectangular shape. Sides A and B of the case are identical as far as

the features given here are concerned. References to Sides A and B of the case can be changed to B or A,

respectively. When the opening of the one is a head and spindle window for the spindle and the optical head

of the drive, that of the other is an access window for the disk clamping apparatus. A shutter uncovers the

windows upon insertion into the drive, and automatically covers them upon removal from the drive. The case

has features that enable a drive to reject a mis-inserted cartridge, to inhibit writing, sensor holes, detents for

autoloading and a vertical use, gripper slots for an autochanger, label areas and side identification marks.

Sides A and B of the case have the same configuration.

6.2 General description of the Type 2 case (Figure 2)

The Type 2 case has the same features as the Type 1 case, but with some differences. The shape of the case

is different on Side A and on Side B. Side A does not need to have a location hole, an alignment hole,

Reference Surfaces, a write-inhibit hole, sensor holes and sensing areas. The case has an opening closed by

a cover. This cover can be opened. In open position, the disk can be taken out of the case. Sensor hole A1 is

originally closed. If the disk has been removed from the case, then this hole remains permanently open,

2 © ISO/IEC 2004 – All rights reserved

indicating that the original disk contained in the case has been removed at least once or has been replaced by

another disk.

6.3 General description of the Type 3 case (Figure 2)

The Type 3 case is identical with Type 2 case except that the sensor hole A1 is always open.

Case Side A

Reference surface S3

Identification mark

of Case Side A

Edge for shutter opener

Disk Side B

Shutter

Reference1 surface S1

Reference surface S4

Location hole

Sensor holes

Detent for

for disk Side B

autoloading

Write-inhibit hole

Insertion slot

for disk Side B

Spindle and head window

Label area

Alignment hole

Detent for vertical use

Gripper slot

Reference surface S2

Sensing area

01-0088-A

Figure 1 - General view of the Type 1 case, seen from Side A

© ISO/IEC 2004 – All rights reserved 3

Case Side A

Identification mark

Edge for the shutter opener of Case Side A

Disk Side B

Shutter

Detent for

autoloading

Detent for vertical use

Insertion slot

Spindle and head window

Label area

Opening cover

Gripper slot

01-0089-A

Figure 2 - General view of the Type 2 and Type 3 cases, seen from Side A

6.4 General description of the Type 4 case (Figure 3)

The Type 4 case has the same features as the Type 1 case, but with some differences. The case has an

opening closed by a cover. This cover can be opened. In open position, the disk can be taken out of the case.

If the disk has been removed from the case, then the sensor hole A1 and B1 remain permanently open,

indicating that the original disk contained in the case has been removed at least once or has been replaced by

another disk.

6.5 General description of the Type 5 case (Figure 3)

The Type 5 case is identical with Type 4 case except that the sensor hole A1 and B1 are always open.

4 © ISO/IEC 2004 – All rights reserved

Case Side A

Reference surface S3

Side A identification mark

Edge for shutter opener

Disk Side B

Shutter

Reference surface S1

Reference surface S4

Location hole

Detent for

Sensor holes

Autoloading

for disk Side B

Write-inhibit hole

Insertion slot

for disk Side B

Spindle and head window

Label area

Opening cover

Reference surface S2

Alignment hole

Detent for vertical use

Gripper slot

Sensing area

01-0045-A

Figure 3 - General view of the Type 4 and Type 5 cases, seen from Side A

6.6 General description of the Type 6 case (Figure 4)

The case is a rigid protective container of rectangular shape. It consists of a body and a disk holder. This disk

holder can be taken out of the body and then the disk can be taken out of the case. Sensor hole A1 and B1

are originally closed. If the disk holder has been taken out of the body, then these holes remain permanently

open, indicating that the original disk contained in the case has been removed at least once or has been

replaced by another disk. Sides A and B of the case are identical as far as the features given here are

concerned. References to Sides A and B of the case can be changed to B or A, respectively. When the

opening of the one is a head and spindle window for the spindle and the optical head of the drive, that of the

other is an access window for the disk clamping apparatus. A shutter uncovers the windows upon insertion

into the drive, and automatically covers them upon removal from the drive. The case has features that enable

a drive to reject a mis-inserted cartridge, to inhibit writing, sensor holes, detents for autoloading and a vertical

use, gripper slots for an autochanger, label areas and side identification marks.

Sides A and B of the case have the same configuration.

6.7 General description of the Type 7 case (Figure 5)

The Type 7 case has the same features as the Type 6 case, but with some differences. The shape of the case

is different on Side A and on Side B. Side A does not need to have a location hole, an alignment hole,

Reference Surfaces, a write-inhibit hole, sensor holes and sensing areas. Sensor hole A1 is originally closed.

If the disk holder has been taken out of the body, then this hole remains permanently open, indicating that the

© ISO/IEC 2004 – All rights reserved 5

original disk contained in the case has been removed at least once or has been replaced by another disk.

Side B of this case shall not have label area.

6.8 General description of the Type 8 case (Figure 4)

The Type 8 case is identical with Type 6 case except that the sensor hole A1 and B1 are always open.

6.9 General description of the Type 9 case (Figure 5)

The Type 9 case is identical with Type 7 case except that the sensor hole A1 is always open.

Reference surface S4

Case Side A

Disk Side B

Label area

Shutter

Reference surface S3

Reference surface S2

Alignment hole

Detent for

autoloading

Disk holder

Spindle and head window

Side A identification mark

Write-inhibit hole

for disk Side B

Location hole

Mis-insertion Sensor holes for

protection slot disk Side B

Reference surface S1

Detent for vertical use

01-0046-A

Figure 4 - General view of the Type 6 and Type 8 cases, seen from Side A

6 © ISO/IEC 2004 – All rights reserved

Case Side A

Disk Side B

Label area

Shutter

Label area

Detent for autoloading

Disk holder

Mis-insertion protection slot

Side A identification mark

Spindle and head window

Mis-insertion protection slot

Detent for vertical use

01-0047-A

Figure 5 - General view of the Type 7 and Type 9 cases, seen from Side A

7 General requirements

7.1 Environments

7.1.1 Test environment

The test environment is the environment where the air immediately surrounding the case has the following

properties:

Temperature: 23 °C ± 2 °C

Relative humidity: 50 % ± 5 %

Atmospheric pressure: 86 kPa to 106 kPa

No condensation on or in the case or cartridge shall occur. Before testing, the case or cartridge shall be

conditioned in this environment for 48 hours minimum.

Unless otherwise stated, all tests and measurements shall be made in this test environment.

7.1.2 Operating environment

The case shall meets all requirements of this International Standard in the specified test environment and

provide mechanical interchange over the specified ranges of environmental parameters in the operating

environment. When the case according to this International Standard contains a DVD-RAM disk according to

Standard ISO/IEC 17592, they constitute together a cartridge. This cartridge shall meet the requirements of

this clause and provides for data interchange.

© ISO/IEC 2004 – All rights reserved 7

The operating environment is the environment where the air immediately surrounding the case or cartridge

has the following properties:

Temperature: 5 °C to 60 °C

Relative humidity: 3 % to 85 %

3 3

Absolute humidity: 1 g/m to 30 g/m

Temperature gradient: 10 °C /h max.

Relative humidity gradient: 10 %/h max.

No condensation on or in the case or cartridge shall occur. If the case or cartridge has been exposed to

conditions outside those specified in this clause, it shall be acclimatized in the operating environment for at

least 2 h before use.

7.1.3 Storage environment

The storage environment is defined as an environment where the air immediately surrounding the case or

cartridge has the following properties.

Temperature: -10 °C to 50 °C

Relative humidity: 3 % to 85 %

3 3

Absolute humidity: 1 g/m to 30 g/m

Atmospheric pressure: 75 kPa to 106 kPa

Temperature gradient: 10 °C /h max.

Relative humidity gradient: 10 %/h max.

No condensation on or in the case or cartridge shall occur.

7.1.4 Transportation

This does not specify requirements for transportation; guidance is given in annex E.

7.2 Temperature shock

The case shall withstand a temperature shock of up to 20°C when inserted into, or removed from, the drive.

7.3 Safety requirement

The case shall satisfy the safety requirements of Standard ECMA-287, when used in the intended manner or

in any foreseeable use in an information processing system.

7.4 Flammability

The case shall be made from materials shall be of materials that, if ignited from a match flame, shall not

continue to burn in a still carbon dioxide atmosphere.

8 © ISO/IEC 2004 – All rights reserved

Section 2 - Dimensional and mechanical characteristics of the case for 120 mm disks

8 Dimensional characteristics

The dimensions of the case shall be referred to three orthogonal Reference Planes X, Y and Z. The case shall

be constrained such that four reference surfaces S1 to S4 on Side B of the case lie in Reference Plane Z. The

intersection of the three planes defines the centre of the location hole. The centre of the alignment hole shall

lie on the intersection of Reference Planes X and Z. Refer to annex A. A dimension of a feature referenced to

one of the planes is the shortest distance from the feature to the plane.

Side A of the Type 1, Type 4 and Type 5 cases are referred to as the three orthogonal Reference Planes X, Y'

and Z', where

− Y' is a plane parallel to Reference Plane Y at a nominal distance of 102,0 mm,

− Z' is a plane parallel to Reference Plane Z at a nominal distance of 8,0 mm.

8.1 Dimensions of the Type 1 case

The dimensions of the Type 1 case shall be measured in the test environment (see 7.1.1). The dimensions of

the case in an operating environment (see 7.1.2) can be estimated from the dimensions specified in this

clause.

8.1.1 Overall dimensions (Figure 6)

The total length of the case shall be

L = 135,5 mm ± 0,4 mm

At a width

L = 3,6 mm min

the distance from the top of the case to Reference Plane X shall be

+ 0,3 mm

L = 112,5 mm

- 0,2 mm

from the left-hand and right-hand edges of the case.

The distance from the bottom of the case to Reference Plane X shall be

L = 23,0 mm ± 0,2 mm.

The total width of the case shall be

+ 0,0 mm

L = 124,6 mm

- 0,5 mm

The distance from the left-hand side of the case to Reference Plane Y shall be

+ 0,2 mm

L = 113,3 mm

- 0,4 mm

The distance from the right-hand side of the case to Reference Plane Y shall be

+ 0,1 mm

L = 11,3 mm

- 0,3 mm.

The two corners of the top shall be rounded off with a radius

R = 4,0 mm ± 0,2 mm

© ISO/IEC 2004 – All rights reserved 9

centred at

L = 4,0 mm ± 0,1 mm

from the edge of the case and

L = 3,5 mm ± 0,1 mm

from the top of the case.

The two corners of the bottom shall be rounded off with a radius

R = 4,0 mm ± 0,2 mm.

In the zones delimited by

L = 6,0 mm

from the left-hand and right-hand edges of the case, there shall be the continuous guide areas running from

the top to Reference Plane X of the case, with a width

L = 0,8 mm min.

The thickness of the case shall be

+ 0,2 mm

L = 8,0 mm

- 0,1 mm.

The eight long edges of the case shall be rounded off with a radius

R = 0,5 mm ± 0,1 mm.

8.1.2 Location hole (Figure 6)

The centre of the location hole shall coincide with the intersection of Reference Planes X, Y and Z.

The diameter of the hole shall be

+ 0,05 mm

D = 4,00 mm

- 0,00 mm

Its depth shall be

L = 1,2 mm min.

The room below the location hole shall be free by

L = 5,0 mm min.

below Reference Plane Z

The diameter of the free room shall be at least equal to D .

The lead-in edges shall be rounded off with a radius

R = 0,5 mm ± 0,1 mm.

8.1.3 Alignment hole (Figure 6)

The centre of the alignment hole shall lie on the intersection of the Reference Planes X and Z at a distance

L = 102,0 mm ± 0,2 mm

from Reference Plane Y.

The alignment hole shall have a substantially rectangular shape. Its dimensions shall be

+ 0,05 mm

L = 4,00 mm

0,00 mm

10 © ISO/IEC 2004 – All rights reserved

+ 0,2 mm

L = 5,6 mm

0.00 mm

Its depth shall be equal to L . The room below the alignment hole shall be free by at least L . The

113 114

dimensions of the free room shall be at least L and L .

116 117

The lead-in edges shall be rounded off with a radius R .

8.1.4 Reference surfaces (Figure 7)

There shall be four reference surfaces S1, S2, S3 and S4 on Side B of the case.

Surfaces S1 and S2 shall be circular with a diameter

D = 7,0 mm min.

S1 shall be centred on the location hole, and S2 shall be centred on the alignment hole.

Surfaces S3 and S4 shall be rectangular with dimensions

L = 8,2 mm max.

L = 110,2 mm max.

from Reference Plane Y and

L = 87,0 mm max.

L = 108,0 mm min.

from Reference Plane X, except in the areas of the detents for autoloading.

8.1.5 Insertion slots (Figure 8)

The case shall have two symmetrical insertion slots.

The bottom of the slots shall be at a distance

L = 60,0 mm ± 0,2 mm

from Reference Plane X.

The depth measured from the edge of the case shall be

+ 0,2 mm

L = 2,0 mm

- 0,0 mm.

The side of the insertion slots parallel to Reference Plane Z shall be at a distance

L = 2,5 mm ± 0,1 mm

from Reference Plane Z. The width of the insertion slots shall be

+ 0,2 mm

L = 3,0 mm

- 0,0 mm.

The slots shall have a lead-in slope defined by

L = 7,0 mm ± 0,2 mm

from the top of the case and an angle

α = 7,5° ± 1,0°.

© ISO/IEC 2004 – All rights reserved 11

8.1.6 Detents (Figure 8)

The case shall have two symmetrical detents intended for autoloading. The detents shall be through Side A

and Side B.

The position and dimensions of the detents shall be

R = 0,5 mm max.

L = 100,5 mm ± 0,3 mm

L = 93,0 mm ± 0,3 mm

L = 3,3 mm ± 0,1 mm

L = 2,5 mm ± 0,1 mm.

The outside edges of the detents shall be rounded off with a radius

R = 0,5 mm ± 0,1 mm.

The bottom of the case shall have two symmetrical detents intended for clamping a cartridge in case of

vertical use. Their dimensions shall be

L = 3,0 mm ± 0,1 mm

L = 3,0 mm ± 0,1 mm

L = 1,0 mm ± 0,1 mm

The centre of one of these detents shall lie on Reference Plane Y and the centre of the other hall be at a

distance

L = 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...