ISO 9000-2:1997

(Main)Quality management and quality assurance standards — Part 2: Generic guidelines for the application of ISO 9001, ISO 9002 and ISO 9003

Quality management and quality assurance standards — Part 2: Generic guidelines for the application of ISO 9001, ISO 9002 and ISO 9003

Normes pour le management de la qualité et l'assurance de la qualité — Partie 2: Lignes directrices génériques pour l'application de l'ISO 9001, l'ISO 9002 et l'ISO 9003

Standardi za vodenje in zagotavljanje kakovosti - 2. del: Splošne smernice za uporabo standardov ISO 9001, ISO 9002 in ISO 9003

General Information

- Status

- Withdrawn

- Publication Date

- 11-Jun-1997

- Withdrawal Date

- 11-Jun-1997

- Technical Committee

- ISO/TC 176/SC 2 - Quality systems

- Drafting Committee

- ISO/TC 176/SC 2 - Quality systems

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 26-Apr-2001

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 12-May-2008

- Effective Date

- 15-Apr-2008

Buy Documents

ISO 9000-2:1997 - Quality management and quality assurance standards

ISO 9000-2:1997 - Normes pour le management de la qualité et l'assurance de la qualité

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

ISO 9000-2:1997 is a standard published by the International Organization for Standardization (ISO). Its full title is "Quality management and quality assurance standards — Part 2: Generic guidelines for the application of ISO 9001, ISO 9002 and ISO 9003". This standard covers: Quality management and quality assurance standards — Part 2: Generic guidelines for the application of ISO 9001, ISO 9002 and ISO 9003

Quality management and quality assurance standards — Part 2: Generic guidelines for the application of ISO 9001, ISO 9002 and ISO 9003

ISO 9000-2:1997 is classified under the following ICS (International Classification for Standards) categories: 03.100.70 - Management systems; 03.120.10 - Quality management and quality assurance. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 9000-2:1997 has the following relationships with other standards: It is inter standard links to SIST ISO 9000-2:1996, ISO 9000-2:1993. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 9000-2:1997 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-avgust-1998

Standardi za vodenje in zagotavljanje kakovosti - 2. del: Splošne smernice za

uporabo standardov ISO 9001, ISO 9002 in ISO 9003

Quality management and quality assurance standards -- Part 2: Generic guidelines for

the application of ISO 9001, ISO 9002 and ISO 9003

Normes pour le management de la qualité et l'assurance de la qualité -- Partie 2: Lignes

directrices génériques pour l'application de l'ISO 9001, l'ISO 9002 et l'ISO 9003

Ta slovenski standard je istoveten z: ISO 9000-2:1997

ICS:

03.120.10 Vodenje in zagotavljanje Quality management and

kakovosti quality assurance

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

INTERNATIONAL

IS0

STANDARD

9000-2

Second edition

1997-06-I 5

Quality management and quality assurance

standards -

Part 2:

Generic guidelines for the application of

IS0 9001, IS0 9002 and IS0 9003

Normes pour le management de la qua/M et / ‘assurance de la qua/it& -

Parfie 2: Lignes directrices ghkriques pour I ’applica tion de / ‘/SO 900 1,

/ ‘/SO 9002 et IWO 9003

Reference number

IS0 9000-2: 1997(E)

IS0 9000=2:1997(E)

Page

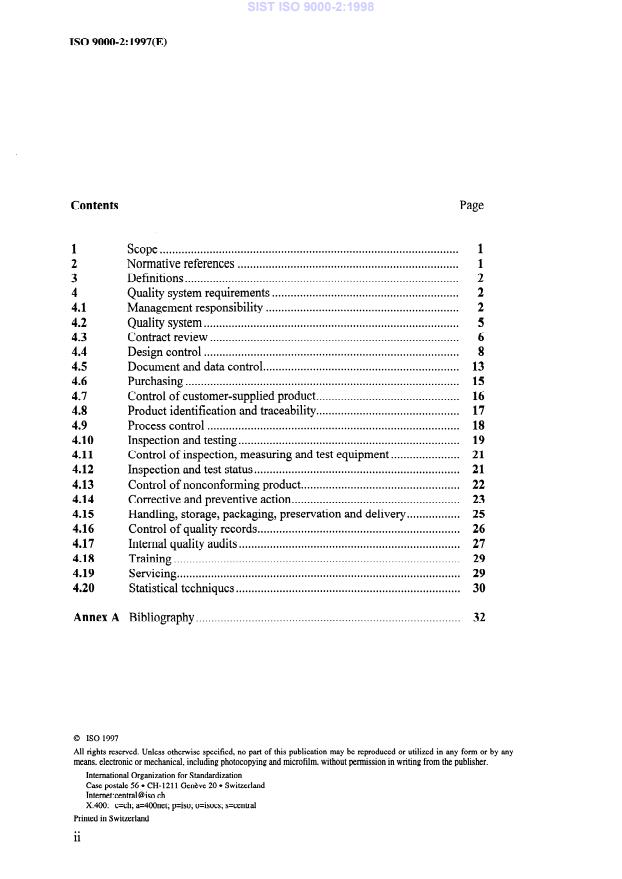

Contents

................................................................................................

1 Scope

Normative references .

Definitions .

............................................................

4 Quality system requirements

..............................................................

41 0 Management responsibility

..................................................................................

42 0 Quality system

................................................................................

43 0 Contract review

.................................................................................. 8

44 l Design control

...............................................................

45 l Document and data control

46 . Purchasing .

.............................................. 16

47 l Control of customer-supplied product

..............................................

48 0 Product identification and traceability

49 Process control .

....................................................................... 19

4 ’10 Inspection and testing

...................... 21

4 ’11 Control of inspection, measuring and test equipment

4 ’12 Inspection and test status .

................................................... 22

4 ’13 Control of nonconforming product

Corrective and preventive action .

4 ’14

.................

4 ’15 Handling, storage, packaging, preservation and delivery

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 ’16 Control of quality records

.......................................................................

4 ’17 Internal quality audits

4 ’18 Training .

4 ’19 Servicing .

4 ’a 20 Statistical techniques .

Annex A Bibliography . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0 IS0 1997

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any

means, electronic or mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Organization for Standardization

Case postale 56 l CH- 1211 Geneve 20 l Switzerland

1ntemet:centra.l @iso.ch

X.400: c=ch; a=4OOnet; p=iso; o=isocs; s=central

Printed in Switzerland

ii

@ IS0 IS0 9000=2:1997(E)

Foreword

IS0 (the International Organization for Standardization) is a worldwide federation of

national standards bodies (IS0 member bodies). The work of preparing International

Standards is normally carried out through IS0 technical committees. Each member

body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, governmental

and non-governmental, in liaison with ISO, also take part in the work. IS0 collaborates

closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

Draft International Standards adopted by the technical committees are circulated to the

member bodies for voting. Publication as an International Standard requires approval

by at least 75 % of the member bodies casting a vote.

International Standard IS0 9000-2 was prepared by Technical Committee ISO/TC 176,

Quality management and quality assurance, Subcommittee SC 2, Quality systems.

This second edition cancels and replaces the first edition (IS0 9000-2: 1993), which has

been technically revised.

IS0 9000 consists of the following parts, under the general title Quality management

and quality assurance standards

- Part 1: Guidelines for selection and use

- Part 2: Generic guidelines for the application of IS0 9001, IS0 9002 and IS0 9003

-

Part 3: Guidelines for the application of IS0 9001 to the development, supply and

maintenance of software

- Part 4: Guide to dependability management

Annex A of this part of IS0 9000 is for information only.

. . .

IS0 9000=2:1997(E)

Introduction

This part of IS0 9000 gives guidance for the application of IS0 9001, IS0 9002 and

IS0 9003. To facilitate cross-reference to those standards, this part of IS0 9000 has the

same clause structure as IS0 9001, IS0 9002 and IS0 9003.

In general, the number and scope of the quality system elements and procedures

required for quality assurance are greatest in IS0 9001 and least in IS0 9003. For all

clauses, the guidelines of this part of IS0 9000 should be applied in a manner consistent

with the scope and requirements of the corresponding clause, if present, in the standard

involved (i.e. IS0 9001, IS0 9002 or IS0 9003). Reference should be made to

subclause 8.3 of IS0 9000-l : 1994 for guidance on the appropriate extent and degree of

demonstration.

IS0 9000-l gives an overview of the IS0 9000 series of International Standards, and

explains the use of the entire series. IS0 9004-l gives guidance for designing and

installing a quality management system.

This part of IS0 9000 does not duplicate the guidance to users that is given in other IS0

guidance standards such as IS0 9000-1, IS0 9000-3, IS0 9004-l and IS0 9004-2.

iv

IS0 9000-2: 1997(E)

INTERNATIONAL STANDARD @ Iso

Quality management and quality assurance standards -

Part 2:

Generic guidelines for the application of IS0 9001, IS0 9002 and

IS0 9003

1 Scope

This part of IS0 9000 gives guidance on the application of the 1994 versions of IS0 9001,

IS0 9002 and IS0 9003.

It does not add to, or otherwise change, the requirements of IS0 9001, IS0 9002 or IS0 9003.

In the case of conflicting interpretations of IS0 9001, IS0 9002 or IS0 9003 on the one

hand, and IS0 9000-2 on the other, the interpretation of the text in IS0 9001, IS0 9002 or

IS0 9003 takes precedence. The use of ‘should’ in this part of IS0 9000 does not weaken the

requirements expressed as ‘shall’ in IS0 9001, IS0 9002 and IS0 9003.

This part of IS0 9000 gives guidance for the following users:

a) suppliers involved in applications of IS0 9001, IS0 9002 or IS0 9003;

b) customers and third parties.

2 Normative references

The following standards contain provisions which, through reference in this text, constitute

provisions of this part of IS0 9000. At the time of publication, the editions indicated were

valid. All standards are subject to revision, and parties to agreements based on this part of

IS0 9000 are encouraged to investigate the possibility of applying the most recent editions of

the standards indicated below. Members of IEC and IS0 maintain registers of currently valid

International Standards.

IS0 8402: 1994, Quality management and quality assurance - Vocabulary.

Model for quality assurance in design, development,

IS0 9001: 1994, Quality systems -

production, installation and servicing.

IS0 9002: 1994, Quality systems - Model for quality assurance in production, installation

and servicing.

Model for quality assurance injinal inspection and test.

IS0 9003: 1994, Quality systems -

@ IS0

IS0 9000=2:1997(E)

3 Definitions

For the purposes of this part of IS0 9000, the definitions given in IS0 8402 and the following

apply*

contract: Agreed requirements between a supplier and customer transmitted by any

31 .

means.

[ISO 90011

product: Result of activities or processes.

32 .

NOTE 1 A product may include service, hardware, processed materials, software or a combination

thereof.

ies or processed materials) or in .tangi ble (e.g.

NOTE 2 A product can be tangible (e.g. assembl

knowledge or concepts), or a combination thereof.

NOTE 3 For the purposes of this International Standard, the term ‘product’ applies to the intended

product offering only and not to unintended ‘by-products’ affecting the environment. This differs

from the definition given in IS0 8402.

[ISO 90011

33 0 specified requirements

Product requirements prescribed by the customer and agreed by the supplier.

1)

Requirements prescribed by the supplier that are perceived as satisfying a market

2)

need.

34 tender: Offer made by a supplier in response to an invitation to satisfy a contract

aL.rd to provide product.

[ISO 900 l]

4 Quality system requirements

41 a Management responsibility

4.1.1 Quality policy

The supplier ’s management with executive responsibility (see 4.1.2.1) is required to develop

and define its quality policy, quality objectives and commitment in (a) recorded statement(s).

This is required to be relevant to its organizational goals, and the expectations and needs of

its customers. The statement(s) should be published throughout the organization and be seen

to be fully supported by the management.

@ IS0 IS0 9000=2:1997(E)

All employees, including newly hired, part-time and temporary employees, should be trained

so that they understand the objectives of the organization and the commitment required to

achieve these objectives. The policy should be expressed in language that is easy to

understand and the objectives should be achievable, planned and periodically reviewed.

Management should continuously demonstrate visible commitment to the quality policy by

activities which may include, but not be limited to, the following:

ensuring that the organization ’s personnel understand and implement the quality

policy;

ensuring that the organization ’s personnel have quality objectives consistent with

the organization ’s overall objectives;

initiating, managing and following up on the implementation of the quality

policy, including implementation and maintenance of the quality system;

not accepting deviations from the quality policy in any part or aspect of the

organization;

providing adequate resources and training to support quality system development

and implementation. (See 4.1.2.2.)

4.1.2 Organization

4.1.2.1 Responsibility and authority

Management with executive responsibility is that person or group of persons within an

organization with the necessary level of authority for making policy and setting objectives,

planning their implementation, reviewing achievement and taking corrective action. The

supplier should clearly identify those persons having such executive responsibility.

In particular the personnel having the responsibility and authority to make decisions that

control all the elements of the quality system and processes should be identified and the job

requirements defined and documented (see 4.18).

4.1.2.2 Resources

Consideration needs to be given by the supplier ’s management to the identification and

provision of adequate resources needed to implement its quality policy and achieve its

objectives as well as to satisfy customer needs and expectations. The following should be

considered:

personnel to plan, manage, perform work, control and carry out verification

activities;

awareness of standards, procedures and other documented practices that are

needed;

@ IS0

ISO9000=2:1997(E)

I

training and qualifications (see 4.18);

planning design, development and production activities to allow sufficient time to

perform the work;

equipment and processes, including acquisition of new equipment or technology;

means to access quality records.

4.1.2.3 Management representative

Within the supplier ’s organization, a management representative with delegated authority is

required to be appointed for arranging and overseeing the working of the quality system. This

management representative is required to be appointed by management with executive

responsibility.

The functions of the management representative may be totally related to quality system

activities or be in conjunction with other functions and responsibilities within the

organization. If the management representative has other functions to perform, there should

be no conflict of interest between the responsibilities for the other functions and those for the

quality system. The management representative should have the authority to ensure that the

requirements of IS0 9001, IS0 9002 or IS0 9003 are satisfied and that compliance is

maintained, together with the responsibility to ensure that they are operated throughout the

organization.

The defined role should include reporting on the suitability and effectiveness of the quality

system as a basis for improvement, management review, and liaison, as necessary, with

customers, subcontractors and any other external parties on quality matters.

4.1.3 Management review

The supplier ’s management with executive responsibility, should review the quality system.

This may include, but not be limited to, the following:

the adequacy of the organizational structure, including its staffing and other

resources;

conformity to IS0 900 1, IS0 9002 or IS0 9003, and effective implementation of

the quality system;

compliance with quality policy;

I

information based on customer feedback, internal feedback (such as results of

internal audits), process performance and product performance, as well as

corrective and preventive ictions taken.

The intervals between reviews shoul d be carefully planned and periodically reviewed to

ensure the continuing suitability and effectiveness of the quality system. The management

@ IS0 IS0 9000=2:1997(E)

review process, frequency of reviews and levels of inputs will depend on the individual

circumstance. Some organizations have found that annual management reviews are

acceptable.

Management should focus on trends that may indicate problems. Chronic problem areas

should receive special attention. Actions that are required following changes to the quality

system determined during management review should be implemented in a timely manner.

The effectiveness of any changes should be evaluated. Records of such reviews should be

maintained (see 4.16).

42 0 Quality system

4.2.1 General

The implementation of a quality system by the supplier is most effective when those in the

organization understand its intention and how it functions, in particular, in the area of their

responsibility and its interface with other parts of the system. The quality manual has an

important role in this regard, for both internal and external parties. To give a coherent view

of the quality system, the quality manual should include the quality policy, a description of

the organization, and identify the quality system procedures with appropriate cross-references

to more detailed documentation. The quality manual could, for example, be one document

supported by several levels of other documents, each level becoming progressively more

detailed. There may also be an overall system manual, one or more specific procedural

manuals, work instructions and reference documents. Together, these documents define the

quality system. Further guidance on development of quality manuals is given in IS0 100 13.

4.2.2. Quality system procedures

Documented quality system procedures are required for applicable requirements of IS0

9001, IS0 9002 and IS0 9003 and should be consistent with the supplier ’s quality policy. It

is important to recognise that the structure and level of detail required in these procedures

should be tailored to the needs of the organization ’s personnel, which will depend upon

methods used and the training requirements, skills and qualifications of such personnel, as

indicated in 4.18.

A documented procedure usually specifies the purpose and scope of an activity:

what shall be done by whom;

I

when, where, and how it shall be done;

-

what materials, equipment and documents shall be used; and

how an activity shall be controlled and recorded.

Documented procedures may make reference to work instructions that define how an activity

is performed.

@ IS0

ISO9000=2:1997(E)

4.2.3 Quality planning

The supplier needs to show that planning activities have been performed, and that they

establish the means by which the requirements for quality will be met. Planning should

include the application of the quality system elements, and how the product quality

requirements will be met.

This may require the following.

a) For managerial and operational planning, preparing the application of the quality

system.

b) For product planning, setting out in a quality plan or in any other documented

procedures the specific quality practices, resources and sequence of activities

relevant to a particular product, project or contract.

More guidance on quality plans is given in IS0 10005.

43 a Contract review

4.3.1 General

In the situation where a tender is offered or a contract or order is to be established between a

supplier and a customer, the means of achieving satisfaction lies in the contract review

process.

Contract review is one of the supplier ’s primary interfaces with its customers. The

documented procedures should include a review of customer requirements (whether

expressed in a tender, contract or order, which may be written or verbal) and how customer

requirements are reviewed and communicated within the organization.

The contract review is prior to accepting a contract or an order.

4.3.2 Review

The importance of a thorough understanding of the customer ’s needs, from initial contact,

through tendering or receiving verbal orders, to the formulation of the contract, or order and

in all subsequent stages cannot be overstated. Often, dialogue will be necessary to achieve

this understanding, that should clearly establish the customer ’s requirements as to the product,

delivery and other critical factors. Where a verbal statement of requirement is received from

the customer, the supplier should ensure that an order (statement of requirements) is

understood, adequately documented and agreed to by the customer.

Contract review is a process that includes the following:

a) review of the requirement; this may be appropriate at the tendering or order entry

stage and at subsequent stages prior to acceptance of the contract or the order;

@ IS0 IS0 9000=2:1997(E)

b) agreement within the supplier ’s organization that

I

the requirements have been defined,

I

the requirements are understood,

I

the supplier has the capability to meet the requirements of the contract, by going

through a defined process to verify that the necessary resources and facilities are

available to fulfil all the requirements of the contract;

resolution of any differences with the customer;

cl

d) contract review of a standard product (e.g. “off-the-shelf’ items, a “commodity

item ”, a catalogue item with published specification, etc.) can be as simple as

verifying the accuracy of the information on the order;

e) the requirements of the contract, where appropriate, may be translated into the

terminology, tolerances, and other necessary information for designing,

purchasing and process control;

f) preliminary quality plan or documented procedures, where appropriate, may be

developed to give an understanding of how to implement the contract

successfully and support the contract review process.

It is beneficial for the supplier to adopt a contract or order review procedure that has the

following features:

affected parties have an opportunity and adequate time to review the contract;

I

a checklist or some other means (e.g. a standard form) is available for reviewers

to verify and record that they have reviewed and understood the requirements of

the contract or order;

a method is available for reviewers to question the requirements of the contract or

order, to have their questions considered and to have differences with other

affected parties resolved.

4.3.3 Amendment to contract

When customer requirements change, consideration should be given to repeating the contract

review procedure (see 4.3.2). It is beneficial for the supplier to have a procedure for reviews

by the same departmental functions that reviewed the original contract or accepted order.

Before such changes come into effect, there should be methods available to ensure that all

relevant changes are communicated to those affected.

4.3.4 Records

In all cases, it should be sufficient to retain records that the review has been performed (see

4.16). For internal purposes, however, records of the evaluation associated with the contract

@ IS0

ISO9000=2:1997(E)

review may be retained in cases such as complex or critical projects. These records should

give objective evidence for audits, and facilitate the following:

post-delivery project review;

process improvement; and

the generation of proposals for future projects.

44 0 Design control

4.4.1 General

The essential quality aspects and the regulatory requirements such as safety, performance, and

dependability of a product are established during the design and development phase.

Deficient design can be a major cause of quality problems.

In considering design control, it is important to note that the design process may apply to

various activities in differing styles and timescales. Such aspects are related to products, as

well as the process associated with product design. The supplier should consider all phases of

the design associated with product design and all phases of the design process for which

controlled procedures are necessary.

4.4.2 Design and development planning

The supplier should establish procedures for design and development planning and, where

appropriate,include the following:

identification, scope and objectives;

sequential and parallel work schedules;

timing, frequency, and nature of design verification and validation activities;

evaluation of the safety, performance and dependability incorporated in the

product design;

I

methods of product measurement, test and acceptance criteria;

assignment of responsibilities.

Design and development plans should be integrated with any other plans and verification

procedures related to the product and plans should be updated as necessary.

IS0 9000=2:1997(E)

@ IS0

The supplier should clearly assign responsibilities for specific design leadership and other

design work functions to qualified personnel. The personnel in these functions should have

access to information and the resources to complete the work.

Design activities should be defined to the level of detail necessary for carrying out the design

process.

4.4.3 Organizational and technical interfaces

When input to the design is from a variety of sources, the inter-relationships and interfaces, as

well as the pertinent responsibilities and authorities, should be defined, documented,

coordinated, and controlled.

Many organizational functions, both internal and external, may contribute to the design

process; examples are as follows:

research and development;

marketing and sales;

purchasing;

quality assurance and quality management;

engineering;

materials technology;

production/manufacturing;

service groups;

facilities management;

warehousing/transportation/logistics;

communications;

information systems.

They should also establish, but not limit themselves to, the following:

what information should be received and transmitted;

identification of sending and receiving groups;

the purpose of the information transmitted;

identification of transmittal methods;

document transmittal and records maintenance.

@ IS0

ISO9000=2:1997(E)

4.4.4 Design input

User needs (through marketing) or customer requirements (through contract) should be

established during contract review (see 4.3) that, together with relevant statutory legislation,

will form the design input requirements.

Design inputs are typically in the form of product requirement specifications and/or product

description with specifications relating to configuration, composition, incorporated elements,

and other design features.

All pertinent design inputs (such as performance, functional, descriptive, environmental,

safety and regulatory requirements) should be defined, reviewed and recorded by the supplier.

The design inputs should describe all requirements to the greatest possible extent; they lay

the foundation and provide a unified approach to the design. Details agreed between

customer and supplier on how customer, statutory and regulatory requirements will be met

should be included.

The record of the design inputs should also include the resolutions of any

incomplete, ambiguous or conflicting requirements that have been identified at the contract

review and/or design verification stages or related design control activities.

materials, and processes requiring

The design inputs should identify design criteria,

development and analysis, including prototype testing to verify their adequacy. Design inputs

should be prepared in a way that facilitates periodic updates. They should indicate ‘when’ or

‘what criteria’ will cause the inputs to be updated, who is responsible for the update, and under

what circumstances the customer will get a copy. Design inputs prepared in this way serve as

the definitive up-to-date reference document as the design progresses to completion.

4.4.5 Design output

Throughout the design process, the requirements contained in the design description are

translated by the supplier into outputs. Design outputs should be documented in terms that

can be verified and validated against design input requirements and need to contain or make

reference to acceptance criteria; examples of these can be found in the following:

drawings and parts list;

specifications (including process and materials specifications);

instructions;

I

software;

I

servicing procedures.

Design outputs are the product requirements used for purchasing, production, installation,

inspection and testing, and servicing. Because of their impact on follow-on activities, it is

important that the outputs are reviewed and approved before release.

@ IS0 ISO9000=2:1997(E)

4.4.6 Design review

Design reviews should be planned. In order to achieve a degree of objectivity, they need to

involve all functions, both internal and external, concerned with the design stage being

reviewed. Design staff and other specialist personnel should also participate as required.

Design review may be a regulatory requirement for certain types of product. The timing and

frequency of these reviews will be influenced by the maturity, complexity and cost of the

product being designed. Records of such reviews should be maintained (see 4.16).

The competence of the participants in the design reviews should be adequate to permit them

to examine designs and their implications. Design reviews may consider questions such as

the following.

Do designs satisfy all specified requirements for the product?

Are product design and processing capabilities compatible?

Are safety considerations considered?

Do designs meet functional and operational requirements, for example,

performance and dependability objectives?

Have appropriate materials and/or facilities been selected?

e)

Is there adequate compatibility of materials, components and/or service elements?

f)

Is the design satisfactory for all anticipated environmental and load conditions?

g)

Are components or service elements standardized and do they provide for

h)

reliability, availability and maintainability?

Is there a provision in tolerances, and/or configuration, for interchangeability and

replacement?

.

Are plans for implementing the design technically feasible (e.g. purchasing,

J)

production, installation, inspection and testing)?

Where computer software has been used in design computations, modelling or

k)

analyses, has the software been appropriately validated, authorized, verified and

placed under configuration control?

Have the inputs to such software, and the outputs, been appropriately verified and

1)

documented?

Are the assumptions made during the design process valid?

ml

Are the results of model or prototype testing considered?

n)

@ IS0

IS0 9000=2:1997(E)

4.4.7 Design verification

IS0 9001 describes design control measures (e.g. design reviews, tests and demonstrations,

alternative calculations and comparison with a proven design) by which design verification

may be established by the supplier. Design verification is a necessary check to ensure that the

design outputs conform to specified requirements (design inputs). This is an ongoing activity

Design

and in some instances a combination of these measures may be necessary.

verification measures should be recorded (see 4.16).

The timing and personnel involved in these verifications should be considered in the design

and development planning phase.

When alternative calculations or comparison with a proven design are employed as forms of

design verification, the appropriateness of the alternative calculation method, and/or proven

design, should be reviewed in relation to this new application.

When tests and demonstrations are employed as a form of design verification, the safety and

performance of the product should be verified under conditions that are representative of the

full range of circumstances of actual use. The product units employed for tests and

demonstrations should be produced under the expected production conditions.

At any stage before release when the review of design outputs, is employed as a form of

design verification, this should be in accordance with relevant standards, practices and

predetermined acceptance criteria.

4.4.8 Design validation

Design validation is necessary to confirm that the end product fulfils the specified

It may be necessary to involve the customer in design

requirements for its intended use.

validation.

After successful design verification, a design validation should be performed under defined

conditions for the use of the final product. However, it may need to be performed at earlier

stages during product development if there are features that it is not possible or practical to

validate at the final stage. Conversely, there will be other situations where validation can

only be performed by observation during initial use of the product.

The results of the examination, tests and demonstrations carried out under design validation

should be included in the design records.

4.4.9 Design changes

Design of a product may be changed or modified for a number of reasons, for example:

omissions or errors (e.g. in calculation, material selection, etc.) during the design

phase which have been identified afterwards;

@ IS0 ISO9000=2:1997(E)

mamfacturing, installation and/or servicing difficulties found after the design

phase;

the customer or subcontractor requests changes;

the function or performance of a product is to be improved;

changes to safety, regulatory, or other requirements;

design review (see 4.4.6), design verification (see 4.4.7) or design validation (see

4.4.8) requires change;

corrective or preventive action requires change (see 4.14).

Any changes to design inputs should be identified and reviewed by the supplier to determine

whether they influence the previously approved design review, verification or validation

results. Design changes in one component of a product should be evaluated for their

influence on the whole. Improving one characteristic may have unforeseen adverse influence

on another.

When significant design changes are made, the verification procedure should also be

reviewed and modified as appropriate.

Procedures should be established to communicate the new design output to all concerned, to

record any design changes and to ensure, as well as document, that all authorized design

changes and only those are implemented (see 4.5.3).

45 0 Document and data control

4.5.1 General

Document and data control should include those documents and data pertinent to design,

purchasing, processing, quality standards, inspection of materials and the quality system

documents. Information and/or instructions in documents and data can be recorded,

transmitted or received using a variety of media (e.g. hard copy, magnetic disks or tapes).

Documents describe or control how things are to be done and should be revised to reflect

changing circumstances. Data comprise information upon which a decision may be made;

data may be contained in documents or other forms.

4.5.2 Document and data approval and issue

The supplier ’s system should provide a clear and precise control of procedures and

responsibilities for approval, issue, distribution, and administration of internal and external

documentation and data, including the removal or identification (to prevent misuse) of

obsolete documents. This can be accomplished, for example, by maintaining a master list or

equivalent document control procedure of documents or data identifying the level of

approval, distribution (location of copies) and revision status. A supplier ’s internal written

procedures should describe the following:

@ IS0

IS0 9000=2:1997(E)

how the documentation and data for these functions should be controlled;

who is responsible for the control;

what is to be controlled;

where and when the control is to take place.

Applicable documents and data should be accessible in the relevant places of work.

4.5.3 Document and data changes

Recognizing that supplier documentation or data may be subject to revision and change,

controls should exist for the preparation, handling, issue and recording of changes. This

applies not only to internal documentation and data but also to externally updated

documentation (e.g. national standards) and data.

The supplier should establish a procedure for controlling changes in documentation and data,

which should

provide for control of all types of documentation or data media;

follow documented procedures;

ensure accurate updating of documents and data;

provide for using only authorized documents and data when implementing

changes;

-

preclude confusion, especially where there is a multiplicity of sources authorizing

changes and releasing documents and data;

record the reasons why a change was made.

Consideration should be given to the effect that the proposed changes may have on other parts

of the system or the product. Actions may be needed before a change is implemented to

assess the effect of the change on other parts of the organization and notify them as

appropriate.

Planned circulation of a change proposal to personnel in the affected functions can assist in

avoiding disruption. Timing of implementation of the change may be an important factor,

particularly when several changes of documentation or data are to be coordinated.

@ IS0 IS0 9000=2:1997(E)

46 a Purchasing

4.6.1 General

To ensure that purchased products that become part of, or affect the quality of, the supplier ’s

product conform to specified requirements as well as statutory or regulatory requirements,

purchasing should be planned and carried out by the supplier under adequate control. This

should include, but not be limited to, the following:

evaluation and selection of subcontractors (see 4.6.2);

clear and unambiguous purchasing requirements (see 4.6.3);

the performance of suitable verification (see 4.6.4);

receiving inspection procedures (see 4.10.2).

The supplier should establish an effective working relationship and feedback system with its

subcontractors.

4.6.2 Evaluation of subcontractors

In developing methods to ensure the conformity of purchased product, the supplier is required

to establish that all subcontractors have the capability of supplying products meeting the

specified requirements.

The supplier should operate a documented procedure to evaluate the capabilities of

subcontractors. The extent of the evaluation varies according to the importance of the

purchased product and its impact on the final product.

An evaluation may vary from a comprehensive audit of the subcontractor ’s quality system to

the acceptance of an evaluation and approval by reference to historical data (e.g. records of

past performance or certified products and quality system registration schemes). In any event,

the supplier is required to be able to demonstrate that formal consideration was given to the

evaluation and that the selection of a subcontractor was based on an appraisal appropriate to

the product being purchased.

The supplier should be able to demonstrate that subcontractors are being evaluated on the

basis of performance. Records of acceptable subcontractors should be maintained (see 4.16).

4.6.3 Purchasing data

The supplier ’s purchasing data should define the specified requirements to the subcontractor

to ensure the quality of the purchased product, including technical product requirements,

calibration services, special processes and inspection and test activities. This may be done, in

part, by reference to other applicable technical information such as national or international

standards, test methods, etc. Another approach is for information to be clearly and precisely

stated to the subcontractor on the purchase order. Responsibilities for reviewing and

”

@ IS0

ISO9000=2:1997(E)

approving the purchasing data should be clearly assigned to appropriate personnel. The

revision status of documents referenced in the purchasing data should be identified.

4.6.4 Verification of purchased product

4.6.4.1 Supplier verification at subcontractor ’s premises

When contractually specified, the supplier may be involved with verification activities at the

subcontractor ’s premises.

The supplier should include in purchasing documents special clauses or statements regarding

verification procedures, and product release methods (e.g. product shipment should have prior

approval of the supplier) when verification is to be carried out at the subcontractor ’s facilities.

4.6.4.2 Customer verification of subcontracted product

When specified by the customer, the supplier should include in subcontracts special clauses

or statements when verification is contractually required at source (e.g. the subcontractor ’s

facilities).

When specified in the contract, the customer may extend verification activities to the facilities

of the subcontractor to assure that the product fulfils the specified requirements. In such

cases, the supplier should arrange for the customer to verify the quality of the subcontractor ’s

product and, if necessary, the effectiveness of the process.

Where the contract provides, the customer may use the supplier ’s data to decide which of the

products to be purchased will require verification at source and to decide the nature and

extent of such verification.

If the customer, on verification of the subcontractor ’s product, expresses satisfaction, the

supplier should not take this as an opportunity to relax controls. The supplier retains full

responsibility for the quality of the product being supplied to the customer.

47 a Control of customer-supplied product

The supplier, upon receipt of customer-supplied product that is furnished to the supplier for

use in meeting the requirements of the contract, accepts responsibilities for prevention of

damage and for identification, preservation, storage, handling and use while that product is in

the supplier ’s possession.

The supplier should therefore establish arrangements, as necessary, for the following:

I

examination of the product upon receipt to check the quantity received and its

identity, and to detect any damage in transit;

IS0 9000=2:1997(E)

-

periodic inspection during storage to detect any signs of deterioration, to check

the limitations on time in storage, to assure maintenance of proper conditions and

to determine the current state of the product;

-

compliance with any contractual requirements;

identification and safeguarding of the supplied product to prevent any

unauthorized use or improper disposal.

The responsibility should be defined for reporting unsuitability to the customer, who is

responsible for providing acceptable product within the terms of the contract. Records of

products that are lost, damaged or otherwise unsuitable for use should be maintained (see

4.16).

The supplier should consider the significance of customer-supplied product during contract

review, particularly when the customer-supplied product is a service (e.g. the use of a

The supplier should be able to show documentary

customer ’s transport for delivery).

evidence that this is being done, where appropriate. The supplier should obtain from the

customer, as appropriate, information or requirements concerning handling, storage and

maintenance of customer-supplied product.

When necessary, the need for calibration of customer-supplied tools and equipment should be

specified by the customer.

48 l Product identification and traceability

Where appropriate the supplier should define the means for product identification This may

be done by marking, tagging or the location of the product or its container. For example, on

visually identical parts where the functional

...

INTERNATIONAL

IS0

STANDARD

9000-2

Second edition

1997-06-I 5

Quality management and quality assurance

standards -

Part 2:

Generic guidelines for the application of

IS0 9001, IS0 9002 and IS0 9003

Normes pour le management de la qua/M et / ‘assurance de la qua/it& -

Parfie 2: Lignes directrices ghkriques pour I ’applica tion de / ‘/SO 900 1,

/ ‘/SO 9002 et IWO 9003

Reference number

IS0 9000-2: 1997(E)

IS0 9000=2:1997(E)

Page

Contents

................................................................................................

1 Scope

Normative references .

Definitions .

............................................................

4 Quality system requirements

..............................................................

41 0 Management responsibility

..................................................................................

42 0 Quality system

................................................................................

43 0 Contract review

.................................................................................. 8

44 l Design control

...............................................................

45 l Document and data control

46 . Purchasing .

.............................................. 16

47 l Control of customer-supplied product

..............................................

48 0 Product identification and traceability

49 Process control .

....................................................................... 19

4 ’10 Inspection and testing

...................... 21

4 ’11 Control of inspection, measuring and test equipment

4 ’12 Inspection and test status .

................................................... 22

4 ’13 Control of nonconforming product

Corrective and preventive action .

4 ’14

.................

4 ’15 Handling, storage, packaging, preservation and delivery

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 ’16 Control of quality records

.......................................................................

4 ’17 Internal quality audits

4 ’18 Training .

4 ’19 Servicing .

4 ’a 20 Statistical techniques .

Annex A Bibliography . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0 IS0 1997

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any

means, electronic or mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Organization for Standardization

Case postale 56 l CH- 1211 Geneve 20 l Switzerland

1ntemet:centra.l @iso.ch

X.400: c=ch; a=4OOnet; p=iso; o=isocs; s=central

Printed in Switzerland

ii

@ IS0 IS0 9000=2:1997(E)

Foreword

IS0 (the International Organization for Standardization) is a worldwide federation of

national standards bodies (IS0 member bodies). The work of preparing International

Standards is normally carried out through IS0 technical committees. Each member

body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, governmental

and non-governmental, in liaison with ISO, also take part in the work. IS0 collaborates

closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

Draft International Standards adopted by the technical committees are circulated to the

member bodies for voting. Publication as an International Standard requires approval

by at least 75 % of the member bodies casting a vote.

International Standard IS0 9000-2 was prepared by Technical Committee ISO/TC 176,

Quality management and quality assurance, Subcommittee SC 2, Quality systems.

This second edition cancels and replaces the first edition (IS0 9000-2: 1993), which has

been technically revised.

IS0 9000 consists of the following parts, under the general title Quality management

and quality assurance standards

- Part 1: Guidelines for selection and use

- Part 2: Generic guidelines for the application of IS0 9001, IS0 9002 and IS0 9003

-

Part 3: Guidelines for the application of IS0 9001 to the development, supply and

maintenance of software

- Part 4: Guide to dependability management

Annex A of this part of IS0 9000 is for information only.

. . .

IS0 9000=2:1997(E)

Introduction

This part of IS0 9000 gives guidance for the application of IS0 9001, IS0 9002 and

IS0 9003. To facilitate cross-reference to those standards, this part of IS0 9000 has the

same clause structure as IS0 9001, IS0 9002 and IS0 9003.

In general, the number and scope of the quality system elements and procedures

required for quality assurance are greatest in IS0 9001 and least in IS0 9003. For all

clauses, the guidelines of this part of IS0 9000 should be applied in a manner consistent

with the scope and requirements of the corresponding clause, if present, in the standard

involved (i.e. IS0 9001, IS0 9002 or IS0 9003). Reference should be made to

subclause 8.3 of IS0 9000-l : 1994 for guidance on the appropriate extent and degree of

demonstration.

IS0 9000-l gives an overview of the IS0 9000 series of International Standards, and

explains the use of the entire series. IS0 9004-l gives guidance for designing and

installing a quality management system.

This part of IS0 9000 does not duplicate the guidance to users that is given in other IS0

guidance standards such as IS0 9000-1, IS0 9000-3, IS0 9004-l and IS0 9004-2.

iv

IS0 9000-2: 1997(E)

INTERNATIONAL STANDARD @ Iso

Quality management and quality assurance standards -

Part 2:

Generic guidelines for the application of IS0 9001, IS0 9002 and

IS0 9003

1 Scope

This part of IS0 9000 gives guidance on the application of the 1994 versions of IS0 9001,

IS0 9002 and IS0 9003.

It does not add to, or otherwise change, the requirements of IS0 9001, IS0 9002 or IS0 9003.

In the case of conflicting interpretations of IS0 9001, IS0 9002 or IS0 9003 on the one

hand, and IS0 9000-2 on the other, the interpretation of the text in IS0 9001, IS0 9002 or

IS0 9003 takes precedence. The use of ‘should’ in this part of IS0 9000 does not weaken the

requirements expressed as ‘shall’ in IS0 9001, IS0 9002 and IS0 9003.

This part of IS0 9000 gives guidance for the following users:

a) suppliers involved in applications of IS0 9001, IS0 9002 or IS0 9003;

b) customers and third parties.

2 Normative references

The following standards contain provisions which, through reference in this text, constitute

provisions of this part of IS0 9000. At the time of publication, the editions indicated were

valid. All standards are subject to revision, and parties to agreements based on this part of

IS0 9000 are encouraged to investigate the possibility of applying the most recent editions of

the standards indicated below. Members of IEC and IS0 maintain registers of currently valid

International Standards.

IS0 8402: 1994, Quality management and quality assurance - Vocabulary.

Model for quality assurance in design, development,

IS0 9001: 1994, Quality systems -

production, installation and servicing.

IS0 9002: 1994, Quality systems - Model for quality assurance in production, installation

and servicing.

Model for quality assurance injinal inspection and test.

IS0 9003: 1994, Quality systems -

@ IS0

IS0 9000=2:1997(E)

3 Definitions

For the purposes of this part of IS0 9000, the definitions given in IS0 8402 and the following

apply*

contract: Agreed requirements between a supplier and customer transmitted by any

31 .

means.

[ISO 90011

product: Result of activities or processes.

32 .

NOTE 1 A product may include service, hardware, processed materials, software or a combination

thereof.

ies or processed materials) or in .tangi ble (e.g.

NOTE 2 A product can be tangible (e.g. assembl

knowledge or concepts), or a combination thereof.

NOTE 3 For the purposes of this International Standard, the term ‘product’ applies to the intended

product offering only and not to unintended ‘by-products’ affecting the environment. This differs

from the definition given in IS0 8402.

[ISO 90011

33 0 specified requirements

Product requirements prescribed by the customer and agreed by the supplier.

1)

Requirements prescribed by the supplier that are perceived as satisfying a market

2)

need.

34 tender: Offer made by a supplier in response to an invitation to satisfy a contract

aL.rd to provide product.

[ISO 900 l]

4 Quality system requirements

41 a Management responsibility

4.1.1 Quality policy

The supplier ’s management with executive responsibility (see 4.1.2.1) is required to develop

and define its quality policy, quality objectives and commitment in (a) recorded statement(s).

This is required to be relevant to its organizational goals, and the expectations and needs of

its customers. The statement(s) should be published throughout the organization and be seen

to be fully supported by the management.

@ IS0 IS0 9000=2:1997(E)

All employees, including newly hired, part-time and temporary employees, should be trained

so that they understand the objectives of the organization and the commitment required to

achieve these objectives. The policy should be expressed in language that is easy to

understand and the objectives should be achievable, planned and periodically reviewed.

Management should continuously demonstrate visible commitment to the quality policy by

activities which may include, but not be limited to, the following:

ensuring that the organization ’s personnel understand and implement the quality

policy;

ensuring that the organization ’s personnel have quality objectives consistent with

the organization ’s overall objectives;

initiating, managing and following up on the implementation of the quality

policy, including implementation and maintenance of the quality system;

not accepting deviations from the quality policy in any part or aspect of the

organization;

providing adequate resources and training to support quality system development

and implementation. (See 4.1.2.2.)

4.1.2 Organization

4.1.2.1 Responsibility and authority

Management with executive responsibility is that person or group of persons within an

organization with the necessary level of authority for making policy and setting objectives,

planning their implementation, reviewing achievement and taking corrective action. The

supplier should clearly identify those persons having such executive responsibility.

In particular the personnel having the responsibility and authority to make decisions that

control all the elements of the quality system and processes should be identified and the job

requirements defined and documented (see 4.18).

4.1.2.2 Resources

Consideration needs to be given by the supplier ’s management to the identification and

provision of adequate resources needed to implement its quality policy and achieve its

objectives as well as to satisfy customer needs and expectations. The following should be

considered:

personnel to plan, manage, perform work, control and carry out verification

activities;

awareness of standards, procedures and other documented practices that are

needed;

@ IS0

ISO9000=2:1997(E)

I

training and qualifications (see 4.18);

planning design, development and production activities to allow sufficient time to

perform the work;

equipment and processes, including acquisition of new equipment or technology;

means to access quality records.

4.1.2.3 Management representative

Within the supplier ’s organization, a management representative with delegated authority is

required to be appointed for arranging and overseeing the working of the quality system. This

management representative is required to be appointed by management with executive

responsibility.

The functions of the management representative may be totally related to quality system

activities or be in conjunction with other functions and responsibilities within the

organization. If the management representative has other functions to perform, there should

be no conflict of interest between the responsibilities for the other functions and those for the

quality system. The management representative should have the authority to ensure that the

requirements of IS0 9001, IS0 9002 or IS0 9003 are satisfied and that compliance is

maintained, together with the responsibility to ensure that they are operated throughout the

organization.

The defined role should include reporting on the suitability and effectiveness of the quality

system as a basis for improvement, management review, and liaison, as necessary, with

customers, subcontractors and any other external parties on quality matters.

4.1.3 Management review

The supplier ’s management with executive responsibility, should review the quality system.

This may include, but not be limited to, the following:

the adequacy of the organizational structure, including its staffing and other

resources;

conformity to IS0 900 1, IS0 9002 or IS0 9003, and effective implementation of

the quality system;

compliance with quality policy;

I

information based on customer feedback, internal feedback (such as results of

internal audits), process performance and product performance, as well as

corrective and preventive ictions taken.

The intervals between reviews shoul d be carefully planned and periodically reviewed to

ensure the continuing suitability and effectiveness of the quality system. The management

@ IS0 IS0 9000=2:1997(E)

review process, frequency of reviews and levels of inputs will depend on the individual

circumstance. Some organizations have found that annual management reviews are

acceptable.

Management should focus on trends that may indicate problems. Chronic problem areas

should receive special attention. Actions that are required following changes to the quality

system determined during management review should be implemented in a timely manner.

The effectiveness of any changes should be evaluated. Records of such reviews should be

maintained (see 4.16).

42 0 Quality system

4.2.1 General

The implementation of a quality system by the supplier is most effective when those in the

organization understand its intention and how it functions, in particular, in the area of their

responsibility and its interface with other parts of the system. The quality manual has an

important role in this regard, for both internal and external parties. To give a coherent view

of the quality system, the quality manual should include the quality policy, a description of

the organization, and identify the quality system procedures with appropriate cross-references

to more detailed documentation. The quality manual could, for example, be one document

supported by several levels of other documents, each level becoming progressively more

detailed. There may also be an overall system manual, one or more specific procedural

manuals, work instructions and reference documents. Together, these documents define the

quality system. Further guidance on development of quality manuals is given in IS0 100 13.

4.2.2. Quality system procedures

Documented quality system procedures are required for applicable requirements of IS0

9001, IS0 9002 and IS0 9003 and should be consistent with the supplier ’s quality policy. It

is important to recognise that the structure and level of detail required in these procedures

should be tailored to the needs of the organization ’s personnel, which will depend upon

methods used and the training requirements, skills and qualifications of such personnel, as

indicated in 4.18.

A documented procedure usually specifies the purpose and scope of an activity:

what shall be done by whom;

I

when, where, and how it shall be done;

-

what materials, equipment and documents shall be used; and

how an activity shall be controlled and recorded.

Documented procedures may make reference to work instructions that define how an activity

is performed.

@ IS0

ISO9000=2:1997(E)

4.2.3 Quality planning

The supplier needs to show that planning activities have been performed, and that they

establish the means by which the requirements for quality will be met. Planning should

include the application of the quality system elements, and how the product quality

requirements will be met.

This may require the following.

a) For managerial and operational planning, preparing the application of the quality

system.

b) For product planning, setting out in a quality plan or in any other documented

procedures the specific quality practices, resources and sequence of activities

relevant to a particular product, project or contract.

More guidance on quality plans is given in IS0 10005.

43 a Contract review

4.3.1 General

In the situation where a tender is offered or a contract or order is to be established between a

supplier and a customer, the means of achieving satisfaction lies in the contract review

process.

Contract review is one of the supplier ’s primary interfaces with its customers. The

documented procedures should include a review of customer requirements (whether

expressed in a tender, contract or order, which may be written or verbal) and how customer

requirements are reviewed and communicated within the organization.

The contract review is prior to accepting a contract or an order.

4.3.2 Review

The importance of a thorough understanding of the customer ’s needs, from initial contact,

through tendering or receiving verbal orders, to the formulation of the contract, or order and

in all subsequent stages cannot be overstated. Often, dialogue will be necessary to achieve

this understanding, that should clearly establish the customer ’s requirements as to the product,

delivery and other critical factors. Where a verbal statement of requirement is received from

the customer, the supplier should ensure that an order (statement of requirements) is

understood, adequately documented and agreed to by the customer.

Contract review is a process that includes the following:

a) review of the requirement; this may be appropriate at the tendering or order entry

stage and at subsequent stages prior to acceptance of the contract or the order;

@ IS0 IS0 9000=2:1997(E)

b) agreement within the supplier ’s organization that

I

the requirements have been defined,

I

the requirements are understood,

I

the supplier has the capability to meet the requirements of the contract, by going

through a defined process to verify that the necessary resources and facilities are

available to fulfil all the requirements of the contract;

resolution of any differences with the customer;

cl

d) contract review of a standard product (e.g. “off-the-shelf’ items, a “commodity

item ”, a catalogue item with published specification, etc.) can be as simple as

verifying the accuracy of the information on the order;

e) the requirements of the contract, where appropriate, may be translated into the

terminology, tolerances, and other necessary information for designing,

purchasing and process control;

f) preliminary quality plan or documented procedures, where appropriate, may be

developed to give an understanding of how to implement the contract

successfully and support the contract review process.

It is beneficial for the supplier to adopt a contract or order review procedure that has the

following features:

affected parties have an opportunity and adequate time to review the contract;

I

a checklist or some other means (e.g. a standard form) is available for reviewers

to verify and record that they have reviewed and understood the requirements of

the contract or order;

a method is available for reviewers to question the requirements of the contract or

order, to have their questions considered and to have differences with other

affected parties resolved.

4.3.3 Amendment to contract

When customer requirements change, consideration should be given to repeating the contract

review procedure (see 4.3.2). It is beneficial for the supplier to have a procedure for reviews

by the same departmental functions that reviewed the original contract or accepted order.

Before such changes come into effect, there should be methods available to ensure that all

relevant changes are communicated to those affected.

4.3.4 Records

In all cases, it should be sufficient to retain records that the review has been performed (see

4.16). For internal purposes, however, records of the evaluation associated with the contract

@ IS0

ISO9000=2:1997(E)

review may be retained in cases such as complex or critical projects. These records should

give objective evidence for audits, and facilitate the following:

post-delivery project review;

process improvement; and

the generation of proposals for future projects.

44 0 Design control

4.4.1 General

The essential quality aspects and the regulatory requirements such as safety, performance, and

dependability of a product are established during the design and development phase.

Deficient design can be a major cause of quality problems.

In considering design control, it is important to note that the design process may apply to

various activities in differing styles and timescales. Such aspects are related to products, as

well as the process associated with product design. The supplier should consider all phases of

the design associated with product design and all phases of the design process for which

controlled procedures are necessary.

4.4.2 Design and development planning

The supplier should establish procedures for design and development planning and, where

appropriate,include the following:

identification, scope and objectives;

sequential and parallel work schedules;

timing, frequency, and nature of design verification and validation activities;

evaluation of the safety, performance and dependability incorporated in the

product design;

I

methods of product measurement, test and acceptance criteria;

assignment of responsibilities.

Design and development plans should be integrated with any other plans and verification

procedures related to the product and plans should be updated as necessary.

IS0 9000=2:1997(E)

@ IS0

The supplier should clearly assign responsibilities for specific design leadership and other

design work functions to qualified personnel. The personnel in these functions should have

access to information and the resources to complete the work.

Design activities should be defined to the level of detail necessary for carrying out the design

process.

4.4.3 Organizational and technical interfaces

When input to the design is from a variety of sources, the inter-relationships and interfaces, as

well as the pertinent responsibilities and authorities, should be defined, documented,

coordinated, and controlled.

Many organizational functions, both internal and external, may contribute to the design

process; examples are as follows:

research and development;

marketing and sales;

purchasing;

quality assurance and quality management;

engineering;

materials technology;

production/manufacturing;

service groups;

facilities management;

warehousing/transportation/logistics;

communications;

information systems.

They should also establish, but not limit themselves to, the following:

what information should be received and transmitted;

identification of sending and receiving groups;

the purpose of the information transmitted;

identification of transmittal methods;

document transmittal and records maintenance.

@ IS0

ISO9000=2:1997(E)

4.4.4 Design input

User needs (through marketing) or customer requirements (through contract) should be

established during contract review (see 4.3) that, together with relevant statutory legislation,

will form the design input requirements.

Design inputs are typically in the form of product requirement specifications and/or product

description with specifications relating to configuration, composition, incorporated elements,

and other design features.

All pertinent design inputs (such as performance, functional, descriptive, environmental,

safety and regulatory requirements) should be defined, reviewed and recorded by the supplier.

The design inputs should describe all requirements to the greatest possible extent; they lay

the foundation and provide a unified approach to the design. Details agreed between

customer and supplier on how customer, statutory and regulatory requirements will be met

should be included.

The record of the design inputs should also include the resolutions of any

incomplete, ambiguous or conflicting requirements that have been identified at the contract

review and/or design verification stages or related design control activities.

materials, and processes requiring

The design inputs should identify design criteria,

development and analysis, including prototype testing to verify their adequacy. Design inputs

should be prepared in a way that facilitates periodic updates. They should indicate ‘when’ or

‘what criteria’ will cause the inputs to be updated, who is responsible for the update, and under

what circumstances the customer will get a copy. Design inputs prepared in this way serve as

the definitive up-to-date reference document as the design progresses to completion.

4.4.5 Design output

Throughout the design process, the requirements contained in the design description are

translated by the supplier into outputs. Design outputs should be documented in terms that

can be verified and validated against design input requirements and need to contain or make

reference to acceptance criteria; examples of these can be found in the following:

drawings and parts list;

specifications (including process and materials specifications);

instructions;

I

software;

I

servicing procedures.

Design outputs are the product requirements used for purchasing, production, installation,

inspection and testing, and servicing. Because of their impact on follow-on activities, it is

important that the outputs are reviewed and approved before release.

@ IS0 ISO9000=2:1997(E)

4.4.6 Design review

Design reviews should be planned. In order to achieve a degree of objectivity, they need to

involve all functions, both internal and external, concerned with the design stage being

reviewed. Design staff and other specialist personnel should also participate as required.

Design review may be a regulatory requirement for certain types of product. The timing and

frequency of these reviews will be influenced by the maturity, complexity and cost of the

product being designed. Records of such reviews should be maintained (see 4.16).

The competence of the participants in the design reviews should be adequate to permit them

to examine designs and their implications. Design reviews may consider questions such as

the following.

Do designs satisfy all specified requirements for the product?

Are product design and processing capabilities compatible?

Are safety considerations considered?

Do designs meet functional and operational requirements, for example,

performance and dependability objectives?

Have appropriate materials and/or facilities been selected?

e)

Is there adequate compatibility of materials, components and/or service elements?

f)

Is the design satisfactory for all anticipated environmental and load conditions?

g)

Are components or service elements standardized and do they provide for

h)

reliability, availability and maintainability?

Is there a provision in tolerances, and/or configuration, for interchangeability and

replacement?

.

Are plans for implementing the design technically feasible (e.g. purchasing,

J)

production, installation, inspection and testing)?