ISO 3951-3:2007

(Main)Sampling procedures for inspection by variables — Part 3: Double sampling schemes indexed by acceptance quality limit (AQL) for lot-by-lot inspection

Sampling procedures for inspection by variables — Part 3: Double sampling schemes indexed by acceptance quality limit (AQL) for lot-by-lot inspection

ISO 3951-3:2007 specifies an acceptance sampling system of double sampling schemes for inspection by variables for percent nonconforming. It is indexed in terms of the acceptance quality limit (AQL). The objectives of the methods laid down in ISO 3951-3:2007 are to ensure that lots of acceptable quality have a high probability of acceptance and that the probability of non-accepting inferior lots is as high as practicable. This is achieved by means of the switching rules, which provide automatic protection to the consumer (by means of a switch to tightened inspection or discontinuation of sampling inspection) should a deterioration in quality be detected, and an incentive (at the discretion of the responsible authority) to reduce inspection costs (by means of a switch to a smaller sample size) should consistently good quality be achieved. In ISO 3951-3:2007, the acceptability of a lot is implicitly or explicitly determined from an estimate of the percentage of nonconforming items in the process, based on either one or two random samples of items from the lot. ISO 3951-3:2007 is primarily designed for use under the following conditions: where the inspection procedure is to be applied to a continuing series of lots of discrete products all supplied by one producer using one production process; where the items of product have a single quality characteristic; where the quality characteristic is measurable on a continuous scale; where the measurement error is negligible (i.e. with a standard deviation no more than 10 % of the corresponding process standard deviation); where production is stable (under statistical control) and the quality characteristic is distributed, at least to a close approximation, according to a normal distribution; where the possibility of having to select and inspect a second sample is administratively acceptable; and where a contract or standard defines an upper specification limit, a lower specification limit, or both on the quality characteristic. The procedures in ISO 3951-3:2007 are not suitable for application to lots that have been screened previously for nonconforming items.

Règles d'échantillonnage pour les contrôles par mesures — Partie 3: Plans d'échantillonnage doubles pour le contrôle lot par lot, indexés d'après le niveau de qualité acceptable (NQA)

General Information

- Status

- Published

- Publication Date

- 25-Apr-2007

- Technical Committee

- ISO/TC 69/SC 5 - Acceptance sampling

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 07-Jun-2021

- Completion Date

- 14-Feb-2026

Overview

ISO 3951-3:2007 - Sampling procedures for inspection by variables - Part 3 describes an acceptance sampling system of double sampling schemes indexed by acceptance quality limit (AQL) for lot-by-lot inspection. The standard specifies how to decide lot acceptability from one or two random samples by estimating the percentage nonconforming (items outside specified limits). Its objectives are to give a high probability of acceptance for acceptable lots and strong protection against inferior lots through automatic switching rules (normal, tightened, reduced inspection).

Key topics and requirements

- Double sampling by variables: Inspect a first random sample; accept or reject immediately if results are decisive, otherwise draw a second sample and combine results for a final decision.

- Indexed by AQL: Plans are referenced to the Acceptance Quality Limit (AQL) to align operating characteristics with consumer/producer risk expectations.

- Methods for process variance:

- “s” method - process standard deviation unknown (estimate from sample).

- “σ” method - process standard deviation known or well estimated.

- Switching rules: Automatic switching to tightened inspection or discontinuation on quality deterioration; possible switch to reduced inspection when quality is consistently good.

- Assumptions / applicability conditions:

- Continuing series of lots from a single producer/process.

- Single quality characteristic measured on a continuous scale.

- Measurement error negligible (≤ 10% of process SD).

- Production stable (statistical control) and approximately normally distributed.

- Administrative acceptance of a potential second sample.

- A contract/standard defines upper and/or lower specification limits.

- Limitations: Not suitable for lots already screened for nonconforming items.

Practical applications

ISO 3951-3 is practical for quality and inspection programs where more efficient variable-data sampling is desired compared with attribute plans. Typical users:

- Quality engineers and statisticians designing lot acceptance procedures.

- Purchasing and inspection authorities specifying acceptance criteria in contracts.

- Manufacturers seeking to reduce inspection cost while maintaining consumer protection.

- Third-party inspectors implementing lot-by-lot variable sampling.

Benefits:

- Substantial inspection effort savings (first-sample size often ~40% smaller than corresponding single-sample plans).

- Fast decisions when quality is very good or poor; second sample only needed when results are equivocal.

- Clear framework for switching between inspection levels to balance consumer protection and inspection cost.

Related standards

- ISO 3951 parts 1, 2 and 5 (single sampling, multi-characteristic, sequential plans).

- ISO 2859-1 - attribute-based sampling plans (ISO 3951-3 is complementary and aligned in operating characteristics).

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

ISO 3951-3:2007 is a standard published by the International Organization for Standardization (ISO). Its full title is "Sampling procedures for inspection by variables — Part 3: Double sampling schemes indexed by acceptance quality limit (AQL) for lot-by-lot inspection". This standard covers: ISO 3951-3:2007 specifies an acceptance sampling system of double sampling schemes for inspection by variables for percent nonconforming. It is indexed in terms of the acceptance quality limit (AQL). The objectives of the methods laid down in ISO 3951-3:2007 are to ensure that lots of acceptable quality have a high probability of acceptance and that the probability of non-accepting inferior lots is as high as practicable. This is achieved by means of the switching rules, which provide automatic protection to the consumer (by means of a switch to tightened inspection or discontinuation of sampling inspection) should a deterioration in quality be detected, and an incentive (at the discretion of the responsible authority) to reduce inspection costs (by means of a switch to a smaller sample size) should consistently good quality be achieved. In ISO 3951-3:2007, the acceptability of a lot is implicitly or explicitly determined from an estimate of the percentage of nonconforming items in the process, based on either one or two random samples of items from the lot. ISO 3951-3:2007 is primarily designed for use under the following conditions: where the inspection procedure is to be applied to a continuing series of lots of discrete products all supplied by one producer using one production process; where the items of product have a single quality characteristic; where the quality characteristic is measurable on a continuous scale; where the measurement error is negligible (i.e. with a standard deviation no more than 10 % of the corresponding process standard deviation); where production is stable (under statistical control) and the quality characteristic is distributed, at least to a close approximation, according to a normal distribution; where the possibility of having to select and inspect a second sample is administratively acceptable; and where a contract or standard defines an upper specification limit, a lower specification limit, or both on the quality characteristic. The procedures in ISO 3951-3:2007 are not suitable for application to lots that have been screened previously for nonconforming items.

ISO 3951-3:2007 specifies an acceptance sampling system of double sampling schemes for inspection by variables for percent nonconforming. It is indexed in terms of the acceptance quality limit (AQL). The objectives of the methods laid down in ISO 3951-3:2007 are to ensure that lots of acceptable quality have a high probability of acceptance and that the probability of non-accepting inferior lots is as high as practicable. This is achieved by means of the switching rules, which provide automatic protection to the consumer (by means of a switch to tightened inspection or discontinuation of sampling inspection) should a deterioration in quality be detected, and an incentive (at the discretion of the responsible authority) to reduce inspection costs (by means of a switch to a smaller sample size) should consistently good quality be achieved. In ISO 3951-3:2007, the acceptability of a lot is implicitly or explicitly determined from an estimate of the percentage of nonconforming items in the process, based on either one or two random samples of items from the lot. ISO 3951-3:2007 is primarily designed for use under the following conditions: where the inspection procedure is to be applied to a continuing series of lots of discrete products all supplied by one producer using one production process; where the items of product have a single quality characteristic; where the quality characteristic is measurable on a continuous scale; where the measurement error is negligible (i.e. with a standard deviation no more than 10 % of the corresponding process standard deviation); where production is stable (under statistical control) and the quality characteristic is distributed, at least to a close approximation, according to a normal distribution; where the possibility of having to select and inspect a second sample is administratively acceptable; and where a contract or standard defines an upper specification limit, a lower specification limit, or both on the quality characteristic. The procedures in ISO 3951-3:2007 are not suitable for application to lots that have been screened previously for nonconforming items.

ISO 3951-3:2007 is classified under the following ICS (International Classification for Standards) categories: 03.120.30 - Application of statistical methods. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 3951-3:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 3951-3

First edition

2007-05-01

Sampling procedures for inspection

by variables —

Part 3:

Double sampling schemes indexed

by acceptance quality limit (AQL)

for lot-by-lot inspection

Règles d'échantillonnage pour les contrôles par mesures —

Partie 3: Plans d'échantillonnage doubles pour le contrôle lot par lot,

indexés d'après le niveau de qualité acceptable (NQA)

Reference number

©

ISO 2007

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2007

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2007 – All rights reserved

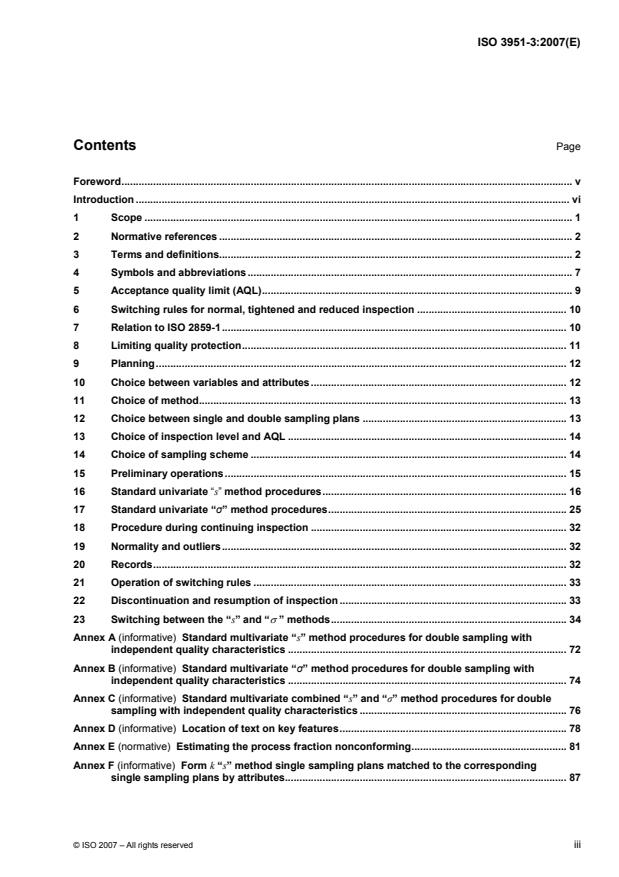

Contents Page

Foreword. v

Introduction . vi

1 Scope. 1

2 Normative references. 2

3 Terms and definitions. 2

4 Symbols and abbreviations . 7

5 Acceptance quality limit (AQL). 9

6 Switching rules for normal, tightened and reduced inspection . 10

7 Relation to ISO 2859-1. 10

8 Limiting quality protection. 11

9 Planning. 12

10 Choice between variables and attributes. 12

11 Choice of method. 13

12 Choice between single and double sampling plans . 13

13 Choice of inspection level and AQL . 14

14 Choice of sampling scheme . 14

15 Preliminary operations. 15

16 Standard univariate “s” method procedures. 16

17 Standard univariate “σ” method procedures. 25

18 Procedure during continuing inspection . 32

19 Normality and outliers. 32

20 Records. 32

21 Operation of switching rules . 33

22 Discontinuation and resumption of inspection . 33

23 Switching between the “s” and “σ ” methods. 34

Annex A (informative) Standard multivariate “s” method procedures for double sampling with

independent quality characteristics . 72

Annex B (informative) Standard multivariate “σ” method procedures for double sampling with

independent quality characteristics . 74

Annex C (informative) Standard multivariate combined “s” and “σ” method procedures for double

sampling with independent quality characteristics . 76

Annex D (informative) Location of text on key features. 78

Annex E (normative) Estimating the process fraction nonconforming. 81

Annex F (informative) Form k “s” method single sampling plans matched to the corresponding

single sampling plans by attributes. 87

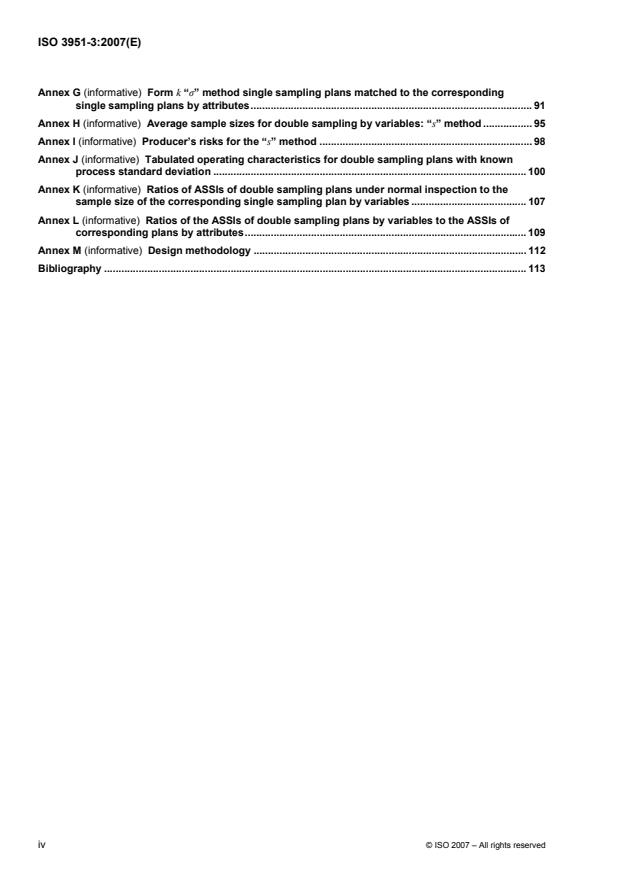

Annex G (informative) Form k “σ” method single sampling plans matched to the corresponding

single sampling plans by attributes. 91

Annex H (informative) Average sample sizes for double sampling by variables: “s” method . 95

Annex I (informative) Producer’s risks for the “s” method . 98

Annex J (informative) Tabulated operating characteristics for double sampling plans with known

process standard deviation . 100

Annex K (informative) Ratios of ASSIs of double sampling plans under normal inspection to the

sample size of the corresponding single sampling plan by variables . 107

Annex L (informative) Ratios of the ASSIs of double sampling plans by variables to the ASSIs of

corresponding plans by attributes. 109

Annex M (informative) Design methodology . 112

Bibliography . 113

iv © ISO 2007 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 3951-3 was prepared by Technical Committee ISO/TC 69, Applications of statistical methods,

Subcommittee SC 5, Acceptance sampling.

ISO 3951 consists of the following parts, under the general title Sampling procedures for inspection by

variables:

⎯ Part 1: Specification for single sampling plans indexed by acceptance quality limit (AQL) for lot-by-lot

inspection for a single quality characteristic and a single AQL

⎯ Part 2: General specification for single sampling plans indexed by acceptance quality limit (AQL) for lot-

by-lot inspection of independent quality characteristics

⎯ Part 3: Double sampling schemes indexed by acceptance quality limit (AQL) for lot-by-lot inspection

⎯ Part 5: Sequential sampling plans indexed by acceptance quality limit (AQL) for inspection by variables

(known standard deviation)

The following part is under preparation:

⎯ Part 4: Procedures for assessment of declared quality levels

Introduction

Inspection by variables for percentage nonconforming items, as described in this part of ISO 3951, includes

several possible modes, the combination of which leads to a presentation which may appear quite

complicated to the user:

a) procedures for unknown process standard deviation (the “s” method), or procedures for where the

process standard deviation is originally unknown then estimated with fair precision, or known since the

start of inspection (the “σ” method);

b) a single specification limit, or double specification limits with separate, combined or complex control;

c) normal inspection, tightened inspection or reduced inspection;

d) Form k plans and Form p* plans;

e) a single quality characteristic (the univariate case) or a number of unrelated quality characteristics (the

multivariate independent case).

The text has been arranged so that the simpler procedures may be implemented without necessarily

understanding the more complicated procedures. The main text of this part of ISO 3951 is confined to the

univariate case. The multivariate independent cases are treated separately in Annex A for the “s” method, in

Annex B for the “σ ” method and in Annex C for combined “s” method and “σ” method procedures. Annex D

facilitates the use of the main text of the standard by directing the user to the clauses and tables concerning

any univariate situation with which he might be confronted; it only deals with Clauses 16, 17, 21, 22 and 23

and, in every case, it is necessary to have read Clauses 1 to 15 and Clauses 18 to 20 first.

This part of ISO 3951 is complementary to the double sampling plans and procedures of ISO 2859-1. When

specified by the responsible authority, it would be valid to reference both ISO 3951-3 and ISO 2859-1 in a

product specification, a contract, inspection instructions, or other documents, and the provisions set forth

therein shall govern. The “responsible authority” can then be designated in one of these documents.

In all parts of ISO 3951:

⎯ the acronym AQL stands for “acceptance quality limit” rather than “acceptable quality level”, in order to

more accurately reflect its function;

⎯ procedures are given for the case where the process standard is unknown (the “s” method) and for the

case where it may be presumed to be known (the “σ” method);

⎯ the sampling plans have been chosen so that their operating characteristic curves closely match those of

the corresponding single sampling plans in ISO 2859-1;

⎯ minimal statistical theory has been given (it being planned ultimately to provide this in a guidance

document to sampling procedures for inspection by variables);

⎯ text, charts and tables that are only informative have been consigned to annexes wherever practicable.

In none of the parts have methods been given based on the sample range, now that the availability of

computers and calculators with a standard deviation function key is so widespread. Data for acceptance

sampling by variables is often substantially more expensive to acquire than data for sampling by attributes,

and the “s” method makes more efficient use of these data.

vi © ISO 2007 – All rights reserved

The coverage of ISO 3951-1 is constrained to the case of a single, normally distributed, quality characteristic

with a single class of nonconformity, and includes the case of combined control of double specification limits.

ISO 3951-2 provides a more comprehensive treatment of single sampling plans by variables, including

procedures for separate and complex control of double specification limits. Procedures are also given for

multiple independent quality characteristics and/or multiple AQLs.

ISO 3951-3 provides plans for double sampling by variables, which on average provide substantial savings of

inspection effort in comparison with plans for single sampling by variables. The savings are achieved by first

selecting from the lot and inspecting a random sample that is typically nearly 40 % smaller than that of the

corresponding single sampling plan. If these inspection results satisfy an acceptance criterion, an immediate

decision is made to accept the lot without further inspection. Alternatively, if the inspection results satisfy a

non-acceptance criterion, an immediate decision not to accept the lot is made without further inspection. Thus,

when quality is very good or very poor, the saving in inspection effort can amount to nearly 40 %. Only when

the inspection results from the first sample are equivocal is a second random sample, of the same size as the

first, selected; the acceptability of the lot is then resolved by combining the results of the first and second

samples and determining whether they satisfy a second acceptance criterion.

This publication does not purport to include all the necessary provisions of a contract. Users are responsible

for its correct application.

INTERNATIONAL STANDARD ISO 3951-3:2007(E)

Sampling procedures for inspection by variables —

Part 3:

Double sampling schemes indexed by acceptance quality limit

(AQL) for lot-by-lot inspection

1 Scope

This part of ISO 3951 specifies an acceptance sampling system of double sampling schemes for inspection by

variables for percent nonconforming. It is indexed in terms of the acceptance quality limit (AQL).

The objectives of the methods laid down in this part of ISO 3951 are to ensure that lots of acceptable quality

have a high probability of acceptance and that the probability of non-accepting inferior lots is as high as

practicable. This is achieved by means of the switching rules, which provide

⎯ automatic protection to the consumer (by means of a switch to tightened inspection or discontinuation of

sampling inspection) should a deterioration in quality be detected, and

⎯ an incentive (at the discretion of the responsible authority) to reduce inspection costs (by means of a

switch to a smaller sample size) should consistently good quality be achieved.

In this part of ISO 3951, the acceptability of a lot is implicitly or explicitly determined from an estimate of the

percentage of nonconforming items in the process, based on either one or two random samples of items from

the lot.

This part of ISO 3951 is primarily designed for use under the following conditions:

a) where the inspection procedure is to be applied to a continuing series of lots of discrete products all

supplied by one producer using one production process; if there are different producers or production

processes, apply this part of ISO 3951 to each one separately;

b) where the items of product have a single quality characteristic (for multiple quality characteristics, see

informative Annexes A, B and C);

c) where the quality characteristic is measurable on a continuous scale;

d) where the measurement error is negligible (i.e. with a standard deviation of no more than 10 % of the

corresponding process standard deviation);

e) where production is stable (under statistical control) and the quality characteristic is distributed, at least to

a close approximation, according to a normal distribution;

CAUTION — The procedures in this part of ISO 3951 are not suitable for application to lots that have

been screened previously for nonconforming items.

f) where the possibility of having to select and inspect a second sample is administratively acceptable;

g) where a contract or standard defines an upper specification limit U, a lower specification limit L or both

on the quality characteristic. An item is deemed to conform if its measured quality characteristic x

satisfies the appropriate one of the following inequalities:

1) x W L (i.e. the lower specification limit is not violated);

2) x u U (i.e. the upper specification limit is not violated);

3) x W L and x u U (i.e. neither the lower nor the upper specification limit is violated).

NOTE Inequalities 1) and 2) are called cases with a “single specification limit”, and 3) is the case with “double

specification limits”. For double specification limits, a further distinction is made between combined control, separate

control and complex control, as follows:

— combined control is where a single AQL applies to nonconformity beyond both limits;

— separate control is where separate AQLs apply to nonconformity beyond each of the limits;

— complex control is where one AQL applies to nonconformity beyond the limit that is of greater seriousness, and a

larger AQL applies to the total nonconformity beyond both limits.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 3534-1, Statistics — Vocabulary and symbols — Part 1: General statistical terms and terms used in

probability

ISO 3534-2:2006, Statistics — Vocabulary and symbols — Part 2: Applied statistics

3 Terms and definitions

For the purposes of this part of ISO 3951, the definitions given in ISO 3534-1, ISO 3534-2 and the following

apply. References are given in square brackets for definitions that have been re-expressed in the vocabulary

of this part of ISO 3951 for the user’s convenience.

3.1

inspection by variables

inspection by measuring the magnitude(s) of the characteristic(s) of an item

[ISO 3534-2:2006, definition 4.1.4]

3.2

sampling inspection

inspection of selected items in the group under consideration

[ISO 3534-2:2006, definition 4.1.6]

3.3

acceptance sampling inspection

acceptance inspection where the acceptability is determined by means of sampling inspection

[ISO 3534-2:2006, definition 4.1.8]

2 © ISO 2007 – All rights reserved

3.4

double sampling inspection, double sampling

acceptance sampling inspection based initially on a first sample, of size n , which leads to a decision to

accept, non-accept, or to inspect a second sample, of size n , before taking the decision whether or not to

accept

NOTE 1 The decisions are made according to defined rules.

NOTE 2 In this part of ISO 3951, both sample sizes are equal and denoted by i.e. n = n = n.

n,

1 2

3.5

acceptance sampling inspection by variables

acceptance sampling inspection in which the acceptability of the process is determined statistically from

measurements on specified quality characteristics of each item in a sample from a lot

[ISO 3534-2:2006, definition 4.2.11]

NOTE An acceptable process is a process that generates nonconforming items at a rate no worse than the AQL.

3.6

process average

rate at which nonconforming items are generated by a process

3.7

acceptance quality limit

AQL

worst tolerable product quality level

NOTE See Clause 5.

3.8

quality level

quality expressed as a rate of nonconforming units

3.9

limiting quality

LQ

quality level, when a lot is considered in isolation, which, for the purposes of acceptance sampling inspection,

is limited to a low probability of acceptance (in this part of ISO 3951: 10 %)

NOTE See Clause 8.

3.10

nonconformity

non-fulfilment of a requirement

[ISO 9000:2005, definition 3.6.2]

NOTE 1 Nonconformity will generally be classified by its degree of seriousness, such as:

Class A. Nonconformity of a type considered to be of the highest concern for the product or service. Such types of

nonconformity will typically be assigned very small AQL values.

Class B. Nonconformity of a type considered to have the next lower degree of concern; this is typically assigned a larger

AQL value than that in class A and smaller than that in class C if a third class exists, and so on.

The number of classes and the assignment into a class should be appropriate to the quality requirements of the specific

situation.

NOTE 2 The main text of this part of ISO 3951 deals with the univariate case, for which there will be either one or two

classes of nonconformity.

3.11

nonconforming unit

unit with one or more nonconformities

[ISO 3534-2:2006, definition 1.2.15]

3.12

“s” method acceptance sampling plan

acceptance sampling plan by variables using the sample mean(s) and sample standard deviation(s)

NOTE See Clause 16.

3.13

“σ” method acceptance sampling plan

acceptance sampling plan by variables using the sample mean(s) and the presumed value(s) of the process

standard deviation(s)

NOTE See Clause 17.

3.14

specification limit

limiting value stated for a characteristic

[ISO 3534-2:2006, definition 3.1.3]

3.15

lower specification limit

L

specification limit that defines the lower limiting value

[ISO 3534-2:2006, definition 3.1.5]

3.16

upper specification limit

U

specification limit that defines the upper limiting value

[ISO 3534-2:2006, definition 3.1.4]

3.17

combined control

requirement when nonconformity beyond both the upper and the lower specification limits of a quality

characteristic belongs to the same class to which a single AQL is applied

NOTE 1 See 5.3, 16.4 and 17.4.

NOTE 2 The use of a combined AQL requirement implies that nonconformities beyond either specification limit are

believed to be of equal, or at least roughly equal, importance to the lack of integrity of the product.

3.18

separate control

requirement when nonconformity beyond the upper and the lower specification limits of a quality characteristic

belongs to different classes, to which separate AQLs are applied

NOTE See 5.3, 16.3 and 17.3.

4 © ISO 2007 – All rights reserved

3.19

complex control

requirement when nonconformity beyond both the upper and the lower specification limits of a quality

characteristic belongs to one class and nonconformity beyond either the upper or the lower specification limit

belongs to a different class, with separate AQLs being applied to the two classes

NOTE See 5.3, 16.5 and 17.5.

3.20

acceptability constants

k, p*

constants depending on the specified value of the acceptance quality limit, sample size and inspection

severity, used in the criteria for accepting the lot in an acceptance sampling plan by variables

NOTE 1 See Clauses 16 and 17.

NOTE 2 For double sampling, there will be three such pairs of acceptability constants, one for acceptance at the first

sample, one for non-acceptance at the first sample and one for acceptance with the combined first and second samples.

3.21

quality statistic

Q

〈acceptance sampling〉 function of the specification limit, the sample mean, and the sample or process

standard deviation, used in assessing the acceptability of a lot

[ISO 3534-2:2006, definition 4.4.9]

NOTE See also 3.22 and 3.23.

3.22

lower quality statistic

Q

L

function of the lower specification limit, the sample mean, and the sample or process standard deviation

NOTE See Clause 4 for further details.

3.23

upper quality statistic

Q

U

function of the upper specification limit, the sample mean, and the sample or process standard deviation

NOTE See Clause 4 for further details.

3.24

maximum sample standard deviation

MSSD

s

max

largest sample standard deviation for a given sample size code letter and acceptance quality limit for which it

is possible to satisfy an acceptance criterion for double specification limits when the process variability is

unknown

NOTE 1 The MSSD depends on whether the double specification limits are under combined, separate or complex

control and on the inspection severity (i.e. normal, tightened or reduced).

NOTE 2 See 16.4.2 and Table 16, 17 or 18.

NOTE 3 For double sampling plans, there are two MSSDs under each combination of inspection severity and type of

control, one for the first sample and one for the combined first and second samples.

3.25

maximum process standard deviation

MPSD

σ

max

largest process standard deviation for a given sample size code letter and acceptance quality limit for which it

is possible to satisfy an acceptance criterion for double specification limits under all inspection severities (i.e.

normal, tightened or reduced) when the process variability is known

NOTE 1 An MPSD depends on whether the double specification limits are under combined, separate or complex

control, but does not depend on the inspection severity or on whether the sample is the first or second.

NOTE 2 See 17.3, 17.4 and 17.5 and Tables 19, 20 and 21.

3.26

switching rule

instruction within an acceptance sampling scheme for changing from one acceptance sampling plan to

another of greater or lesser severity based on demonstrated quality history

NOTE 1 Normal, tightened or reduced inspection, or discontinuation of inspection, are examples of severity of sampling.

[ISO 3534-2:2006, definition 4.3.4]

NOTE 2 See Clause 21.

3.27

measurement

set of operations having the object of determining the value of a quantity

[ISO 3534-2:2006, definition 3.2.1]

3.28

average sample size

ASSI

average number of units in a sample inspected per lot in reaching decisions to accept or not to accept when

using a given acceptance sampling scheme

NOTE ASSI is dependent on the actual quality level of the submitted lots.

[ISO 3534-2:2006, definition 4.7.3]

3.29

responsible authority

concept used to maintain the neutrality of this part of ISO 3951, irrespective of whether it is being invoked or

applied by the first, second or third party

NOTE 1 The responsible authority may be:

a) the quality department within a supplier's organization (first party);

b) the purchaser or procurement organization (second party);

c) an independent verification or certification authority (third party);

d) any of a), b) or c), differing according to function (see Note 2) as described in a written agreement between two of the

parties, for example a document between supplier and purchaser.

NOTE 2 The duties and functions of a responsible authority are outlined in this part of ISO 3951 (see 5.3, 6, 10, 11,

16.4.3.2.1, 17.1, 19.1, 20.2, 21.4, 23.1, 23.2 and 23.3).

6 © ISO 2007 – All rights reserved

4 Symbols and abbreviations

4.1 Symbols

For the purposes of this part of ISO 3951, the following symbols apply.

Ac acceptance number

factor given in Table 29 for determining the upper control limit for sample standard deviations

c

u

(see 23.2)

factor given in Tables 16, 17 and 18 for combined control of double specification limits, relating the

f

s

maximum sample standard deviation (MSSD) to the difference between U and L, for normal,

tightened and reduced inspection respectively (see 16.4.2 and 16.4.3.1)

NOTE 1 f and f represent respectively the factors applicable to the standard deviation of the first

s,1 s,c

sample and to the combined standard deviation of the first and second samples.

factor given in Tables 19, 20 and 21 that relates the maximum process standard deviation (MPSD)

f

σ

to the difference between U and L, for combined, separate and complex control respectively

(see 17.4 and 17.5)

Form k acceptability constant

k

NOTE 2 k , k and k represent respectively the Form k acceptability and non-acceptability constants at the

a r c

first sample and the acceptability constant for the combined first and second samples.

L lower specification limit (as a suffix to a variable, denotes its value at L).

µ process mean

N lot size (number of items in a lot)

n sample size (number of items in each sample)

p process fraction nonconforming

pˆ estimate of the process fraction nonconforming

ˆ

p estimate of the process fraction nonconforming below the lower specification limit

L

pˆ estimate of the process fraction nonconforming above the upper specification limit

U

*

Form p* acceptability constant, the largest acceptable value of the estimate of the process fraction

p

nonconforming

** *

NOTE 3 pp, and p represent respectively the Form p* acceptability and non-acceptability constants at

ar c

the first sample and the acceptability constant for the combined first and second samples.

P probability of acceptance

a

Q quality statistic

lower quality statistic

Q

L

NOTE 4 Q is defined as ()xL−/s when the process standard deviation is unknown, and ()xL−/σ when

L

it is presumed to be known.

NOTE 5 Q is defined as ()xL−/s or ()xL−/σ; Q is defined as ()xL−/s or ()xL−/σ.

L,1 11 1 L,c cc c

upper quality statistic

Q

U

NOTE 6 Q is defined as ()Ux−/s when the process standard deviation is unknown, and ()Ux−/σ when

U

it is presumed to be known.

NOTE 7 Q is defined as ()Ux− /s or ()Ux− /σ; Q is defined as ()Ux− /s or ()Ux− /σ.

U ,1 11 1 U,c cc c

s

sample standard deviation of the measured values of the quality characteristic, also an estimate of

the process standard deviation, i.e.

⎛⎞

nn

n

⎟

⎜

2 ⎟

⎜

nx − x ⎟

()xx−

⎜

∑ ∑∑jj

j ⎟

⎜

⎟

⎜ ⎟

jj==11⎝⎠

j=1

s==

nn−−11()n

maximum allowable sample standard deviation (see 3.24)

s

max

NOTE 8 s and s represent, respectively, the maximum standard deviation for the first sample and

1,max c,max

the maximum standard deviation for the combined first and second samples (see also f ).

s

σ standard deviation of a process whose inherent variability is under statistical control

NOTE 9 σ , the square of the standard deviation, is known as the process variance.

σ maximum allowable process standard deviation (see 3.25 and also f )

max σ

U upper specification limit (as a suffix to a variable, denotes its value at U)

x measured value of the quality characteristic for the jth item of a sample

j

x arithmetic mean of the measured values of the quality characteristic in a sample, i.e.

n

x

∑ j

j=1

x=

n

NOTE 10 xx, and x represent, respectively, the mean of the first sample, the mean of the second sample

12 c

and the mean of the first and second samples combined. As the first and second sample sizes are equal, the

combined sample mean takes the simple form xx=+()x/2.

c1 2

x lower acceptance value for x

L

x upper acceptance value for x

U

4.2 Abbreviations

AQL acceptance quality limit

ASSI average sample size

LQ limiting quality

MSSD maximum sample standard deviation

MPSD maximum process standard deviation

MVUE minimum variance unbiased estimator

OC operating characteristic

8 © ISO 2007 – All rights reserved

5 Acceptance quality limit (AQL)

5.1 Concept

The AQL is the quality level that is the worst tolerable process average when a continuing series of lots is

submitted for acceptance sampling. Although individual lots with quality as bad as the acceptance quality limit

might be accepted with fairly high probability, the designation of an acceptance quality limit does not suggest

that this is a desirable quality level. The sampling schemes found in this part of ISO 3951, with their rules for

switching and for discontinuation of sampling inspection, are designed to encourage suppliers to have process

averages consistently better than the AQL, thereby protecting the consumer from the situation where the long

run process average is worse than the AQL. Otherwise, there is a high risk that the inspection severity will be

switched to tightened inspection, under which the criteria for lot acceptance become more demanding. Once

on tightened inspection, unless action is taken to improve the process, it is very likely that the rule requiring

discontinuation of sampling inspection will be invoked pending such improvement.

5.2 Use

The AQL, together with the sample size code letter, is used to index the sampling plans in this part of

ISO 3951.

5.3 Specifying AQLs

The AQL to be used will be designated in the product specification, in the contract or by the responsible

authority. In the case

a) where an upper specification limit for the quality characteristic is given, or

b) where a lower specification limit is given,

then a single AQL applies to the indicated limit.

Where both upper and lower specification limits are given for the quality characteristic, three further cases can

be identified:

c) combined control of double specification limits, where a single AQL applies to the total percentage

nonconforming beyond both limits;

d) separate control, where separate AQLs apply to the percent nonconforming beyond each limit;

e) complex control, where one AQL applies to the percent nonconforming beyond the limit that is of greater

seriousness, while a larger AQL applies to the total percent nonconforming beyond both limits.

Acceptance tests shall be carried out according to the provisions of this part of ISO 3951 for each AQL. The

lot shall only be accepted if the AQL requirement is satisfied in cases a), b) or c), or if both AQL requirements

are satisfied in cases d) or e).

5.4 Preferred AQLs

The sixteen AQLs given in this part of ISO 3951, ranging in value from 0,01 % to 10 % nonconforming, are

described as preferred AQLs. If, for any product or service, an AQL is designated other than a preferred AQL,

then this part of ISO 3951 is not applicable. (See 14.2.)

5.5 Caution

From the above description of the AQL concept, it follows that the desired protection can only be assured

when a continuing series of lots is provided for inspection.

5.6 Limitation

The designation of an AQL does not imply that the supplier has the right to knowingly supply any

nonconforming items of product.

6 Switching rules for normal, tightened and reduced inspection

Switching rules discourage the producer from operating at a quality level that is worse than the AQL. This part

of ISO 3951 prescribes a switch to tightened inspection when inspection results indicate that the process

average is not satisfactory. It further prescribes a discontinuation of sampling inspection altogether if tightened

inspection fails to stimulate the producer into rapidly improving his production process.

Tightened inspection and the discontinuation rule are integral, and therefore obligatory, procedures of this part

of ISO 3951 if the protection implied by the AQL is to be maintained.

This part of ISO 3951 also provides the possibility of switching to reduced inspection when inspection results

indicate that the quality level is stable and reliable at a level significantly better than the AQL. This practice is,

however, optional (at the discretion of the responsible authority).

When there is sufficient evidence from the control charts (see 20.1) that the variability is in statistical control,

consideration should be given to switching to the “σ” method. If this appears advantageous, the consistent

value of s (the sample standard deviation) shall be taken as σ (see 23.1).

When it has been necessary to discontinue sampling inspection, inspection should not be resumed until action

has been taken by the producer to improve the quality of the submitted product.

Details of the operation of the switching rules are given in Clauses 21, 22 and 23.

7 Relation to ISO 2859-1

7.1 Similarities to ISO 2859-1

a) The double sampling plans by variables in this part of ISO 3951 are complementary to the double

sampling plans by attributes provided in ISO 2859-1; the two documents share a common philosophy and,

as far as possible, their procedures and vocabulary are the same.

b) Both standards use the AQL to index the sampling plans and the preferred values used in this document

are identical to those given for percent nonconforming in ISO 2859-1 (i.e. from 0,01 % to 10 %).

c) In this part of ISO 3951, lot size and inspection level (inspection level II in default of other instructions)

determine a sample size code letter. Then, general tables give the sample sizes to be taken and the

acceptability criteria, indexed by the sample size code letter and the AQL. Separate tables are given for

the “s” and “σ ” methods, and for normal, tightened and reduced inspection.

d) In this part of ISO 3951, the first and second sample sizes of the double sampling plans are the same.

e) The switching rules are essentially equivalent.

f) The operating characteristic (OC) curves of the variables plans in this part of ISO 3951 are closely

matched to those of the corresponding single sampling attributes plans in ISO 2859-1 (see Annex M).

g) The classification of nonconformities by degree of seriousness into class A, class B, etc., remains

unchanged.

10 © ISO 2007 – All rights reserved

7.2 Differences from ISO 2859-1

a) Determination of acceptability. Acceptability for an ISO 2859-1 attributes double sampling plan for

percent nonconforming is determined by the numbers of nonconforming items found in the samples.

Acceptability for a plan for inspection by variables is based on the distances of the estimated process

means from the specification limit(s) in terms of the estimated or known process standard deviations or,

by implication, the estimated process fractions nonconforming. In this part of ISO 3951, two methods are

considered: the “s” method for use when the process standard deviation σ is unknown and the “σ” method

for use when σ is presumed to be known. In the case of a single specification limit, or for separate control

of double specification limits, acceptability is determined most easily by comparing quality statistics with

“Form k” acceptability constants (see 16.2, 16.3, 17.2 and 17.3). For combined or complex control of

double specification limits, acceptability is determined by comparing estimates of the process percent

nonconforming for each class of nonconformity with “Form p*” constants (see 16.4, 16.5, 17.4 and 17.5).

(Annexes A, B and C provide procedures for two or more unrelated quality characteristics.)

b) Normality. In ISO 2859-1, there is no requirement relating to the distribution of the characteristics.

However, in this part of ISO 3951, it is necessary for the efficient operation of the plans that the

measurements should be distributed according to a normal distribution (or at least a close approximation

to a normal distribution), either originally or after a known transformation.

c) Sample sizes. Unlike the sample sizes in ISO 2859-1, the sample sizes along rows of the master tables

in this part of ISO 3951 are not constant. This was necessary to obtain closely matched OC curves [see

7.1 f)].

d) Producer’s risk. For process quality precisely at the AQL, the producer’s risk (see 8.3) that a lot will not

be accepted is similar, but not identical, to the corresponding producer’s risk in ISO 2859-1 (see Annex I).

e) Average sample sizes (ASSIs). The ASSIs of double sampling schemes by variables are generally

much smaller than the ASSIs for corresponding schemes by attributes at any given process quality level

(see Annex L).

f) Multiple sampling plans. No multiple sampling plans are given in this part of ISO 3951.

g) Average outgoing quality limit (AOQL). The AOQL concept applies when 100 % inspection and

rectification is feasible for non-accepted lots. It follows that the AOQL concept cannot be applied under

destructive or expensive testing. As variables plans will generally be used under these circumstances, no

tables of AOQL have been included in this part of ISO 3951.

8 Limiting quality protection

8.1 Use of individual plans

This part of ISO 3951 is intended to be used as a system employing tightened, normal and reduced inspection

on a continuing series of lots to provide consumer protection while assuring the producer that acceptance will

be very likely to occur if quality is better than the AQL.

Sometimes specific individual plans are selected from this part of ISO 3951 and used without the switching

rules. For example, a purchaser might be using the plans for verification purposes only. This is not the

intended application of the system given in this part of ISO 3951 and its use in this way should not be referred

to as “inspection in compliance with ISO 3951-3”. When used in such a way, ISO 3951-3 simply represents a

collection of individual double sampling plans indexed by AQL. The operating characteristic curves and other

measures of a plan so chosen should be assessed individually from the tables provided.

8.2 Consumer’s risk quality tables

If the series of lots is not long enough to allow the switching rules to be applied, it might be desirable to limit

the selection of sampling plans to those, associated with a designated AQL value, that give consumer’s risk

quality not more than the specified limiting quality protection. Sampling plans for this purpose may be selected

by choosing a consumer’s risk quality (CRQ) and a consumer’s risk to be associated with it, and then referring

to the tables on Charts C to R (see Figures 2 to 15).

8.3 Producer’s risk tables

The producer’s risk is the probability of non-acceptance under either the “s” or “σ ” methods for lots produced

when the process average equals the AQL. The producer’s risks of the double sampling plans of this part of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...