ISO/IEC 17342:2004

(Main)Information technology — 80 mm (1,46 Gbytes per side) and 120 mm (4,70 Gbytes per side) DVD re-recordable disk (DVD-RW)

Information technology — 80 mm (1,46 Gbytes per side) and 120 mm (4,70 Gbytes per side) DVD re-recordable disk (DVD-RW)

ISO/IEC 17342:2004 specifies the mechanical, physical and optical characteristics of an 80 mm and a 120 mm DVD re-recordable disk to enable the interchange of such disks. It specifies the quality of the pre-recorded, unrecorded and the recorded signals, the format of the data, the format of the information zone, the format of the unrecorded zone, and the recording method, thereby allowing for information interchange by means of such disks.

Technologies de l'information — Disque DVD réenregistrable (DVD-RW) de 80 mm (1,46 Go par face) et 120 mm (4,70 Go par face)

General Information

- Status

- Published

- Publication Date

- 11-Jul-2004

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 21-Aug-2020

- Completion Date

- 12-Feb-2026

Relations

- Consolidated By

ISO 10993-6:2016 - Biological evaluation of medical devices — Part 6: Tests for local effects after implantation - Effective Date

- 06-Jun-2022

Overview - ISO/IEC 17342:2004 (DVD-RW 80 mm & 120 mm)

ISO/IEC 17342:2004 defines the mechanical, physical and optical characteristics of 80 mm (≈1.46 Gbytes/side) and 120 mm (≈4.70 Gbytes/side) DVD re‑recordable (DVD‑RW) discs to enable reliable interchange between media and drives. The standard specifies requirements for pre‑recorded, unrecorded and recorded signals, the data and information‑zone formats, the unrecorded zone, and the recording method - plus test and measurement conditions used to verify conformance.

Key topics and requirements

- Dimensional and mechanical characteristics: overall dimensions, clamping zone, information zone layout, mass, moment of inertia, runout and balance requirements that affect drive compatibility.

- Optical parameters: substrate thickness, refractive index, reflectivity (recorded and unrecorded), polarity of reflectivity modulation and birefringence limits to ensure correct read/write performance.

- Operational signals: quality and formats of high‑frequency (HF) read signals, jitter, random errors, defects and servo signals (radial/tangential push‑pull, differential phase tracking).

- Data format and addressing: frame structure, identification data (ID), error detection codes, information‑zone and unrecorded‑zone formats to support interoperable data exchange.

- Measurement & conformance tools: reference measurement devices such as Pick‑Up Heads (PUH), normalized servo transfer functions and specified test conditions for recorded and unrecorded disks.

- Environmental and safety criteria: test, operating, storage and transportation environments; safety and flammability considerations relevant to media handling and manufacturing.

- Recording method and write strategy: prescribed approaches and test practices for writing to DVD‑RW media to ensure reliable recorded signal quality.

Practical applications - who uses this standard

- Optical disc manufacturers and media suppliers: to design and produce DVD‑RW discs that meet interoperability requirements.

- Drive, PUH and optical pickup designers: to tune servo, optics and firmware for correct tracking, focus and read/write performance.

- Test laboratories and QA teams: to perform acceptance testing, conformance verification and manufacturing quality control using defined measurement procedures.

- System integrators, duplication services and archival professionals: to select compatible media and drives for reliable data storage, duplication and long‑term preservation.

- Firmware developers and device manufacturers: to implement addressing, error detection and read/write strategies consistent with the DVD‑RW format.

Related standards

- Complementary ISO/IEC standards cover other optical media (CD, DVD and rewritable formats) and may be consulted for cross‑compatibility, media labeling and broader optical‑storage system requirements.

Keywords: ISO/IEC 17342, DVD‑RW, 80 mm DVD, 120 mm DVD, optical disc standard, DVD re‑recordable, mechanical characteristics, optical parameters, data format, servo signals, conformance testing.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

NYCE

Mexican standards and certification body.

Sponsored listings

Frequently Asked Questions

ISO/IEC 17342:2004 is a standard published by the International Organization for Standardization (ISO). Its full title is "Information technology — 80 mm (1,46 Gbytes per side) and 120 mm (4,70 Gbytes per side) DVD re-recordable disk (DVD-RW)". This standard covers: ISO/IEC 17342:2004 specifies the mechanical, physical and optical characteristics of an 80 mm and a 120 mm DVD re-recordable disk to enable the interchange of such disks. It specifies the quality of the pre-recorded, unrecorded and the recorded signals, the format of the data, the format of the information zone, the format of the unrecorded zone, and the recording method, thereby allowing for information interchange by means of such disks.

ISO/IEC 17342:2004 specifies the mechanical, physical and optical characteristics of an 80 mm and a 120 mm DVD re-recordable disk to enable the interchange of such disks. It specifies the quality of the pre-recorded, unrecorded and the recorded signals, the format of the data, the format of the information zone, the format of the unrecorded zone, and the recording method, thereby allowing for information interchange by means of such disks.

ISO/IEC 17342:2004 is classified under the following ICS (International Classification for Standards) categories: 35.220.30 - Optical storage devices. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/IEC 17342:2004 has the following relationships with other standards: It is inter standard links to ISO 10993-6:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO/IEC 17342:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO/IEC

STANDARD 17342

First edition

2004-07-15

Information technology — 80 mm

(1,46 Gbytes per side) and 120 mm

(4,70 Gbytes per side) DVD re-recordable

disk (DVD-RW)

Technologies de l'information — Disque DVD réenregistrable

(DVD-RW) de 80 mm (1,46 Go par face) et 120 mm (4,70 Go par face)

Reference number

©

ISO/IEC 2004

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO/IEC 2004

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO/IEC 2004 – All rights reserved

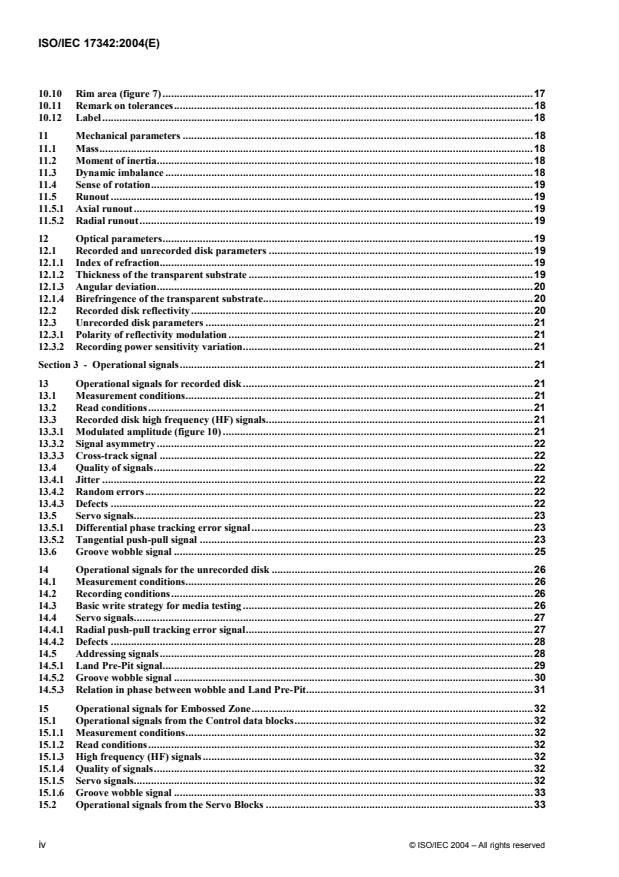

Contents Page

Foreword. vii

Section 1 - General . 1

1 Scope . 1

2 Conformance . 1

2.1 Optical Disk. 1

2.2 Generating system. 1

2.3 Receiving system. 2

3 Normative references . 2

4 Terms and definitions . 2

5 Conventions and notations . 4

5.1 Representation of numbers . 4

5.2 Names. 5

6 Acronyms . 5

7 General description of the disk. 6

8 General requirement.7

8.1 Environments . 7

8.1.1 Test environment . 7

8.1.2 Operating environment. 7

8.1.3 Storage environment.7

8.1.4 Transportation. 8

8.2 Safety requirements . 8

8.3 Flammability . 8

9 Reference measurement devices . 8

9.1 Pick-Up Head (PUH).8

9.1.1 PUH for measuring recorded disks . 8

9.1.2 PUH for measuring unrecorded disks . 9

9.2 Measurement conditions . 11

9.2.1 Recorded and unrecorded disk. 11

9.2.2 Recorded disk . 11

9.2.3 Unrecorded disk. 11

9.3 Normalized servo transfer function. 11

9.4 Reference servo for axial tracking. 11

9.5 Reference servo for radial tracking . 12

Section 2 - Dimensional, mechanical and physical characteristics of the disk . 13

10 Dimensional characteristics (figures 6, 7 and 8). 13

10.1 Overall dimensions (figure 6) . 15

10.2 First transition area (figure 6). 15

10.3 Second transition area (figure 6) . 15

10.4 Clamping Zone (figure 6) . 16

10.5 Third transition area (figure 6) . 16

10.6 R-Information Zone (figure 6). 16

10.6.1 Sub-divisions of the R-Information Zone. 16

10.7 Information Zone (figure 6) . 16

10.7.1 Sub-divisions of the Information zone . 16

10.8 Track geometry. 17

10.9 Channel bit length. 17

© ISO/IEC 2004 – All rights reserved iii

10.10 Rim area (figure 7).17

10.11 Remark on tolerances.18

10.12 Label.18

11 Mechanical parameters .18

11.1 Mass.18

11.2 Moment of inertia.18

11.3 Dynamic imbalance .18

11.4 Sense of rotation.19

11.5 Runout .19

11.5.1 Axial runout.19

11.5.2 Radial runout.19

12 Optical parameters.19

12.1 Recorded and unrecorded disk parameters .19

12.1.1 Index of refraction.19

12.1.2 Thickness of the transparent substrate .19

12.1.3 Angular deviation.20

12.1.4 Birefringence of the transparent substrate.20

12.2 Recorded disk reflectivity.20

12.3 Unrecorded disk parameters .21

12.3.1 Polarity of reflectivity modulation .21

12.3.2 Recording power sensitivity variation.21

Section 3 - Operational signals.21

13 Operational signals for recorded disk.21

13.1 Measurement conditions.21

13.2 Read conditions.21

13.3 Recorded disk high frequency (HF) signals.21

13.3.1 Modulated amplitude (figure 10) .21

13.3.2 Signal asymmetry.22

13.3.3 Cross-track signal .22

13.4 Quality of signals.22

13.4.1 Jitter .22

13.4.2 Random errors.22

13.4.3 Defects .22

13.5 Servo signals.23

13.5.1 Differential phase tracking error signal.23

13.5.2 Tangential push-pull signal .23

13.6 Groove wobble signal .25

14 Operational signals for the unrecorded disk .26

14.1 Measurement conditions.26

14.2 Recording conditions.26

14.3 Basic write strategy for media testing .26

14.4 Servo signals.27

14.4.1 Radial push-pull tracking error signal.27

14.4.2 Defects .28

14.5 Addressing signals.28

14.5.1 Land Pre-Pit signal.29

14.5.2 Groove wobble signal .30

14.5.3 Relation in phase between wobble and Land Pre-Pit.31

15 Operational signals for Embossed Zone.32

15.1 Operational signals from the Control data blocks.32

15.1.1 Measurement conditions.32

15.1.2 Read conditions.32

15.1.3 High frequency (HF) signals.32

15.1.4 Quality of signals.32

15.1.5 Servo signals.32

15.1.6 Groove wobble signal .33

15.2 Operational signals from the Servo Blocks .33

iv © ISO/IEC 2004 – All rights reserved

15.2.1 Measurement conditions . 33

15.2.2 Read conditions. 33

15.2.3 Servo signals . 34

15.2.4 Addressing signals . 34

Section 4 - Data format. 35

16 General. 35

17 Data Frames (figure 23) . 35

17.1 Identification Data (ID). 36

17.2 ID Error Detection Code. 36

17.3 RSV . 37

17.4 Error Detection Code. 37

18 Scrambled Frames . 37

19 ECC Block configuration . 38

20 Recording Frames. 40

21 Modulation . 41

22 Physical Sectors . 41

23 Suppress control of the d.c. component . 43

24 Linking scheme. 44

24.1 Structure of linking. 44

24.2 2K-Link and 32K-Link . 44

24.3 Lossless-Link . 45

Section 5 - Format of the Information Zone. 47

25 General description of the Information Zone . 47

25.1 Layout of the Information Zone . 47

25.2 Physical Sector numbering. 47

26 Lead-in and Lead-out Zone. 48

26.1 Lead-in Zone. 48

26.1.1 Initial Zone . 49

26.1.2 Buffer Zone 0. 49

26.1.3 RW-Physical Format Information Zone. 49

26.1.4 Reference Code Zone . 52

26.1.5 Buffer Zone 1. 52

26.1.6 Control Data Zone . 52

26.1.7 Extra Border Zone. 56

26.2 Lead-out Zone. 57

Section 6 - Format of the Unrecorded Zone . 57

27 General description of the Unrecorded Zone. 57

27.1 Layout of the Unrecorded Zone . 57

27.2 ECC Block address . 57

27.3 ECC Block numbering . 58

28 Pre-pit Data format. 58

28.1 General description. 58

28.2 Pre-pit block structure. 60

28.3 Pre-pit data block configuration. 62

28.3.1 Relative address. 63

28.3.2 ECC Block address data configuration. 64

28.3.3 Parity A and Parity B. 64

28.3.4 Field ID0. 65

28.3.5 Field ID1. 65

28.3.6 Field ID2 and ID5 . 67

28.3.7 Field ID3 and Field ID4. 74

© ISO/IEC 2004 – All rights reserved v

29 Data structure of R-Information Zone.75

29.1 Layout of Power Calibration Area and Recording Management Area .75

29.2 Structure of the Power Calibration Area .75

29.3 Data configuration of the Recording Management Area (RMA).76

29.3.1 Sector format of the Recording Management Area (figure 62).76

29.3.2 The data structure of RMA .78

29.3.3 Recording Management Data (RMD) .79

Annex A (normative) Measurement of the angular deviation αααα.96

Annex B (normative) Measurement of birefringence.98

Annex C (normative) Measurement of the differential phase tracking error .101

Annex D (normative) Measurement of light reflectance .105

Annex E (normative) Tapered cone for disk clamping.107

Annex F (normative) Measurement of jitter.108

Annex G (normative) 8-to-16 Modulation with RLL (2,10) requirements.111

Annex H (normative) Optimum Power Control .121

Annex J (normative) Measurement of the groove wobble amplitude .124

Annex K (normative) Measurement methods for the operational signals for an unrecorded disk .126

Annex L (normative) NBCA Code .127

Annex M (normative) Border Zone.133

Annex N (normative) Write Strategy Options .143

Annex P (normative) Measurement method of the Land Pre-Pit signal .145

Annex Q (informative) Transportation .146

Annex R (informative) Erase operation and Format operation .147

vi © ISO/IEC 2004 – All rights reserved

Foreword

ISO (the International Organization for Standardization) and IEC (the International Electrotechnical

Commission) form the specialized system for worldwide standardization. National bodies that are members of

ISO or IEC participate in the development of International Standards through technical committees

established by the respective organization to deal with particular fields of technical activity. ISO and IEC

technical committees collaborate in fields of mutual interest. Other international organizations, governmental

and non-governmental, in liaison with ISO and IEC, also take part in the work. In the field of information

technology, ISO and IEC have established a joint technical committee, ISO/IEC JTC 1.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of the joint technical committee is to prepare International Standards. Draft International

Standards adopted by the joint technical committee are circulated to national bodies for voting. Publication as

an International Standard requires approval by at least 75 % of the national bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO and IEC shall not be held responsible for identifying any or all such patent rights.

ISO/IEC 17342 was prepared by Ecma International (as ECMA-338) and was adopted, under a special “fast-

track procedure”, by Joint Technical Committee ISO/IEC JTC 1, Information technology, in parallel with its

approval by national bodies of ISO and IEC.

© ISO/IEC 2004 – All rights reserved vii

INTERNATIONAL STANDARD ISO/IEC 17342:2004(E)

Information technology — 80 mm (1,46 Gbytes per side) and

120 mm (4,70 Gbytes per side) DVD re-recordable disk

(DVD-RW)

Section 1 - General

1 Scope

This International Standard specifies the mechanical, physical and optical characteristics of an 80 mm and a

120 mm DVD Re-recordable disk to enable the interchange of such disks. It specifies the quality of the pre-

recorded, unrecorded and the recorded signals, the format of the data, the format of the information zone, the

format of the unrecorded zone, and the recording method, thereby allowing for information interchange by

means of such disks. This disk is identified as a DVD Re-recordable (DVD-RW) disk.

This International Standard specifies

− 80 mm and 120 mm nominal diameter disks that may be either single or double sided,

− the conditions for conformance,

− the environments in which the disk is to be operated and stored,

− the mechanical and physical characteristics of the disk, so as to provide mechanical interchange between

data processing systems,

− the format of the pre-recorded information on an unrecorded disk, including the physical disposition of the

tracks and sectors, the error correcting codes and the coding method used,

− the format of the data and the recorded information on the disk, including the physical disposition of the

tracks and sectors, the error correcting codes and the coding method used,

− the characteristics of the signals from pre-recorded and unrecorded areas on the disk, enabling data

processing systems to read the pre-recorded information and to write to the disks,

− the characteristics of the signals recorded on the disk, enabling data processing systems to read the data

from the disk.

This International Standard provides for interchange of disks between disk drives. Together with a standard for

volume and file structure, it provides for full data interchange between data processing systems.

2 Conformance

2.1 Optical Disk

A claim of conformance shall specify the type of the disk, i.e. its size and whether it is single-sided or double

sided. An optical disk shall be in conformance with this International Standard if it meets the mandatory

requirements specified for this type.

2.2 Generating system

A generating system shall be in conformance with this International Standard if the optical disk it generates is in

accordance with 2.1.

© ISO/IEC 2004 – All rights reserved 1

2.3 Receiving system

A receiving system shall be in conformance with this International Standard if it is able to handle an optical disk

according to 2.1.

3 Normative references

The following referenced documents are indispensable for the application of this document. For dated references, only

the edition cited applies. For undated references, the latest edition of the referenced document (including any

amendments) applies.

ISO/IEC 10646-1:2000, Information technology — Universal Multiple-Octet Coded Character Set (UCS) —

Part 1: Architecture and Basic Multilingual Plane

ECMA-287:2002, Safety of electronic equipment

4 Terms and definitions

For the purposes of this document, the following definitions apply.

4.1

Block SYNC Guard Area

The recorded area in the first ECC block of the contiguous area of which recording is started from the unrecorded area by

using 32K-Link.

4.2

Border Zone

The linking region that prevents the pick-up head from over running on an unrecorded area when a disk is played back in

a partially recorded state.

4.3

Channel bit

The elements by which, after modulation, the binary values ZERO and ONE are represented on the disk by marks.

4.4

Clamping Zone

The annular part of the disk within which a clamping force is applied by a clamping device.

4.5

Data Zone

The zone between the Lead-in Zone and the Lead-out Zone in which user data is recorded.

4.6

Data Recordable Zone

The zone that is available to record user data.

4.7

Digital Sum Value (DSV)

The arithmetic sum obtained from a bit stream by allocating the decimal value 1 to bits set to ONE and the decimal value

–1 to bits set to Zero.

4.8

Disk at once recording

A recording mode in which the Lead-in Zone, the user data and the Lead-out Zone are recorded sequentially.

2 © ISO/IEC 2004 – All rights reserved

4.9

Disk Reference Plane

A plane defined by the perfectly flat annular surface of an ideal spindle onto which the Clamping Zone of the disk is

clamped, and which is normal to the axis of rotation.

4.10

ECC Block address

The address embossed on the land as the Pre-pit Information, which represents the absolute physical address of the track

used to define the recording position of each area. The address is equal to the bit-inverted numbers from b23 to b4 of the

Physical Sector Number recorded in the groove.

NOTE The "ECC Block address" definition is specific to this Standard.

4.11

Erase

Irradiating the recording layer with dc power and restoring the operational signals before recording.

4.12

Error Correction Code (ECC)

A mathematical computation yielding check bytes used for the detection and correction of errors in data.

4.13

Error Detection Code

A code designed to detect certain kinds of errors in data.

Error Detection Code consists of data and the error detection parity.

4.14

Finalization

The action in which the Lead-in Zone and the Lead-out Zone are recorded.

4.15

Groove

The wobbled guidance track.

4.16

Incremental recording

A recording mode in which the disk is recorded in several distinct recording operations (for example at different times

and using different recording drives). In this recording mode, the specified linking scheme shall be used.

4.17

Information Zone

The zone comprising the Lead-in Zone, the Data Zone and the Lead-out Zone.

4.18

Land

The area between the grooves.

4.19

Land Pre-Pit (LPP)

Pits embossed on the land during the manufacture of the disk substrate, which contain address information.

4.20

Lead-in Zone

The zone comprising Physical sectors adjacent to the inside of the Data Zone.

4.21

Lead-out Zone

The zone comprising Physical sectors adjacent to the outside of the Data Zone.

© ISO/IEC 2004 – All rights reserved 3

4.22

Recording Management Area (RMA)

The area containing the Recording Management Data (RMD), situated adjacent to the inside of the Lead-in Zone.

4.23

Recording Management Data (RMD)

The information about the recording on the disk, including information on each recording mode.

4.24

Restricted Overwrite

A recording mode where ECC block(s) are recorded onto any portion of recorded ECC block(s) or concatenated to the

most outer recorded ECC block(s) using the Linking scheme.

4.25

R-Information Zone

The zone comprising the Power Calibration Area (PCA) and the Recording Management Area (RMA).

4.26

RZone

Continuous ECC blocks assigned to user data during Incremental recording mode and Restricted Overwrite mode.

4.27

Sector

The smallest addressable part of a track in the information zone of a disk that can be accessed independently of other

addressable parts.

4.28

Substrate

A transparent layer of the disk, provided for mechanical support of the recording or recorded layer, through which the

optical beam accesses the recordable / recorded layer.

4.29

Track

A 360° turn of a continuous spiral of recorded marks or groove.

4.30

Track pitch

The distance between adjacent average physical track centrelines of the wobbled grooves for the unrecorded disk, or

between adjacent physical track centrelines of the successive recorded marks for the recorded disk, measured in the radial

direction.

4.31

Zone

An annular area of the disk.

5 Conventions and notations

5.1 Representation of numbers

A measured value is rounded off to the least significant digit of the corresponding specified value. For instance,

it implies that a specified value of 1,26 with a positive tolerance of + 0,01 and a negative tolerance of - 0,02

allows a range of measured values from 1,235 to 1,275.

Numbers in decimal notations are represented by the digits 0 to 9.

Numbers in hexadecimal notation are represented by the hexadecimal digits 0 to 9 and A to F in parentheses.

The setting of bits is denoted by ZERO and ONE.

4 © ISO/IEC 2004 – All rights reserved

Numbers in binary notations and bit patterns are represented by strings of digits 0 and 1, with the most

significant bit shown to the left.

Negative values of numbers in binary notation are given as Two’s complement.

In each field the data is recorded so that the most significant byte (MSB), identified as Byte 0, is recorded first

and the least significant byte (LSB) last. In a field of 8n⋅bits, bit b shall be the most significant bit (msb)

(8n-1)

and bit b the least significant bit (lsb). Bit b is recorded first.

0 (8n-1)

5.2 Names

The names of entities, e.g. specific tracks, fields, areas, zones, etc. are given a capital initial.

6 Acronyms

AP Amplitude of the land Pre-Pit signal (without wobble amplitude)

AR Aperture Ratio (of the Land Pre-Pit after recording)

BP Byte Position

BPF Band Pass Filter

CLV Constant Linear Velocity

CNR Carrier to Noise Ratio

CPR_MAI Copyright Management Information

DCC DC Component Suppress Control

DS Defect Status

DSV Digital Sum Value

ECC Error Correction Code

EDC Error Detection Code

HF High Frequency

ID Identification Data

LA Lead-out Attribute

IED ID Error Detection (code)

LPF Low-Pass Filter

LPP Land Pre-Pit

lsb least significant bit

LSB Least Significant Byte

msb most significant bit

MSB Most Significant Byte

NBCA Narrow Burst Cutting Area

NRZI Non Return to Zero Inverted

OPC Optimum Power Control

PBS Polarizing Beam Splitter

PCA Power Calibration Area

PI Parity (of the) Inner (code)

PLL Phase Locked Loop

PO Parity (of the) Outer (code)

PSN Physical Sector Number

PUH Pick-Up Head

RBP Relative Byte Position

RBW Resolution Bandwidth

RESYNC Re-Synchronization

RMA Recording Management Area

RMD Recording Management Data

RS Reed-Solomon (code)

RSDS RMA Segment Defect Status

SYNC Synchronization

© ISO/IEC 2004 – All rights reserved 5

7 General description of the disk

The 80 mm and 120 mm optical disks that are the subject of this International Standard consist of two substrates

bonded together by an adhesive layer, so that the recording layer (single-sided disk) or recording layers (double-

sided disk) are on the inside. The centring of the disk is performed on the edge of the centre hole of the

assembled disk on the side currently read. Clamping is performed in the Clamping Zone. The DVD Re-

recordable Disk (DVD-RW) may be either double-sided or single-sided with respect to the number of recording

layers. A double-sided disk has a recording layer on the inside of each substrate. A single-sided disk has one

substrate with the recording layer on the inside and a dummy substrate without a recording layer. A recorded

disk provides for the data to be read many times by an optical beam of a drive. Figure 1 shows schematically a

double-sided (Type 2S) and a single-sided (Type 1S) disk.

Type 1S consists of a substrate, a single recording layer, an adhesive layer, and a dummy substrate. The

recording layer can be accessed from one side only. The nominal capacity is 1,46 Gbytes for an 80 mm disk and

4,70 Gbytes for a 120 mm disk.

Type 2S consists of two substrates, two recording layers, and an adhesive layer. From one side of the disk only

one recording layer can be accessed. The nominal total capacity is 2,92 Gbytes for an 80 mm disk and 9,40

Gbytes for a 120 mm disk.

Figure 1 - Disk outline

6 © ISO/IEC 2004 – All rights reserved

8 General requirement

8.1 Environments

8.1.1 Test environment

The test environment is the environment where the air immediately surrounding the disk has the following

properties.

a) For dimensional measurements b) For other measurements

temperature: 23 °C ± 2 °C 15 °C to 35 °C

relative humidity: 45 % to 55 % 45 % to 75 %

atmospheric pressure: 86 kPa to 106 kPa 86 kPa to 106 kPa

Unless otherwise stated, all tests and measurements shall be made in this test environment.

8.1.2 Operating environment

8.1.2.1 Recorded and unrecorded disk

This International Standard requires that an optical disk which meets all mandatory requirements of this

International Standard in the specified test environment provides data interchange over the specified ranges of

environmental parameters in the operating environment.

Disks used for data interchange shall be operated under the following conditions, when mounted in the drive

supplied with voltage and measured on the outside surface of the disk.

The disk exposed to storage conditions shall be conditioned in the operating environment for at least two hours

before operating.

temperature: -25 °C to 70 °C

relative humidity: 3 % to 95 %

3 3

absolute humidity: 0,5 g/m to 60 g/m

temperature gradient: 15 °C/h max.

relative humidity gradient: 10 %/h max.

There shall be no condensation of moisture on the disk.

8.1.2.2 Environmental conditions during recording

The disk e

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...