ISO 27914:2017

(Main)Carbon dioxide capture, transportation and geological storage — Geological storage

Carbon dioxide capture, transportation and geological storage — Geological storage

ISO 27914:2017 a) establishes requirements and recommendations for the geological storage of CO2 streams, the purpose of which is to promote commercial, safe, long-term containment of carbon dioxide in a way that minimizes risk to the environment, natural resources, and human health, b) is applicable for both onshore and offshore geological storage within permeable and porous geological strata including hydrocarbon reservoirs where a CO2 stream is not being injected for the purpose of hydrocarbon production or for storage in association with CO2-EOR, c) includes activities associated with site screening and selection, characterization, design and development, operation of storage sites, and preparation for site closure, d) recognizes that site selection and management are unique for each project and that intrinsic technical risk and uncertainty will be dealt with on a site-specific basis, e) acknowledges that permitting and approval by regulatory authorities will be required throughout the project life cycle, including the closure period, although the permitting process is not included in ISO 27914:2017, f) provides requirements and recommendations for the development of management systems, community and other stakeholder engagement, risk assessment, risk management and risk communication, g) does not apply to, modify, interpret, or supersede any national or international regulations, treaties, protocols or instruments otherwise applicable to the activities addressed in ISO 27914:2017, and h) does not apply to or modify any property rights or interests in the surface or the subsurface (including mineral rights), or any pre-existing commercial contract or arrangement relating to such property. The life cycle of a CO2 geological storage project covers all aspects, periods, and stages of the project, from those that lead to the start of the project (including site screening, selection, characterization, assessment, engineering, permitting, and construction), through the start of injection and proceeding through subsequent operations until cessation of injection and culminating in the post-injection period, which includes a closure period. Figure 1 illustrates the limits of ISO 27914:2017.

Capture, transport et stockage géologique du dioxyde de carbone — Stockage géologique

L'ISO 27914:2017 a) établit les exigences et recommandations relatives au stockage géologique de flux de CO2, dont le but est de promouvoir le confinement à long terme et en toute sécurité du dioxyde de carbone à l'échelle commerciale, de manière à réduire le plus possible les risques pour l'environnement, les ressources naturelles et la santé humaine, b) s'applique aussi bien au stockage géologique à terre et en mer dans des strates géologiques perméables et poreuses, y compris les réservoirs d'hydrocarbures où un flux de CO2 n'est pas injecté aux fins de la production d'hydrocarbures ou en vue d'un stockage en association avec la RAH-CO2, c) englobe les activités liées au tri et à la sélection de site, la caractérisation, l'étude, le développement, l'exploitation des sites de stockage et la préparation en vue de leur fermeture, d) reconnaît que le choix et la gestion du site sont propres à chaque projet et que les risques techniques et incertitudes intrinsèques seront traités selon une approche spécifique à chaque site, e) reconnaît que des permis et des approbations devront être obtenus auprès des autorités de réglementation tout au long du cycle de vie d'un projet, période de fermeture incluse, bien que le présent document ne traite pas du processus de délivrance des permis, f) fournit des exigences et des recommandations pour l'élaboration de systèmes de management, la participation des collectivités et autres parties prenantes, l'appréciation du risque, le management et la communication sur les risques, g) ne s'applique pas à, ni ne modifie, interprète ou remplace, tout règlement, traité, protocole ou instrument national ou international par ailleurs applicable aux activités couvertes par le présent document, et h) ne s'applique pas aux, ni ne modifie les, droits de propriété ou les intérêts sur les biens en surface ou en subsurface (y compris les droits miniers), ou tout contrat commercial pré existant ou toute disposition afférant à cette propriété. Le cycle de vie d'un projet de stockage géologique de CO2 couvre tous les aspects, périodes et phases du projet, allant de son lancement (y compris le tri de site, la sélection, la caractérisation, l'évaluation, l'étude technique, l'obtention de permis et la construction), en passant par le début de l'injection et les opérations ultérieures jusqu'à l'arrêt de l'injection, et se terminant par la période de post-injection incluant une période de fermeture. La Figure 1 illustre le périmètre du présent document.

Zajetje, transport in geološko shranjevanje ogljikovega dioksida - Geološko shranjevanje

Standard ISO 27914:2017:

a) določa zahteve in priporočila za geološko shranjevanje tokov CO2 z namenom spodbujanja komercialnega, varnega in dolgoročnega shranjevanja ogljikovega dioksida na način, s katerim se zmanjša tveganje za okolje, naravne vire in zdravje ljudi;

b) se uporablja za geološko shranjevanje na kopnem in na morju v prepustnih oziroma poroznih geoloških plasteh, vključno z nahajališči ogljikovodikov, pri čemer se tok CO2 ne uporablja za namen proizvodnje ogljikovodikov ali za shranjevanje v povezavi s CO2-EOR;

c) vključuje dejavnosti, povezane s pregledom in izbiro lokacije, karakterizacijo, načrtovanjem in razvojem, delovanjem lokacije ter pripravo na zaprtje lokacije;

d) upošteva, da sta izbira in upravljanje lokacije edinstvena za posamezni projekt ter da bosta notranje tehnično tveganje in negotovost obravnavana na podlagi posamezne lokacije;

e) potrjuje, da bosta dovoljenje in odobritev s strani regulativnih organov potrebna v vseh fazah izvajanja projekta, vključno z obdobjem zaprtja lokacije, čeprav postopek izdajanja dovoljenj ni vključen v standard ISO 27914:2017;

f) podaja zahteve in priporočila za razvoj sistemov upravljanja, vključevanje skupnosti in drugih deležnikov, oceno tveganja, obvladovanje tveganj ter obveščanje o tveganjih;

g) se ne uporablja za nacionalne ali mednarodne predpise, pogodbe, protokole ali instrumente, ki se drugače uporabljajo za dejavnosti, obravnavane v standardu ISO 27914:2017, in jih ne spreminja, razlaga ali nadomešča; ter

h) se ne uporablja za lastninske pravice oziroma interese na površju ali pod njim (vključno s pravicami izkoriščanja mineralnih virov) ali katero koli že obstoječo poslovno pogodbo ali dogovor v zvezi s tako lastnino ter jih ne spreminja.

Življenjski cikel projekta geološkega shranjevanja CO2 zajema vse vidike, obdobja in faze projekta, od tistih na začetku projekta (vključno s pregledom in izbiro lokacije, karakterizacijo, oceno, inženiringom, izdajo dovoljenj in gradnjo), prek začetka vbrizgavanja in izvajanja nadaljnjih postopkov do prenehanja vbrizgavanja ter zaključka v obdobju po vbrizgavanju, ki vključuje obdobje zaprtja lokacije. Slika 1 prikazuje omejitve standarda ISO 27914:2017.

General Information

- Status

- Published

- Publication Date

- 12-Oct-2017

- Technical Committee

- ISO/TC 265 - Carbon dioxide capture, transportation, and geological storage

- Drafting Committee

- ISO/TC 265/WG 3 - Storage

- Current Stage

- 9092 - International Standard to be revised

- Start Date

- 25-Jan-2022

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 06-Jun-2022

Overview

ISO 27914:2017 - Carbon dioxide capture, transportation and geological storage - Geological storage - establishes requirements and recommendations to enable safe, long‑term geological storage of CO2. The standard promotes commercial, safe containment of CO2 streams that minimizes risks to the environment, natural resources and human health. It applies to onshore and offshore storage in permeable, porous strata (including hydrocarbon reservoirs) except where CO2 injection is for hydrocarbon production or CO2‑EOR. ISO 27914:2017 covers the full project life cycle from site screening and selection through injection, operation, cessation of injection and the post‑injection (closure) period.

Key topics and technical requirements

ISO 27914:2017 covers both management and technical aspects. Main topic areas include:

- Management systems: project scope, roles and responsibilities, documentation, communication, resources and competence, stakeholder engagement.

- Site screening, selection and characterization: geological and hydrogeological evaluation, confining strata, baseline geochemical and geomechanical data, well characterization.

- Modelling: geostatistical models, flow, geochemical and geomechanical modelling to assess storage behaviour and capacity.

- Risk management: structured risk assessment, evaluation criteria, risk treatment plans, risk communication and consultation.

- Well infrastructure: materials selection, well design, cementing, groundwater protection, corrosion control, construction, completion and wellbore monitoring.

- Project boundaries and lifecycle: organizational, operational and project delineation, and closure planning.

- Stakeholder and community engagement: requirements and recommendations for transparent communication throughout the project life cycle.

The standard provides requirements and recommendations rather than prescriptive technical recipes; it acknowledges that site selection and management are project‑specific and that regulatory permitting is required though permitting processes are not included in the document.

Practical applications

ISO 27914:2017 is used to:

- Develop and document CO2 storage project management systems and technical plans.

- Guide site screening, characterization and modelling to support storage feasibility and design.

- Structure risk assessments, mitigation and communication strategies to protect health, safety and the environment.

- Define well integrity, materials and monitoring needs during construction, operation and closure.

- Support transparency with stakeholders and provide a framework aligned with best practices for long‑term containment.

Who should use it

- CO2 geological storage project operators and engineering teams

- Subsurface and reservoir geoscientists and modelers

- Drilling and well integrity engineers

- Environmental, health & safety and risk managers

- Regulators and permitting authorities (for reference)

- Consultants, auditors and investors evaluating storage projects

Limitations and relations

ISO 27914:2017 does not supersede national/international laws, treaties or property rights, nor does it cover permitting procedures. It should be used alongside applicable regulations and complementary standards for monitoring, measurement and verification.

Buy Documents

ISO 27914:2017 - Carbon dioxide capture, transportation and geological storage -- Geological storage

ISO 27914:2017 - Capture, transport et stockage géologique du dioxyde de carbone -- Stockage géologique

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

ISO 27914:2017 is a standard published by the International Organization for Standardization (ISO). Its full title is "Carbon dioxide capture, transportation and geological storage — Geological storage". This standard covers: ISO 27914:2017 a) establishes requirements and recommendations for the geological storage of CO2 streams, the purpose of which is to promote commercial, safe, long-term containment of carbon dioxide in a way that minimizes risk to the environment, natural resources, and human health, b) is applicable for both onshore and offshore geological storage within permeable and porous geological strata including hydrocarbon reservoirs where a CO2 stream is not being injected for the purpose of hydrocarbon production or for storage in association with CO2-EOR, c) includes activities associated with site screening and selection, characterization, design and development, operation of storage sites, and preparation for site closure, d) recognizes that site selection and management are unique for each project and that intrinsic technical risk and uncertainty will be dealt with on a site-specific basis, e) acknowledges that permitting and approval by regulatory authorities will be required throughout the project life cycle, including the closure period, although the permitting process is not included in ISO 27914:2017, f) provides requirements and recommendations for the development of management systems, community and other stakeholder engagement, risk assessment, risk management and risk communication, g) does not apply to, modify, interpret, or supersede any national or international regulations, treaties, protocols or instruments otherwise applicable to the activities addressed in ISO 27914:2017, and h) does not apply to or modify any property rights or interests in the surface or the subsurface (including mineral rights), or any pre-existing commercial contract or arrangement relating to such property. The life cycle of a CO2 geological storage project covers all aspects, periods, and stages of the project, from those that lead to the start of the project (including site screening, selection, characterization, assessment, engineering, permitting, and construction), through the start of injection and proceeding through subsequent operations until cessation of injection and culminating in the post-injection period, which includes a closure period. Figure 1 illustrates the limits of ISO 27914:2017.

ISO 27914:2017 a) establishes requirements and recommendations for the geological storage of CO2 streams, the purpose of which is to promote commercial, safe, long-term containment of carbon dioxide in a way that minimizes risk to the environment, natural resources, and human health, b) is applicable for both onshore and offshore geological storage within permeable and porous geological strata including hydrocarbon reservoirs where a CO2 stream is not being injected for the purpose of hydrocarbon production or for storage in association with CO2-EOR, c) includes activities associated with site screening and selection, characterization, design and development, operation of storage sites, and preparation for site closure, d) recognizes that site selection and management are unique for each project and that intrinsic technical risk and uncertainty will be dealt with on a site-specific basis, e) acknowledges that permitting and approval by regulatory authorities will be required throughout the project life cycle, including the closure period, although the permitting process is not included in ISO 27914:2017, f) provides requirements and recommendations for the development of management systems, community and other stakeholder engagement, risk assessment, risk management and risk communication, g) does not apply to, modify, interpret, or supersede any national or international regulations, treaties, protocols or instruments otherwise applicable to the activities addressed in ISO 27914:2017, and h) does not apply to or modify any property rights or interests in the surface or the subsurface (including mineral rights), or any pre-existing commercial contract or arrangement relating to such property. The life cycle of a CO2 geological storage project covers all aspects, periods, and stages of the project, from those that lead to the start of the project (including site screening, selection, characterization, assessment, engineering, permitting, and construction), through the start of injection and proceeding through subsequent operations until cessation of injection and culminating in the post-injection period, which includes a closure period. Figure 1 illustrates the limits of ISO 27914:2017.

ISO 27914:2017 is classified under the following ICS (International Classification for Standards) categories: 13.020.40 - Pollution, pollution control and conservation. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 27914:2017 has the following relationships with other standards: It is inter standard links to ISO 27914. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 27914:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2022

Zajetje, transport in geološko shranjevanje ogljikovega dioksida - Geološko

shranjevanje

Carbon dioxide capture, transportation and geological storage - Geological storage

Capture, transport et stockage géologique du dioxyde de carbone - Stockage géologique

Ta slovenski standard je istoveten z: ISO 27914:2017

ICS:

13.020.40 Onesnaževanje, nadzor nad Pollution, pollution control

onesnaževanjem in and conservation

ohranjanje

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

INTERNATIONAL ISO

STANDARD 27914

First edition

2017-10

Carbon dioxide capture,

transportation and geological

storage — Geological storage

Capture, transport et stockage géologique du dioxyde de carbone —

Stockage géologique

Reference number

©

ISO 2017

© ISO 2017, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2017 – All rights reserved

Contents Page

Foreword .vi

Introduction .vii

1 Scope . 1

2 Normative references . 2

3 Terms and definitions . 2

4 Management systems . 9

4.1 Scope of activities . 9

4.1.1 General. 9

4.1.2 Storage project operator’s roles and responsibilities . 9

4.1.3 Stakeholder identification and engagement .10

4.1.4 Storage project delineation .10

4.2 Project boundaries .11

4.2.1 Responsibility .11

4.2.2 Organizational boundaries .11

4.2.3 Operational boundaries .11

4.3 Management commitment to principles.11

4.3.1 General.11

4.3.2 Internal principles .12

4.3.3 External principles .12

4.3.4 Health, safety, and environmental principles .12

4.4 Planning and decision-making .13

4.4.1 General.13

4.4.2 Intellectual property . .13

4.5 Resources .13

4.5.1 General.13

4.5.2 Competence of personnel .13

4.5.3 Equipment management .13

4.6 Communications .13

4.6.1 General.13

4.6.2 Public communications .14

4.6.3 Internal communications .14

4.7 Documentation .14

4.7.1 General.14

4.7.2 Information management .14

5 Site screening, selection, and characterization .14

5.1 General .14

5.2 Site screening .15

5.3 Site selection .16

5.4 Site characterization and assessment .18

5.4.1 General.18

5.4.2 Geological and hydrogeological characterization of the storage unit .18

5.4.3 Characterization of confining strata .18

5.4.4 Baseline geochemical characterization .19

5.4.5 Baseline geomechanical characterization .19

5.4.6 Well characterization .20

5.5 Modelling .20

5.5.1 General.20

5.5.2 Geostatic model .20

5.5.3 Flow modelling .21

5.5.4 Geochemical modelling .22

5.5.5 Geomechanical modelling .24

6 Risk management .26

6.1 General .26

6.2 Objectives.26

6.3 Process .26

6.4 Context .27

6.4.1 General.27

6.4.2 Context elements .27

6.5 Risk evaluation criteria .27

6.6 Risk management plan .28

6.7 Risk assessment .28

6.7.1 General.28

6.7.2 Risk identification .29

6.7.3 Risk analysis .29

6.7.4 Risk evaluation .30

6.8 Risk treatment plan .31

6.9 Review and documentation .31

6.9.1 Review . .31

6.9.2 Documentation .32

6.10 Risk communication and consultation .33

6.10.1 General.33

6.10.2 Objectives .33

6.10.3 Scope of risk communication and consultation activities .33

6.10.4 Performance goals .34

7 Well infrastructure .34

7.1 General .34

7.1.1 Scope .34

7.1.2 Documentation .34

7.2 Materials .35

7.2.1 Conditions for use .35

7.2.2 Materials selection .35

7.2.3 Material requirements .35

7.3 Design .36

7.3.1 General.36

7.3.2 Safety .36

7.3.3 Wells .36

7.3.4 Tubulars .37

7.4 Construction and completions .38

7.4.1 General.38

7.4.2 Cementing .38

7.4.3 Groundwater protection .38

7.4.4 Post-cementing evaluation and remediation .39

7.4.5 Completion and stimulation .39

7.4.6 Wellbore monitoring requirements .39

7.5 Corrosion control .39

7.5.1 General.39

7.5.2 Well maintenance .39

7.5.3 Cathodic protection systems .40

7.5.4 Environmental compatibility .40

7.6 Evaluation of wells .40

7.6.1 General.40

7.6.2 Legacy wells .40

7.6.3 Inspection and testing .41

7.7 Recompletion and workover of wells .41

7.7.1 General.41

7.7.2 Conditions for recompletion and workover of wells .41

7.7.3 Wellbore integrity .41

7.8 Abandonment of wells .42

7.8.1 General.42

7.8.2 Evaluation of existing abandoned wells .42

iv © ISO 2017 – All rights reserved

7.8.3 Abandonment .42

8 CO storage site injection operations .42

8.1 General .42

8.1.1 Objectives .42

8.1.2 Scope of operations .43

8.2 Design of CO injection operations .43

8.2.1 General.43

8.2.2 Components of operations design .43

8.2.3 Injection design parameters .43

8.2.4 Storage facility design plan .44

8.3 Operations and maintenance plan .45

8.3.1 General.45

8.3.2 Operational protocols and maintenance schedules .45

8.3.3 Recording management of change .45

8.3.4 Communication plan .45

8.3.5 Safety plan .45

8.3.6 Security plan .46

8.4 Injection operations .46

8.4.1 General.46

8.4.2 Injection .46

8.4.3 Shutdown .47

8.5 Data acquisition, monitoring and testing .47

8.5.1 General.47

8.5.2 Surface equipment and injection line data .48

8.5.3 Wellbore monitoring .48

8.5.4 Well testing .49

8.5.5 Corrosion mitigation .50

8.6 Well intervention (workovers) .50

9 Monitoring and verification .50

9.1 Purpose .50

9.2 M&V program periods .51

9.2.1 General.51

9.2.2 Pre-injection period monitoring .51

9.2.3 Injection period monitoring .51

9.2.4 Closure period monitoring .51

9.3 M&V program objectives .52

9.4 M&V plan design .52

9.4.1 M&V program procedures and practices .52

9.4.2 M&V plan specifications .53

9.4.3 M&V program contingency monitoring .54

10 Site closure .54

10.1 General .54

10.2 Criteria for site closure .54

10.3 Closure plan .55

10.4 Closure qualification process .55

10.4.1 Process .55

10.4.2 Documentation .56

10.4.3 Related activities .56

Bibliography .57

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 265, Carbon dioxide capture,

transportation, and geological storage.

vi © ISO 2017 – All rights reserved

Introduction

Geological storage of carbon dioxide (CO ) is recognized as a key technology for abatement of CO

2 2

emissions to the atmosphere or ocean and is an essential component in the process of carbon dioxide

[1]

capture and storage (CCS) . The objective of this document is to provide recommendations for the safe

and effective storage of CO in subsurface geologic formations through all phases of a storage project

life cycle (see Figure 1). While CCS is a nascent industry, this document is supported by a wide range

of operational experiences in pilot to commercial scale carbon dioxide storage projects that have used

methods and technologies mostly developed and widely deployed by the oil and gas industry including

CO -enhanced oil recovery (EOR). This document applies to injection of CO into geologic units for the

2 2

sole purpose of storage and does not apply to CO injection for hydrocarbon recovery, or storage of

CO that occurs in association with carbon dioxide enhanced hydrocarbon recovery. [ISO 29716 is in

development to address carbon dioxide storage using enhanced oil recovery (CO -EOR)]. This document

is supplemented by recommended practice manuals for CO storage and numerous standards and

technical recommendations developed for the oil and gas industry. [See Bibliography for selected

references (References [1] to [12])].

INTERNATIONAL STANDARD ISO 27914:2017(E)

Carbon dioxide capture, transportation and geological

storage — Geological storage

1 Scope

This document

a) establishes requirements and recommendations for the geological storage of CO streams, the

purpose of which is to promote commercial, safe, long-term containment of carbon dioxide in a way

that minimizes risk to the environment, natural resources, and human health,

b) is applicable for both onshore and offshore geological storage within permeable and porous

geological strata including hydrocarbon reservoirs where a CO stream is not being injected for the

purpose of hydrocarbon production or for storage in association with CO -EOR,

c) includes activities associated with site screening and selection, characterization, design and

development, operation of storage sites, and preparation for site closure,

d) recognizes that site selection and management are unique for each project and that intrinsic

technical risk and uncertainty will be dealt with on a site-specific basis,

e) acknowledges that permitting and approval by regulatory authorities will be required throughout

the project life cycle, including the closure period, although the permitting process is not included

in this document,

f) provides requirements and recommendations for the development of management systems,

community and other stakeholder engagement, risk assessment, risk management and risk

communication,

g) does not apply to, modify, interpret, or supersede any national or international regulations, treaties,

protocols or instruments otherwise applicable to the activities addressed in this document, and

h) does not apply to or modify any property rights or interests in the surface or the subsurface

(including mineral rights), or any pre-existing commercial contract or arrangement relating to

such property.

The life cycle of a CO geological storage project covers all aspects, periods, and stages of the project,

from those that lead to the start of the project (including site screening, selection, characterization,

assessment, engineering, permitting, and construction), through the start of injection and proceeding

through subsequent operations until cessation of injection and culminating in the post-injection period,

which includes a closure period. Figure 1 illustrates the limits of this document.

NOTE 1 This document does not address any post-closure period or specify post-closure period requirements.

This document does not apply to

— the post-closure period,

— injection of CO for enhancing production of hydrocarbons or for storage associated with CO -EOR,

2 2

— disposal of other acid gases except as considered part of the CO stream,

— disposal of waste and other matter added for purpose of disposal,

— CO injection and storage in coal, basalt, shale and salt caverns, or

— underground storage using any form of buried container.

NOTE 2 This document may not be suitable for research projects, for example, those with a primary objective

to test technologies or methods of monitoring.

NOTE 3 The closure period in this document does overlap with the post-closure phase of the EU regulatory

definition. This document, however, is not concerned with transfer of liability.

Figure 1 — Entities involved in the storage project life cycle

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

abandonment

process and procedures used to permanently end the operation of a well

Note 1 to entry: Well abandonment is designed to eliminate the physical hazard of the well (the hole in the

ground), eliminate a pathway for migration of contamination, and prevent changes in the hydrogeologic system,

such as the changes in hydraulic head and the mixing of formation fluids between hydraulically distinct strata.

3.2

acceptable risk

risk (3.39) borne by the project operator (3.33) and others, having regard to legal obligations and

management policies

3.3

area of review

geographical area(s) of a storage project (3.56), or part of it, designated for assessment of the extent to

which a storage project, or part of it, could affect life and human health, the environment, competitive

development of other resources, or infrastructure

Note 1 to entry: The delineation of an area of review defines the outer perimeters on the land surface or seabed

and water surface within which assessments will be conducted as may be required by regulatory authorities.

3.4

baseline

reference basis for comparison against which project performance is monitored or measured

2 © ISO 2017 – All rights reserved

3.5

biosphere

realm of living organisms including the atmosphere, on the ground surface and in soils, in oceans and

seas, in surface waters such as rivers and lakes, and in the subsurface above the storage complex (3.54)

3.6

carbon dioxide (CO ) plume

region within geologic strata where CO is present in free phase

3.7

carbon dioxide (CO ) stream

stream consisting overwhelmingly of carbon dioxide

Note 1 to entry: The stream is a fluid mixture that may include any incidental associated substances derived

from the source materials or the capture process and any substances added to the stream to enable or improve

the injection process and/or trace substances added to assist in CO migration detection.

3.8

casing

pipe material placed inside a drilled hole to prevent the surrounding strata from collapsing into the hole

Note 1 to entry: There are many acceptable variations on casing design but typical types of casing in most

injection wells are:

a) surface casing, i.e. the outermost casing that extends from the surface to the base of the lowermost protected

groundwater (3.37);

b) intermediate casing is one or more strings of casing installed between the surface and long-string casing for

various design reasons;

c) long-string casing, which extends from the surface to or through protected groundwater to the bottom of

the well.

3.9

casing shoe

reinforcing steel collar that is screwed onto the bottom joint of the casing (3.8) to prevent abrasion or

distortion of the casing when it is forced past obstructions on the wall of the borehole

3.10

closure period

period between the cessation of injection and the demonstration of compliance with the criteria for site

closure (3.52)

3.11

containment

retention of CO and formation fluids within a storage complex (3.54)

3.12

corrective action

action taken to correct material irregularities or to contain breaches in order to prevent or minimize

damage to, or release of CO from, a storage complex (3.54)

Note 1 to entry: Corrective actions are implemented after an irregularity has occurred to help prevent or

minimize damage.

3.13

decommission

take an engineered system or component out of service, render it inoperative, dismantle and

decontaminate it

3.14

element of concern

valued element or objective for which risk (3.39) is evaluated and managed

3.15

elevated pressure zone

zone within a storage complex (3.54) where there is sufficient pressure to cause flow of formation

fluids through a pathway from the storage unit(s) (3.59) to outside the storage complex into economic

resources, protected groundwater (3.37), or the biosphere (3.5)

3.16

event

material occurrence or change in a particular set of circumstances

3.17

geological storage

long-term containment (3.11) of CO2 streams (3.7) in subsurface geological formations

Note 1 to entry: Long-term means the minimum period necessary for CO geological storage to be considered an

effective and environmentally safe climate change mitigation option.

Note 2 to entry: The term “sequestration” has been used by a number of countries and organizations instead of

“storage” (e.g. the international “Carbon Sequestration Leadership Forum”). The two terms are considered to be

synonymous, and only “storage” is used in this document.

Note 3 to entry: Within the context of this document, geological storage

a) is applicable to permeable and porous strata that do not contain protected groundwater (3.37),

b) is applicable to nonproducing hydrocarbon reservoirs, and

c) does not apply to

1) CO injection and storage in unmineable coal beds, basalt formations, shales, and salt caverns,

2) CO injection and storage in any formations containing producible hydrocarbons, and

3) underground storage in materials involving the use of any form of man-made containers.

3.18

geosphere

solid earth below the ground surface and bottom of rivers and other bodies of water on land, and below

the sea bottom offshore

3.19

injectivity

rate and pressure at which fluids can be pumped into the storage unit (3.59) without fracturing the

storage unit

3.20

leakage

unintended release of fluid out of a pre-defined containment (3.11)

Note 1 to entry: In this document, the pre-defined containment is the storage complex (3.54).

3.21

legacy well

pre-existing well within the area of review (3.3) of a CO storage project (3

...

INTERNATIONAL ISO

STANDARD 27914

First edition

2017-10

Carbon dioxide capture,

transportation and geological

storage — Geological storage

Capture, transport et stockage géologique du dioxyde de carbone —

Stockage géologique

Reference number

©

ISO 2017

© ISO 2017, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2017 – All rights reserved

Contents Page

Foreword .vi

Introduction .vii

1 Scope . 1

2 Normative references . 2

3 Terms and definitions . 2

4 Management systems . 9

4.1 Scope of activities . 9

4.1.1 General. 9

4.1.2 Storage project operator’s roles and responsibilities . 9

4.1.3 Stakeholder identification and engagement .10

4.1.4 Storage project delineation .10

4.2 Project boundaries .11

4.2.1 Responsibility .11

4.2.2 Organizational boundaries .11

4.2.3 Operational boundaries .11

4.3 Management commitment to principles.11

4.3.1 General.11

4.3.2 Internal principles .12

4.3.3 External principles .12

4.3.4 Health, safety, and environmental principles .12

4.4 Planning and decision-making .13

4.4.1 General.13

4.4.2 Intellectual property . .13

4.5 Resources .13

4.5.1 General.13

4.5.2 Competence of personnel .13

4.5.3 Equipment management .13

4.6 Communications .13

4.6.1 General.13

4.6.2 Public communications .14

4.6.3 Internal communications .14

4.7 Documentation .14

4.7.1 General.14

4.7.2 Information management .14

5 Site screening, selection, and characterization .14

5.1 General .14

5.2 Site screening .15

5.3 Site selection .16

5.4 Site characterization and assessment .18

5.4.1 General.18

5.4.2 Geological and hydrogeological characterization of the storage unit .18

5.4.3 Characterization of confining strata .18

5.4.4 Baseline geochemical characterization .19

5.4.5 Baseline geomechanical characterization .19

5.4.6 Well characterization .20

5.5 Modelling .20

5.5.1 General.20

5.5.2 Geostatic model .20

5.5.3 Flow modelling .21

5.5.4 Geochemical modelling .22

5.5.5 Geomechanical modelling .24

6 Risk management .26

6.1 General .26

6.2 Objectives.26

6.3 Process .26

6.4 Context .27

6.4.1 General.27

6.4.2 Context elements .27

6.5 Risk evaluation criteria .27

6.6 Risk management plan .28

6.7 Risk assessment .28

6.7.1 General.28

6.7.2 Risk identification .29

6.7.3 Risk analysis .29

6.7.4 Risk evaluation .30

6.8 Risk treatment plan .31

6.9 Review and documentation .31

6.9.1 Review . .31

6.9.2 Documentation .32

6.10 Risk communication and consultation .33

6.10.1 General.33

6.10.2 Objectives .33

6.10.3 Scope of risk communication and consultation activities .33

6.10.4 Performance goals .34

7 Well infrastructure .34

7.1 General .34

7.1.1 Scope .34

7.1.2 Documentation .34

7.2 Materials .35

7.2.1 Conditions for use .35

7.2.2 Materials selection .35

7.2.3 Material requirements .35

7.3 Design .36

7.3.1 General.36

7.3.2 Safety .36

7.3.3 Wells .36

7.3.4 Tubulars .37

7.4 Construction and completions .38

7.4.1 General.38

7.4.2 Cementing .38

7.4.3 Groundwater protection .38

7.4.4 Post-cementing evaluation and remediation .39

7.4.5 Completion and stimulation .39

7.4.6 Wellbore monitoring requirements .39

7.5 Corrosion control .39

7.5.1 General.39

7.5.2 Well maintenance .39

7.5.3 Cathodic protection systems .40

7.5.4 Environmental compatibility .40

7.6 Evaluation of wells .40

7.6.1 General.40

7.6.2 Legacy wells .40

7.6.3 Inspection and testing .41

7.7 Recompletion and workover of wells .41

7.7.1 General.41

7.7.2 Conditions for recompletion and workover of wells .41

7.7.3 Wellbore integrity .41

7.8 Abandonment of wells .42

7.8.1 General.42

7.8.2 Evaluation of existing abandoned wells .42

iv © ISO 2017 – All rights reserved

7.8.3 Abandonment .42

8 CO storage site injection operations .42

8.1 General .42

8.1.1 Objectives .42

8.1.2 Scope of operations .43

8.2 Design of CO injection operations .43

8.2.1 General.43

8.2.2 Components of operations design .43

8.2.3 Injection design parameters .43

8.2.4 Storage facility design plan .44

8.3 Operations and maintenance plan .45

8.3.1 General.45

8.3.2 Operational protocols and maintenance schedules .45

8.3.3 Recording management of change .45

8.3.4 Communication plan .45

8.3.5 Safety plan .45

8.3.6 Security plan .46

8.4 Injection operations .46

8.4.1 General.46

8.4.2 Injection .46

8.4.3 Shutdown .47

8.5 Data acquisition, monitoring and testing .47

8.5.1 General.47

8.5.2 Surface equipment and injection line data .48

8.5.3 Wellbore monitoring .48

8.5.4 Well testing .49

8.5.5 Corrosion mitigation .50

8.6 Well intervention (workovers) .50

9 Monitoring and verification .50

9.1 Purpose .50

9.2 M&V program periods .51

9.2.1 General.51

9.2.2 Pre-injection period monitoring .51

9.2.3 Injection period monitoring .51

9.2.4 Closure period monitoring .51

9.3 M&V program objectives .52

9.4 M&V plan design .52

9.4.1 M&V program procedures and practices .52

9.4.2 M&V plan specifications .53

9.4.3 M&V program contingency monitoring .54

10 Site closure .54

10.1 General .54

10.2 Criteria for site closure .54

10.3 Closure plan .55

10.4 Closure qualification process .55

10.4.1 Process .55

10.4.2 Documentation .56

10.4.3 Related activities .56

Bibliography .57

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 265, Carbon dioxide capture,

transportation, and geological storage.

vi © ISO 2017 – All rights reserved

Introduction

Geological storage of carbon dioxide (CO ) is recognized as a key technology for abatement of CO

2 2

emissions to the atmosphere or ocean and is an essential component in the process of carbon dioxide

[1]

capture and storage (CCS) . The objective of this document is to provide recommendations for the safe

and effective storage of CO in subsurface geologic formations through all phases of a storage project

life cycle (see Figure 1). While CCS is a nascent industry, this document is supported by a wide range

of operational experiences in pilot to commercial scale carbon dioxide storage projects that have used

methods and technologies mostly developed and widely deployed by the oil and gas industry including

CO -enhanced oil recovery (EOR). This document applies to injection of CO into geologic units for the

2 2

sole purpose of storage and does not apply to CO injection for hydrocarbon recovery, or storage of

CO that occurs in association with carbon dioxide enhanced hydrocarbon recovery. [ISO 29716 is in

development to address carbon dioxide storage using enhanced oil recovery (CO -EOR)]. This document

is supplemented by recommended practice manuals for CO storage and numerous standards and

technical recommendations developed for the oil and gas industry. [See Bibliography for selected

references (References [1] to [12])].

INTERNATIONAL STANDARD ISO 27914:2017(E)

Carbon dioxide capture, transportation and geological

storage — Geological storage

1 Scope

This document

a) establishes requirements and recommendations for the geological storage of CO streams, the

purpose of which is to promote commercial, safe, long-term containment of carbon dioxide in a way

that minimizes risk to the environment, natural resources, and human health,

b) is applicable for both onshore and offshore geological storage within permeable and porous

geological strata including hydrocarbon reservoirs where a CO stream is not being injected for the

purpose of hydrocarbon production or for storage in association with CO -EOR,

c) includes activities associated with site screening and selection, characterization, design and

development, operation of storage sites, and preparation for site closure,

d) recognizes that site selection and management are unique for each project and that intrinsic

technical risk and uncertainty will be dealt with on a site-specific basis,

e) acknowledges that permitting and approval by regulatory authorities will be required throughout

the project life cycle, including the closure period, although the permitting process is not included

in this document,

f) provides requirements and recommendations for the development of management systems,

community and other stakeholder engagement, risk assessment, risk management and risk

communication,

g) does not apply to, modify, interpret, or supersede any national or international regulations, treaties,

protocols or instruments otherwise applicable to the activities addressed in this document, and

h) does not apply to or modify any property rights or interests in the surface or the subsurface

(including mineral rights), or any pre-existing commercial contract or arrangement relating to

such property.

The life cycle of a CO geological storage project covers all aspects, periods, and stages of the project,

from those that lead to the start of the project (including site screening, selection, characterization,

assessment, engineering, permitting, and construction), through the start of injection and proceeding

through subsequent operations until cessation of injection and culminating in the post-injection period,

which includes a closure period. Figure 1 illustrates the limits of this document.

NOTE 1 This document does not address any post-closure period or specify post-closure period requirements.

This document does not apply to

— the post-closure period,

— injection of CO for enhancing production of hydrocarbons or for storage associated with CO -EOR,

2 2

— disposal of other acid gases except as considered part of the CO stream,

— disposal of waste and other matter added for purpose of disposal,

— CO injection and storage in coal, basalt, shale and salt caverns, or

— underground storage using any form of buried container.

NOTE 2 This document may not be suitable for research projects, for example, those with a primary objective

to test technologies or methods of monitoring.

NOTE 3 The closure period in this document does overlap with the post-closure phase of the EU regulatory

definition. This document, however, is not concerned with transfer of liability.

Figure 1 — Entities involved in the storage project life cycle

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

abandonment

process and procedures used to permanently end the operation of a well

Note 1 to entry: Well abandonment is designed to eliminate the physical hazard of the well (the hole in the

ground), eliminate a pathway for migration of contamination, and prevent changes in the hydrogeologic system,

such as the changes in hydraulic head and the mixing of formation fluids between hydraulically distinct strata.

3.2

acceptable risk

risk (3.39) borne by the project operator (3.33) and others, having regard to legal obligations and

management policies

3.3

area of review

geographical area(s) of a storage project (3.56), or part of it, designated for assessment of the extent to

which a storage project, or part of it, could affect life and human health, the environment, competitive

development of other resources, or infrastructure

Note 1 to entry: The delineation of an area of review defines the outer perimeters on the land surface or seabed

and water surface within which assessments will be conducted as may be required by regulatory authorities.

3.4

baseline

reference basis for comparison against which project performance is monitored or measured

2 © ISO 2017 – All rights reserved

3.5

biosphere

realm of living organisms including the atmosphere, on the ground surface and in soils, in oceans and

seas, in surface waters such as rivers and lakes, and in the subsurface above the storage complex (3.54)

3.6

carbon dioxide (CO ) plume

region within geologic strata where CO is present in free phase

3.7

carbon dioxide (CO ) stream

stream consisting overwhelmingly of carbon dioxide

Note 1 to entry: The stream is a fluid mixture that may include any incidental associated substances derived

from the source materials or the capture process and any substances added to the stream to enable or improve

the injection process and/or trace substances added to assist in CO migration detection.

3.8

casing

pipe material placed inside a drilled hole to prevent the surrounding strata from collapsing into the hole

Note 1 to entry: There are many acceptable variations on casing design but typical types of casing in most

injection wells are:

a) surface casing, i.e. the outermost casing that extends from the surface to the base of the lowermost protected

groundwater (3.37);

b) intermediate casing is one or more strings of casing installed between the surface and long-string casing for

various design reasons;

c) long-string casing, which extends from the surface to or through protected groundwater to the bottom of

the well.

3.9

casing shoe

reinforcing steel collar that is screwed onto the bottom joint of the casing (3.8) to prevent abrasion or

distortion of the casing when it is forced past obstructions on the wall of the borehole

3.10

closure period

period between the cessation of injection and the demonstration of compliance with the criteria for site

closure (3.52)

3.11

containment

retention of CO and formation fluids within a storage complex (3.54)

3.12

corrective action

action taken to correct material irregularities or to contain breaches in order to prevent or minimize

damage to, or release of CO from, a storage complex (3.54)

Note 1 to entry: Corrective actions are implemented after an irregularity has occurred to help prevent or

minimize damage.

3.13

decommission

take an engineered system or component out of service, render it inoperative, dismantle and

decontaminate it

3.14

element of concern

valued element or objective for which risk (3.39) is evaluated and managed

3.15

elevated pressure zone

zone within a storage complex (3.54) where there is sufficient pressure to cause flow of formation

fluids through a pathway from the storage unit(s) (3.59) to outside the storage complex into economic

resources, protected groundwater (3.37), or the biosphere (3.5)

3.16

event

material occurrence or change in a particular set of circumstances

3.17

geological storage

long-term containment (3.11) of CO2 streams (3.7) in subsurface geological formations

Note 1 to entry: Long-term means the minimum period necessary for CO geological storage to be considered an

effective and environmentally safe climate change mitigation option.

Note 2 to entry: The term “sequestration” has been used by a number of countries and organizations instead of

“storage” (e.g. the international “Carbon Sequestration Leadership Forum”). The two terms are considered to be

synonymous, and only “storage” is used in this document.

Note 3 to entry: Within the context of this document, geological storage

a) is applicable to permeable and porous strata that do not contain protected groundwater (3.37),

b) is applicable to nonproducing hydrocarbon reservoirs, and

c) does not apply to

1) CO injection and storage in unmineable coal beds, basalt formations, shales, and salt caverns,

2) CO injection and storage in any formations containing producible hydrocarbons, and

3) underground storage in materials involving the use of any form of man-made containers.

3.18

geosphere

solid earth below the ground surface and bottom of rivers and other bodies of water on land, and below

the sea bottom offshore

3.19

injectivity

rate and pressure at which fluids can be pumped into the storage unit (3.59) without fracturing the

storage unit

3.20

leakage

unintended release of fluid out of a pre-defined containment (3.11)

Note 1 to entry: In this document, the pre-defined containment is the storage complex (3.54).

3.21

legacy well

pre-existing well within the area of review (3.3) of a CO storage project (3.56) that was drilled for a

different purpose than CO injection or monitoring (3.27) of the respective CO storage project

2 2

3.22

likelihood

chance of something happening, expressed qualitatively or quantitatively and described using general

terms or mathematically, e.g. by specifying a probability or frequency of occurrence over a given period

4 © ISO 2017 – All rights reserved

3.23

liner

casing (3.8) string that does not extend to the surface

3.24

management of change

procedure used when making a change to the process equipment or operating procedures to detail

changes made and to document steps taken to inform and train operating personnel and relevant

stakeholders on process changes

3.25

mechanical integrity

mechanical condition of a well, such that engineered components maintain their original dimensions

and functions, solid geological materials are kept out of the wellbore, and fluids including CO are

prevented from uncontrolled flow into, o

...

NORME ISO

INTERNATIONALE 27914

Première édition

2017-10

Capture, transport et stockage

géologique du dioxyde de carbone —

Stockage géologique

Carbon dioxide capture, transportation and geological storage —

Geological storage

Numéro de référence

©

ISO 2017

DOCUMENT PROTÉGÉ PAR COPYRIGHT

© ISO 2017

Tous droits réservés. Sauf prescription différente ou nécessité dans le contexte de sa mise en oeuvre, aucune partie de cette

publication ne peut être reproduite ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique,

y compris la photocopie, ou la diffusion sur l’internet ou sur un intranet, sans autorisation écrite préalable. Une autorisation peut

être demandée à l’ISO à l’adresse ci-après ou au comité membre de l’ISO dans le pays du demandeur.

ISO copyright office

Case postale 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Tél.: +41 22 749 01 11

Fax: +41 22 749 09 47

E-mail: copyright@iso.org

Web: www.iso.org

Publié en Suisse

ii © ISO 2017 – Tous droits réservés

Sommaire Page

Avant-propos .vi

Introduction .vii

1 Domaine d’application . 1

2 Références normatives . 2

3 Termes et définitions . 2

4 Systèmes de management .10

4.1 Périmètre des activités .10

4.1.1 Généralités .10

4.1.2 Rôles et responsabilités de l’exploitant d’un projet de stockage .10

4.1.3 Identification et participation des parties prenantes .11

4.1.4 Délimitation du projet de stockage .11

4.2 Limites du projet .12

4.2.1 Responsabilités .12

4.2.2 Périmètre organisationnel.12

4.2.3 Périmètre opérationnel .12

4.3 Engagement de la direction à des principes .12

4.3.1 Généralités .12

4.3.2 Principes internes .13

4.3.3 Principes externes .13

4.3.4 Principes applicables en matière de santé, de sécurité et d’environnement .13

4.4 Planification et prise de décision .14

4.4.1 Généralités .14

4.4.2 Propriété intellectuelle .14

4.5 Ressources .14

4.5.1 Généralités .14

4.5.2 Compétences du personnel .14

4.5.3 Gestion des équipements .14

4.6 Communication .14

4.6.1 Généralités .14

4.6.2 Communication publique .15

4.6.3 Communication interne .15

4.7 Documentation .15

4.7.1 Généralités .15

4.7.2 Management de l’information .15

5 Tri, sélection et caractérisation de site .16

5.1 Généralités .16

5.2 Tri de site .16

5.3 Sélection du site .18

5.4 Caractérisation et évaluation du site .19

5.4.1 Généralités .19

5.4.2 Caractérisation géologique et hydrogéologique de l’unité de stockage .19

5.4.3 Caractérisation des strates de confinement .20

5.4.4 Caractérisation géochimique de référence.20

5.4.5 Caractérisation géomécanique de référence .21

5.4.6 Caractérisation du puits .21

5.5 Modélisation.21

5.5.1 Généralités .21

5.5.2 Modèle géostatique .22

5.5.3 Modélisation des écoulements .23

5.5.4 Modélisation géochimique .24

5.5.5 Modélisation géomécanique .27

6 Management du risque .28

6.1 Généralités .28

6.2 Objectifs .28

6.3 Processus .28

6.4 Contexte .29

6.4.1 Généralités .29

6.4.2 Éléments contextuels .29

6.5 Critères d’évaluation du risque .30

6.6 Plan de management du risque .30

6.7 Appréciation du risque .31

6.7.1 Généralités .31

6.7.2 Identification des risques .31

6.7.3 Analyse des risques .32

6.7.4 Évaluation des risques .33

6.8 Plan de traitement des risques .33

6.9 Revue et documentation .34

6.9.1 Revue.34

6.9.2 Documentation .35

6.10 Communication et concertation sur les risques .36

6.10.1 Généralités .36

6.10.2 Objectifs .36

6.10.3 Étendue des activités de communication et de concertation sur les risques .36

6.10.4 Objectifs de performance .37

7 Infrastructure des puits .37

7.1 Généralités .37

7.1.1 Domaine d’application .37

7.1.2 Documentation .38

7.2 Matériaux .38

7.2.1 Conditions d’utilisation .38

7.2.2 Choix des matériaux.38

7.2.3 Exigences relatives aux matériaux .38

7.3 Conception .39

7.3.1 Généralités .39

7.3.2 Sécurité .39

7.3.3 Puits .40

7.3.4 Matériel tubulaire .41

7.4 Construction et complétion .42

7.4.1 Généralités .42

7.4.2 Cimentation .42

7.4.3 Protection des eaux souterraines .42

7.4.4 Évaluation et réparation après la cimentation.42

7.4.5 Complétion et stimulation .43

7.4.6 Exigences en matière de surveillance des puits.43

7.5 Contrôle de la corrosion .43

7.5.1 Généralités .43

7.5.2 Maintenance des puits .43

7.5.3 Systèmes de protection cathodique .43

7.5.4 Compatibilité environnementale .44

7.6 Évaluation des puits .44

7.6.1 Généralités .44

7.6.2 Puits antérieurs.44

7.6.3 Contrôle et essais . . .45

7.7 Reprise et reconditionnement des puits.45

7.7.1 Généralités .45

7.7.2 Conditions pour la reprise et le reconditionnement des puits .45

7.7.3 Intégrité du forage .45

7.8 Abandon des puits .46

7.8.1 Généralités .46

7.8.2 Évaluation des puits abandonnés existants .46

iv © ISO 2017 – Tous droits réservés

7.8.3 Abandon .46

8 Opérations d’injection du site de stockage de CO .47

8.1 Généralités .47

8.1.1 Objectifs .47

8.1.2 Domaine d’application des opérations .47

8.2 Conception des opérations d’injection de CO .

2 47

8.2.1 Généralités .47

8.2.2 Composants de la conception des opérations .47

8.2.3 Paramètres de dimensionnement de l’injection .48

8.2.4 Plan de conception des installations de stockage .49

8.3 Plan d’exploitation et de maintenance .49

8.3.1 Généralités .49

8.3.2 Protocoles opérationnels et plannings de maintenance.49

8.3.3 Gestion des enregistrements relatifs aux changements .50

8.3.4 Plan de communication .50

8.3.5 Plan de sécurité .50

8.3.6 Plan de sûreté .50

8.4 Opérations d’injection .50

8.4.1 Généralités .50

8.4.2 Injection .51

8.4.3 Arrêt .51

8.5 Acquisition de données, surveillance et essais .52

8.5.1 Généralités .52

8.5.2 Données concernant les équipements de surface et les conduites d’injection .52

8.5.3 Surveillance du puits .53

8.5.4 Essais en puits .53

8.5.5 Atténuation de la corrosion .55

8.6 Interventions sur le puits (reconditionnements) .55

9 Surveillance et vérification .55

9.1 Finalité .55

9.2 Périodes du programme de surveillance et de validation .56

9.2.1 Généralités .56

9.2.2 Surveillance de la période de pré-injection .56

9.2.3 Surveillance de la période d’injection .56

9.2.4 Surveillance de la période de fermeture .56

9.3 Objectifs du programme de surveillance et de validation .57

9.4 Conception du plan de S&V .57

9.4.1 Modes opératoires et pratiques du programme de S&V .57

9.4.2 Spécifications du plan de S&V .58

9.4.3 Surveillance de contingence du programme de S&V .59

10 Fermeture du site .59

10.1 Généralités .59

10.2 Critères de fermeture du site .59

10.3 Plan de fermeture .60

10.4 Processus de qualification de la fermeture .61

10.4.1 Processus .61

10.4.2 Documentation .61

10.4.3 Activités connexes .62

Bibliographie .63

Avant-propos

L'ISO (Organisation internationale de normalisation) est une fédération mondiale d'organismes

nationaux de normalisation (comités membres de l'ISO). L'élaboration des Normes internationales est

en général confiée aux comités techniques de l'ISO. Chaque comité membre intéressé par une étude

a le droit de faire partie du comité technique créé à cet effet. Les organisations internationales,

gouvernementales et non gouvernementales, en liaison avec l'ISO participent également aux travaux.

L'ISO collabore étroitement avec la Commission électrotechnique internationale (IEC) en ce qui

concerne la normalisation électrotechnique.

Les procédures utilisées pour élaborer le présent document et celles destinées à sa mise à jour sont

décrites dans les Directives ISO/IEC, Partie 1. Il convient, en particulier de prendre note des différents

critères d'approbation requis pour les différents types de documents ISO. Le présent document a été

rédigé conformément aux règles de rédaction données dans les Directives ISO/IEC, Partie 2 (voir www

.iso .org/ directives).

L'attention est attirée sur le fait que certains des éléments du présent document peuvent faire l'objet de

droits de propriété intellectuelle ou de droits analogues. L'ISO ne saurait être tenue pour responsable

de ne pas avoir identifié de tels droits de propriété et averti de leur existence. Les détails concernant

les références aux droits de propriété intellectuelle ou autres droits analogues identifiés lors de

l'élaboration du document sont indiqués dans l'Introduction et/ou dans la liste des déclarations de

brevets reçues par l'ISO (voir www .iso .org/ brevets).

Les appellations commerciales éventuellement mentionnées dans le présent document sont données

pour information, par souci de commodité, à l’intention des utilisateurs et ne sauraient constituer un

engagement.

Pour une explication de la nature volontaire des normes, la signification des termes et expressions

spécifiques de l'ISO liés à l'évaluation de la conformité, ou pour toute information au sujet de l'adhésion

de l'ISO aux principes de l’Organisation mondiale du commerce (OMC) concernant les obstacles

techniques au commerce (OTC), voir le lien suivant: www .iso .org/ avant -propos.

Le présent document a été élaboré par le comité technique ISO/TC 265, Captage du dioxyde de carbone,

transport et stockage géologique.

vi © ISO 2017 – Tous droits réservés

Introduction

Le stockage géologique du dioxyde de carbone (CO ) est reconnu en tant que technologie-clé pour

la réduction des émissions de CO dans l’atmosphère ou les océans et est un composant essentiel du

[1]

processus de captage et de stockage du dioxyde de carbone (CSC) . Le présent document a pour

objectif de fournir des recommandations pour le stockage sûr et efficace du CO dans les formations

géologiques souterraines à toutes les phases du cycle de vie d’un projet de stockage (voir Figure 1).

Bien que le CSC soit un secteur industriel naissant, le présent document s’appuie sur un large éventail

d’expériences opérationnelles allant de projets pilotes jusqu’à des projets commerciaux de stockage

du dioxyde de carbone qui ont utilisé des méthodes et des technologies essentiellement développées

et largement déployées par l’industrie pétrolière et gazière, y compris la récupération assistée des

hydrocarbures (RAH) à l’aide de CO . Le présent document s’applique à l’injection de CO dans les unités

2 2

géologiques aux seules fins de stockage et ne s’applique pas à l’injection de CO pour la récupération

des hydrocarbures, ou au stockage de CO associé à la récupération assistée des hydrocarbures à

l’aide de dioxyde de carbone. [L’ISO 29716, qui traite du stockage du dioxyde de carbone en utilisant la

récupération assistée des hydrocarbures (RAH-CO ), est en cours d’élaboration]. Le présent document

est complété par des manuels de pratiques recommandées pour le stockage du CO , ainsi que par de

nombreuses normes et recommandations techniques développées pour l’industrie pétrolière et gazière

[voir la Bibliographie pour les références sélectionnées (Références [1] à [12])].

NORME INTERNATIONALE ISO 27914:2017(F)

Capture, transport et stockage géologique du dioxyde de

carbone — Stockage géologique

1 Domaine d’application

Le présent document

a) établit les exigences et recommandations relatives au stockage géologique de flux de CO , dont le

but est de promouvoir le confinement à long terme et en toute sécurité du dioxyde de carbone à

l’échelle commerciale, de manière à réduire le plus possible les risques pour l’environnement, les

ressources naturelles et la santé humaine,

b) s’applique aussi bien au stockage géologique à terre et en mer dans des strates géologiques

perméables et poreuses, y compris les réservoirs d’hydrocarbures où un flux de CO n’est pas

injecté aux fins de la production d’hydrocarbures ou en vue d’un stockage en association avec la

RAH-CO ,

c) englobe les activités liées au tri et à la sélection de site, la caractérisation, l’étude, le développement,

l’exploitation des sites de stockage et la préparation en vue de leur fermeture,

d) reconnaît que le choix et la gestion du site sont propres à chaque projet et que les risques techniques

et incertitudes intrinsèques seront traités selon une approche spécifique à chaque site,

e) reconnaît que des permis et des approbations devront être obtenus auprès des autorités de

réglementation tout au long du cycle de vie d’un projet, période de fermeture incluse, bien que le

présent document ne traite pas du processus de délivrance des permis,

f) fournit des exigences et des recommandations pour l’élaboration de systèmes de management, la

participation des collectivités et autres parties prenantes, l’appréciation du risque, le management

et la communication sur les risques,

g) ne s’applique pas à, ni ne modifie, interprète ou remplace, tout règlement, traité, protocole ou

instrument national ou international par ailleurs applicable aux activités couvertes par le présent

document, et

h) ne s’applique pas aux, ni ne modifie les, droits de propriété ou les intérêts sur les biens en surface

ou en subsurface (y compris les droits miniers), ou tout contrat commercial pré existant ou toute

disposition afférant à cette propriété.

Le cycle de vie d’un projet de stockage géologique de CO couvre tous les aspects, périodes et phases

du projet, allant de son lancement (y compris le tri de site, la sélection, la caractérisation, l’évaluation,

l’étude technique, l’obtention de permis et la construction), en passant par le début de l’injection et

les opérations ultérieures jusqu’à l’arrêt de l’injection, et se terminant par la période de post-injection

incluant une période de fermeture. La Figure 1 illustre le périmètre du présent document.

NOTE 1 Le présent document ne couvre pas la période de post-fermeture et ne spécifie aucune exigence

relative à cette période.

Le présent document ne s’applique pas

— à la période de post-fermeture,

— à l’injection de CO destinée à améliorer la production d’hydrocarbures ou au stockage associé à la

RAH-CO ,

— à l’élimination d’autres gaz acides à l’exception de ceux considérés comme faisant partie du flux de CO ,

— à l’élimination de déchets et autres matières ajoutées aux fins d’élimination,

— à l’injection et au stockage du CO dans le charbon, le basalte, le schiste et les cavités salines, ou

— au stockage souterrain utilisant une quelconque forme de conteneur enterré.

NOTE 2 Le présent document peut s’avérer inadapté pour les projets de recherche, tels que ceux dont le

principal objectif est d’expérimenter des technologies ou des méthodes de surveillance.

NOTE 3 La période de fermeture spécifiée dans le présent document chevauche la phase de post-fermeture

de la définition réglementaire de l’UE. En revanche, le présent document ne s’intéresse pas au transfert de

responsabilité.

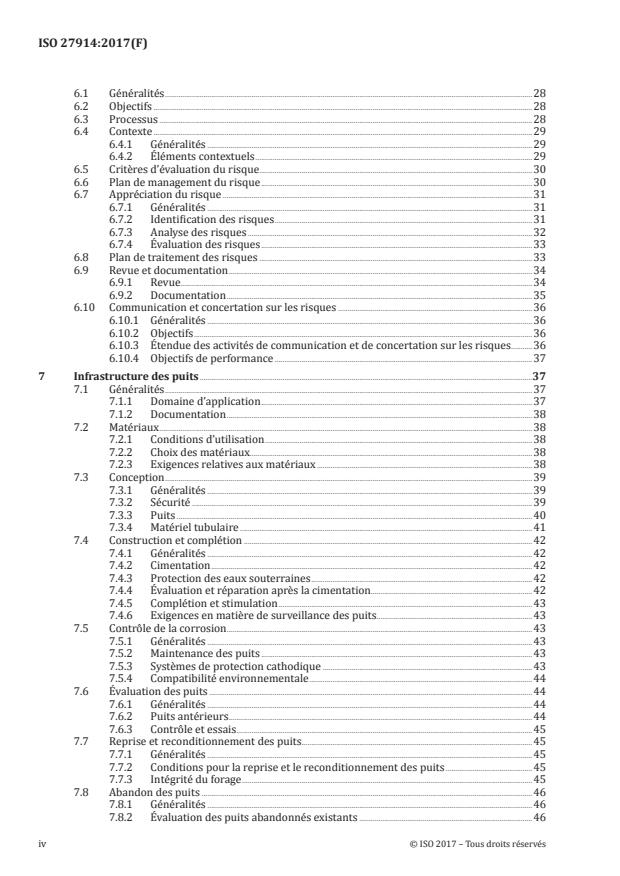

Figure 1 — Entités intervenant dans le cycle de vie d’un projet de stockage

2 Références normatives

Le présent document ne contient aucune référence normative.

3 Termes et définitions

Pour les besoins du présent document, les termes et définitions suivants s’appliquent.

L’ISO et l’IEC tiennent à jour des bases de données terminologiques destinées à être utilisées en

normalisation, consultables aux adresses suivantes:

— IEC Electropedia: disponible à l’adresse http:// www .electropedia .org/

— ISO Online browsing platform: disponible à l’adresse https:// www .iso .org/ obp

3.1

abandon

processus et modes opératoires mis en œuvre pour l’arrêt définitif de l’exploitation d’un puits

Note 1 à l'article: L’abandon est destiné à éliminer tout risque physique du puits (présence d’un trou dans le sol)

et toute voie de migration de contamination, ainsi qu’à empêcher des modifications du système hydrogéologique,

telles que les variations de la charge hydraulique et le mélange de fluides de formation entre des strates

hydrauliquement distinctes.

3.2

risque acceptable

risque (3.39) supporté par l’exploitant du projet (3.33) et d’autres parties, compte tenu des obligations

légales et des politiques en matière de management

2 © ISO 2017 – Tous droits réservés

3.3

zone d’examen

zone(s) géographique(s) d’un projet de stockage (3.56) ou de l’une de ses parties, identifiée(s) pour

évaluer dans quelle mesure ce projet, ou l’une de ses parties, pourrait affecter la vie et la santé humaine,

l’environnement, le développement concurrentiel d’autres ressources ou les infrastructures

Note 1 à l'article: La délimitation d’une zone d’examen définit le périmètre extérieur à la surface du sol ou du fond

marin et de l’eau, à l’intérieur duquel seront réalisées les évaluations qui peuvent être exigées par les autorités de

réglementation.

3.4

ligne de base

base de comparaison par rapport à laquelle les performances du projet sont surveillées ou mesurées

3.5

biosphère

ensemble des organismes vivant dans l’atmosphère, à la surface du sol et dans les sols, les océans et les

mers, dans les eaux de surface telles que les rivières et les lacs, et en subsurface au-dessus du complexe

de stockage (3.54)

3.6

panache de dioxyde de carbone (CO )

région des strates géologiques où le CO est présent en phase libre

3.7

flux de dioxyde de carbone (CO )

flux essentiellement constitué de dioxyde de carbone

Note 1 à l'article: Ce flux est un mélange de fluides qui peut contenir des substances accidentellement associées

dérivées des matières d’origine ou du procédé de captage, ainsi que des substances ajoutées au flux afin de

permettre ou d’améliorer le processus d’injection et/ou des substances traces ajoutées pour faciliter la détection

de la migration du CO .

3.8

tubage

éléments tubulaires placés à l’intérieur d’un puits pour empêcher les strates environnantes de

s’effondrer dans le trou

Note 1 à l'article: Bien qu’il existe de nombreuses variantes de conception acceptables, les types de tubage

habituellement utilisés dans la plupart des puits d’injection sont: