ISO 8423:1991/Cor 1:1993

(Corrigendum)Sequential sampling plans for inspection by variables for percent nonconforming (known standard deviation) — Technical Corrigendum 1

Sequential sampling plans for inspection by variables for percent nonconforming (known standard deviation) — Technical Corrigendum 1

Amends values in table 1 and subclause C.2.3 and equations in subclauses 3.2.2.1 and 3.2.3.1.

Plans d'échantillonnage progressif pour le contrôle par mesures des pourcentages de non conformes (écart-type connu) — Rectificatif technique 1

Sequential sampling plans for inspection by variables for percent nonconforming (known standard deviation) - Technical corrigendum 1

General Information

- Status

- Withdrawn

- Publication Date

- 01-Sep-1993

- Withdrawal Date

- 01-Sep-1993

- Technical Committee

- ISO/TC 69/SC 5 - Acceptance sampling

- Drafting Committee

- ISO/TC 69/SC 5 - Acceptance sampling

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 27-Aug-2008

- Completion Date

- 14-Feb-2026

Relations

- Consolidated By

ISO 9163:2005 - Textile glass — Rovings — Manufacture of test specimens and determination of tensile strength of impregnated rovings - Effective Date

- 06-Jun-2022

- Effective Date

- 06-Jun-2022

- Effective Date

- 16-Oct-2025

- Effective Date

- 15-Apr-2008

- Effective Date

- 15-Apr-2008

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

ISO 8423:1991/Cor 1:1993 is a corrigendum published by the International Organization for Standardization (ISO). Its full title is "Sequential sampling plans for inspection by variables for percent nonconforming (known standard deviation) — Technical Corrigendum 1". This standard covers: Amends values in table 1 and subclause C.2.3 and equations in subclauses 3.2.2.1 and 3.2.3.1.

Amends values in table 1 and subclause C.2.3 and equations in subclauses 3.2.2.1 and 3.2.3.1.

ISO 8423:1991/Cor 1:1993 is classified under the following ICS (International Classification for Standards) categories: 03.120.30 - Application of statistical methods. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 8423:1991/Cor 1:1993 has the following relationships with other standards: It is inter standard links to ISO 9163:2005, ISO 8423:1991, ISO 3951-5:2006, ISO 8423:2008; is excused to ISO 8423:1991. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 8423:1991/Cor 1:1993 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

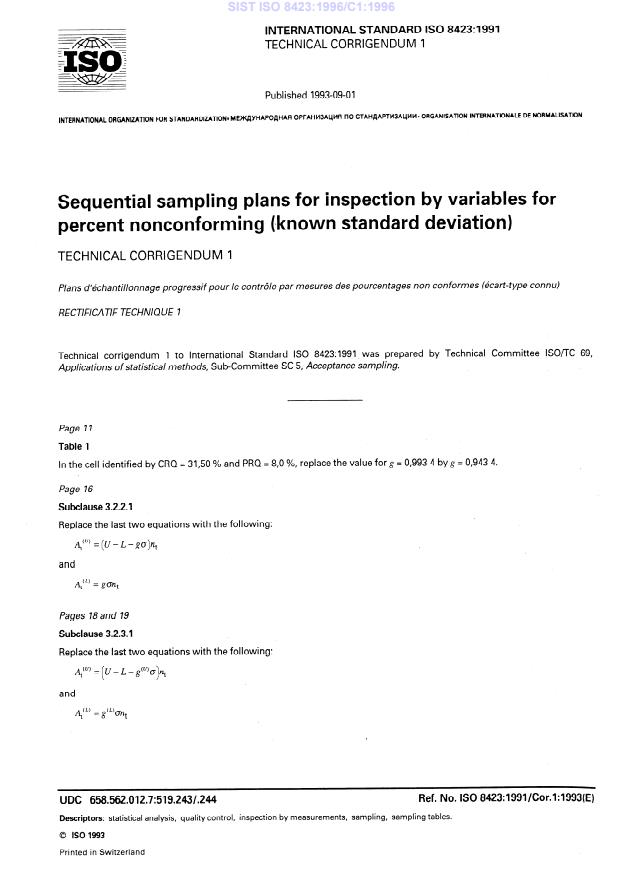

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Sequential sampling plans for inspection by variables for percent nonconforming (known standard deviation) - Technical corrigendum 1ISO 8423:1991/Cor 1:199303.120.30Application of statistical methodsICS:Ta slovenski standard je istoveten z:ISO 8423:1991/Cor 1:1993SIST ISO 8423:1996/C1:1996en01-september-1996SIST ISO 8423:1996/C1:1996SLOVENSKI

STANDARD

INTERNATIONAL STANDARD ISO 8423:1991 --/u/llx\- TECHNICAL CORRIGENDUM 1 +Iso; ÖLS Published 1993-09-01 INTERNATIONAL OAGANUATION FOR STANDARDIZATION. ME~YHAPO~HAR OPrAHl43ALlHR n0 CTAH~APTH3AL&lH. ORGANlSAllON INlERNATlONALE DE NORMALISATlON Sequential sampling Plans for ~inspection by variables for percent nonconforming (known Standard deviation) TECHNICAL CORRIGENDUM 1 Plans dkhantillonnage progressif pour Ie contrGle par mesures des pourcentages non conformes (Ecart-type connu) RECTIFlCATlF TECHN

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...