ISO 7884-4:1987

(Main)Glass — Viscosity and viscometric fixed points — Part 4: Determination of viscosity by beam bending

Glass — Viscosity and viscometric fixed points — Part 4: Determination of viscosity by beam bending

A method of determining the dynamic viscosity of glass on a rod-shaped test specimen, i.e. a beam, supported at its end is specified. The viscous deflection rate of the beam is measured under given load at the midpoint between the supports. In addition the viscosity-temperature relationship and the dependence of the viscosity on the thermal history of the sample can be determined. The theoretical basis relations and the apparatus including method of measurements are described.

Verre — Viscosité et points viscosimétriques fixes — Partie 4: Détermination de la viscosité par flexion de barreau

General Information

- Status

- Published

- Publication Date

- 25-Nov-1987

- Technical Committee

- ISO/TC 48 - Laboratory equipment

- Drafting Committee

- ISO/TC 48 - Laboratory equipment

- Current Stage

- 9020 - International Standard under periodical review

- Start Date

- 15-Oct-2025

- Completion Date

- 15-Oct-2025

Overview

ISO 7884-4:1987 - "Glass - Viscosity and viscometric fixed points - Part 4: Determination of viscosity by beam bending" specifies a laboratory method for measuring the dynamic viscosity of glasses using a rod‑shaped test specimen (a beam) supported at its ends. The standard describes the theoretical basis, required apparatus and measurement procedures: a controlled load is applied at midspan and the viscous deflection rate (midpoint sag vs time) is recorded. From the measured sag, span, cross‑sectional moment of inertia and load the dynamic viscosity is calculated. The method covers a broad viscosity range (~10^9 to 10^15 dPa·s) and includes guidance on temperature control, calibration and sample thermal history.

Key topics and technical requirements

- Test principle: Measure midpoint deflection rate under a known load and convert to dynamic viscosity using beam bending relations and geometric properties of the specimen.

- Specimens: Rod‑shaped beams with rectangular (thickness h, width b) or circular (diameter d) cross sections; must be homogeneous, bubble‑free and properly annealed.

- Apparatus:

- Electrically heated viscometer furnace with temperature uniformity (≤ ±1 °C) and programmable temperature‑time control (heating rates up to ~6 °C/min).

- Thermocouples: Type S (Pt‑10%Rh/Pt) or Type K (NiCr/Ni) per IEC 584‑1, low thermal inertia and properly calibrated.

- Supports and loading assembly (yoke, bending edge, loading rod), support stand materials (vitreous silica or alumina), and loading pieces with accurately known masses.

- Displacement measurement: LVDTs or comparable transducers to record midpoint deflection and total deflection with high resolution.

- Measurement controls:

- Small‑deflection and small‑deflection‑rate assumptions apply (relative midpoint deflection z should remain < 0.05).

- Support ratio and span constraints determine validity of simplified equations; calibration with a reference glass is required when support ratio limits are exceeded.

- Care to avoid devitrification; consider thermal history effects for viscosities > 10^12 dPa·s (structure equilibration may be slow).

- Calibration and traceability: Verify instrument using a reference glass of known viscosity; check span, parallelism and thermal distribution routinely.

Applications and users

- Practical for glass manufacturers, quality control and R&D labs that need accurate viscosity‑temperature relationships for melts and glasses.

- Used by materials scientists, process engineers and instrument calibration labs for:

- Determining viscometric fixed points and softening/annealing behavior.

- Characterizing thermal‑history effects and viscoelastic (Newtonian/linear) response.

- Calibrating other viscometers and validating process models for forming, drawing or annealing operations.

Related standards

- ISO 7884 series: Part 1 (principles) and Parts 2, 3, 5–8 covering alternative viscometric methods (rotation, fibre elongation, sinking bar, softening/annealing points).

- IEC 584‑1 (thermocouple reference tables) for thermocouple selection and calibration.

Keywords: ISO 7884-4, glass viscosity, beam bending, viscometric method, dynamic viscosity, viscometer furnace, thermocouples, LVDT, viscoelastic behavior.

Frequently Asked Questions

ISO 7884-4:1987 is a standard published by the International Organization for Standardization (ISO). Its full title is "Glass — Viscosity and viscometric fixed points — Part 4: Determination of viscosity by beam bending". This standard covers: A method of determining the dynamic viscosity of glass on a rod-shaped test specimen, i.e. a beam, supported at its end is specified. The viscous deflection rate of the beam is measured under given load at the midpoint between the supports. In addition the viscosity-temperature relationship and the dependence of the viscosity on the thermal history of the sample can be determined. The theoretical basis relations and the apparatus including method of measurements are described.

A method of determining the dynamic viscosity of glass on a rod-shaped test specimen, i.e. a beam, supported at its end is specified. The viscous deflection rate of the beam is measured under given load at the midpoint between the supports. In addition the viscosity-temperature relationship and the dependence of the viscosity on the thermal history of the sample can be determined. The theoretical basis relations and the apparatus including method of measurements are described.

ISO 7884-4:1987 is classified under the following ICS (International Classification for Standards) categories: 81.040.01 - Glass in general. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 7884-4:1987 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL STANDARD

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION

ORGANISATION INTERNATIONALE DE NORMALISATION

MEXjJYHAPOAHAR OPrAHM3AL&lFl fl0 CTAH~APTM3AYMM

Glass - Vkcosity and viscometric fixed Points -

Part 4 :

Determination of viscosity by beam bending

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of

national Standards bodies (ISO member bedies). The work of preparing International

Standards is normally carried out through ISO technical committees. Esch member

body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, govern-

mental and non-governmental, in liaison with ISO, also take part in the work.

Draft International Standards adopted by the technical committees are circulated to

the member bodies for approval before their acceptance as International Standards by

the ISO Council. They are approved in accordance with ISO procedures requiring at

least 75 % approval by the member bodies voting.

International Standard ISO 7884-4 was prepared by Technical Committee ISO/TC 48,

Laboratory glassware and related apparatus.

Users should note that all International Standards undergo revision from time to time

and that any reference made herein to any other International Standard implies its

latest edition, unless othetwise stated.

International Organkation for Standardkation, 1987

Printed in Switzerland

ISO 7884-4 : 1987 (E)

INTERNATIONAL STANDARD

Viscosity and viscometric fixed Points -

Glass -

Part 4 :

Determination of viscosity by beam bending

viscosity is possible only with Newtonian or linear-viscoelastic

0 Introduction

behaviour of the glass. The procedures are sensitive to interference by

devitrification of the Sample. With viscosities above 1012 dPas the ad-

International Standard ISO 7884, Glass - Viscosity and

justment of the structure equilibrium within the glass is perceptibly

viscometric fixed Points, consists of the following separate

delayed with respect to the temperature setting. For tests within this

Parts:

range it should be agreed whether it is necessary to wait for the final

equilibrium viscosity at a given temperature or to take the viscosity

Part 1: Principles for determining viscosity and viscometric

value corresponding to a conventional temperature-time Programme

fixed poin ts.

(sec 6.3).

Part 2: Determination of viscosity b y ro ta tion viscometers.

Part 3 : Determination of viscosity b y fibre elonga tion 2 Reference

viscome ter.

IEC Publication 584-1, Thermocouples - Part 1: Reference

Part 4: Determination of viscosity by beam bending.

tables.

Part 5: Determination of working Point by sinking bar

viscometer.

3 Principle

Part 6: Determination of softening Point.

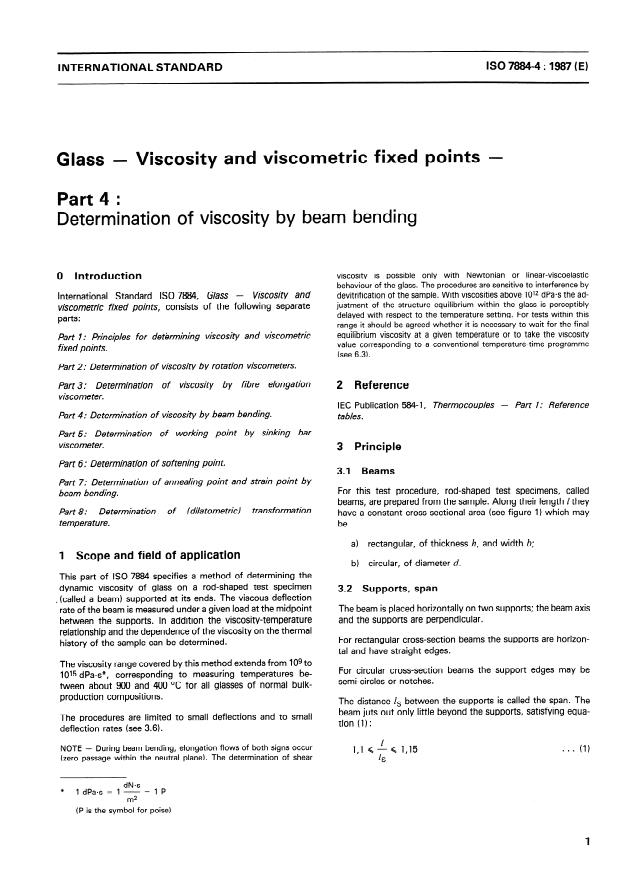

3.1 Beams

Part 7: Determination of annealing Point and strain Point by

For this test procedure, rod-shaped test specimens, called

beam bending.

beams, are prepared from the Sample. Along their length I they

o f (dila tome tric) transforma tion

Part 8: Determination

have a constant Cross-sectional area (see figure 1) which may

temperature.

be

a) rectangular, of thickness h, and width b;

1 Scope and field of application

b) circular, of diameter d.

This part of ISO 7884 specifies a method of determining the

dynamic viscosity of glass on a rod-shaped test specimen

3.2 Supports, span

. (called a beam) supported at its ends. The viscous deflection

The beam is placed horizontally on two supports; the beam axis

rate of the beam is measured under a given load at the midpoint

and the supports are perpendicular.

between the supports. In addition the viscosity-temperature

relationship and the dependence of the viscosity on the thermal

For rectangular Cross-section beams the supports are horizon-

history of the Sample tan be determined.

tal and have straight edges.

The viscosity range covered by this method extends from 109 to

For circular Cross-section beams the support edges may be

1015 dPas*, corresponding to measuring temperatures be-

semi-circles or notches.

tween about 900 and 400 OC for all glasses of normal bulk-

production compositions.

The distance Zs between the supports is called the span. The

beam juts out only little beyond the supports, satisfying equa-

The procedures are limited to small deflections and to small

tion (1):

deflection rates (see 3.6).

NOTE - During beam bending, elongation flows of both signs occur

- < 1,15 . . .

1,l < (1)

(Zero passage within the neutral plane). The determination of shear

k

dNs

*

1 dPas = 1 z = 1 P

(P is the Symbol for Poise)

ISO 7884-4 : 1987 (E)

Cross-sections of the beams

A supports

bending edge, unloaded

BO

bending edge, loaded (elastically deformed beam)

Bl

bending edge, sagged Position Af after measuring time At (Af is the interval between B, and Bz)

Bz

beam length

span; Position of bending edge at ls/2

k

forte of the load

FO

b beam width

(rectangular Cross-section)

beam thickness

h

d beam diameter (circular Cross-section)

Figure 1 - Principle of viscosity determination by beam bending

3.5 Flow

33 . Load, loading pieces, bending edge

The load consists of all Parts of the measuring device on which When the forte of the load (disregarding the dead-weight) acts

upon a beam free from defects and showing Newtonian or

gravity acts to produce a forte on the beam by means of the

bending edge, i.e. the loading pieces (variable) and the loading linear-viscoelastic behaviour, and all elastic deformations after

applying the load have faded out and thereupon the sag is suffi-

rod together with yoke and bending edge (given for the in-

The load exerts a vertically ciently small, the flow is described by equation (2) as follows:

dividual measuring device).

downward directed forte F. upon the central Cross-sectional

area of the beam (distance ls/2 from both supports). The bend-

df 1, Fo

. . .

ing edge is horizontal and parallel to the supports. (2)

dt=

144 r,r

3.4 Dead-weight

The dead-weight Sterns from the beam; it tan be taken into ac-

dt is the midpoint deflection rate, with which the bend-

dfl

count by calculation - see equations (13) to (15). Within the

ing edge moves downward (sec figure 1);

span, the forte of the dead-weight acts in the same sense as

that of the load. The dead-weight of the overhanging Parts of

is the Cross-sectional moment of inertia of the beam;

the beam produces a forte component opposed to the forte of

the load; this part of the dead-weight tan be neglected if equa-

is the span;

tion (1) is respected.

k

ISO 7884-4 : 1987 (E)

of the beam caused by the load and - if necessary - the

is the dynamic viscosity of the glass.

YI

deflections during previous flows.

the Trouton ratio 3 and some in-

NOTE - The factor 144 comprises

Measuring devices with 4 < 13 shall be checked by means of a

tegration factors.

beam made from a reference glassl) and the results empirically

with a rec-

The Cross-sectional moment of inertia for beams

corrected, if necessary.

tangular Cross-section is described by equation (3)

Relative deflections z > 0,05 are not permissible. Beams

h3b deflected down to this limiting value may be turned over for a

. . .

r, = - (3)

further run (see also 6.3.3).

NOTES

and that for beams with a circular Cross-section, by equation

1 The correcting calculations known from the statics of an elastic

(4) :

beam with moderate support ratios q = 10 are subject to the condition

nd4

that supports are freely movable against one another in the direction of

. . .

rc = - (4)

the span. Using the test set-up this is not possible for the flow;

therefore mathematical corrections are not available.

During the measuring time At the beam sags below the bend-

2 The dimensions and loads recommended in ISO 7884-7 are taken

ing edge for a distance Af. The viscosity is calculated according into account. In view of a more uniform temperature distribution,

shorter beams are proposed. The essential differente in comparison

to equation (5) :

with ISO 7884-7 is that:

l:Atm

a) viscosities tan be calculated from the bending rates (therefore

. , .

=681- (5)

r

only considerably smaller relative midpoint deflections are admit-

Vf *

ted);

b) the viscosity of the delivered Sample having its own thermal

history is determined, if necessary (therefore the Sample is not

is the viscosity in decipascal seconds;

heated up to 1012 dPas, and furthermore no viscosities are deter-

mined for decreasing temperatures).

in millimetres during measuring

Af is the sag of the

time At;

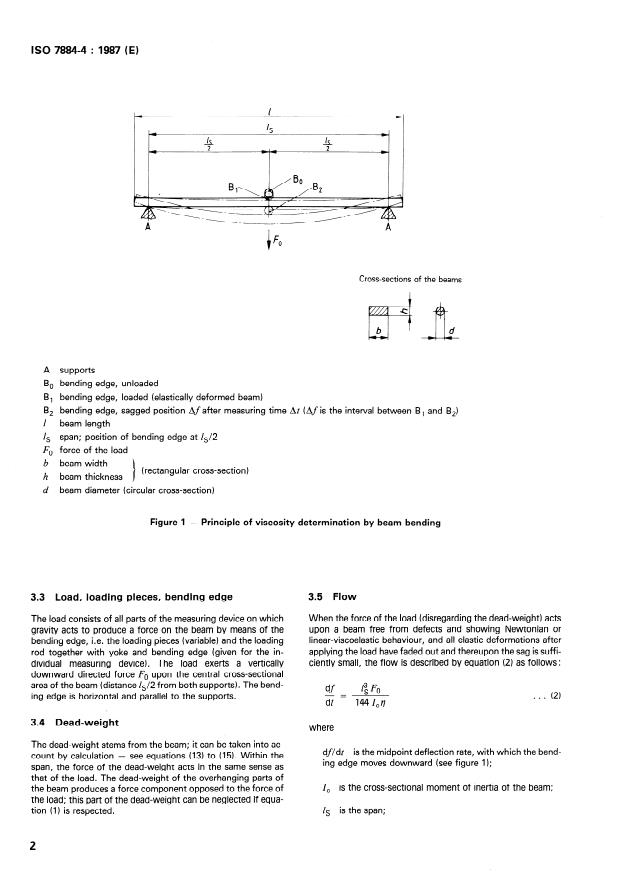

4 Apparatus

is the Cross-sectio nal mo ment of in milli to

The requirements for components of the beam bending testing

the fout-th power;

device are given in 4.1 to 4.6. Figure 2 Shows an example of a

At is the measuring time in seconds;

testing device.

is the mass of the load in grams;

m

4.1 Viscometer furnace

is the span in millimetres.

k Electrically heated furnace for temperatures up to about

900 OC. The introduction of thermocouples for the determina-

When calculating the viscosity it may be necessa ry to take cor-

tion of temperature and temperature distribution along the

7.3)

rections into account tsee 7.1 to

beam shall be possible. Temperature differentes within the

beam shall not exceed 1 OC.

3.6 Range of applicability of the simplified

The furnace shall be controlled by a device for maintaining a

calculations

constant temperature within & 1 OC or better within the work-

ing space of the furnace and for the adjustment of linear

Equations (2) and (5) hold only for very thin beams and very

temperature-time Programmes with heating rates up to

small deflections. That range is characterized by the support

6 OC/min.

ratio 4 according to equation (6) or equation (7) :

The furnace and its control device for the temperature-time

Programme shall be such that the furnace, starting from a con-

=-

. , . (6)

4 ;

stant temperature level, reaches the required heating rate at the

latest 5 min afterwards and maintains it to L- 10 %.

121s

=

. . . (7)

4.2 Temperature measuring and indicating

q d

instruments

and also by the relative midpoint deflection z:

4.2.1 The alumina-insulated platinum-10 % rhodium/plati-

num (type S according to IEC 584-1) thermocouples or nickel-

f

=-

. . .

(8)

2 I

1,

chromium/nickel (type K according to IEC 584-1) thermo-

‘

s

couples shall exhibit low thermal inertia (the diameter of the

In equation (8) f is the total midpoint deflection of the beam, wires should be not greater than 0,5 mm). The wires shall have

i.e. f is the sum of the deflection Af during the measuring time a sufficient length within the furnace (with respect to heat con-

At according to equation (5) together with the elastic deflection duction along the wires).

See for example ISO 7884-1 : 1987, annex B, “Examples of certified reference glasses for viscometric calibration”.

1)

ISO 7884-4 : 1987 (El

-

-

X

4 B 5 6

l

/

I I

.

I

_~-

1 1 4

1 Support stand, made from vitreous silica 6 Test specimen (beam)

2 Frame, made from a suitable temperature-resistant low- 7 Locking rod, made from vitreous silica

expansion metal alloy

8 Upper part of viscometer furnace: vertically movable cap

3 Supports

9 Loading rod, made from vitreous silica

4 Locking counterpoise, made from a suitable temperature-

A and B : Hot junctions of thermocouples (see 4.2)

resistant Iow-expansion metal alloy

5 Yoke with bending edge, locking edges and Suspension of

the loading rod, made from a suitable temperature-resistant

low-expansion metal alloy

Example of a testing device for the beam bending method

Figure 2 -

ISO 7884-4 : 1987 (E)

4.2.2 Control thermocouples should be located as close as 4.5 Loading device

possible to the furnace windings for fast response. The hot

junction of the measurement thermocouples, however, shall be

4.5.1 Yoke and loading rod

placed in the immediate vicinity of the beam (see A in figure 2).

The axial temperature distribution along the beam shall be

The yoke and bending edge are made from chromium-nicke1

monitored by further thermocouples (see B in figure 2). In ac-

alloy or hard porcelain. The radius of curvature of the bending

cordante with ISO 7884-1, the measurement thermocouples

edge tan vary Getween 0,5 and 2 mm; the cylindrical surface is

shall be calibrated and the calibration checked regularly.

ground and polished.

4.2.3 The electrical output of the thermocouples shall be To prevent sticking of the beam to the bending edge, Strips of

determined at zero current by means of potentiometers, or

platinum or nicke1 foil (about 0,Ol mm thick) may be inter-

high-resistance electronie amplifiers having a sensitivity of 1 PV posed.

for type S (according to IEC 584-1), or 4 PV for type K (accord-

ing to IEC 584-1) thermocouples. Precautions shall be taken NOTE - A greater radius of curvature is advantageous multiple

for use

that the ice-bath for the cold junction is maintained at 0 OC of the beam after turning it over.

throughout the test. If the temperature measuring equipment is

fitted with automatic cold junction compensation, the ice-bath The loading rod connects the yoke within the viscometer fur-

nace to the loading pieces underneath. The loading rod shall be

tan be omitted.

made from the same material as the support stand tube (see

4.4.2) with respect to similar thermal expansion characteristics.

Loading pieces

43 .

A set of loading pieces with masses from about IO to 200 g (for

4.5.2 Locking the yoke

arrangements according to 6.2.3, up to 1 000 g) made from

brass, nickel-plated or equivalent material. The masses of the

A device is needed for lowering the bending edge onto the

loading pieces shall be determined to 0,Ol g. The mass of the

beam and for lifting it after the test. The device shall ensure

loading rod including the core of the displacement pick-up

that the parallelism between the lowered bending edge and the

together with the yoke and the bending edge tan be limited to

supports is better than Io and that the edge is less than 0,5 mm

about 10 g.

from the median plane.

NOTE - A detailed device whic h is able to fulfil these requirements is

4.4 Beam support

given as an example in figure 2.

4.4.1 Frame

4.6 Equipment for the determi nation of the midpoint

deflection rate

The frame shall be sufficiently rigid against bending and torsion

and be made from a suitable temperature-resistant low-

expansion metal alloy or hard porcelain. The front sides of the

4.6.1 Moving indicator (including transducer core) as Point

frame bear sufficiently broad (IO to 15 mm) supports with a

of Observation for the determination of the deflection rate,

radius of curvature of about 0,5 mm, the surfaces of the sup-

placed beneath the viscometer furnace.

ports being ground and polished. The span, i.e. the distance

between the two lines of contact to the bottom surface of the

4.6.2 Device for the determination sf the midpoint

beam, shall be determined to 0,05 mm. Parallelism deviations

deflection Af during the measuring time At according to

of the two lines of contact should not exceed 0,05 mm, after

equation (5). Deflections of 0,l mm shall be determined to 1 %

the frame has been annealed. After prolonged use, span and

(see also tables 1 and 2).

parallelism shall be checked.

To prevent sticking of the beam to the support, Strips of

4.6.3 Device for the determination of the total beam

platinum or nicke1 foil (about 0,Ol mm thick) may be inter-

deflection f monitoring the limiting condition for the relative

posed.

deflection z < 0,05 with a sensitivity of 0,l mm.

NOTE - Linearly variable differential transformers (LVDTs) with a

4.4.2 Support stand

removable core are suitable for the deflection determination. A

measurable elevation adjustment of the coil is then sufficient for the

The support stand bears the frame upon its upper front surface.

determination of fi whilst the measurement of Af (sec 4.6.2) is achiev-

In the example shown in figure 2 it is set up separately from the

ed by means of the electronie meter of the LVDT having several sen-

furnace. The stand shall be equipped with an adjustment

sitivity ranges. With this testing method, recording of the values

device for the horizontal support of the beam.

measured should be aimed at. Alternatively, a measuring microscope

with scale micrometers (for Ajl and mounted upon a cathetometer

The support stand is made from vitreous silica. If temperatures

base (for J) may be used.

between 750 and 900 OC are often applied, and/or if alkali con-

tamination is suspected, alumina refractory as a material for the

4.6.4 Measuring device for time intervals ranging from 10

support stand is a useful alternative.

to IO 000 s for the determination of the measuring time At ac-

NOTE - Another example for a possible construction of the beam sup- cording to equation (5). Systematic deviations of the measur-

port is shown in ISO 7884-7. In that case the supports are machined ing device shall be determined to 0,2 % and shall be taken into

directly into the top of the stand tube.

account.

ISO 7884-4 : 1987 (E)

5.4 Special requirements

4.7 Devices for measuring the beam dimensions

Special requirements concerning the treatment of Sample and

4.7.1 Sliding gauge (vernier division l/lO is sufficient) for

beam shall be agreed upon, especially in the following cases:

the determination of the beam length 1.

a) for samples delivered in the form of grains, the condi-

tions for melting and annealing the rod las-drawn or cast

4.7.2 Micrometer caliper for the determination of beam

from the melt), from which the test specimen will be

diameter d or beam thickness h and width b.

prepared;

b) for specially annealed samples, the highest tempera-

tures to which the beams tan be exposed without affecting

Preparation of test specimens

this annealing treatment.

5.1 State of delivery

6 Procedure

The supplied glass Sample shall be uniform, bubble-free,

homogeneous and annealed. lt shall consist of pieces large

6.1 Calibration of the testing device

enough to permit the preparation of the test specimens.

Generally, the beam bending measurement is an absolute

5.2 Preparation of the beams

determination of the viscosity, i.e. the viscosity is calculated

(see 3.5 and 7.2) from the dimensions of the finished test

Rectangular beams shall be made from the Sample by cold

specimen and from the span Is. An examination is recommen-

working, e.g. diamond-saw tut and mill ground. Cylindrical ded by means of a beam of equal dimensions and made from a

beams shall be either flame drawn or centreless ground.

reference glass of known viscosity. This is necessary for sup-

port ratios 4 < 13 (sec 3.6 and 7.3).

The beams shall not have any scratches or defects. The dimen-

The calibration includes the adjustment of the frame for

sions shall be within the ranges specified in 6.2.1, 6.2.2 and

6.2.3 and figures 3 and 4. horizontal positioning of the plane defined by both supports.

Subsequently the highest temperature is set that might occur in

this testing device, and after cooling down

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...