ISO/TR 19716:2016

(Main)Nanotechnologies — Characterization of cellulose nanocrystals

Nanotechnologies — Characterization of cellulose nanocrystals

ISO/TR 19716:2016 reviews commonly used methods for the characterization of cellulose nanocrystals (CNCs), including sample preparation, measurement methods and data analysis. Selected measurands for characterization of CNCs for commercial production and applications are covered. These include CNC composition, morphology and surface characteristics.

Nanotechnologies — Caractérisation des nanocristaux de cellulose

General Information

- Status

- Published

- Publication Date

- 27-Apr-2016

- Technical Committee

- ISO/TC 229 - Nanotechnologies

- Drafting Committee

- ISO/TC 229 - Nanotechnologies

- Current Stage

- 6060 - International Standard published

- Start Date

- 28-Apr-2016

- Due Date

- 08-May-2016

- Completion Date

- 08-May-2016

Relations

- Consolidated By

ISO 22632:2019 - Adhesives — Test methods for adhesives for floor and wall coverings — Shear test - Effective Date

- 06-Jun-2022

Overview

ISO/TR 19716:2016 - Nanotechnologies - Characterization of cellulose nanocrystals (CNCs) is a Technical Report from ISO/TC 229 that reviews commonly used methods for CNC characterization. The report summarizes best practices for sample preparation, measurement methods and data analysis/interpretation for key measurands relevant to commercial production and application of cellulose nanocrystals. It covers CNC composition, morphology and surface characteristics but does not prescribe specific standard test methods or address post-production modifications or CNC-containing products.

Key Topics

The Technical Report provides a structured review of measurement approaches and analytical considerations for CNCs, including:

- Sample preparation and data analysis: guidance on preparing CNC suspensions and interpreting measurement results for reproducible reporting.

- Composition and chemistry:

- Chemical composition and surface functional groups (e.g., determination of sulfate half‑esters and carboxylic acids).

- Degree of polymerization, crystallinity (CrI) assessment and moisture content.

- Detection of contaminants and residual biomass-derived impurities (including metal ions).

- Analytical techniques discussed: XRD (X‑ray diffraction), ssNMR (solid‑state NMR), FTIR, ICP‑MS/OES, and titration/ion‑exchange methods.

- Morphology and sizing:

- Microscopy: TEM, SEM/FE‑SEM and AFM for length and cross‑section distributions and image analysis considerations.

- Light‑scattering: dynamic light scattering (DLS) for hydrodynamic diameter and polydispersity.

- Surface characteristics:

- Specific surface area (BET) and surface charge (electrophoretic mobility, zeta potential).

- Surface composition techniques such as XPS (X‑ray photoelectron spectroscopy).

- Miscellaneous properties:

- Thermal properties (TGA, DSC) and rheological behaviour (viscosity) relevant to processing and end‑use.

Applications

ISO/TR 19716:2016 is useful for stakeholders working with cellulose nanocrystals, including:

- Researchers and R&D teams developing CNC synthesis, characterization protocols and new CNC‑based materials.

- Manufacturers and quality control laboratories aiming to characterize production batches and ensure consistent material quality.

- Standards developers and regulatory bodies seeking an overview of measurement issues and candidate measurands for future normative standards.

- Product formulators (composites, coatings, rheology modifiers, biomedical materials, optical films) who need to understand how CNC properties influence performance.

Related Standards

- The report references ISO/TS 80004‑2 (nanotechnology - vocabulary/terminology) and notes ongoing ISO/TC 229 work on cellulose nanomaterial terminology. It also cites the existence of national guidance (e.g., CSA Z5100) and CNC reference materials released in earlier years.

Keywords: ISO/TR 19716:2016, cellulose nanocrystals, CNC characterization, nanotechnologies, crystallinity, TEM, AFM, DLS, surface charge, BET, XRD.

Frequently Asked Questions

ISO/TR 19716:2016 is a technical report published by the International Organization for Standardization (ISO). Its full title is "Nanotechnologies — Characterization of cellulose nanocrystals". This standard covers: ISO/TR 19716:2016 reviews commonly used methods for the characterization of cellulose nanocrystals (CNCs), including sample preparation, measurement methods and data analysis. Selected measurands for characterization of CNCs for commercial production and applications are covered. These include CNC composition, morphology and surface characteristics.

ISO/TR 19716:2016 reviews commonly used methods for the characterization of cellulose nanocrystals (CNCs), including sample preparation, measurement methods and data analysis. Selected measurands for characterization of CNCs for commercial production and applications are covered. These include CNC composition, morphology and surface characteristics.

ISO/TR 19716:2016 is classified under the following ICS (International Classification for Standards) categories: 07.030 - Physics. Chemistry; 07.120 - Nanotechnologies. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/TR 19716:2016 has the following relationships with other standards: It is inter standard links to ISO 22632:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO/TR 19716:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

TECHNICAL ISO/TR

REPORT 19716

First edition

2016-05-01

Nanotechnologies — Characterization

of cellulose nanocrystals

Nanotechnologies — Caractérisation des nanocristaux de cellulose

Reference number

©

ISO 2016

© ISO 2016, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – All rights reserved

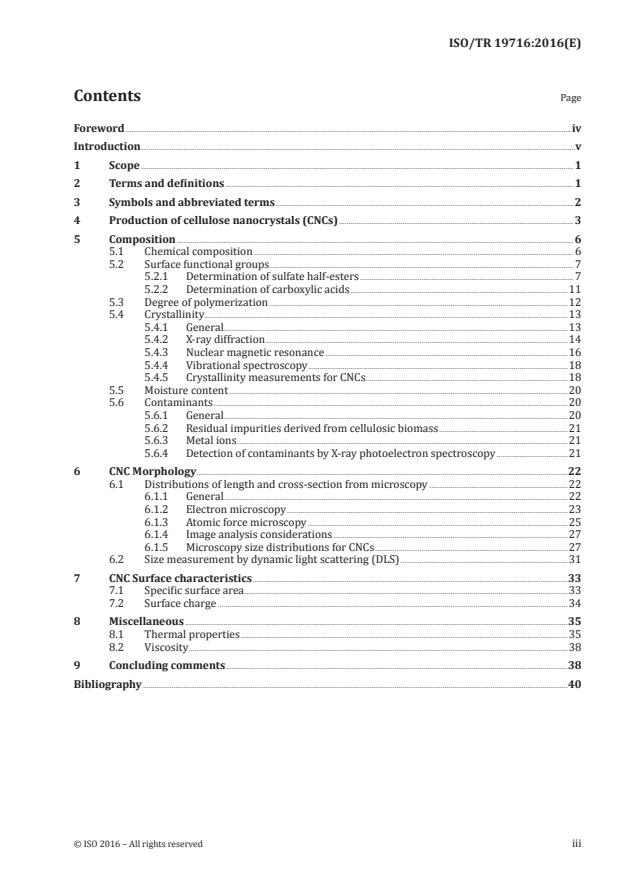

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Terms and definitions . 1

3 Symbols and abbreviated terms . 2

4 Production of cellulose nanocrystals (CNCs) . 3

5 Composition . 6

5.1 Chemical composition . 6

5.2 Surface functional groups . 7

5.2.1 Determination of sulfate half-esters . 7

5.2.2 Determination of carboxylic acids .11

5.3 Degree of polymerization .12

5.4 Crystallinity . .13

5.4.1 General.13

5.4.2 X-ray diffraction .14

5.4.3 Nuclear magnetic resonance .16

5.4.4 Vibrational spectroscopy .18

5.4.5 Crystallinity measurements for CNCs .18

5.5 Moisture content .20

5.6 Contaminants .20

5.6.1 General.20

5.6.2 Residual impurities derived from cellulosic biomass .21

5.6.3 Metal ions .21

5.6.4 Detection of contaminants by X-ray photoelectron spectroscopy .21

6 CNC Morphology .22

6.1 Distributions of length and cross-section from microscopy .22

6.1.1 General.22

6.1.2 Electron microscopy .23

6.1.3 Atomic force microscopy .25

6.1.4 Image analysis considerations .27

6.1.5 Microscopy size distributions for CNCs .27

6.2 Size measurement by dynamic light scattering (DLS) .31

7 CNC Surface characteristics .33

7.1 Specific surface area .33

7.2 Surface charge .34

8 Miscellaneous .35

8.1 Thermal properties .35

8.2 Viscosity .38

9 Concluding comments .38

Bibliography .40

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 229, Nanotechnologies.

iv © ISO 2016 – All rights reserved

Introduction

Cellulose nanomaterials, including cellulose nanocrystals (CNCs) and cellulose nanofibrils, are

anticipated to have significant commercial impact. Cellulose nanocrystals are extracted from naturally

occurring cellulose, primarily from wood and annual plants, by acid hydrolysis, or chemical or

[1][2][3]

enzymatic oxidation. Their production from cellulose sources, such as wood pulps makes them a

candidate for use as a potentially non-toxic, biodegradable and sustainable nanomaterial. Furthermore,

the recent demonstration of the feasibility of CNC production on a large scale and the availability of

infrastructure for harvesting raw materials will facilitate their commercial development. CNCs and

cellulose nanofibrils are produced in a number of countries on pilot, pre-commercial or commercial

scales. Estimates of the market potential for cellulosic nanomaterials are as high as 35 million metric

[4][5]

tons annually, depending on the predicted applications and the estimated market penetration.

Standards for characterization of CNCs are required for material certification to allow sustained

commercial development and applications.

Cellulose nanocrystals are nanorods that have high aspect ratio, surface area and mechanical strength

and assemble to give a chiral nematic phase with unique optical properties. They are smaller than

cellulose nanofibrils and have a higher crystalline content. These properties, plus the ability to control

CNC surface charge and chemistry for dispersion in a variety of matrices, lead to potential applications

in many areas including nanocomposite materials, paints and adhesives, optical films and devices,

rheology modifiers, catalysts and biomedical products. There are currently no International Standards

for this emerging commercial nanomaterial, although an ISO/TC 229 project on terminology is in

progress, a Canadian National Standard (CSA Z5100) was published in 2014 and two CNC reference

materials were released in 2013. This Technical Report reviews information on sample preparation,

data collection and data analysis/interpretation for the measurands that are predicted to be important

for the development of commercial products containing CNCs. Information for the following CNC

properties is included: composition (crystallinity, surface functional groups, degree of polymerization

and contaminants), morphology as assessed by microscopy and light scattering methods, surface

charge and specific surface area, viscosity and thermal stability. The Technical Report reviews various

approaches that have been used for specific properties, but does not recommend standard methods or

provide detailed information on the techniques. The coverage is restricted to CNCs as produced and

does not extend to post-production modified CNCs or CNC-enhanced materials or products.

TECHNICAL REPORT ISO/TR 19716:2016(E)

Nanotechnologies — Characterization of cellulose

nanocrystals

1 Scope

This Technical Report reviews commonly used methods for the characterization of cellulose

nanocrystals (CNCs), including sample preparation, measurement methods and data analysis. Selected

measurands for characterization of CNCs for commercial production and applications are covered.

These include CNC composition, morphology and surface characteristics.

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.1

agglomerate

collection of weakly or medium strongly bound particles where the resulting external surface area is

similar to the sum of the surface areas of the individual components

Note 1 to entry: The forces holding an agglomerate together are weak forces, for example, van der Waals forces or

simple physical entanglement.

Note 2 to entry: Agglomerates are also termed secondary particles and the original source particles are termed

primary particles.

[SOURCE: ISO/TS 80004-2:2015, 3.3]

2.2

aggregate

particle comprising strongly bonded or fused particles where the resulting external surface area is

significantly smaller than the sum of surface areas of the individual components

Note 1 to entry: The forces holding an aggregate together are strong forces, for example, covalent bonds, or those

resulting from sintering or complex physical entanglement, or otherwise combined former primary particles.

Note 2 to entry: Aggregates are also termed secondary particles and the original source particles are termed

primary particles.

[SOURCE: ISO/TS 80004-2:2015, 3.4]

2.3

nanocrystal

nano-object with a crystalline structure

[SOURCE: ISO/TS 80004-2:2015, 4.15]

2.4

nanofibre

nano-object with two external dimensions in the nanoscale and the third dimension significantly larger

Note 1 to entry: The largest external dimension is not necessarily in the nanoscale.

Note 2 to entry: The terms nanofibril and nanofilament can also be used.

2.5

nano-object

discrete piece of material with one, two or three external dimensions in the nanoscale

Note 1 to entry: The second and third external dimensions are orthogonal to the first dimension and to each other.

[SOURCE: ISO/TS 80004-2:2015, 2.2]

2.6

nanorod

solid nanofibre

[SOURCE: ISO/TS 80004-2:2015, 4.7]

2.7

nanoscale

size range from approximately 1 nm to 100 nm

Note 1 to entry: Properties that are not extrapolations from a larger size will typically, but not exclusively, be

exhibited in this size range. For such properties the size limits are considered approximate.

Note 2 to entry: The lower limit in this definition (approximately 1 nm) is introduced to avoid single and small

groups of atoms from being designated as nano-objects or elements of nanostructures, which might be implied

by the absence of a lower limit.

[SOURCE: ISO/TS 80004-2:2015, 2.1]

3 Symbols and abbreviated terms

For the purposes of this document, the following symbols and abbreviated terms apply.

AEC anion-exchange chromatography

AFM atomic force microscopy

BET Brunauer-Emmett-Teller (method for determination of specific surface area)

CrI crystallinity index (also CI)

CNC(s) cellulose nanocrystal(s)

CP-MAS cross polarization magic angle spinning

d hydrodynamic diameter

h

DP degree of polymerization

D translational diffusion coefficient

t

DSC differential scanning calorimetry

DLS dynamic light scattering

ε dielectric constant

EM electron microscopy

FE-SEM field emission-scanning electron microscopy

FTIR Fourier transform infrared spectroscopy

2 © ISO 2016 – All rights reserved

GLC gas-liquid chromatography

ICP-MS inductively coupled plasma-mass spectrometry

ICP-OES inductively coupled plasma-optical emission spectroscopy

ID isotope dilution

IR infrared

k Boltzmann constant

PI polydispersity

ssNMR solid state nuclear magnetic resonance

SEC size exclusion chromatography

SEM scanning electron microscopy

TEM transmission electron microscopy

TEMPO 2,2,6,6-tetramethyl-1-piperidinyloxy free radical

TGA thermogravimetric analysis

U electrophoretic mobility

E

η viscosity

XPS X-ray photoelectron spectroscopy

XRD X-ray diffraction

4 Production of cellulose nanocrystals (CNCs)

Cellulose is a linear polysaccharide composed of anhydroglucose units linked by an oxygen atom between

the C1 and C4 carbons of adjacent glucose rings. In cellulose biosynthesis individual, polysaccharide

chains are assembled by an enzyme complex into an elementary fibril with stacked chains held together

by hydrogen bonding. The number and organization of polymer chains is specific to the organism. These

elementary fibrils are further assembled to give larger structures that contain ordered (crystalline), as

well as disordered cellulose and other components that depend on the organism.

Cellulose nanocrystals are formed from one or more elementary fibrils and contain primarily

crystalline and paracrystalline regions. CNCs have length and cross-sectional dimensions that depend

on the cellulose source with typical aspect ratios between 5 and 50 and do not exhibit branching or

network-like structures. The term nanocrystalline cellulose is synonomous with CNCs and the term

nanowhiskers has also been used frequently in the literature. Cellulose nanofibrils are typically larger

than CNCs and are branched, entangled and agglomerated structures. The nanofibrils have crystalline,

paracrystalline and amorphous regions and can contain non-cellulosic components. They have cross-

[6]

sections between 5 nm and 50 nm and aspect ratios that are greater than 50. An ISO/TC 229 project

aimed at standardizing the terminology for cellulose nanomaterials has recently been initiated.

Cellulose nanocrystals are produced from a variety of cellulose sources, primarily wood and other

[2][3][7][8][9][10][11][12][13]

plants, but also algae, bacteria and tunicates. Their extraction from cellulose-

containing biomass begins with mechanical and/or chemical pre-treatment to remove non-cellulose

components, reduce the particle size and increase the exposed surface area. This is followed by a

hydrolysis or oxidation step that digests the more reactive amorphous cellulose and liberates CNCs from

the larger cellulose fibrils (Figure 1). Acid hydrolysis with sulfuric acid is the most widely used method

for CNC production in both research laboratories and pilot scale commercial facilities, although other

[2][3][7][8][9][14][15]

acids (e.g. hydrochloric, phosphoric, phosphotungstic) have also been employed. In

attempts to minimize the use of strong acids, a variety of other processes have also been examined

including ultrasonication-assisted hydrolysis (with or without an iron chloride catalyst), enzymatic

[16][17][18]

oxidation and ammonium persulfate oxidation. After the acid hydrolysis or oxidation step,

CNCs are purified by a combination of centrifugation or filtration and washing steps, followed by

dialysis to remove residual salt and/or acids. A typical sequence for CNC production by acid hydrolysis

is illustrated in Figure 2.

Key

1 micro-fibril

2 disordered

3 crystalline

4 elementary fibrils

5 hydrolysis or oxidation

6 cellulose

7 cellulose fibril

8 cellulose nanocrystals

Figure 1 — Cartoon description of the formation of CNCs from larger cellulose fibrils

4 © ISO 2016 – All rights reserved

—

—

—

—

—

—

—

,

—

—

—

—

Figure 2 — Overview of a typical process for production of CNCs by acid hydrolysis

CNCs produced by sulfuric acid hydrolysis have negatively-charged sulfate half-esters on their surface

which result in stable aqueous colloidal suspensions. Negatively charged CNCs are also formed by

phosphoric acid hydrolysis, whereas hydrochloric acid gives uncharged CNCs with only surface

hydroxyl groups. Oxidation catalysed by TEMPO (2,2,6,6-tetramethyl-1-piperidinyloxy free radical)

can be used to convert surface hydroxyls to carboxylic acids for CNCs generated using either sulfuric or

[19][20] [16]

hydrochloric acid. Oxidation with ammonium persulfate also generates carboxylated CNCs.

The CNC dimensions vary with the source of the cellulose; CNCs derived from wood pulps typically have

average lengths of 100 nm to 200 nm and cross-sections of 4 nm to 9 nm, whereas those from bacterial

and tunicate sources can be considerably larger, with lengths of 1 μm to 2 μm and cross-sections up to

50 nm (as reviewed in Reference [2]). The preparation method, acid or oxidant concentration, reaction

time and temperature, and sonication steps during purification also affect the CNC dimensions and the

[21][22][23][24][25][26][27]

overall yield and kinetics.

The acidic CNC suspensions produced by acid hydrolysis can be used in never-dried form. However,

in most cases the proton can be replaced by other cations by neutralizing the CNC suspension with

aqueous bases, such as hydroxides (XOH) or carbonates (X CO ), to give a salt form of the CNCs (X-CNC,

2 3

where X is the counterion associated with the anionic group). The pH-neutral sodium form, Na-CNC,

is most typically produced commercially and at large scale by in-line neutralization of H-CNCs with

sodium hydroxide (NaOH) or sodium carbonate (Na CO ). Advantages, such as the water-dispersability

2 3

[28]

of the dried product, allowing spray-dried or freeze-dried CNCs to be stored and shipped in the dry

form at significantly lower cost and then re-suspended at the point of use, account for this preference.

Proton counterions are most often exchanged for others by neutralization of the acidic groups with

[29]

aqueous hydroxide bases, but this can also be accomplished by treatment with the appropriate ion-

[30]

exchange resin.

Dry CNC samples are prepared from the initial aqueous suspensions by evaporation, oven-drying, freeze-

drying (lyophilization), or spray-drying. Some characterization methods require dry samples, whereas

others employ a dilute suspension of CNCs. If the CNCs are already available as an aqueous suspension,

the sample can be diluted to the required concentration using deionized water or dilute buffer or salt

(NaCl) solution. Dry samples can be redispersed in pure water; general guidelines for dispersion of

[31]

powders in liquids can be found in ISO 14887 . Although an ultrasonic treatment step is typically used

to break up aggregates and agglomerates, a lack of reproducibility might contribute to variability of

results, as summarized in a recent study aimed at standardizing procedures for ultrasonic dispersion of

[32]

nanoparticles. It is not trivial to obtain redispersed samples of CNCs that have size distributions and

levels of aggregates or agglomerates that are similar to those of a purified, but never-dried, sample. An

early study showed that films of CNCs with fully protonated sulfate half-esters could not be redispersed

after drying, whereas CNCs with monovalent cations, such as sodium were redispersed with mild

[29]

ultrasonic treatment to give stable colloidal suspensions that were similar to those prior to drying.

Detailed procedures for the redispersion of the neutral sodium-form of CNCs prepared by evaporation,

[28]

lyophilization or spray-drying have been reported. The counterion and moisture content of the dry

CNCs and the sonication conditions (energy, CNC concentration) were all shown to affect the CNC (re)

dispersibility. While the sodium-form CNCs were fully dispersible when completely dried, the protonated

CNCs were only fully dispersible above a threshold water content of 4 wt %.

In this Technical Report, emphasis is placed on CNCs manufactured using sulfuric acid, with sulfate

half-ester groups on the cellulose surface (cellulose sulfate); unless otherwise noted, all examples are

for this form of CNCs. This reflects the emphasis on this material, in both commercial and research

laboratories. Most of the characterization methods are also applicable, in some cases with appropriate

adjustments, to other chemical forms of CNCs or cellulose nanofibres. For example, the detection and

quantification of surface functional groups is specific to the specific CNC production method. The

nature of the CNC counterion is important for some measurands, notably determination of the surface

charge due to sulfate half-ester or carboxylate groups by conductometric titration (see 5.2.1 and 5.2.2)

and zeta potential (see 7.2). Unless otherwise mentioned, the particular counterion in the CNC sample

does not affect the characterization methods discussed in this Technical Report.

Cellulose nanocrystals have specific physico-chemical properties associated with both the underlying

cellulose particle and the surface chemistry imposed by its manufacturing process. At the point of

commercialization, it is necessary to clarify the several descriptive systems that have been used in this

field: the geometric forms in nanotechnology, the industrial production method, and the chemical form

used in national regulations. All three are found in the recent approval under Canada’s New Substances

[33]

Notification Regulations as it provides the following:

a) chemical description (cellulose, hydrogen sulfate, sodium salt with a total sulfur content greater

than or equal to 0,5 % and less than or equal to 1,0 % by weight);

b) production method description (obtained from sulfuric acid hydrolysis of bleached pulp);

c) geometric description of length (nominal length of 100 nm ± 50 nm) and cross-section (cross-

sectional dimensions of less than or equal to 10 nm). As suggested in ISO 12805, composition,

length, diameter and surface area are the critical parameters to be considered first in setting

[34]

specifications.

5 Composition

5.1 Chemical composition

The chemical identity of CNCs as cellulose can be assessed by a qualitative identification test employed

for microcrystalline cellulose; dispersion of dry CNCs in iodinated zinc chloride will result in a violet-

[35]

blue colour. Their composition can also be verified by elemental analysis, based on the formula

[(C H O ) ] and taking into account surface functional groups if their degree of substitution is known.

6 10 5 n

6 © ISO 2016 – All rights reserved

Although elemental analysis provides some information on surface functionality (e.g. % S for sulfate

half-esters), more detailed tests are typically used to quantify surface functional groups (see 5.2). The

identity of inorganic metal counterions for CNCs with anionic surface groups can be determined by

inductively coupled plasma-optical emission spectroscopy (ICP-OES) using the procedure outlined

in 5.4.1 for sulfur. The density of CNCs has usually been assumed to be the same as other types of

[2] 3 3

cellulose, as confirmed by a recent determination of 1,56 g/cm and 1,63 g/cm for the densities of

[36]

sulfated and unsulfated CNCs.

5.2 Surface functional groups

5.2.1 Determination of sulfate half-esters

CNCs extracted by sulfuric acid hydrolysis have sulfate half-ester groups on their surface. The

concentration of these negatively charged groups determines the CNC surface charge density and

controls the colloidal stability of CNCs in aqueous suspension, along with the self-assembly behaviour

and rheological properties. Two approaches have been used to determine the sulfate half-ester content.

[26][27]

The first relies on measurement of total sulfur content by elemental analysis. In cases where

the sample has been purified to ensure removal of all residual unbound sulfate ions, the total sulfur

[37]

content can be converted directly to the CNC sulfate half-ester content. The second approach uses

conductometric titration of the acidic sulfate half-ester groups on the CNC surface using an aqueous

base. Both methods are described in this Clause, followed by a comparison of results for various CNCs.

Measurement of the total sulfur content can be accomplished by elemental analysis or by ICP-OES using

a spectrometer equipped with a concentric nebulizer, a cyclonic spray chamber and a quartz torch

with a quartz injector tube, optimized according to the manufacturer’s specifications. The sample is

completely solubilized by microwave assisted sample digestion using high purity nitric and hydrochloric

acids in high pressure closed vessels or, by wet ashing with strong acids, such as nitric and perchloric.

[38]

A block digestion system can be used to evaporate excess acids after the initial digestion. Analyses

are conducted by ICP-OES using the sulfur emission lines at 180,669 nm and 181,972 nm. Calibration is

accomplished by the method of additions (to compensate for any residual matrix interferences) in which

incremental spikes of sulfur as sulfate are prepared from a standard sulfur solution (e.g. a primary

standard, such as NIST SRM 3154). Samples can be diluted to ensure linearity of response. Samples are

gravimetrically spiked with at least two incremental levels of appropriate amounts of known calibration

standard. The levels should be chosen such that the spike results in a one to twofold increase in the total

sulfur concentration in the sample with each spike and the analytical response is linear. The calculation

of the concentration of sulfur requires a three point (minimum) standard additions calibration. Since the

slope of the standard additions calibration function for the sample and blank are likely not equivalent,

separate calibrations for C and C should be performed. Note that although total sulfur content can

s blk

also be obtained by inductively coupled plasma mass spectrometry (ICP-MS, see 5.6.3) ICP-OES is the

more reliable and straightforward method unless the sulfur concentration is very low.

The sulfate half-ester content can be determined by conductometric titration of the acidic sulfate half-

[30][39]

ester groups on the CNC surface using an aqueous base, such as sodium hydroxide. This is the

[40]

most commonly used method for this purpose. The sample should first be purified by extensive

dialysis to remove any residual ions and then treated with H-form strong acid cation-exchange resin to

ensure fully protonated sulfate half-esters. Commonly, CNC samples are diluted or re-dispersed with

deionized water (typically to ≤1,5 wt %) and dialyzed against pure water until the pH and conductivity

of the water surrounding the membranes no longer changes and approaches that of pure water. Hollow-

fibre membrane dialysis systems can also be used, they reduce dialysis time by drastically increasing

the exchange surface area and maintaining a large concentration gradient via counter-current sample

and dialysate flow. Prior to CNC protonation, the H-form strong acid cation-exchange resin should

be rinsed with a large excess of pure water until the filtrate is colourless and identical in pH and

conductivity to the wash water. A large excess of resin should be added to dialyzed CNC suspension

at a sufficiently low CNC concentration to ensure no coagulation, and the sample shaken to ensure

uniform mixing. The resin is then removed by filtration. Multiple successive treatments with fresh

resin might be required to achieve full protonation, particularly if the CNCs are in neutral salt form.

Alternatively, passing the diluted suspension through a column filled with such resin results in faster

[37]

treatment. Such treatment ensures complete protonation of a pure CNC suspension containing

no residual dissolved ions, yielding a 1:1 ratio of sulfate half-esters to protons and ensuring accurate

titration results. The concentration of the final protonated CNC sample is determined gravimetrically,

a sample of known volume is weighed and placed in a beaker with a dilute salt (NaCl) solution and

[30]

titrated against dilute sodium hydroxide using titration conditions optimized from the literature.

[41]

The sample conductivity is measured once the sample has equilibrated after the addition of each

aliquot of NaOH. Equivalence points are determined from the intersection of the regression lines fit to

the data points in the distinct regions of the titration curve (Figure 3).

8 © ISO 2016 – All rights reserved

a) H-CNCs containing strong acid sulfate half-ester groups and a small quantity of weak acid

carboxylic acid groups

b) TEMPO-oxidized CNCs generated with two different concentrations of oxidant

Key

X volume NaOH added (ml)

Y conductivity (μS/cm)

X′ volume NaOH (ml)

Y′ conductivity (mS/cm)

[37][42]

SOURCE Beck et al. 2014 and Habibi et al. 2006.

Figure 3 — Schematic illustration of conductometric titration curves

When interpreting conductometric titration data, it is important not to confuse the protons that are

actually detected (by neutralization with sodium hydroxide) with the sulfate half-ester content that is

calculated from the titration results. The calculations are based on the assumption that the protons in

the sample are in a 1:1 ratio with the sulfate half-ester groups. Despite this caveat, the titration method

does not require specialized and expensive equipment, and can be very useful for quality control during

CNC production.

Typical sulfate half-ester and sulfur content values for wood-based and other CNCs measured by

titration and elemental analysis are shown in Table 1. The differences between values obtained by

these two approaches have been discussed in the literature for CNCs of varying degrees of protonation.

[30][37][39][43][44] [40]

Titration values are often lower than those found by elemental analysis; this is

primarily due to insufficient sample preparation of the CNCs analysed by titration, notably failure to

ensure that the CNCs are fully protonated following purification by dialysis. Sodium-form CNCs are an

extreme example for which the sulfate half-ester content would not be measurable by conductometric

titration but would be by elemental analysis, such as ICP-OES. Treatment with mixed bed ion-exchange

resin (which contains hydroxide form anion exchange resin) has also been found to remove elemental

sulfur from CNC samples, and as such it is recommended to completely avoid the use of mixed bed ion-

[37]

exchange in CNC suspension purification; only dialysis should be used. Alternatively, the presence of

contamination in the form of sulfur-containing species, such as sulfate ions will yield erroneously high

elemental analysis (and conductometric titration, if they are protonated) results. This illustrates the

importance of dialysis for CNC suspension purification.

Differences between sulfate half-ester/sulfur contents measured by titration and elemental analysis

methods, respectively, might also be caused by the presence of sulfate half-ester groups that are

[39]

inaccessible to titrant or other forms of sulfur, introduced during biosynthesis of the source

[45]

cellulose. Owing to these discrepancies, if elemental analysis is used to estimate CNC surface charge

from sulfate half-esters, it is recommended to perform concurrent elemental analysis of the cellulose

source of the CNCs being studied to obtain an estimate of sulfur. It is important to understand that total

sulfur (measured by elemental analysis methods, such as ICP), titratable sulfur (protonated sulfate

half-ester groups that are accessible to titrant), sulfate half-ester content contributing to surface charge

(all surface sulfate half-ester groups) and total sulfate half-ester content (sulfate half-ester groups that

are titrant-accessible and -inaccessible, if any) are not necessarily equivalent values. However, a recent

study has shown that total sulfur and titratable sulfur are equivalent for softwood kraft pulp-derived

[37]

CNCs, indicating that all sulfate half-esters are at the surface. In general, elemental analysis of the

source cellulose and CNCs combined with conductometric titration of protonated CNCs will give the

most complete picture. Elemental analysis of CNCs extracted from the same source by HCl hydrolysis

might also be helpful in determining the “base sulfur content” of the CNCs. The above recommendations

are particularly important if knowledge of the precise quantitative surface charge or sulfur content

is required. Sulfur contents determined by the different methods typically vary by no more than

around 0,1 wt %, provided the CNCs contain no sulfur-containing impurities and are fully protonated if

[37]

required.

An additional complication in assessing sulfate half-ester content arises for samples that have

been extracted by sulfuric acid hydrolysis and then subjected to TEMPO-catalysed oxidation to

generate surface carboxylic acids. It is difficult to measure sulfate half-ester (strong acid) content by

conductometric titration if significant levels of weakly acidic carboxylic acids are present, but sulfate

half-esters can be determined in the presence of low quantities of carboxylic acid groups as shown in

[39][43]

Figure 3 a) for a non-oxidized CNC sample with a small number of weak carboxylic acid groups.

Finally, the surface sulfur content has also been measured by X-ray photoelectron spectroscopy (XPS).

[20][40][46][47][48][49]

Values typically range between 0,3 to 0,6 atomic % S, although in a few cases the

sulfur content was reported to be too low to be detected. In several examples, the surface sulfur content

has been compared to conductometric titration results for CNCs with sulfur content similar to the data in

[20][40][48]

Table 1. In one study, both methods showed lower sulfur content for desulfated CNCs than for the

[40]

initial CNCs obtained by sulfuric acid hydrolysis. However, quantitative agreement was poor, with the

sulfur content showing a sixfold change by titration but only a twofold change by XPS. Although the film

thickness was not reported, one should in principle obtain the same sulfur content for the two methods

when films of a single monolayer of CNCs are measured by XPS, since the depth penetration of ~10 nm is

greater than the particle cross-section (see 5.6.4 for more details on XPS measurements of CNCs).

10 © ISO 2016 – All rights reserved

Table 1 — Sulfate half-ester and sulfur contents (in mmol/kg CNC) for various CNC samples

Elemental

Titration

analysis

Cellulose source (standard Pre-treatment Reference

(standard

a

deviation)

a

deviation)

Dialysis, mixed bed

b

Cotton 205 (10) 220 (20) [44]

ion-exchange resin

Softwood (bleached kraft

c

84 240 Dialysis [39]

pulp)

Bacteria (Nata de coco) 5 — Dialysis [19]

Dialysis, mixed bed

Hardwood (eucalyptus) 250 — [21]

ion-exchange resin

Softwood (bleached sulfite Dialysis, mixed bed

290 (35) — [21]

pulp) ion-exchange resin

Softwood (dissolving-grade

d

293 0,57 atom % Dialysis [40]

sulfite pulp)

Dialysis, strong acid

e

Cotton 221 (6) 193 [30]

cation-exchange resin

Dialysis, mixed bed

e

Cotton 181 (6) 193 [30]

ion-exchange resin

Softwood (bleached kraft Dialysis, strong acid

f

225 (15) 225 (15) [37]

pulp) cation-exchange resin

a

Standard deviation is listed when it was provided in the literature reference.

b

Elemental analysis technique not specified.

c

Elemental analysis by X-ray fluorescence analysis.

d

Elemental analysis by XPS (based on C, O and S content).

e

Elemental analysis by quantitative conversion of sulfur to SO by combustion. The analyser uses IR or thermal

conductivity to detect sulfur in the combustion gases.

f

Elemental analysis by ICP-OES (total sulfur).

5.2.2 Determination of carboxylic acids

The carboxylate content of oxidized CNCs can be determined by conductometric titration with

sodium hydroxide using a similar approach to that described in 5.2.1. Typically, a known amount of

a strong acid, such as hydrochloric acid (HCl) is added prior to titration, ensuring full protonation of

[41][50][51]

the weak carboxylic acid groups. The carboxylate content is determined by extrapolating

and intersecting the three linear portions of the curve (strong acid, weak acid, excess titrant) to give

the two equivalence points (strong acid and total acid). Subtracting the strong acid content from the

total acid content gives the weak acid (carboxylate) content [Figure 3 b)]. As described in 5.4.1, the

presence of strong acid sulfate half-ester groups hinders the determination of carboxylic acid content

by conductometric titration in sulfated CNCs that have been highly oxidized (e.g. by TEMPO-mediated

oxidation).

Determination of surface carboxylic acids by conductometric titration has typically been reported as

[51]

degree of oxidation, which is defined as the mass fraction of carboxyl groups in the CNC sample. In

several cases, the degree of oxidation has been measured as a function of the oxidant/cellulose ratio

for TEMPO-catalysed oxidation; a plateau value is obtained that is hypothesized to represent complete

[19][42]

conversion of accessible surface hydroxyl groups to carboxylic acids. Reported degrees of

[16][42][50][52]

oxidation between 0,1 and 0,2 are typical; in two cases the degree of oxidation corresponds

[19][50]

to ~900 mmol/kg, which is considerably higher than the typical values of 200 mmol/kg for

sulfate half-esters (Table 1). Note that complete oxidation of surface hydroxyl groups will give different

degrees of oxidation for CNC particles with different surface area/mass ratios. In cases where the

fraction of surface, cellulose chains has been estimated based on the unit cell parameters for individual

[42][52]

crystallites, the predicted degree of oxidation is similar to that obtained experimentally.

Carboxylic acid groups have also been quantified by Fourier transform infrared spectroscopy (FTIR)

−1 [20]

using the strong absorption band due to the carbonyl stretch of the carboxylic acid at 1 634 cm .

[42][51][52] −1

The degree of oxidation is calculated as the ratio of the intensity of the 1 634 cm band to

−1

that of strongest cellulose backbone band at 1 050 cm . Note that use of the carbonyl stretch of the

−1

carboxylate anion at 1 608 cm should be avoided due to interference from adsorbed water in this

[51]

region. In several cases, the FTIR method was shown to be in reasonable agreement with the results

[20][42][52]

from conductometric titration, although it has been

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...