ISO 10384:2012

(Main)Hot-rolled carbon steel sheet as defined by chemical composition

Hot-rolled carbon steel sheet as defined by chemical composition

ISO 10384:2012 applies to hot-rolled carbon steel sheet as defined by chemical composition. The product is generally used in the heat-treated condition after hot or cold working, press forming or cutting by the customer. For example, the product is used for general machinery such as sprocket wheels, chain links, washers, knife blades and agricultural implements.

Tôles en acier au carbone laminées à chaud définies par leur composition chimique

General Information

Relations

Overview

ISO 10384:2012 specifies requirements for hot‑rolled carbon steel sheet defined by chemical composition. It covers material grades (S08C through S58C), typical product forms (coils and cut lengths), nominal thickness ranges, chemical analysis and reporting, surface condition, descaling/oiling options, marking and inspection. The sheet is generally supplied for further heat treatment and customer forming (hot or cold) and is commonly used for machinery parts such as sprocket wheels, chain links, washers, knife blades and agricultural implements.

Key topics and technical requirements

- Chemical composition and grades: Defines heat‑analysis composition limits for grades S08C to S58C and limits on additional elements (Cu, Ni, Cr, Mo, Nb, V, Ti). The sum limits and reporting rules are specified in tables.

- Heat and product analysis: Manufacturer performs a heat analysis for each heat; purchasers may request product analysis. Sampling follows ISO 14284 and permissible deviations between heat and product analysis are provided.

- Dimensions and forms: Typical thickness range is about 0.8 mm to 12.5 mm; widths normally ≥ 600 mm (narrower widths may be slit from wide sheet). Dimensional and shape tolerances are referenced to ISO 16160.

- Surface condition and descaling: Hot‑rolled sheet carries oxide/scale. Descaling by pickling or mechanical means (grit/shot blasting) is addressed - purchaser should specify method because mechanical descaling can affect hardness/ductility.

- Oiling and rust protection: Descaled sheet is usually oiled to deter rust; the standard explains oiling is not a forming lubricant and that unoiled material can be supplied on request with limited supplier responsibility for oxidation.

- Tests available on request: Purchaser may request tests such as depth of decarburization (ISO 3887), non‑metallic inclusions (ISO 4967), grain size (ISO 643), hardness (ISO 6507‑1, ISO 6508‑1) and microstructure. Tensile properties are generally not specified because parts are heat treated after delivery.

- Marking and documentation: Minimum marking (manufacturer, ISO number, grade, order number, dimensions, lot and mass) and options for heat‑analysis and test reports are specified. Coil inside/outside diameter and mass limits should be agreed at order.

Applications and users

Who uses ISO 10384:2012:

- Steel producers and mills (for product specification and certification)

- OEMs and fabricators specifying raw material for stamped, formed or heat‑treated parts

- Procurement and quality engineers who require material traceability, heat analyses and acceptance testing

- Product designers and metallurgists selecting carbon steel grades for machinery, agricultural implements and abrasion‑resistant components

Related standards (normative references)

- ISO 14284 - sampling for chemical analysis

- ISO 16160 - dimensional and shape tolerances for hot‑rolled sheet

- ISO 3887, ISO 4967, ISO 643, ISO 6507‑1, ISO 6508‑1 - optional tests referenced by ISO 10384

Keywords: ISO 10384:2012, hot‑rolled carbon steel sheet, chemical composition, S40C, heat analysis, product analysis, descaling, coil marking, ISO 16160.

Frequently Asked Questions

ISO 10384:2012 is a standard published by the International Organization for Standardization (ISO). Its full title is "Hot-rolled carbon steel sheet as defined by chemical composition". This standard covers: ISO 10384:2012 applies to hot-rolled carbon steel sheet as defined by chemical composition. The product is generally used in the heat-treated condition after hot or cold working, press forming or cutting by the customer. For example, the product is used for general machinery such as sprocket wheels, chain links, washers, knife blades and agricultural implements.

ISO 10384:2012 applies to hot-rolled carbon steel sheet as defined by chemical composition. The product is generally used in the heat-treated condition after hot or cold working, press forming or cutting by the customer. For example, the product is used for general machinery such as sprocket wheels, chain links, washers, knife blades and agricultural implements.

ISO 10384:2012 is classified under the following ICS (International Classification for Standards) categories: 77.140.50 - Flat steel products and semi-products. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 10384:2012 has the following relationships with other standards: It is inter standard links to ISO 10384:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ISO 10384:2012 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 10384

Fourth edition

2012-12-15

Hot-rolled carbon steel sheet as

defined by chemical composition

Tôles en acier au carbone laminées à chaud définies par leur

composition chimique

Reference number

©

ISO 2012

© ISO 2012

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any

means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the

address below or ISO’s member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2012 – All rights reserved

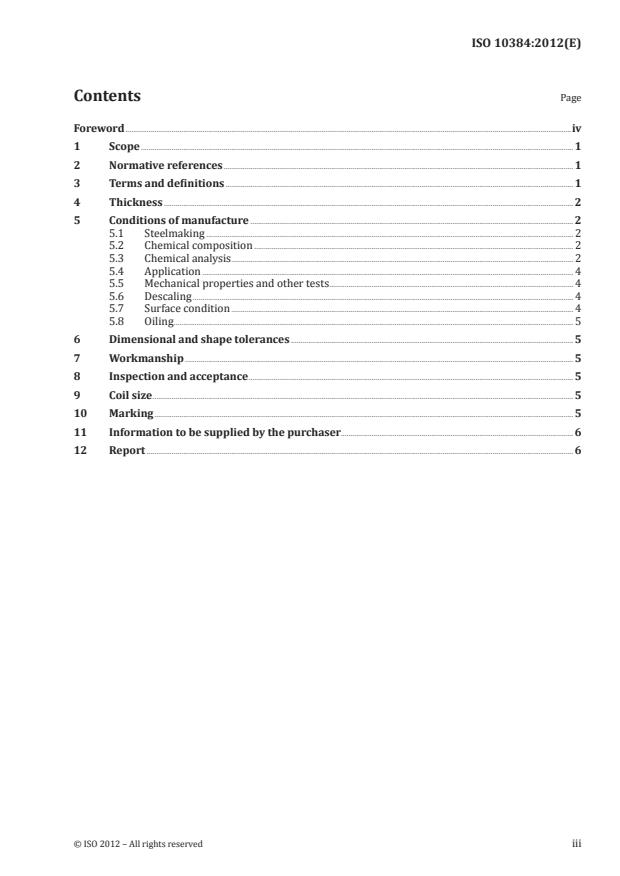

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Thickness . 2

5 Conditions of manufacture . 2

5.1 Steelmaking . 2

5.2 Chemical composition . 2

5.3 Chemical analysis . 2

5.4 Application . 4

5.5 Mechanical properties and other tests . 4

5.6 Descaling . 4

5.7 Surface condition . 4

5.8 Oiling . 5

6 Dimensional and shape tolerances . 5

7 Workmanship . 5

8 Inspection and acceptance . 5

9 Coil size . 5

10 Marking . 5

11 Information to be supplied by the purchaser. 6

12 Report . 6

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International

Standards adopted by the technical committees are circulated to the member bodies for voting.

Publication as an International Standard requires approval by at least 75 % of the member bodies

casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 10384 was prepared by Technical Committee ISO/TC 17, Steel, Subcommittee SC 12, Continuous mill

flat rolled products.

This fourth edition cancels and replaces the third edition (ISO 10384:2008), which has been

technically revised.

iv © ISO 2012 – All rights reserved

INTERNATIONAL STANDARD ISO 10384:2012(E)

Hot-rolled carbon steel sheet as defined by chemical

composition

1 Scope

This International Standard applies to hot-rolled carbon steel sheet as defined by chemical composition.

The product is generally used in the heat-treated condition after hot or cold working, press forming

or cutting by the customer. For example, the product is used for general machinery such as sprocket

wheels, chain links, washers, knife blades and agricultural implements.

NOTE 1 Hot-rolled sheet up to but not including 3 mm in thickness is commonly known as “sheet”. Hot-rolled

sheet 3 mm and over in thickness is commonly known as either “sheet” or “plate”.

NOTE 2 Steel sheet that is to be subjected to subsequent rerolling is not covered by this International Standard.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the reference document (including any amendments) applies.

ISO 643, Steels — Micrographic determination of the apparent grain size

ISO 3887, Steels — Determination of depth of decarburization

ISO 4967, Steel — Determination of content of nonmetallic inclusions — Micrographic method using

standard diagrams

ISO 6507-1, Metallic materials — Vickers hardness test — Part 1: Test method

ISO 6508-1, Metallic materials — Rockwell hardness test — Part 1: Test method (scales A, B, C, D, E, F,

G, H, K, N, T)

ISO 14284, Steel and iron — Sampling and preparation of samples for the determination of chemical composition

ISO 16160, Hot-rolled steel sheet products — Dimensional and shape tolerances

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

hot-rolled steel sheet

product obtained by rolling heated steel through a continuous hot strip mill or other hot rolling processes

that produce a coiled product to the required sheet thickness and tolerances

Note 1 to entry: The product has a surface covered with oxide or scale resulting from the hot rolling operation.

3.2

hot-rolled descaled steel sheet

hot-rolled steel sheet from which oxide or scale has been removed, usually by pickling in an acid solution

Note 1 to entry: Descaling may also be performed by appropriate mechanical means.

3.3

mill edge

normal edge without any definite contour produced in hot rolling

Note 1 to entry: Mill edges can contain some irregularities such as cracked or torn edges or thin (feathered) edges.

3.4

sheared edge

normal edge obtained by shearing, slitting or trimming a mill edge product

Note 1 to entry: Normal processing does not necessarily provide a definite positioning of the slitting burr.

4 Thickness

4.1 Hot-rolled carbon steel sheet based on chemical composition is manufactured from killed steel

of the chemical compositions listed in Table 1. It is usually produced in the range of thicknesses from

0,8 mm to 12,5 mm inclusive, and in widths of 600 mm and over, in coils and cut lengths.

4.2 Hot-rolled carbon steel sheet less than 600 mm wide may be slit from wide sheet and will be

considered as sheet.

5 Conditions of manufacture

5.1 Steelmaking

Unless otherwise agreed by the interested parties, the processes used in making the steel and in

manufacturing hot-rolled sheet are left to the discretion of the manufacturer. On request, the purchaser

shall be informed of the steelmaking process used.

5.2 Chemical composition

The chemical composition (heat analysis) shall comply with the

...

기사 제목: ISO 10384:2012 - 화학 조성에 따른 핫-압연 탄소강판 기사 내용: ISO 10384:2012는 화학 조성에 따라 정의된 핫-압연 탄소강판에 적용되는 표준이다. 이 제품은 일반적으로 고강도 열처리 상태로 사용되며, 고객에 의해 핫 또는 콜드 워킹, 압연 또는 절단 후에 사용된다. 예를 들어, 이 제품은 스프로켓 휠, 체인 링크, 와셔, 나이프 블레이드 및 농업용 도구와 같은 일반 기계에 사용된다.

記事のタイトル:ISO 10384:2012 - 化学組成によって定義される熱間圧延炭素鋼板 記事内容:ISO 10384:2012は、化学組成によって定義される熱間圧延炭素鋼板に適用される標準です。この製品は一般に、顧客によってホットまたはコールド加工、プレス成形、または切削された後、熱処理状態で使用されます。たとえば、この製品はスプロケットホイール、チェーンリンク、ワッシャー、ナイフの刃、農業用具など、一般機械に使用されます。

ISO 10384:2012 is a standard that applies to hot-rolled carbon steel sheet, specifically defined by its chemical composition. This product is typically used in a heat-treated state after undergoing processes such as hot or cold working, press forming, or cutting done by the customer. It finds application in various industries, including general machinery, where it is used to make items like sprocket wheels, chain links, washers, knife blades, and agricultural implements.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...