ISO 14896:2006

(Main)Plastics - Polyurethane raw materials - Determination of isocyanate content

Plastics - Polyurethane raw materials - Determination of isocyanate content

ISO 14896:2006 specifies two methods for the measurement of the isocyanate content of aromatic isoocyanates used as polyurethane raw materials. Method A is primarily applicable to refined toluene diisocyanate (TDI), methylene-bis-(4-phenylisocyanate) (MDI) and their prepolymers. Method B is applicable to refined, crude or modified isocyanates derived from toluene diisocyanate, methylene-bis-(4-phenylisocyanate) and polymethylene polyphenylisocyanate. It can also be used for isomer mixtures of toluene diisocyanate, methylene-bis-(4-phenylisocyanate) and polymethylene polyphenylisocyanate. Other aromatic isocyanates may be analysed by this method if precautions are taken to verify suitability. It is not applicable to blocked isocyanates.

Plastiques — Matières premières des polyuréthannes — Détermination de la teneur en isocyanate

General Information

Relations

Frequently Asked Questions

ISO 14896:2006 is a standard published by the International Organization for Standardization (ISO). Its full title is "Plastics - Polyurethane raw materials - Determination of isocyanate content". This standard covers: ISO 14896:2006 specifies two methods for the measurement of the isocyanate content of aromatic isoocyanates used as polyurethane raw materials. Method A is primarily applicable to refined toluene diisocyanate (TDI), methylene-bis-(4-phenylisocyanate) (MDI) and their prepolymers. Method B is applicable to refined, crude or modified isocyanates derived from toluene diisocyanate, methylene-bis-(4-phenylisocyanate) and polymethylene polyphenylisocyanate. It can also be used for isomer mixtures of toluene diisocyanate, methylene-bis-(4-phenylisocyanate) and polymethylene polyphenylisocyanate. Other aromatic isocyanates may be analysed by this method if precautions are taken to verify suitability. It is not applicable to blocked isocyanates.

ISO 14896:2006 specifies two methods for the measurement of the isocyanate content of aromatic isoocyanates used as polyurethane raw materials. Method A is primarily applicable to refined toluene diisocyanate (TDI), methylene-bis-(4-phenylisocyanate) (MDI) and their prepolymers. Method B is applicable to refined, crude or modified isocyanates derived from toluene diisocyanate, methylene-bis-(4-phenylisocyanate) and polymethylene polyphenylisocyanate. It can also be used for isomer mixtures of toluene diisocyanate, methylene-bis-(4-phenylisocyanate) and polymethylene polyphenylisocyanate. Other aromatic isocyanates may be analysed by this method if precautions are taken to verify suitability. It is not applicable to blocked isocyanates.

ISO 14896:2006 is classified under the following ICS (International Classification for Standards) categories: 83.080.10 - Thermosetting materials. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 14896:2006 has the following relationships with other standards: It is inter standard links to ISO 14896:2006/Amd 1:2007, ISO 14896:2000/Cor 1:2005, ISO 14896:2009, ISO 14896:2000; is excused to ISO 14896:2006/Amd 1:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ISO 14896:2006 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 14896

Second edition

2006-06-01

Plastics — Polyurethane raw materials —

Determination of isocyanate content

Plastiques — Matières premières des polyuréthannes — Détermination

de la teneur en isocyanate

Reference number

©

ISO 2006

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2006

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2006 – All rights reserved

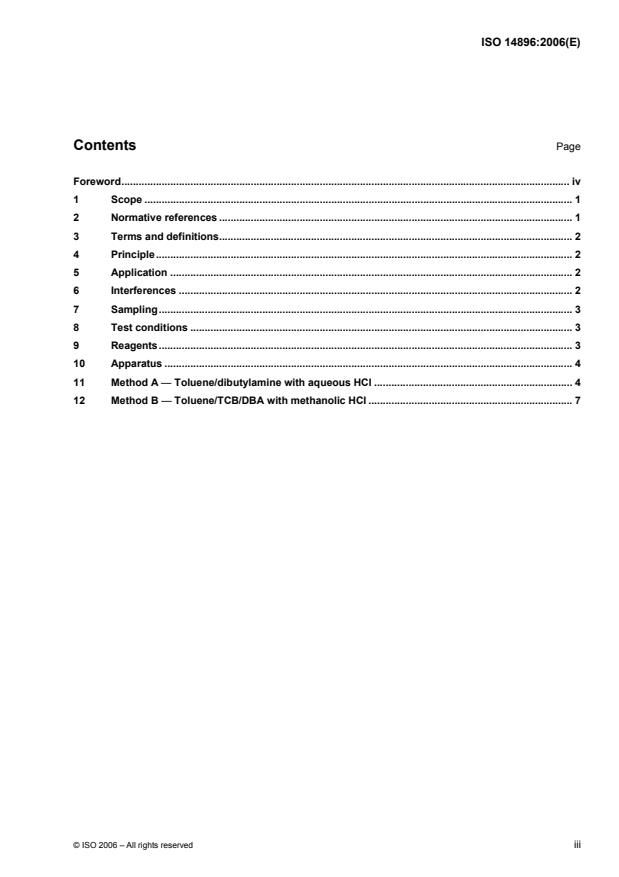

Contents Page

Foreword. iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions. 2

4 Principle. 2

5 Application . 2

6 Interferences . 2

7 Sampling. 3

8 Test conditions . 3

9 Reagents. 3

10 Apparatus . 4

11 Method A — Toluene/dibutylamine with aqueous HCI . 4

12 Method B — Toluene/TCB/DBA with methanolic HCI . 7

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 14896 was prepared by Technical Committee ISO/TC 61, Plastics, Subcommittee SC 12, Thermosetting

materials.

This second edition cancels and replaces the first edition (ISO 14896:2000), of which it constitutes a minor

revision the purpose of which was to combine the standard with its Technical Corrigendum

ISO 14896:2000/Cor.1:2005.

iv © ISO 2006 – All rights reserved

INTERNATIONAL STANDARD ISO 14896:2006(E)

Plastics — Polyurethane raw materials — Determination of

isocyanate content

SAFETY STATEMENT — Persons using this document should be familiar with normal laboratory

practice, if applicable. This document does not purport to address all of the safety concerns, if any,

associated with its use. It is the responsibility of the user to establish appropriate safety and health

practices and to ensure compliance with any regulatory requirements.

1 Scope

This lnternational Standard specifies two methods for the measurement of the isocyanate content of aromatic

isoocyanates used as polyurethane raw materials. Method A is primarily applicable to refined toluene

diisocyanate (TDI), methylene-bis-(4-phenylisocyanate) (MDI) and their prepolymers. Method B is applicable

to refined, crude or modified isocyanates derived from toluene diisocyanate, methylene-bis-

(4-phenylisocyanate) and polymethylene polyphenylisocyanate. It can also be used for isomer mixtures of

toluene diisocyanate, methylene-bis-(4-phenylisocyanate) and polymethylene polyphenylisocyanate. Other

aromatic isocyanates may be analysed by this method if precautions are taken to verify suitability. It is not

applicable to blocked isocyanates.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 385, Laboratory glassware — Burettes

ISO 648, Laboratory glassware — One-mark pipettes

ISO 3696, Water for analytical laboratory use — Specification and test methods

ISO 4787, Laboratory glassware — Volumetric glassware — Methods for use and testing of capacity

ISO 4788, Laboratory glassware — Graduated measuring cylinders

ISO 6353-1, Reagents for chemical analysis — Part 1: General test methods

ISO 6353-2, Reagents for chemical analysis — Part 2: Specifications — First series

ISO 6353-3, Reagents for chemical analysis — Part 3: Specifications — Second series

ISO 14898:1999, Plastics — Aromatic isocyanates for use in the production of polyurethane — Determination

of acidity

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

polyurethane

polymer prepared by the reaction of an organic di- or polyisocyanate with compounds containing two or more

hydroxyl groups

NOTE Polyurethanes may be thermosetting, thermoplastic, rigid or soft and flexible, cellular or non-cellular.

3.2

assay

percent by mass of a specific isocyanate present in a sample

3.3

isocyanate content

NCO content

percent by mass of the NCO groups present in a sample

3.4

amine equivalent

mass of sample that will combine with 1 gram-equivalent of dibutylamine

4 Principle

4.1 Method A

The isocyanate sample is reacted with an excess of dibutylamine in toluene to form the corresponding

substituted urea. After cooling to room temperature, acetone is added as a co-solvent, then the reaction

mixture is back-titrated with standardized aqueous HCI using potentiometric or colorimetric end point

determination.

4.2 Method B

The isocyanate sample is reacted with an excess of dibutylamine in a toluene/trichlorobenzene solvent to form

the corresponding substituted urea. After cooling to room temperature, the reaction mixture is diluted with

methanol and back-titrated potentiometrically or colorimetrically with methanolic hydrochloric acid.

5 Application

These test methods can be used for research or for quality control purposes to characterize isocyanates used

in polyurethane products.

6 Interferences

Phosgene, the carbamyl chloride of the isocyanate, hydrogen chloride and any other acidic or basic

compounds will interfere. In refined isocyanates, these impurities are usually present in such small amounts

that they do not affect the determination; however, some crude or modified isocyanates may contain acidities

of up to approximately 0,3 %, so the value reported for the NCO content of unrefined isocyanates should

preferably be designated as “corrected” or “uncorrected” for acidity.

2 © ISO 2006 – All rights reserved

7 Sampling

Since organic isocyanates react with atmospheric moisture, take special precautions in sampling (see

warning). Usual sampling methods (for example, sampling an open drum with a thief), even when conducted

rapidly, can cause contamination of the sample with insoluble ureas; therefore, blanket the sample with a dry

inert gas (e.g. nitrogen, argon or dried air) at all times.

WARNING — Organic isocyanates are hazardous when absorbed through the skin, or when the

vapours are breathed. Provide adequate ventilation and wear protective gloves and eyeglasses.

8 Test conditions

Since isocyanates react with moisture, keep the laboratory humidity low, preferably below 50 % relative

humidity.

9 Reagents

Use reagent-grade chemicals in all tests. Unless otherwise indicated, it is intended that all reagents shall

conform to the specifications of ISO 6353-1, ISO 63535-2 and ISO 6353-3. Other grades may be used,

provided that it is first determined that the reagent is of sufficiently high purity to permit its use without

lessening the accuracy of the determination. Unless otherwise indicated, references to water shall be

understood to mean grade 3 water as defined in ISO 3696.

9.1 Acetone (method A).

9.2 Toluene, dried over type 4A molecular sieve.

9.3 di-n-butylamine solution, 1 mol/l (method A).

Dilute 129 g of di-n-butylamine to 1 litre with toluene.

9.4 di-n-butylamine solution, 2 mol/l (method B).

Dilute 258 g of di-n-butylamine to 1 litre with toluene.

9.5 Aqueous hydrochloric acid, 1 mol/l (method A).

Prepare 1 mol/l aqueous hydrochloric acid and standardize frequently enough to detect changes of

0,001 mol/l.

9.6 Methanolic hydrochloric acid, 1 mol/l (method B).

Prepare 1 mol/l hydrochloric acid in methanol and standardize frequently enough to detect changes of

0,001 mol/l.

NOTE In order to have homogeneous solutions, it is recommended that methanolic HCI be used in this procedure. If

desired, aqueous HCI can be used; however, turbidity will be encountered in some titrations. It is recommended that

200 ml to 250 rnl of methanol be added to the reacted product to minimize the formation of two layers. Experience has

shown that, if the mixtures are agitated vigorously, inhomogeneity can be tolerated without adversely affecting the results.

9.7 Bromophenol blue indicator solution, for colorimetric titration: 0,04 % aqueous solution of

bromophenol blue sodium salt, reagent grade, or 0,04 % solution of bromophenol blue in acetone.

9.8 1,2,4-Trichlorobenzene (TCB), dried over type 4A molecular sieve (method B).

9.9 Methanol (method B).

10 Apparatus

10.1 Potentiometric titrator or pH-meter, accurate to 0,1 mV or better, equipped with a pair of electrodes or

a combination glass-calomel electrode (filled with a 1 mol/l lithium chloride solution in methanol, or an

equivalent solution) and a piston burette having a 20 ml capacity.

10.2 Syringes, 2 ml and 5 ml, and syringes with a large orifice suitable for weighing v

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...