ISO 17458-5:2013

(Main)Road vehicles — FlexRay communications system — Part 5: Electrical physical layer conformance test specification

Road vehicles — FlexRay communications system — Part 5: Electrical physical layer conformance test specification

ISO 17458-5:2013 specifies the conformance test for the electrical physical layer of the FlexRay communications system. ISO 17458-5:2013 defines a test that considers ISO 9646 and ISO 17458-4. It provides a standardized way to verify whether FlexRay Bus Driver and Active Star products are compliant to ISO 17458-4. The primary motivation is to ensure a level of interoperability of FlexRay Bus Drivers and Active Stars from different sources in a system environment. ISO 17458-5:2013 provides all necessary technical information to ensure that test results will be identical even on different test systems, provided that the particular test suite and the test system are compliant to the content of ISO 17458-5:2013.

Véhicules routiers — Système de communications FlexRay — Partie 5: Spécification d'essai de conformité de la couche d'application électrique

General Information

- Status

- Published

- Publication Date

- 20-Jan-2013

- Technical Committee

- ISO/TC 22/SC 31 - Data communication

- Drafting Committee

- ISO/TC 22/SC 31/WG 3 - In-vehicle networks

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 02-Jul-2025

- Completion Date

- 14-Feb-2026

Overview

ISO 17458-5:2013 - Road vehicles - FlexRay communications system - Part 5: Electrical physical layer conformance test specification - defines a standardized conformance test for the electrical physical layer of the FlexRay communications system. The standard specifies tests that verify whether FlexRay Bus Driver and Active Star products conform to the electrical layer requirements of ISO 17458-4. By referencing ISO 9646 (conformance testing methodology) and ISO 17458-4, ISO 17458-5:2013 ensures reproducible test results and supports interoperability of FlexRay components from different manufacturers.

Key topics and technical requirements

- Scope of testing: Electrical physical layer conformance for FlexRay Bus Drivers and Active Stars.

- Test methodology: Uses the ISO 9646 conformance testing approach and aligns with requirements of ISO 17458-4 to define test cases and procedures.

- Reproducibility: Provides detailed technical information so test results remain identical across compliant test suites and test systems.

- Device focus:

- FlexRay Bus Driver - electrical signaling, timing, and interface behaviour.

- Active Star - active network topology elements that affect bus electrical characteristics.

- Interoperability emphasis: Tests are designed to reveal non-conformances that would prevent reliable multi-vendor integration in vehicle systems.

- Test system requirements: Specifies the level of detail needed for test suites and measurement setups to ensure consistent outcomes on different platforms.

Practical applications

- Component validation: Use ISO 17458-5:2013 to validate that Bus Drivers and Active Stars meet the electrical layer requirements before integration.

- Supplier qualification: OEMs and Tier‑1s can require conformance testing as part of supplier acceptance and quality assurance.

- Interoperability testing: Ensures devices from different vendors interoperate reliably in FlexRay networks used in advanced vehicle applications.

- Certification and compliance: Test labs can apply the standard to provide objective compliance reports for product releases.

- System integration: Helps system integrators identify electrical-layer issues early in development and avoid field failures.

Who should use this standard

- Automotive OEMs and system integrators

- Tier‑1 / Tier‑2 suppliers of FlexRay hardware (Bus Drivers, Active Stars)

- Independent test laboratories and certification bodies

- Hardware test engineers and electrical validation teams

Related standards

- ISO 17458-4 - Electrical physical layer specification (referenced normative requirements)

- ISO 9646 - Conformance testing methodology (testing framework referenced by this part)

- Other parts of the ISO 17458 (FlexRay) series for protocol and system-level requirements

Keywords: ISO 17458-5:2013, FlexRay, electrical physical layer, conformance test, FlexRay Bus Driver, Active Star, interoperability, ISO 17458-4, ISO 9646, automotive communications.

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

AIAG (Automotive Industry Action Group)

American automotive industry standards and training.

Sponsored listings

Frequently Asked Questions

ISO 17458-5:2013 is a standard published by the International Organization for Standardization (ISO). Its full title is "Road vehicles — FlexRay communications system — Part 5: Electrical physical layer conformance test specification". This standard covers: ISO 17458-5:2013 specifies the conformance test for the electrical physical layer of the FlexRay communications system. ISO 17458-5:2013 defines a test that considers ISO 9646 and ISO 17458-4. It provides a standardized way to verify whether FlexRay Bus Driver and Active Star products are compliant to ISO 17458-4. The primary motivation is to ensure a level of interoperability of FlexRay Bus Drivers and Active Stars from different sources in a system environment. ISO 17458-5:2013 provides all necessary technical information to ensure that test results will be identical even on different test systems, provided that the particular test suite and the test system are compliant to the content of ISO 17458-5:2013.

ISO 17458-5:2013 specifies the conformance test for the electrical physical layer of the FlexRay communications system. ISO 17458-5:2013 defines a test that considers ISO 9646 and ISO 17458-4. It provides a standardized way to verify whether FlexRay Bus Driver and Active Star products are compliant to ISO 17458-4. The primary motivation is to ensure a level of interoperability of FlexRay Bus Drivers and Active Stars from different sources in a system environment. ISO 17458-5:2013 provides all necessary technical information to ensure that test results will be identical even on different test systems, provided that the particular test suite and the test system are compliant to the content of ISO 17458-5:2013.

ISO 17458-5:2013 is classified under the following ICS (International Classification for Standards) categories: 43.040.15 - Car informatics. On board computer systems. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 17458-5:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 17458-5

First edition

2013-02-01

Road vehicles — FlexRay

communications system —

Part 5:

Electrical physical layer conformance

test specification

Véhicules routiers — Système de communications FlexRay —

Partie 5: Spécification d'essai de conformité de la couche d'application

électrique

Reference number

©

ISO 2013

This CD-ROM contains the publication ISO 17458-5:2013 in portable document format (PDF), which can be

viewed using Adobe® Acrobat® Reader.

Adobe and Acrobat are trademarks of Adobe Systems Incorporated.

© ISO 2013

All rights reserved. Unless required for installation or otherwise specified, no part of this CD-ROM may be reproduced, stored in a retrieval

system or transmitted in any form or by any means without prior permission from ISO. Requests for permission to reproduce this product

should be addressed to

ISO copyright office Case postale 56 CH-1211 Geneva 20 Switzerland

Internet copyright@iso.org

Reproduction may be subject to royalty payments or a licensing agreement.

Violators may be prosecuted.

Published in Switzerland

ii © ISO 2013 – All rights reserved

Installation

If this publication has been packaged as a zipped file, do NOT open the file from the CD-ROM, but copy it to

the desired location in your local environment. On

...

INTERNATIONAL ISO

STANDARD 17458-5

First edition

2013-02-01

Road vehicles— FlexRay

communications system —

Part 5:

Electrical physical layer conformance

test specification

Véhicules routiers — Système de communications FlexRay —

Partie 5: Spécification d'essai de conformité de la couche d'application

électrique

Reference number

©

ISO 2013

© ISO 2013

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2013 – All rights reserved

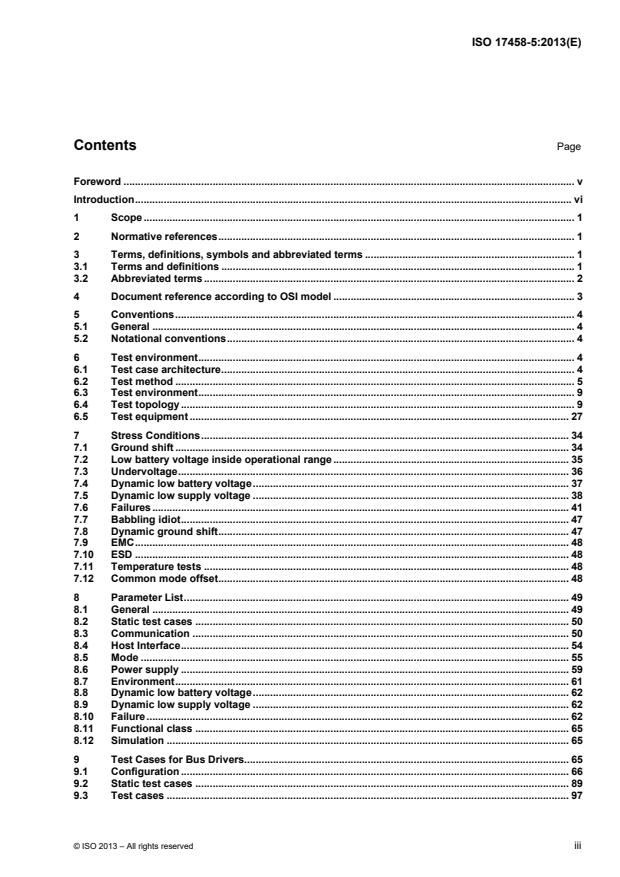

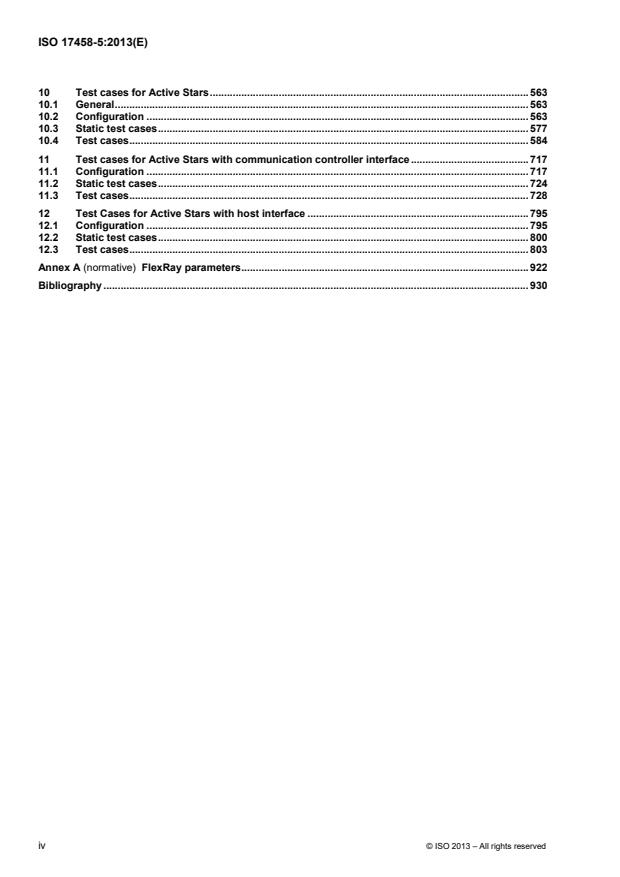

Contents Page

Foreword . v

Introduction . vi

1 Scope . 1

2 Normative references . 1

3 Terms, definitions, symbols and abbreviated terms . 1

3.1 Terms and definitions . 1

3.2 Abbreviated terms . 2

4 Document reference according to OSI model . 3

5 Conventions . 4

5.1 General . 4

5.2 Notational conventions . 4

6 Test environment . 4

6.1 Test case architecture . 4

6.2 Test method . 5

6.3 Test environment . 9

6.4 Test topology . 9

6.5 Test equipment . 27

7 Stress Conditions . 34

7.1 Ground shift . 34

7.2 Low battery voltage inside operational range . 35

7.3 Undervoltage . 36

7.4 Dynamic low battery voltage . 37

7.5 Dynamic low supply voltage . 38

7.6 Failures . 41

7.7 Babbling idiot . 47

7.8 Dynamic ground shift . 47

7.9 EMC . 48

7.10 ESD . 48

7.11 Temperature tests . 48

7.12 Common mode offset . 48

8 Parameter List . 49

8.1 General . 49

8.2 Static test cases . 50

8.3 Communication . 50

8.4 Host Interface . 54

8.5 Mode . 55

8.6 Power supply . 59

8.7 Environment . 61

8.8 Dynamic low battery voltage . 62

8.9 Dynamic low supply voltage . 62

8.10 Failure . 62

8.11 Functional class . 65

8.12 Simulation . 65

9 Test Cases for Bus Drivers. 65

9.1 Configuration . 66

9.2 Static test cases . 89

9.3 Test cases . 97

10 Test cases for Active Stars . 563

10.1 General . 563

10.2 Configuration . 563

10.3 Static test cases . 577

10.4 Test cases . 584

11 Test cases for Active Stars with communication controller interface . 717

11.1 Configuration . 717

11.2 Static test cases . 724

11.3 Test cases . 728

12 Test Cases for Active Stars with host interface . 795

12.1 Configuration . 795

12.2 Static test cases . 800

12.3 Test cases . 803

Annex A (normative) FlexRay parameters . 922

Bibliography . 930

iv © ISO 2013 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 17458-5 was prepared by Technical Committee ISO/TC 22, Road vehicles, Subcommittee SC 3,

Electrical and electronic equipment.

ISO 17458 consists of the following parts, under the general title Road vehicles — FlexRay communications

system:

Part 1: General information and use case definition

Part 2: Data link layer specification

Part 3: Data link layer conformance test specification

Part 4: Electrical physical layer specification

Part 5: Electrical physical layer conformance test specification

Introduction

The FlexRay communications system is an automotive focused high speed network and was developed with

several main objectives which were defined beyond the capabilities of established standardized bus systems

like CAN and some other proprietary bus systems. Some of the basic characteristics of the FlexRay protocol

are synchronous and asynchronous frame transfer, guaranteed frame latency and jitter during synchronous

transfer, prioritization of frames during asynchronous transfer, single or multi-master clock synchronization,

time synchronization across multiple networks, error detection and signalling, and scalable fault tolerance.

The FlexRay communications system is defined for advanced automotive control applications. It serves as a

communication infrastructure for future generation high-speed control applications in vehicles by providing:

A message exchange service that provides deterministic cycle based message transport;

Synchronization service that provides a common time base to all nodes;

Start-up service that provides an autonomous start-up procedure;

Error management service that provides error handling and error signalling;

Wakeup service that addresses the power management needs.

This bus system has been developed with several main objectives which were defined beyond the capabilities

of existing bus systems like CAN and some other proprietary bus systems. This advanced automotive

communication system specifies support for:

Scalable static and dynamic message transmission (deterministic and flexible);

High net data rate of 5 Mbit/sec; gross data rate approximately 10 Mbit/sec;

Scalable fault-tolerance (single and dual channel);

Error containment on the physical layer through an independent Bus Guardian;

Fault tolerant clock synchronisation (global time base).

Since start of development the automotive industry world wide supported the specification development. The

FlexRay communications system has been successfully implemented in production vehicles today.

The ISO 17458 series specifies the use cases, the communication protocol and physical layer requirements of

an in-vehicle communication network called "FlexRay communications system".

This part of ISO 17458 has been established in order to define the use cases for vehicle communication

systems implemented on a FlexRay data link.

To achieve this, it is based on the Open Systems Interconnection (OSI) Basic Reference Model specified in

ISO/IEC 7498-1 [1] and ISO/IEC 10731 [6], which structures communication systems into seven layers. When

mapped on this model, the protocol and physical layer requirements specified by ISO 17458 are broken into:

Diagnostic services (layer 7), specified in ISO 14229-1 [7], ISO 14229-4 [9];

Presentation layer (layer 6), vehicle manufacturer specific;

Session layer services (layer 5), specified in ISO 14229-2 [8];

vi © ISO 2013 – All rights reserved

Transport layer services (layer 4), specified in ISO 10681-2 [5];

Network layer services (layer 3), specified in ISO 10681-2 [5];

Data link layer (layer 2), specified in ISO 17458-2, ISO 17458-3;

Physical layer (layer 1), specified in ISO 17458-4, ISO 17458-5;

in accordance with Table 1.

Table 1 — FlexRay communications system specifications applicable to the OSI layers

Applicability OSI 7 layers FlexRay communications system Vehicle manufacturer enhanced

diagnostics

Application (layer 7) vehicle manufacturer specific ISO 14229-1, ISO 14229-4

Presentation (layer 6)

vehicle manufacturer specific vehicle manufacturer specific

Seven layer

Session (layer 5)

vehicle manufacturer specific ISO 14229-2

according to

ISO 7498-1

Transport (layer 4)

vehicle manufacturer specific

and

ISO 10681-2

ISO/IEC

Network (layer 3) vehicle manufacturer specific

Data link (layer 2)

ISO 17458-2, ISO 17458-3

Physical (layer 1)

ISO 17458-4, ISO 17458-5

Table 1 shows ISO 17458 Parts 2 – 5 being the common standards for the OSI layers 1 and 2 for the FlexRay

communications system and the vehicle manufacturer enhanced diagnostics.

The FlexRay communications system column shows vehicle manufacturer specific definitions for OSI layers

3 – 7.

The vehicle manufacturer enhanced diagnostics column shows application layer services covered by

ISO 14229-4 which have been defined in compliance with diagnostic services established in ISO 14229-1, but

are not limited to use only with them. ISO 14229-4 is also compatible with most diagnostic services defined in

national standards or vehicle manufacturer's specifications. The presentation layer is defined vehicle

manufacturer specific. The session layer services are covered by ISO 14229-2. The transport protocol and

network layer services are specified in ISO 10681.

INTERNATIONAL STANDARD ISO 17458-5:2013(E)

Road vehicles — FlexRay communications system — Part 5:

Electrical physical layer conformance test specification

IMPORTANT — According to ISO 17458-4, the FlexRay communications system was specified

focusing on a data rate of 10 Mbit/s. Therefore this conformance test specification regards the use of

systems with a data rate of 10 Mbit/s only whereas the physical layer also works properly in systems

with data rates in the range from 2,5 Mbit/s to 10 Mbit/s according to ISO 17458-4.

1 Scope

This part of ISO 17458 specifies the conformance test for the electrical physical layer of the FlexRay

communications system.

This part of ISO 17458 defines a test that considers ISO 9646 and ISO 17458-4.

The purpose of this part of ISO 17458 is to provide a standardized way to verify whether FlexRay Bus Driver

and Active Star products are compliant to ISO 17458-4. The primary motivation is to ensure a level of

interoperability of FlexRay Bus Drivers and Active Stars from different sources in a system environment.

This part of ISO 17458 provides all necessary technical information to ensure that test results will be identical

even on different test systems, provided that the particular test suite and the test system are compliant to the

content of this part of ISO 17458.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 17458-1, Road vehicles — FlexRay communications system — Part 1: General information and use case

definition

ISO 17458-2, Road vehicles — FlexRay communications system — Part 2: Data link layer specification

ISO 17458-4, Road vehicles — FlexRay communications system — Part 4: Electrical physical layer

specification

3 Terms, definitions, symbols and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 17458-1, ISO 17458-2, ISO 17458-4

and the following apply.

3.1.1

bus driver – communication controller interface

BD-CC-interface

see “BD-BD interface” when replacing one BD by a CC

3.1.2

cable

term that summarises all necessary components to implement a FlexRay transmission line:

two twisted or untwisted wires to be connected to BP and BM, isolators to mount the wires, an optional shield,

an optional wire to strengthen the shield, an optional sheath, etc.

3.1.3

communication controller – bus driver interface

CC-BD-interface

see “BD-CC-interface”

3.1.4

communication channel

FlexRay allows a single CC to distribute data-frames independent from each other on two different hardware

paths or topologies. From an abstract view each path is named “communication channel”.

3.2 Abbreviated terms

LT lower tester

UT upper tester

2 © ISO 2013 – All rights reserved

4 Document reference according to OSI model

Figure 1 depicts the FlexRay document reference according to OSI model.

ISO 17458-1

FlexRay communications

system - General

information and

use case definition

Vehicle Manufacturer

Enhanced Diagnostics

specific

ISO 14229-1 UDS

Vehicle

Specification, ISO 14229-4

subset

manufacturer

OSI Layer 7

requirements and UDSonFR

specific

Application

use case definition

ISO 22901 ODX

Vehicle

or vehicle

manufacturer

OSI Layer 6

manufacturer

specific

Presentation

specific

ISO 14229-2 UDS ISO 14229-2 UDS Vehicle

Session layer 1 : 1 Session layer manufacturer

OSI Layer 5

services services specific

Session

Standardized Service Primitive Interface

FlexRay communications system

Vehicle

manufacturer

OSI Layer 4

specific

Transport

ISO 10681-2

Communication on

FlexRay –

Communication

layer services

Vehicle

manufacturer

OSI Layer 3

specific

Network

ISO 17458-3

ISO 17458-2

FlexRay

FlexRay

communications system

OSI Layer 2

communications system

- Protocol conformance

Data Link

– Protocol specification

test specification

ISO 17458-5

ISO 17458-4

FlexRay

FlexRay

communications system

communications system

OSI Layer 1

- Electrical physical

- Electrical physical

Physical

layer conformance test

layer specification

specification

Figure 1 — FlexRay document reference according to OSI model

5 Conventions

5.1 General

ISO 17458, ISO 10681 and ISO 14229-4 are based on the conventions specified in the OSI Service

Conventions (ISO/IEC 10731) as they apply for physical layer, protocol, network & transport protocol and

diagnostic services.

5.2 Notational conventions

Notational conventions are listed in ISO 17458-4.

6 Test environment

6.1 Test case architecture

Each test case is specified with the following parts that must all be described unambiguous:

Test case name

a name for this test case.

Test purpose

a description of the motivation for this test case.

Configuration

the state of the test environment for this test case.

Preamble (setup state)

the steps to do before the specified test case could be executed.

Test execution

the description of the execution of this test case.

Postamble

the steps to do after the specified test case in order to have a defined state.

Pass criteria

the criteria to judge the test result.

Test instances

this is an optional part and contains test cases, that are summarised in tabular form because they are

executed separately with only minor changes in comparison to the first test case within this group.

Every test case is independent from the other test cases.

Several test cases are performed with the presence of stress conditions in order to check the robustness of

the IUT. These stress conditions are specified in detail in Clause 7.

The test parameters are FlexRay variables or constants that are defined in ISO 17458-4. These test

parameters are specified in detail in Clause 8.

Every test case starts at the beginning of the preamble and ends after the postamble. There is no delay

between the preamble and the test execution and between the test execution and the postamble.

The pass criteria are related only to the test execution.

4 © ISO 2013 – All rights reserved

Product specific items are not part of this International Standard.

6.2 Test method

6.2.1 General

The FlexRay BD has several interfaces, that are supplied by specified power supplies and stimuli and

observed by external components (signal measurements). The requirements for those generators and signal

measurements are specified in 6.5.

The interfaces of the BD are separated in two parts:

Analog interface

bus (service provider) and supply pins.

Digital interface

the pins for connecting the BD with the FlexRay protocol components.

Each test case describes the used pins for supplying, stimulation and observation.

The used test method for the FlexRay PL regarding [2] is the local test method, see also Figure 2.

The local test method contains a Lower Tester (LT) for the analog interface (bus) and an Upper Tester (UT)

for the digital interface. Both are part of the test system. The coordination of the test cases is done by the test

coordination procedure (TCP).

The whole test is controlled by the supervisor (SV) that is also part of the test system. The SV controls the UT

and LT with the TCP.

Figure 2 depicts the local test method of ISO 9646-1:1994.

Test System

PCO

Upper Tester

ASPs

TCP SV

Lower Tester

S

PDUs

U IUT

T

PCO ASPs

Service Provider

Key

ASP Abstract service primitive

IUT Implementation under test

PCO Point of control and observation

PDU Prodocol data unit

SV Supervisor

SUT System under test

TCP Test control procedure

Figure 2 — Local test method

6.2.2 Upper Tester

The UT has to provide test data, control and observe the IUT at its upper interface. The implementation has to

keep in mind the possibility of two different host interfaces of the IUT as specified in ISO 17458-4.

6 © ISO 2013 – All rights reserved

Figure 3 shows the mandatory signals of the IUT that the conformance test considers:

UT UT

TxD TxEN RxD RxEN BGE INH1 ERRN STBN TxD TxEN RxD RxEN BGE INH1 INTN SPI

IUT IUT

a) Option A b) Option B

Components Connections and supplies

IUT Implementation Under Test BGE Bus guardian enable

UT Upper Tester ERRN Error not

INH1 Inhibit 1

INTN Inhibit n

RxD Receive data

RxEN Receive enable

SPI Serial peripheral interface

STBN Standby not

TxD Transmit data

TxEN Transmit enable not

Figure 3 — Upper Tester

The tasks of the UT are:

Provide test data streams

Change the mode of the IUT

Observe and acquire the error line

Observe and acquire the received data stream

Provide IUT functions to the supervisor

Provide test system functionality to the IUT

6.2.3 Lower Tester

The Lower Tester has to provide data and observe the IUT at its lower interface – the supply and bus interface

of the IUT. Figure 4 shows an overview of the Lower Tester.

IUT

V GND BP BM

CC

LT

Components Connections and supplies

IUT Implementation Under Test BM Bus minus

LT Lower Tester BP Bus plus

GND Ground connection

V Supply voltage for digital signals

CC

Figure 4 — Lower Tester

The tasks of the Lower Tester are:

Generate and control bus failures

Generate ground shift

Control the supply voltages

Provide IUT functions to the supervisor

Provide test system functionality to the IUT

6.2.4 Supervisor

The SV has to control and observe the whole test system and communicates with the IUT via the LT and UT.

The tasks of the SV are:

Control the LT and UT

Observe and acquire the LT and UT

Control and observe optional measurement devices

Execute and coordinate test procedures

Create the test report

8 © ISO 2013 – All rights reserved

6.3 Test environment

The following parameters are constants within the conformance test and used in the standard environment:

Temperature: ambient

Moisture: ambient

Test topology: as described in 6.4

Termination: as described in the test topology; differences are specified in the used test case

Amount of nodes: as described in the test topology

Amount of Stars: as described in the test topology

Baud rate: 10 Mbit/s (gdBit = 100 ns) as part of the harmonized baud rates in the FlexRay consortium

Common mode choke: as specified in 6.4.6

6.4 Test topology

6.4.1 General

The purpose is to test the expected worst case of a possible topology with the maximum number of cascaded

Active Stars, one passive star and one passive bus.

It is sufficient to test only with one physical channel, because the behaviour of the physical layer is

independent from the number of used channels in a communication network.

The used test topology is described in the following subclauses and shown in Figure 5.

Figure 5 depicts the conformance test topology.

N

CS

T

BS BS BS

3 2 1

2 4

PS T AS T

T

CS

T T

T

N N N N N N N N N

24 23 22 21 2 14 13 12 11

GND

Components Connections and supplies

AS Active Star GND System ground

BS Bus splice x

x

CS Cable shield connection

N FlexRay node x

X

PS Passive Star

T Bus termination

is not a supply voltage. It is a voltage used as stress condition where BP and BM are short-circuit to this

NOTE 1 VANY

voltage. V is product-specific and varies from the implementation of supply voltages of the IUT and the ground shift.

ANY

NOTE 2 Further details of the cable lengths used in the test topology are given in Table 2.

Figure 5 — Conformance test topology

Description of the test topology:

For detailed description of the AS hardware see 6.4.7.

A detailed description of the passive star hardware is given in 6.4.8.

A detailed description of the passive bus hardware is given in 6.4.9.

Nodes without ground shift stress shall be connected with their negative terminal to one of the ground

splices that are mounted on the stainless steel chassis.

The four ground splices shall be mounted near the nodes and the AS to consider the length of the GND

cables of the nodes and the AS. The following nodes are connected to one of the GND splices:

GND splice 1: Nodes 11, 12, 13 and 14

GND splice 2: Nodes 21, 22, 23 and 24

GND splice 3: Nodes 1, 2 and the AS

GND splice 4: negative terminal of all supplies

10 © ISO 2013 – All rights reserved

1)

Nodes that are stressed with ground shift are connected to a switch that guarantees that these nodes

could be connected directly to ground or are stressed by ground shift. This switch shall be controllable by

the SV. The attenuation of the used switches shall be as small as possible. The switch shall be on the

nodes and the AS. The connections from the switch to the terminals shall be as short as possible.

The ground shift terminal of the nodes and the AS are connected to the positive terminal of the ground

shift generator. The length of this cable is 1 m.

The negative terminal of the ground shift generator is connected to the GND splice of the test system

(chassis). The length of this cable is 1 m.

splice (+) that is mounted on the chassis. The V splice is a

All nodes shall be connected to the V

BAT BAT

separate board on which the splices for the supply voltages are placed.

The AS shall be connected to the V splice (+) for the AS that is mounted on the chassis.

BAT

The AS shall be connected to the V splice (+) for the AS that is mounted on the chassis.

CC

splice (+) for the AS that is mounted on the chassis.

The AS shall be connected to the V

IO

The AS shall be connected to the V splice with a cable length of 3 m.

ANY

Node 24 shall be connected to the V splice (+) for the node that is mounted on the chassis.

BAT

Node 24 shall be connected to the V splice (+) for the node that is mounted on the chassis.

CC

Node 24 shall be connected to the V splice (+) for the node that is mounted on the chassis.

IO

Node 24 shall be connected to the V splice with a cable length of 3 m.

ANY

Node 23 shall be connected to the V splice (+) for the node that is mounted on the chassis.

CC

Node 23 shall be connected to the V splice (+) for the node that is mounted on the chassis.

IO

Node 21 shall be connected to the V splice (+) for the node that is mounted on the chassis.

CC

Node 21 shall be connected to the V splice (+) for the node that is mounted on the chassis.

IO

The chassis shall be a steel plate for the ground connections of the IUTs and the power supply.

The chassis is connected to the negative terminal of the power supply (clamp 31).

The V splice is connected to the positive terminal of the power supply (clamp 30).

BAT

The V splice for the nodes is connected to the positive terminal of the nodes V power supply.

BAT BAT

The V splice for the AS is connected to the positive terminal of the AS V power supply.

BAT BAT

The V splice for the AS is connected to the positive terminal of the first +5 V power supply.

CC

The V splice for the node 24 is connected to the positive terminal of the V power supply for node 24.

BAT BAT

1) The switch shall be on the nodes and the AS. The connections from the switch to the terminals shall be as short as

possible.

The V splice for the node 24 is connected to the positive terminal of the second +5 V power supply.

CC

The V splice for the node 24 is connected to the positive terminal of the V reference voltage.

IO IO

All communication channels shall be terminated regarding ISO 17458-4.

The shield of every link shall be terminated regarding ISO 17458-4.

The bus cables shall meet the requirements of ISO 17458-4; see also 6.4.10.1. All bus cables are

shielded. The shield is only connected at the AS (see also 6.4.3).

The supply cables shall meet the requirements specified in 6.4.10.2.

The following topics are part of the implementation of the conformance test, but have to meet ISO 17458-4:

the type of mounting of the IUTs on the chassis

the type and manufacturer of the cables

the type and manufacturer of the connectors

the type of the splices

the wiring of the IUT

6.4.2 Cable overview of the test topology

Table 2 gives a full overview of the cables of the test topology

Table 2 — Cable overview of test topology

Length

No. Type From To Termination Remarks

m

Active

1 Bus wire Node 1 1 Both ends —

Star

GND

2 Ground wire Node 1 0,5 — —

splice 3

3 Supply wire Node 1 V splice 2 — —

BAT

Active

4 Bus wire Node 2 3,5 Both ends —

Star

This node emulates an ECU in a roof

GND

5 Ground wire Node 2 5 — of a vehicle where no ground splice in

splice 3

the roof is available.

6 Supply wire Node 2 V splice 6 — —

BAT

Bus splice No

7 Bus wire Node 11 0,3 Part of the passive bus

1 termination

GND

8 Ground wire Node 11 0,5 — —

splice 1

9 Supply wire Node 11 V splice 6 — —

BAT

Bus splice Only at

10 Bus wire Node 12 0,3 Part of the passive bus

1 node 12

12 © ISO 2013 – All rights reserved

Length

No. Type From To Termination Remarks

m

GND

11 Ground wire Node 12 0,5 — —

splice 1

12 Supply wire Node 12 V splice 8 — —

BAT

Bus splice No

13 Bus wire Node 13 0,3 Part of the passive bus

2 termination

GND

14 Ground wire Node 13 0,5 — —

splice 1

15 Supply wire Node 13 V splice 9 — —

BAT

Bus splice No

16 Bus wire Node 14 0,3 Part of the passive bus

3 termination

GND

17 Ground wire Node 14 0,5 — —

splice 1

18 Supply wire Node 14 V splice 10 — —

BAT

Passive No

19 Bus wire Node 21 0,25 Connected to the passive star

star termination

GND

20 Ground wire Node 21 0,5 — —

splice 2

21 Supply wire Node 21 V splice 4 — —

BAT

Passive No

22 Bus wire Node 22 0,25 Connected to the passive star

star termination

GND

23 Ground wire Node 22 0,5 — —

splice 2

24 Supply wire Node 22 V splice 3 — —

BAT

Passive Only at

25 Bus wire Node 23 1 Connected to the passive star

star node 23

GND

26 Ground wire Node 23 0,5 — —

splice 2

27 Supply wire Node 23 V splice 5 — —

BAT

Ground shift V

GS

28 Node 23 2 — Connected to positive terminal

a

supply

wire

Ground shift

V GND Connected to negative terminal

GS

29 1 —

b

supply splice 4 (ground wire of node 23)

wire

Passive No

30 Bus wire Node 24 0,25 Connected to the passive star

star termination

GND

31 Ground wire Node 24 0,5 — —

splice 2

32 Supply wire Node 24 V splice 4 — —

BAT

Ground shift V

GS

33 Node 24 2 — Connected to positive terminal

a

wire supply

Ground shift V GND Connected to negative terminal

GS

34 1 —

b

wire supply splice 4 (ground wire of node 24)

Length

No. Type From To Termination Remarks

m

Active GND

35 Ground wire 0,5 — —

Star splice 2

Active

36 Supply wire V splice 4 — —

BAT

Star

Active

37 Supply wire V splice 4 — —

CC

Star

Active Passive Only at

38 Bus wire 11 —

Star star Active Star

Active Bus splice Only at

39 Bus Wire 1,5 —

Star 3 Active Star

Ground shift

V Active

GS

40 2 — Connected to positive terminal

a

supply Star

wire

Ground shift V GND Connected to negative terminal

GS

41 1 —

b

supply splice 4 (ground wire of AS)

wire

Bus Bus splice No

42 Bus wire 10 Part of the passive bus

splice 1 2 termination

Bus Bus splice No

43 Bus wire 0,15 Part of the passive bus

splice 2 3 termination

44 Supply wire Battery V splice 3 — V supply for nodes

BAT BAT

GND

45 Ground wire Battery 1,5 — V supply for nodes

BAT

splice 4

46 Supply wire Battery V splice 3 — V supply for AS

BAT BAT

GND

47 Ground wire Battery 1,5 — V supply for AS

BAT

splice 4

V

CC

48 Supply wire V splice 3 — V supply for AS

CC CC

Supply

V GND

CC

49 Ground wire 1,5 — V supply for AS

CC

Supply splice 4

V

IO

50 Supply wire V splice 4 — V supply for AS

CC IO

Supply

V GND

IO

51 Ground wire 1,5 — V supply for AS

IO

Supply splice 4

52 Supply wire Battery V splice 4 — V supply for node 24

BAT BAT

GND

53 Ground wire Battery 1,5 — V supply for node 24

BAT

splice 4

V

CC

54 Supply wire V splice 4 — V supply for node 21, 23 & 24

CC CC

Supply

V GND

CC

55 Ground wire 1,5 — V supply for node 21, 23 & 24

CC

Supply splice 4

V

IO

56 Supply wire V splice 4 — V supply for node 21, 23 & 24

IO IO

Supply

V GND

IO

57 Ground wire 1,5 — V supply for node 21, 23 & 24

IO

Supply splice 4

Passive GND

58 Ground wire 0,3 — Ground connection of PS

star splice 2

14 © ISO 2013 – All rights reserved

Length

No. Type From To Termination Remarks

m

V

any

59 Stress wire Node 24 3 — Stress voltage for node 24

supply

V Active

any

60 Stress wire 3 — Stress voltage for AS

supply Star

Active

61 Bus wire Node 1 1 Both ends —

Star

GND

62 Ground wire Node 1 0,5 — —

splice 3

Battery

63 Supply wire Node 1 2 — —

splice

Active

64 Bus wire Node 2 3,5 Both ends —

Star

GND

65 Ground wire Node 2 5 — —

splice 3

Battery

66 Supply wire Node 2 6 — —

splice

Bus splice No

67 Bus wire Node 11 0,3 Part of the passive bus

1 termination

GND

68 Ground wire Node 11 0,5 — —

splice 1

Battery

69 Supply wire Node 11 6 — —

splice

Bus splice Only at

70 Bus wire Node 12 0,3 Part of the passive bus

1 node 12

GND

71 Ground wire Node 12 0,5 — —

splice 1

Battery

72 Supply wire Node 12 8 — —

splice

Bus splice No

73 Bus wire Node 13 0,3 Part of the passive bus

2 termination

GND

74 Ground wire Node 13 0,5 — —

splice 1

Battery

75 Supply wire Node 13 9 — —

splice

Bus splice No

76 Bus wire Node 14 0,3 Part of the passive bus

3 termination

GND

77 Ground wire Node 14 0,5 — —

splice 1

Battery

78 Supply wire Node 14 10 — —

splice

Passive No

79 Bus wire Node 21 0,25 Connected to the passive star

star termination

GND

80 Ground wire Node 21 0,5 — —

splice 2

Battery

81 Supply wire Node 21 4 — —

splice

Length

No. Type From To Termination Remarks

m

Passive No

82 Bus wire Node 22 0,25 Connected to the passive star

star termination

GND

83 Ground wire Node 22 0,5 — —

splice 2

Battery

84 Supply wire Node 22 3 — —

splice

Passive Only at

85 Bus wire Node 23 1 Connected to the passive star

star node 23

GND

86 Ground wire Node 23 0,5 — —

splice 2

Battery

87 Supply wire Node 23 5 — —

splice

Ground shift

VGS

88 Node 23 2 — Connected to positive terminal

a

wire supply

Ground shift V GND Connected to negative terminal

GS

89 1 —

b

wire supply splice 4 (ground wire of node 23)

Passive No

90 Bus wire Node 24 0,25 Connected to the passive star

star termination

GND

91 Ground wire Node 24 0,5 — —

splice 2

Battery

92 Supply wire Node 24 4 — —

splice

Ground shift V

GS

93 Node 24 2 — Connected to positive terminal

a

wire supply

Ground shift

V GND Connected to negative terminal

GS

94 1 —

b

supply splice 4 (ground wire of node 24)

wire

Active GND

95 Ground wire 0,5 — —

Star splice 2

Active

96 Supply wire V splice 4 — —

BAT

Star

Active

97 Supply wire V splice 4 — —

CC

Star

Active Passive Only at

98 Bus wire 11 —

Star star Active Star

Active Bus splice Only at

99 Bus Wire 1,5 —

Star 3 Active Star

Ground shift V Active

GS

100 2 — Connected to positive terminal

a

wire supply Star

Ground shift V GND Connected to negative terminal

GS

101 1 —

b

wire supply splice 4 (ground wire of AS)

Bus Bus splice No

102 Bus wire 10 Part of the passive bus

splice 1 2 termination

Bus Bus splice No

103 Bus wire 0,15 Part of the passive bus

splice 2 3 termination

Battery

104 Supply wire Battery 3 — V supply for nodes

BAT

splice

16 © ISO 2013 – All rights reserved

Length

No. Type From To Termination Remarks

m

GND

105 Ground wire Battery 1,5 — V supply for nodes

BAT

splice 4

Battery

106 Supply wire Battery 3 — V supply for AS

BAT

splice

GND

107 Ground wire Battery 1,5 — V supply for AS

BAT

splice 4

V

CC

108 Supply wire V splice 3 — V supply for AS

CC CC

Supply

V GND

CC

109 Ground wire 1,5 — V supply for AS

CC

Supply splice 4

V

IO

110 Supply wire V splice 4 — V supply for AS

CC IO

Supply

V GND

IO

111 Ground wire 1,5 — V supply for AS

IO

Supply splice 4

Battery

112 Supply wire Battery 4 — V supply for node 24

BAT

splice

GND

113 Ground wire Battery 1,5 — V supply for node 24

BAT

splice 4

V

CC

114 Supply wire V splice 4 — V supply for node 21 & 24

CC CC

Supply

V GND

CC

115 Ground wire 1,5 — V supply for node 21 & 24

CC

Supply splice 4

V

IO

116 Supply wire V splice 4 — V supply for node 21 & 24

IO IO

Supply

V GND

IO

117 Ground wire 1,5 — V supply for node 21 & 24

IO

Supply splice 4

Passive GND

118 Ground wire 0,3 — Ground connection of PS

star splice 2

V

any

119 Stress wire Node 24 3 — Stress voltage for node 24

supply

V Active

any

120 Stress wire 3 — Stress voltage for AS

supply Star

a

Positive terminal of the Ground Shift Generator

b

Negative terminal of the Ground Shift Generator

6.4.3 Shield

Each communication link shall have one cable shield connection. The conformance test uses one Active Star,

that is the central point of shield connection in the topology.

Table 3 defines the specified shield connection with bus cable, connectors, Active Star and node:

Table 3 — Shield connection components

Name Description Typ Unit

Damping resistance 1 000 Ω

R

s

Tolerance 1 %

Capacitance 470 nF

C

s

Tolerance 10 %

L , R , R and C Components of the passive star, see 6.4.8.

2 2 3 1

Figure 6 depicts the cable shield connection.

N AS PS N

BC BC BC

C C

s s

L L

R R

s s

R R

2 2

C

CS CS CS

R

Components

AS Active Star

BC Bus cable

CS Cable shield

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...