ISO 22900-2:2009

(Main)Road vehicles — Modular vehicle communication interface (MVCI) — Part 2: Diagnostic protocol data unit application programming interface (D-PDU API)

Road vehicles — Modular vehicle communication interface (MVCI) — Part 2: Diagnostic protocol data unit application programming interface (D-PDU API)

ISO 22900-2:2009 specifies the diagnostic protocol data unit application programming interface (D-PDU API) as a modular vehicle communication interface (MVCI) protocol module software interface and common basis for diagnostic and reprogramming software applications. ISO 22900-2:2009 covers the descriptions of the application programming interface (API) functions and the abstraction of diagnostic protocols, as well as the handling and description of MVCI protocol module features. Sample MVCI module description files accompany ISO 22900-2:2009. Migration from and to the existing standards SAE J2534-1 and RP1210a is addressed. ISO 22900-2:2009 contains a description of how to convert between the APIs. Corresponding wrapper APIs accompany ISO 22900-2:2009. The purpose of ISO 22900-2:2009 is to ensure that diagnostic and reprogramming applications from any vehicle or tool manufacturer can operate on a common software interface, and can easily exchange MVCI protocol module implementations.

Véhicules routiers — Interface de communication modulaire du véhicule (MVCI) — Partie 2: Interface de programmation d'application d'unité de données du protocole de diagnostic (D-PDU API)

General Information

- Status

- Withdrawn

- Publication Date

- 26-Jan-2009

- Withdrawal Date

- 26-Jan-2009

- Technical Committee

- ISO/TC 22/SC 31 - Data communication

- Drafting Committee

- ISO/TC 22/SC 31/WG 5 - Test equipment/Data eXchange Formats

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 25-Jul-2017

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 21-Jul-2012

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

AIAG (Automotive Industry Action Group)

American automotive industry standards and training.

Sponsored listings

Frequently Asked Questions

ISO 22900-2:2009 is a standard published by the International Organization for Standardization (ISO). Its full title is "Road vehicles — Modular vehicle communication interface (MVCI) — Part 2: Diagnostic protocol data unit application programming interface (D-PDU API)". This standard covers: ISO 22900-2:2009 specifies the diagnostic protocol data unit application programming interface (D-PDU API) as a modular vehicle communication interface (MVCI) protocol module software interface and common basis for diagnostic and reprogramming software applications. ISO 22900-2:2009 covers the descriptions of the application programming interface (API) functions and the abstraction of diagnostic protocols, as well as the handling and description of MVCI protocol module features. Sample MVCI module description files accompany ISO 22900-2:2009. Migration from and to the existing standards SAE J2534-1 and RP1210a is addressed. ISO 22900-2:2009 contains a description of how to convert between the APIs. Corresponding wrapper APIs accompany ISO 22900-2:2009. The purpose of ISO 22900-2:2009 is to ensure that diagnostic and reprogramming applications from any vehicle or tool manufacturer can operate on a common software interface, and can easily exchange MVCI protocol module implementations.

ISO 22900-2:2009 specifies the diagnostic protocol data unit application programming interface (D-PDU API) as a modular vehicle communication interface (MVCI) protocol module software interface and common basis for diagnostic and reprogramming software applications. ISO 22900-2:2009 covers the descriptions of the application programming interface (API) functions and the abstraction of diagnostic protocols, as well as the handling and description of MVCI protocol module features. Sample MVCI module description files accompany ISO 22900-2:2009. Migration from and to the existing standards SAE J2534-1 and RP1210a is addressed. ISO 22900-2:2009 contains a description of how to convert between the APIs. Corresponding wrapper APIs accompany ISO 22900-2:2009. The purpose of ISO 22900-2:2009 is to ensure that diagnostic and reprogramming applications from any vehicle or tool manufacturer can operate on a common software interface, and can easily exchange MVCI protocol module implementations.

ISO 22900-2:2009 is classified under the following ICS (International Classification for Standards) categories: 43.040.15 - Car informatics. On board computer systems. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 22900-2:2009 has the following relationships with other standards: It is inter standard links to ISO 22900-2:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 22900-2:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 22900-2

First edition

2009-02-01

Road vehicles — Modular vehicle

communication interface (MVCI) —

Part 2:

Diagnostic protocol data unit application

programming interface (D-PDU API)

Véhicules routiers — Interface de communication modulaire du véhicule

(MVCI) —

Partie 2: Interface de programmation d'application d'unité de données

du protocole de diagnostic (D-PDU API)

Reference number

©

ISO 2009

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2009

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2009 – All rights reserved

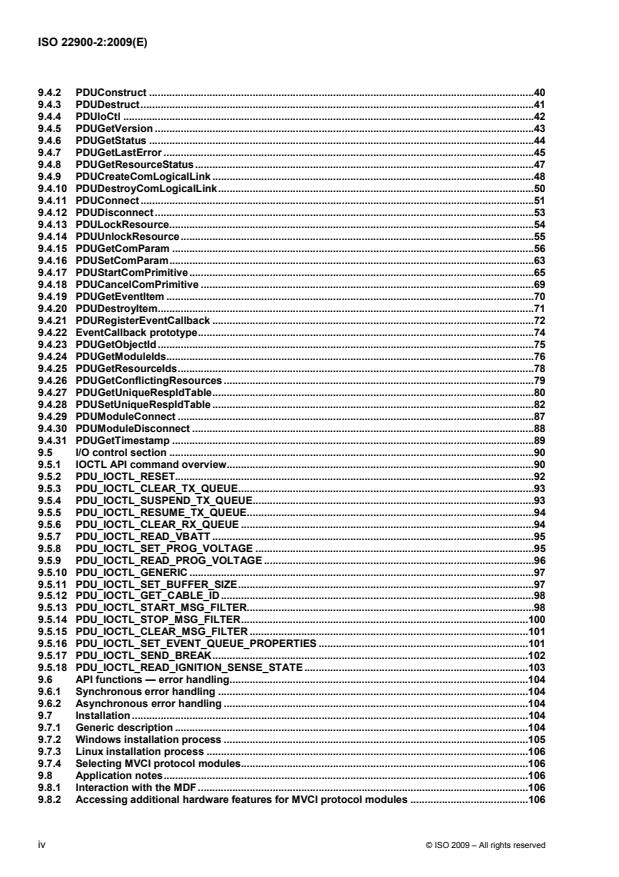

Contents Page

Foreword .vi

Introduction.vii

1 Scope.1

2 Normative references.1

3 Terms and definitions .2

4 Symbols and abbreviated terms .2

5 Specification release version information.4

5.1 Specification release version location .4

5.2 Specification release version.4

6 Modular VCI use cases .4

6.1 OEM merger .4

6.2 OEM cross vehicle platform ECU(s) .4

6.3 Central source diagnostic data and exchange during ECU development .5

6.4 OEM franchised dealer and aftermarket service outlet diagnostic tool support.5

7 Modular VCI software architecture .5

7.1 Overview.5

7.2 Modular VCI D-Server software.6

7.3 Runtime format based on ODX .7

7.4 MVCI protocol module software .7

7.5 MVCI protocol module configurations .7

8 D-PDU API use cases.8

8.1 Overview.8

8.2 Use case 1: Single MVCI protocol module.8

8.3 Use case 2: Multiple MVCI protocol modules supported by same D-PDU API

implementation .9

8.4 Use case 3: Multiple MVCI protocol modules supported by different D-PDU API

implementations .10

9 Diagnostic protocol data unit (D-PDU) API.11

9.1 Software requirements.11

9.1.1 General requirements .11

9.1.2 Vehicle protocol requirements.12

9.1.3 Timing requirements for protocol handler messages .12

9.1.4 Serialization requirements for protocol handler messages.14

9.1.5 Compatibility requirements.15

9.1.6 Timestamp requirements.16

9.2 API function overview and communication principles.17

9.2.1 Terms used within the D-PDU API .17

9.2.2 Function overview.17

9.2.3 General usage.19

9.2.4 Asynchronous and synchronous communication .21

9.2.5 Usage of resource locking and resource unlocking.22

9.2.6 Usage of ComPrimitives .22

9.3 Tool integration .38

9.3.1 Requirement for generic configuration.38

9.3.2 Tool integrator – use case.38

9.4 API functions – interface description.40

9.4.1 Overview.40

9.4.2 PDUConstruct .40

9.4.3 PDUDestruct.41

9.4.4 PDUIoCtl .42

9.4.5 PDUGetVersion .43

9.4.6 PDUGetStatus .44

9.4.7 PDUGetLastError .45

9.4.8 PDUGetResourceStatus.47

9.4.9 PDUCreateComLogicalLink .48

9.4.10 PDUDestroyComLogicalLink.50

9.4.11 PDUConnect.51

9.4.12 PDUDisconnect.53

9.4.13 PDULockResource.54

9.4.14 PDUUnlockResource.55

9.4.15 PDUGetComParam .56

9.4.16 PDUSetComParam.63

9.4.17 PDUStartComPrimitive.65

9.4.18 PDUCancelComPrimitive .69

9.4.19 PDUGetEventItem .70

9.4.20 PDUDestroyItem.71

9.4.21 PDURegisterEventCallback .72

9.4.22 EventCallback prototype.74

9.4.23 PDUGetObjectId.75

9.4.24 PDUGetModuleIds.76

9.4.25 PDUGetResourceIds.78

9.4.26 PDUGetConflictingResources .79

9.4.27 PDUGetUniqueRespIdTable.80

9.4.28 PDUSetUniqueRespIdTable .82

9.4.29 PDUModuleConnect .87

9.4.30 PDUModuleDisconnect .88

9.4.31 PDUGetTimestamp .89

9.5 I/O control section .90

9.5.1 IOCTL API command overview.90

9.5.2 PDU_IOCTL_RESET.92

9.5.3 PDU_IOCTL_CLEAR_TX_QUEUE.93

9.5.4 PDU_IOCTL_SUSPEND_TX_QUEUE.93

9.5.5 PDU_IOCTL_RESUME_TX_QUEUE.94

9.5.6 PDU_IOCTL_CLEAR_RX_QUEUE .94

9.5.7 PDU_IOCTL_READ_VBATT .95

9.5.8 PDU_IOCTL_SET_PROG_VOLTAGE .95

9.5.9 PDU_IOCTL_READ_PROG_VOLTAGE .96

9.5.10 PDU_IOCTL_GENERIC .97

9.5.11 PDU_IOCTL_SET_BUFFER_SIZE.97

9.5.12 PDU_IOCTL_GET_CABLE_ID .98

9.5.13 PDU_IOCTL_START_MSG_FILTER.98

9.5.14 PDU_IOCTL_STOP_MSG_FILTER.100

9.5.15 PDU_IOCTL_CLEAR_MSG_FILTER .101

9.5.16 PDU_IOCTL_SET_EVENT_QUEUE_PROPERTIES .101

9.5.17 PDU_IOCTL_SEND_BREAK.102

9.5.18 PDU_IOCTL_READ_IGNITION_SENSE_STATE .103

9.6 API functions — error handling.104

9.6.1 Synchronous error handling .104

9.6.2 Asynchronous error handling .104

9.7 Installation .104

9.7.1 Generic description .104

9.7.2 Windows installation process .105

9.7.3 Linux installation process .106

9.7.4 Selecting MVCI protocol modules.106

9.8 Application notes.106

9.8.1 Interaction with the MDF.106

9.8.2 Accessing additional hardware features for MVCI protocol modules .106

iv © ISO 2009 – All rights reserved

9.8.3 Documentation and information provided by MVCI protocol module vendors .107

9.8.4 Performance Testing.107

10 Using the D-PDU API with existing applications.108

10.1 SAE J2534-1 and RP1210a existing standards .108

11 Data structures .108

11.1 API functions — data structure definitions .108

11.1.1 Abstract basic data types.108

11.1.2 Definitions .109

11.1.3 Bit encoding for UNUM32 .109

11.1.4 API data structures.110

Annex A (normative) D-PDU API compatibility mappings.123

Annex B (normative) D-PDU API standard ComParams and protocols.141

Annex C (informative) D-PDU API manufacturer specific ComParams and protocols.209

Annex D (normative) D-PDU API constants .211

Annex E (normative) Application defined tags.225

Annex F (normative) Description files .226

Annex G (informative) Resource handling scenarios .269

Annex H (informative) D-PDU API partitioning.274

Annex I (informative) Use case scenarios.278

Annex J (normative) OBD protocol initialization.310

Bibliography.325

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 22900-2 was prepared by Technical Committee ISO/TC 22, Road vehicles, Subcommittee SC 3,

Electrical and electronic equipment.

ISO 22900 consists of the following parts, under the general title Road vehicles — Modular vehicle

communication interface (MVCI):

⎯ Part 1: Hardware design requirements

⎯ Part 2: Diagnostic protocol data unit application programming interface (D-PDU API)

⎯ Part 3: Diagnostic server application programming interface (D-Server API)

vi © ISO 2009 – All rights reserved

Introduction

ISO 22900 is applicable to vehicle electronic control module diagnostics and programming.

This part of ISO 22900 was established in order to more easily exchange software and hardware of vehicle

communication interfaces (VCIs) among diagnostic applications. It defines a generic and protocol independent

software interface towards the modular vehicle communication interface (MVCI) protocol module, such that a

diagnostic application based on this software interface can exchange the MVCI protocol module or add a new

MVCI protocol module with minimal effort. Today, the automotive after market requires flexible usage of

different protocol modules for vehicles of different brands. Many of today's protocol modules are incompatible

with regard to their hardware and software interface, such that, depending on the brand, a different protocol

module is required.

The objective of this part of ISO 22900 is to specify the diagnostic protocol data unit application programming

interface (D-PDU API) as a generic software interface, and to provide a “plug and play” concept for access

onto different MVCI protocol modules from different tool manufacturers. The D-PDU API will address the

generic software interface, the protocol abstraction, its exchangeability as well as the compatibility towards

existing standards such as SAE J2534-1 and RP1210a.

The implementation of the modular VCI concept facilitates co-existence and re-use of MVCI protocol modules,

especially in the after market. As a result, diagnostic or programming applications can be adapted for different

vehicle communication interfaces and different vehicles with minimal effort, thus helping to reduce overall

costs for the tool manufacturer and end user.

Vehicle communication interfaces compliant with ISO 22900 support a protocol-independent D-PDU API as

specified in this part of ISO 22900.

INTERNATIONAL STANDARD ISO 22900-2:2009(E)

Road vehicles — Modular vehicle communication interface

(MVCI) —

Part 2:

Diagnostic protocol data unit application programming

interface (D-PDU API)

1 Scope

This part of ISO 22900 specifies the diagnostic protocol data unit application programming interface

(D-PDU API) as a modular vehicle communication interface (MVCI) protocol module software interface and

common basis for diagnostic and reprogramming software applications.

This part of ISO 22900 covers the descriptions of the application programming interface (API) functions and

the abstraction of diagnostic protocols, as well as the handling and description of MVCI protocol module

features. Sample MVCI module description files accompany this part of ISO 22900.

Migration from and to the existing standards SAE J2534-1 and RP1210a is addressed. This part of ISO 22900

contains a description of how to convert between the APIs. Corresponding wrapper APIs accompany this part

of ISO 22900.

The purpose of this part of ISO 22900 is to ensure that diagnostic and reprogramming applications from any

vehicle or tool manufacturer can operate on a common software interface, and can easily exchange MVCI

protocol module implementations.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 9141-2, Road vehicles — Diagnostic systems — Part 2: CARB requirements for interchange of digital

information

ISO 14229-1, Road vehicles — Unified diagnostic services (UDS) — Part 1: Specification and requirements

ISO 14230 (all parts), Road vehicles — Diagnostic systems — Keyword Protocol 2000

ISO 15031-5, Road vehicles — Communication between vehicle and external equipment for emissions-related

diagnostics — Part 5: Emissions-related diagnostic services

ISO 15765 (all parts), Road vehicles — Diagnostics on Controller Area Networks (CAN)

ISO 22901-1, Road vehicles — Open diagnostic data exchange (ODX) — Part 1: Data model specification

ISO/IEC 8859-1, Information technology — 8-bit single-byte coded graphic character sets — Part 1: Latin

alphabet No. 1

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

application

way of accessing the diagnostic protocol data unit application programming interface (D-PDU API)

NOTE From the perspective of the D-PDU API, it does not make any difference whether an application accesses the

software interface directly, or through an MVCI D-Server. Consequently, in this part of ISO 22900, the term “application”

represents both ways of accessing the D-PDU API.

3.2

ComLogicalLink

logical communication channel towards a single electronic control unit (ECU) or towards multiple electronic

control units

3.3

COMPARAM-SPEC

protocol-specific set of predefined communication parameters (ComParams), the value of which can be

changed in the context of a layer or specific diagnostic service

NOTE This part of the model can also contain OEM-specific ComParams.

3.4

ComPrimitive

smallest aggregation of a communication service or function

EXAMPLE A request message to be sent to an ECU.

3.5

Ethernet

physical network media type

4 Symbols and abbreviated terms

API Application Programming Interface

ASCII American Standard for Character Information Interchange

CAN Controller Area Network

CDF Cable Description File

CLL ComLogicalLink

ComParam Communication Parameter

COP Communication Primitive

CRC Cyclic Redundancy Check

DLC Data Link Connector

DLL Dynamic Link Library

D-PDU Diagnostic Protocol Data Unit

D-Server Diagnostic Server

ECU Electronic Control Unit

2 © ISO 2009 – All rights reserved

HDD Hard Disk Drive

HI Differential Line — High

HW Hardware

IEEE 1394 Firewire serial bus

IFR In-Frame Response

IGN Ignition

IOCTL Input/Output Control

K UART K-Line

KWP Keyword Protocol

L UART L-Line

LOW Differential Line — Low

MDF Module Description File

MVCI Modular Vehicle Communication Interface

ODX Open Diagnostic Data Exchange

OEM Original Equipment Manufacturer

OSI Open Systems Interconnection

PC Personal Computer

PCI Protocol Control Information

PGN Parameter Group Number

PROGV Programmable Voltage

PWM Pulse Width Modulation

RDF Root Description File

RX UART uni-directional receive

SCI Serial Communications Interface

SCP Standard Corporate Protocol

TX UART uni-directional transmit

USB Universal Serial Bus

1)

USDT Unacknowledged segmented data transfer

2)

UUDT Unacknowledged un-segmented data transfer

1) ISO 15765-2 network layer includes protocol control information for segmented data transmission, which results in a

maximum of 7 data bytes for normal addressing and 6 data bytes for extended addressing.

2) Single CAN frames do not include protocol control information, which results in a maximum of 8 data bytes for normal

addressing and 7 data bytes for extended addressing.

VCI Vehicle Communication Interface

VPW Variable Pulse Width

XML Extensible Markup Language

5 Specification release version information

5.1 Specification release version location

Specification release version information is contained in each modular VCI release document specification

under the same clause title “Specification release version information”. It is important to check for feature

support between modular VCI release specifications if the most recent API features shall be implemented.

The D-PDU API supports the reading of version information by the API function call PDUGetVersion.

Release version information is also contained in the following files:

⎯ root description file (RDF);

⎯ module description file (MDF);

⎯ cable description file (CDF);

⎯ D-PDU API library file.

5.2 Specification release version

The specification release version of this part of ISO 22900 is: 2.2.0.

6 Modular VCI use cases

6.1 OEM merger

In the past, several OEMs in the automotive industry have merged into one company.

All companies try to leverage existing (legacy) components and jointly develop new products, which are

common across different vehicle types and badges.

If OEMs already had modular VCI compliant test equipment, it would be simple to connect MVCI protocol

modules from merged OEMs into one chassis or device. All protocols would be supported by a single MVCI

protocol module configuration without any replacement of MVCI protocol module hardware at the dealer site.

The same applies for engineering and some of this concept might also work for production plants (end of line).

6.2 OEM cross vehicle platform ECU(s)

OEMs specify requirements and design electronic systems to be implemented in multiple vehicle platforms in

order to avoid re-inventing a system for different vehicles. The majority of design, normal operation, and

diagnostic data of an electronic system are re-used if installed in various vehicles. The engineering

development centres are located worldwide. A great amount of re-authoring of diagnostic data is performed to

support different engineering test tools.

Providing diagnostic data in an industry standard format like ODX and XML will avoid re-authoring into various

test tool specific formats at different system engineering locations. The D-PDU API supports this re-use

concept by fully abstracting vehicle protocols into the industry supported ComParam descriptions.

4 © ISO 2009 – All rights reserved

6.3 Central source diagnostic data and exchange during ECU development

Single source origin of diagnostic data (as depicted in Figure 1 — Example of central source engineering

diagnostic data process), combined with a verification and feedback mechanism and distribution to the end

users, is highly desirable in order to lower engineering expenses. Engineering, manufacturing, and service

specify which protocol and data shall be implemented in the ECU. This information will be documented in a

structured format like XML. Furthermore, the same structured data files can be used to setup the diagnostic

engineering tools to verify proper communication with the ECU and to perform functional verification and

compliance testing of the ECU. Once all quality goals are met, these structured data files shall be released to

the OEM database. An Open Diagnostic data eXchange (ODX) schema has been developed for the purpose

of supporting these structured formatted files used for ECU diagnosis and validation.

Figure 1 — Example of central source engineering diagnostic data process

6.4 OEM franchised dealer and aftermarket service outlet diagnostic tool support

The service shop uses the modular VCI hardware and software for vehicle diagnosis and enhanced

procedural testing. By using the same engineering, manufacturing, and service functions as those used for

individual ECU testing, the reliability of the data is maintained. A modular VCI protocol module can be used

with any PC (handheld or stationary) and can be utilised as an embedded device.

7 Modular VCI software architecture

7.1 Overview

The modular VCI concept is mainly based on three software components (see Figure 2 — MVCI software

architecture):

⎯ MVCI D-Server software;

⎯ runtime data based on ODX;

⎯ MVCI protocol module software.

The application accesses the MVCI D-Server through the MVCI D-Server API. The D-Server obtains all

required information about the ECU(s) out of the ODX runtime data. Using the ODX runtime data information,

the D-Server converts the application's request into a byte stream, which is called a diagnostic protocol data

unit (D-PDU). The D-PDU is handed over to the MVCI protocol module through the D-PDU API. The MVCI

protocol module transmits the D-PDU to the vehicle's ECU(s). The other way around, the MVCI protocol

module receives the vehicle's response(s) and reports the response data to the D-Server. Again using the

ODX runtime data, the D-Server interprets the D-PDU and provides the interpreted symbolic information to the

application.

NOTE The grey shading of symbols indicates reference to the following International Standards:

⎯ ODX: ISO 22901-1;

⎯ D-Server API: ISO 22900-3;

⎯ D-PDU API: ISO 22900-2;

⎯ MVCI protocol module: ISO 22900-1.

Figure 2 — MVCI software architecture

7.2 Modular VCI D-Server software

The MVCI D-Server is accessible through the MVCI D-Server API. By accessing this API, the application may

browse the available features for each ECU and initiate a request towards an ECU using simple symbolic

expressions. If the request requires input parameters, they can be specified using symbolic expressions as

well. The MVCI D-server takes the symbolic request, including input parameters, and converts them into a

diagnostic request message as defined at the protocol level. The diagnostic request message represents the

diagnostic protocol data unit (D-PDU) as passed to the MVCI protocol module through the D-PDU API. Vice

versa, the D-Server converts diagnostic response messages as retrieved from the MVCI protocol module back

to symbolic information and provides it to the application.

For a detailed description and the complete MVCI D-Server API definition, see ISO 22900-3.

6 © ISO 2009 – All rights reserved

7.3 Runtime format based on ODX

For every conversion from symbolic requests to diagnostic request messages, and vice versa for responses,

the MVCI D-Server obtains the required information from the runtime database. The database defines the

structure of every diagnostic request and response as supported by an ECU. The database defines byte and

bit positions, width, and type of every input and output parameter.

Even though the MVCI D-Server obtains its information from a runtime database, the runtime database and

format are not specified by the MVCI standard. Instead, the MVCI standard defines an exchange format to

import and export the ECU description across OEMs and tool suppliers. The runtime format is left up to the

system designers.

The exchange format is called open diagnostic data exchange format (ODX format). For a detailed description,

see ISO 22901-1.

7.4 MVCI protocol module software

The MVCI protocol module is accessible through the D-PDU API. The application issues diagnostic requests

through the D-PDU API. The MVCI protocol module takes the request D-PDU and transmits it to the vehicle's

ECU(s) according to the vehicle communication protocol. Header type, checksum information, and D-PDU

segmentation depend on the vehicle communication protocol, and shall be handled transparently by the MVCI

protocol module. Also, the MVCI protocol module observes the timing between message frames and requests

and responses on the physical interfaces. After completion, the MVCI protocol module simply has to deliver

the response back to the application or report an error condition.

7.5 MVCI protocol module configurations

The D-PDU API and MVCI protocol modules work in many configurations. A MVCI D-Server is not required as

the application interface to the D-PDU API.

Figure 3 — MVCI configurations shows two such configurations to point out the differences.

Key

A application with MVCI D-Server

B application without MVCI D-Server

NOTE From the perspective of the D-PDU API, it does not make a difference whether an application accesses the

software interface directly, or through an MVCI D-Server. Consequently, in this part of ISO 22900, the term “application”

represents both ways of accessing the D-PDU API.

Figure 3 — MVCI configurations

8 D-PDU API use cases

8.1 Overview

The MVCI protocol module is the key component to exchange implementations of diagnostic protocols among

OEMs and tool suppliers without re-engineering already implemented software. By relying on the D-PDU API,

the application may easily access other or additional MVCI protocol module implementations. In a similar way

to existing standards like SAE J2534-1 and RP1210a, applications compliant to the MVCI standard are

basically independent of the underlying device as long as the required physical interface is supported and no

tool supplier specific feature is required.

Even though the D-PDU API extends the capabilities beyond the definitions of SAE J2534-1 and RP1210a,

the existing standards and their related devices and applications do not become obsolete by introducing the

D-PDU API. Instead, the transition and co-existence of all standards are facilitated to save development and

investment costs. The definition of the D-PDU API is closely related to SAE J2534-1 and RP1210a to allow

mapping of functionality in both directions. However, it extends their definitions to cover the full width of

enhanced diagnostics.

The fulfilment of the following use cases is crucial for the inter-exchange of protocol module implementations

according to MVCI, SAE J2534-1 and RP1210a.

NOTE In the use case figures below, the grey boxes suggest a specific software component architecture. This

representation is not intended to be construed as the only possible architectural solution. Depending on the situation, there

can be more software components, or fewer software components.

8.2 Use case 1: Single MVCI protocol module

The single MVCI protocol module configuration (see Figure 4 — MVCI configuration with single MVCI protocol

module) is the simplest configuration where the D-PDU API implementation and the MVCI protocol module

hardware are obtained from the same vendor. The application will access the single MVCI protocol module

through a single D-PDU API. Parallel access onto multiple D-PDU APIs is not required. Resource handling is

completely covered inside the D-PDU API implementation.

This use case applies to basically all stand-alone MVCI protocol module device configurations.

8 © ISO 2009 – All rights reserved

Figure 4 — MVCI configuration with single MVCI protocol module

8.3 Use case 2: Multiple MVCI protocol modules supported by same D-PDU API

implementation

There are different configurations with multiple MVCI protocol modules. In this use case, a D-PDU API

implementation may support more than one MVCI protocol module at a time, where both modules and

D-PDU API implementations are from a single vendor (see Figure 5 — Multiple MVCI protocol modules

supported by same D-PDU API implementation). The application will access the MVCI protocol modules

through a single D-PDU API. Parallel access onto multiple D-PDU APIs is not required. However, the

application may access and operate the MVCI protocol modules at the same time in parallel if the D-PDU API

implementation provides the capabilities. Resource handling is completely covered inside the D-PDU API

implementation.

This use case applies to MVCI protocol module device configurations where the vendor integrates support for

multiple MVCI protocol modules into one software package.

Figure 5 — Multiple MVCI protocol modules supported by same D-PDU API implementation

8.4 Use case 3: Multiple MVCI protocol modules supported by different D-PDU API

implementations

In most cases, when combining MVCI protocol modules of different suppliers, the MVCI protocol modules are

not accessed through the same D-PDU API implementation (see Figure 6 — Multiple MVCI protocol modules

supported by different D-PDU API implementations). Neither of the implementations knows about the other

suppliers' MVCI protocol modules. It cannot communicate with them, since the D-PDU API does not define an

explicit interface hardware type, nor the communication protocol on the interface. Therefore, MVCI protocol

modules of different suppliers will be addressed through separate D-PDU API implementations. Each

D-PDU API implementation may support more than one MVCI protocol module at a time, and more than one

D-PDU API implementation may co-exist on the same runtime environment at the same time.

The application may access multiple D-PDU APIs (and their MVCI protocol modules) in parallel, if it needs to

use resources of more than one D-PDU API. As a result, each D-PDU API implementation shall be able to run

concurrently with other D-PDU API implementations. As in use case 2, resource handling is completely

covered inside the D-PDU API implementation with respect to one implementation. As use case 3 assumes

multiple D-PDU API implementations not knowing each other, the application is required to handle the

resources across D-PDU API implementations.

This use case applies to MVCI protocol module device configurations where a tool supplier integrates support

for multiple MVCI protocol modules of different vendors into one software package.

10 © ISO 2009 – All rights reserved

Figure 6 — Multiple MVCI protocol modules supported by different D-PDU API implementations

9 Diagnostic protocol data unit (D-PDU) API

9.1 Software requirements

9.1.1 General requirements

The MVCI devices shall be accessed through dynamically linkable software modules, i.e. dynamic link

libraries for Windows systems (DLLs) and/or library modules for Linux system

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...