ISO 5530-4:1983

(Main)Wheat flour - Physical characteristics of doughs - Part 4: Determination of rheological properties using an alveograph

Wheat flour - Physical characteristics of doughs - Part 4: Determination of rheological properties using an alveograph

Farines de blé tendre — Caractéristiques physiques des pâtes — Partie 4: Détermination des caractéristiques rhéologiques au moyen de l'alvéographe

General Information

Relations

Frequently Asked Questions

ISO 5530-4:1983 is a standard published by the International Organization for Standardization (ISO). Its full title is "Wheat flour - Physical characteristics of doughs - Part 4: Determination of rheological properties using an alveograph". This standard covers: Wheat flour - Physical characteristics of doughs - Part 4: Determination of rheological properties using an alveograph

Wheat flour - Physical characteristics of doughs - Part 4: Determination of rheological properties using an alveograph

ISO 5530-4:1983 is classified under the following ICS (International Classification for Standards) categories: 67.060 - Cereals, pulses and derived products. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 5530-4:1983 has the following relationships with other standards: It is inter standard links to SIST ISO 5530-4:1997, ISO 5530-4:1991. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ISO 5530-4:1983 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Standards Content (Sample)

International Standard @ 553014

INTERNATIONAL ORGANIZATION FOR STANDARDIZATIONOMEXAYHAPOAHAfl OPïAHH3AUHfl no CTAHAAPTM3AUMM*ORGANlSATlON INTERNATIONALE DE NORMALISATION

Wheat flour - Physical characteristics of doughs -

L

Part 4 : Determination of rheological properties using an

alveograph

Farines de blé tendre - Caractéristiques physiques des pâtes - Partie 4 : Détermination des caractéristiques rhéologiques au

moyen de I'alvéographe

First edition - 1983-06-01

L

- UDC 664.641.016 Ref. No. IS0 553W4-1983 (E)

c

Descriptors : agricultural products, corn (G.Bi, cereal products, flour (food), doughs, tests, determination, physical properties, test results.

.

s Price based on 7 pages

Foreword

IS0 (the International Organization for standardization) is a worldwide federation of

national standards bodies (IS0 member bodies). The work of developing International

Standards is carried out through IS0 technical committees. Every member body

interested in a subject for which a technical committee has been authorized has the

right to be represented on that committee. International organizations, governmental

and non-governmental, in liaison with ISO, also take part in the work.

Draft International Standards adopted by the technical committees are circulated to

the member bodies for approval before their acceptance as International Standards by

the IS0 Council.

International Standard IS0 5530/4 was developed by Technical Committee

ISOITC 34, Agricultural food products, and was circulated to the member bodies in

November 1981.

It has been approved by the member bodies of the following countries :

Germany, F.R. Portugal

Australia

Brazil Hungary Romania

India South Africa, Rep. of

Canada

Chile Israel Tanzania

Italy United Kingdom

Czechoslovakia

Malaysia USSR

Egypt, Arab Rep. of

Ethiopia New Zealand Yugoslavia

Poland

France

The member bodies of the following countries expressed disapproval of the document

on technical grounds :

Ireland

Philippines

NOTE - This International Standard is based on Standard No. 121 of the International Associ-

ation for Cereal Chemistry (ICC).

O International Organization for Standardization, 1983 0

Printed in Switzerland

INTERNATIONAL STANDARD IS0 5530/4-1983 (E)

Wheat flour - Physical characteristics of doughs -

Part 4 : Determination of rheological properties using an

alveograph

O Introduction IS0 712, Cereals and cereal products - Determination of

'L

moisture content (Routine reference method).

The rheological properties of doughs made from wheat flour

constitute an important factor in their utilization value (for IS0 2170, Cereals and pulses - Sampling of milled products.

breads, rusks and biscuits).

Throughout the transformation process from wheat into bread

3 Principle

or other products, the rheological properties of doughs have

important applications :

Preparation of a dough of constant moisture content from

-

wheat flour and salt water, under specified conditions. Prepara-

judging the quality of new varieties and estimating the

tion of test pieces of standard thickness from the dough. Biax-

utilization value of commercial wheats;

ial extension by inflating into the shape of a bubble. Plotting of

-

the differences in pressure inside the bubble as a function of

determining the proportions of different wheats in mix-

tures before milling and checking the latter; time. Assessment of the properties of the dough from the sur-

face area under the curve and the shape of the curve obtained.

- defining commercial types of flour, determining the

proportions of various flours in a mixture and the constancy

of mixing.

4 Reagents

Determinations using other types of apparatus (farinograph,

extensograph, valorigraph) will form the subjects of parts 1, 2

4.1 Sodium chloride solution.

and 3 of this International Standard.

c

Dissolve 25 g of sodium chloride, of recognized analytical qual-

ity, in distilled water or water of equivalent purity and make up

1 Scope and field of application

to 1 O00 ml.

This part of IS0 5530 specifies a method, using an alveo-

graph,l) of determining certain rheological properties of 4.2 Paraffin oil, sold by pharmacists under the name of

doughs made from wheat flour (Triticum aestivum). petrolatum liquidum (liquid paraffin), which is a purified mix-

ture of natural, liquid saturated hydrocarbons obtained from

petroleum, with an acid value less than or equal to 0,05. Use

2 References paraffin oil having the lowest possible viscosity [not more than

60 mPa.s (60 cP) at 20 OC], or oleic vegetable oil with an acid

IS0 660, Animal and vegetable fats and oils - Detemination value less than 0,4 (see IS0 6601, for example refined African

of acid value and of acidity. 2) groundnut oil.

1) This International Standard has been drawn up on the basis of the Chopin alveograph (see figure 1). which is the only apparatus of this type

presently available.

The manufacturer provides, with the apparatus, a burette graduated in percentages for the moisture content of flour, a planimetric scale and a scale

allowing the extent of inflation to be measured.

At present at the stage of draft. (Revision of ISO/R 660-1968,)

2)

IS0 5630/4-1983 (E)

5 Apparatus 7 Procedure

7.1 Preliminary checks

5.1 Alveographi) (with temperature regulator) having the

following characteristics :

7.1.1 Before each test, check that the temperatures of the

mixer and the alveograph are 24,O f 0,2 OC and 25,O I 0,2 OC

- Rotational frequency of the

respectively. Regulate the thermostat a sufficient time before

mixer blade 59 I 1 min-1

use so that these temperatures have stabilized. Also check

NOTE - Some older models have a rotational frequency of

them while the equipment is in use.

60 f 1 min-l. This difference will not, however, have any effect on

the results.

7.1.2 Check regularly that the equipment is sealed (absence

of hydraulic leakage or air leakage).

- Height of the sheeting guides 12,O f 0,l mm

- Diameter of the sheeting

Check that the water level in the burette is at index

7.1.3

roller : large diameter 40,O f 0,l mrn

mark O.

- Diameter of the sheeting

roller : small diameter 33,3 f 0,l mm

7.1.4 Check regularly the rate at which water rises in the

burette H. The time for water to flow between index marks

-

Inner diameter of the dough

O and 25 shall be exactly 23 I 0,5 s.

cutter 46,O I 0,5 mm

- 7.1.5 Check, using the timer, the period of rotation of the

Diameter of the opening in the

recording drum which shall be exactly 60 s for one revolution

moving plate (diameter of the test

with a current of frequency 50 Hz (or 60 Hz for recent ap-

piece subjected to inflation) 55,O I 0,l mm

paratus having a motor of this type)(or 55 s from stop to stop).

- Theoretical distance between

the fixed and moving plates once NOTE - This corresponds to a linear chart travel of 302.5 mm in 55 s.

they have been clamped down

(equal to the thickness of the test

7.2 Preliminary operations

piece before inflation) 2,67 I 0,Ol mm

7.2.1 Determine the moisture content of the flour by the

-

Volume of the glass burette

method specified in IS0 712.

between index marks O and 25 625 f 10 ml

- Volume of the rubber

7.2.2 If necessary, bring the temperature of the flour to

pear-shaped bulb 18 I 2 ml

20 I 5 OC. The apparatus shall be used in a room where the

temperature is between 18 and 22 OC and the relative humidity

-

Time for emptying the burette

is (65 I 15) %.

between the index

marks O and 25 23,O I 0,5 s

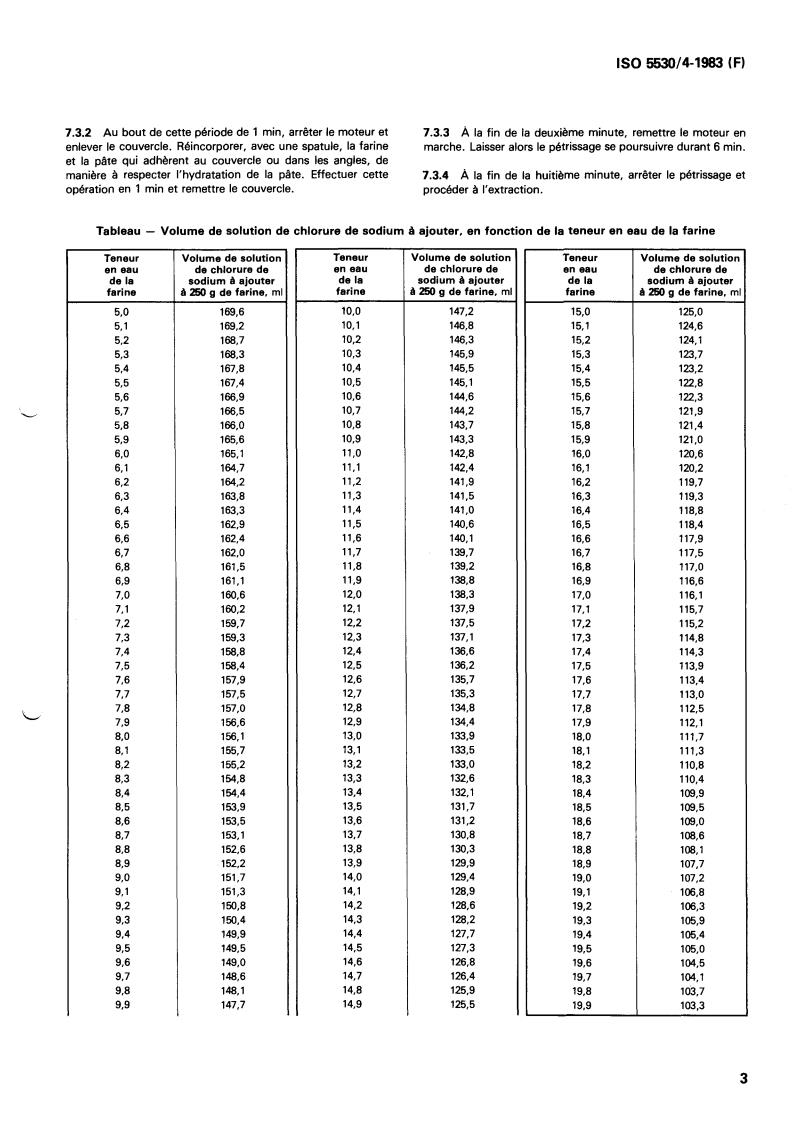

7.2.3 Determine, from the table, the quantity of the sodium

-

chloride solution (4.1) to be used in 7.3.1 to prepare the dough.

Linear speed of the periphery

-,

of the recording drum 5,5 I 0,l mm/s

The values in the table have been calculated to obtain constant

hydration, i.e. that of a dough made from 50 ml of sodium

5.2 Burette, of capacity 160 ml, graduated in 0.25 ml inter-

chloride solution (4.1) and 100 g of flour with a moisture con-

vals, or a burette graduated directly in percentages of moisture

tent of 15 %.

content from 11,6 to 17,8 % (accuracy 0,l %).

7.3 Mixing the dough

Balance, accurate to 0,5 g.

5.3

7.3.1 Place 250 g of flour, weighed to the nearest 0,5 g, in the

5.4 Timer.

mixer. Secure the lid by tightening the two screws. Connect

the mixing blade to the speed reducer. Start the motor and the

5.5 Planimeter and/or planimetric scale.’)

timer. Pour in the required quantity of sodium chloride solution

(4.1) (see the table) in about 20 s through the hole in the lid.

6 Sampling

Leave the dough to form for 1 min (including the 20 s for

Carry out sampling by the method specified in IS0 2170. pouring).

1) This International Standard has been drawn up on the basis of the Chopin alveograph (see figure l), which is the only apparatus of this type

presently available.

The manufacturer provides, with the apparatus, a burette graduated in percentages for the moisture content of flour, a planimetric scale and a scale

allowing the extent of inflation to be measured.

IS0 5530/4-1983 (E)

7.3.3 After this 1 min period (total 2 min), restart the motor.

7.3.2 After this 1 min period, stop the motor and remove the

Allow mixing to continue for 6 min.

cover. Using a spatula, incorporate the flour and dough ad-

hering to the cover or in the corners with the dough, so that all

7.3.4 After a total time of 8 min, stop mixing and proceed

the dough undergoes hydration. Complete this operation in

1 min and replace the lid. with the extrusion.

Table - Volume of sodium chloride solution to be added as a function of the moisture content of the flour

~~

Volume of sodium

Volume of sodium Moisture Volume of sodium Moisture

Moistur

...

Norme internationale @ 553014

INTERNATIONAL ORGANIZATION FOR ÇTANDARDIZATIONOME~I(nYHAP0~HAR OPTAHM3AUMR nO CTAH/lAPTH3ALlMM*ORGANlSATlON INTERNATIONALE DE NORMALISATION

Farines de blé tendre - Caractéristiques physiques des

L

pâtes -

Partie 4 : Détermination des caractéristiques rhéologiques

au moyen de I'alvéographe

Wheat flour - Physical characteristics of doughs - Part 4 : Determination of rheological properties using an alveograph

Première édition - 1983-06-01

CDU 664.641.016 Réf. no : IS0 5530/4-1983 (FI

Descripteurs : produits agricoles, blé, produits céréaliers, farine, pâte à pain, essais, détermination, propriétés physiques, résultats d'essai.

Prix basé sur 7 pages

NORME INTERNATIONALE IS0 5530/4-1983 (F)

Farines de blé tendre - Caractéristiques physiques des

pâtes -

Partie 4 : Détermination des caractéristiques rhéologiques

au moyen de I'alvéographe

O Introduction IS0 712, Céréales et produits céréaliers - Détermination de la

teneur en eau (Méthode de référence pratique).

Les caractéristiques rhéologiques des pâtes obtenues à partir

de farines de blé tendre constituent un facteur important de

IS0 2170, Céréales et légumineuses - Échantillonnage des

leur valeur d'utilisation (valeur boulangère, biscottière, biscui- produits de mouture.

tière).

Tout au long du circuit de transformation des blés en pain ou

3 Principe

autres produits, les caractéristiques rhéologiques des pâtes

trouvent d'importantes applications :

Préparation d'une pâte à teneur en eau constante, à partir

d'une farine de blé tendre et d'eau salée, dans les conditions

-

jugement de la qualité de nouvelles variétés et estima-

spécifiées. Formation d'éprouvettes de pâte d'une épaisseur

tion de la valeur d'utilisation des blés commercialisés:

déterminée. Extension biaxiale par gonflement sous forme de

bulle. Enregistrement graphique des variations de pression à

-

détermination des proportions de divers blés dans les

l'intérieur de la bulle en fonction du temps. Appréciation des

mélanges avant mouture et contrôle de ceux-ci;

caractéristiques de la pâte d'après la surface et la forme des dia-

grammes obtenus.

- définition des types commerciaux de farine, détermina-

tion des proportions de diverses farines dans un mélange et

de la constance de celui-ci.

4 Réactifs

Les déterminations au moyen d'autres appareils (farinographe,

extensographe, valorigraphe) feront l'objet des parties 1, 2 et 3

4.1 Solution de chlorure de sodium.

de la présente Norme internationale.

'L

Dissoudre 25 g de chlorure de sodium de pureté analytique

reconnue dans de l'eau distillée ou de l'eau de pureté équiva-

1 Objet et domaine d'application

lente et compléter à 1 O00 ml.

La présente partie de I'ISO 5530 spécifie une méthode de déter-

mination, au moyen d'un alvéographel), de certaines caracté- 4.2 Huile de paraffine (dite huile de vaseline), vendue en

pharmacie sous le nom de petrolatum liquidum et qui est un

ristiques rhéologiques des pâtes obtenues à partir de farines de

blé tendre ( Triticum aestivum). mélange purifié des hydrocarbures naturels liquides saturés

obtenus à partir du pétrole, ayant un indice d'acide inférieur ou

égal à 0,05. Utiliser l'huile de paraffine ayant la plus faible visco-

2 Références sité possible [égale au maximum à 60 mPa.s (60 cP) à 20 OC],

ou huile végétale oléique ayant un indice d'acide inférieur à

IS0 660, Corps gras d'origines animale et végétale - Détermi- 0,4 (voir IS0 6601, par exemple huile d'arachide d'Afrique

nation de l'indice d'acide et de l'acidité. 2) raffinée.

1) La présente Norme internationale a été établie en fonction de I'alvéographe Chopin (voir figure l), seul appareil de ce type disponible

actuellement.

Avec cet appareil, le constructeur fournit une burette graduée en pourcentage de la teneur en eau de la farine, un abaque planimétrique et un abaque

permettant de mesurer l'indice de gonflement.

2) Actuellement au stade de projet. (Révision de I'ISO/R 660-1968.)

7.3.2 Au bout de cette période de 1 min, arrêter le moteur et 7.3.3 À la fin de la deuxième minute, remettre le mote

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...