ISO 18921:2002

(Main)Imaging materials — Compact discs (CD-ROM) — Method for estimating the life expectancy based on the effects of temperature and relative humidity

Imaging materials — Compact discs (CD-ROM) — Method for estimating the life expectancy based on the effects of temperature and relative humidity

Matériaux pour l'image — Disques compacts (CD-ROM) — Méthode d'estimation de l'espérance de vie basée sur les effets de la température et de l'humidité relative

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 18921

First edition

2002-04-15

Imaging materials — Compact discs

(CD-ROM) — Method for estimating the life

expectancy based on the effects of

temperature and relative humidity

Matériaux pour l'image — Disques compacts (CD-ROM) — Méthode

d'estimation de l'espérance de vie basée sur les effets de la température et

de l'humidité relative

Reference number

ISO 18921:2002(E)

©

ISO 2002

---------------------- Page: 1 ----------------------

ISO 18921:2002(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall not be

edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In downloading this file,

parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation parameters

were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the unlikely event

that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2002

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO's

member body in the country of the requester.

ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.ch

Web www.iso.ch

Printed in Switzerland

©

ii ISO 2002 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 18921:2002(E)

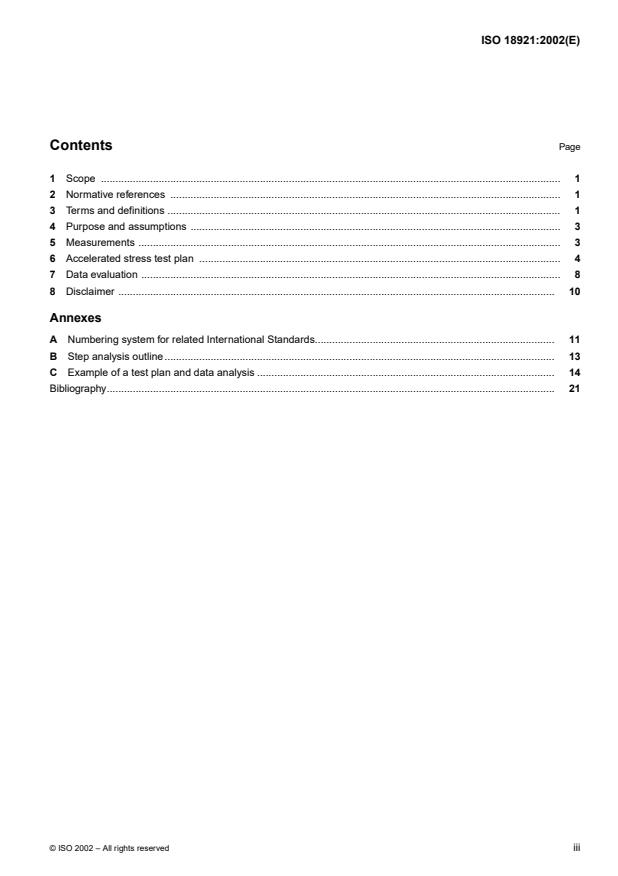

Contents Page

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Purpose and assumptions . 3

5 Measurements . 3

6 Accelerated stress test plan . 4

7 Data evaluation . 8

8 Disclaimer . 10

Annexes

A Numbering system for related International Standards. 11

B Step analysis outline. 13

C Example of a test plan and data analysis . 14

Bibliography. 21

©

ISO 2002 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 18921:2002(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO

member bodies). The work of preparing International Standards is normally carried out through ISO technical

committees. Each member body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, governmental and non-governmental, in

liaison with ISO, also take part in the work. ISO collaborates closely with the International Electrotechnical

Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 3.

Draft International Standards adopted by the technical committees are circulated to the member bodies for voting.

Publication as an International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this International Standard may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights.

International Standard ISO 18921 was prepared by Technical Committee ISO/TC 42, Photography.

This International Standard is one of a series of standards dealing with the physical properties and stability of

imaging materials. To facilitate identification of these International Standards, they are assigned a number within the

block from 18900 – 18999 (see annex A).

Annexes A, B and C of this International Standard are for information only.

©

iv ISO 2002 – All rights reserved

---------------------- Page: 4 ----------------------

INTERNATIONAL STANDARD ISO 18921:2002(E)

Imaging materials — Compact discs (CD-ROM) — Method for

estimating the life expectancy based on the effects of temperature

and relative humidity

1 Scope

This International Standard specifies a test method for estimating the life expectancy (LE) of information stored on

compact disc (CD-ROM) media, including CD audio, but excluding recordable media. Only the effects of temperature

and relative humidity on the media are considered.

2 Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of

this International Standard. For dated references, subsequent amendments to, or revisions of, any of these

publications do not apply. However, parties to agreements based on this International Standard are encouraged to

investigate the possibility of applying the most recent editions of the normative documents indicated below. For

undated references, the latest edition of the normative document referred to applies. Members of ISO and IEC

maintain registers of currently valid International Standards.

ISO/IEC 10149:1995, Information technology — Data interchange on read-only 120mm optical data disks

(CD-ROM)

IEC 60908:1999, Audio recording — Compact disc digital audio system

3 Terms and definitions

For the purposes of this International Standard, the following terms and definitions apply.

3.1

F (t)

probability that a random unit drawn from the population fails by time t, or the fraction of all units in the population

which fails by time t

3.2

R(t)

probability that a unit drawn from the population will survive at least time t, or the fraction of units in the population

that will survive at least time t

NOTE R(t)= 1−F (t).

3.3

baseline

condition representing the disc at time of manufacture

NOTE This is customarily the initial parameter measurement taken prior to any application of stress. The designation is usually

t = 0 for a stress time equal to zero hours.

©

ISO 2002 – All rights reserved 1

---------------------- Page: 5 ----------------------

ISO 18921:2002(E)

3.4

block error rate

BLER

ratio of erroneous blocks to total blocks measured at the input of the first (C1) decoder (before any error correction is

applied)

NOTE The more commonly reported value for BLER is the number of erroneous blocks per second measured at the input of the

C1-decoder during playback at the standard (1×) data rate.

[IEC 60908:1999]

3.5

CD-ROM

compact disc-read only medium

3.6

end-of-life

occurrence of any loss of information

3.7

information

signal or image recorded using the system

3.8

life expectancy

LE

length of time that information is predicted to be retrievable in a system under extended-term storage conditions

3.8.1

standardized life expectancy

SLE

95 % 95 %

minimum life span, predicted with confidence, of of the product stored at a temperature not exceeding

◦

25C5 and a relative humidity (RH) not exceeding 0% RH

3.9

retrievability

ability to access information as recorded

3.10

stress

experimental variable to which the specimen is exposed for the duration of the test interval

NOTE In this International Standard, the stress variables are confined to temperature and relative humidity.

3.11

system

combination of recording medium, hardware, software and documentation necessary to retrieve information

3.12

test cell

device that controls the stress to which the specimen is exposed

3.13

test pattern

distribution of the characters l and 0 within a block and the block-to-block variation

©

2 ISO 2002 – All rights reserved

---------------------- Page: 6 ----------------------

ISO 18921:2002(E)

4 Purpose and assumptions

4.1 Purpose

The purpose of this International Standard is to establish a methodology for estimating the life expectancy of

information stored on CD-ROMs. This methodology provides a technically and statistically sound procedure for

obtaining and evaluating accelerated test data.

4.2 Assumptions

The validity of the procedure defined by this International Standard relies on three assumptions:

— the dominant failure mechanism acting at the usage condition is the same as at the accelerated conditions;

— the dominant failure mechanism is appropriately modelled by an Eyring acceleration model;

— life expectancy is appropriately modelled by the two parameter Weibull distribution (see [1] in the Bibliography).

The shape parameter of the Weibull distribution is assumed to be independent of the stress level.

5 Measurements

5.1 Block error rate (BLER)

The objective of measuring the block error rate (BLER) is to establish a practical estimation of the system's ability to

read the pre-recorded bits using a standard drive. This International Standard considers BLER to be a high level

estimate of the performance of the system. A change in BLER in response to the time at an elevated temperature

and humidity is the principal quality parameter.

The true end-of-life is loss of information. Ideally, each specimen is tested until actual time of failure occurs.

Realistically, this is impractical. For the purposes of this International Standard, the maximum ten-second average of

the BLER, as specified in ISO/IEC 10149, shall be 220. This is very dependent on the system and its use here is an

arbitrary level chosen as a conservative prediction of the onset of unacceptable errors and thereby the end of disc

life.

5.2 Test equipment

5.2.1 Compact disc test system

Any compact disc test system (tester) that is in accordance with ISO/IEC 10149 may be used. The make, model and

version of the test equipment (including software) shall be reported with the test results.

5.2.2 Calibration and repeatability

Calibration according to the tester manufacturer's procedure shall be performed prior to any measurement data

being collected. A calibration disc shall be available from the tester manufacturer.

In addition to the calibration disc, one control disc shall be maintained at ambient conditions and its maximum BLER

measured before and after each data collection interval. A control chart shall be maintained for this control disc with

± 3σ action limits. The mean and standard deviation of the control disc shall be established by collecting at least five

measurements. Should any individual maximum BLER reading exceed the action limit, the problem shall be

corrected and all data collected since the last valid control point shall be remeasured.

If it becomes necessary to replace the tester, a method shall be followed for correlating tester outputs (see [2] in the

Bibliography).

©

ISO 2002 – All rights reserved 3

---------------------- Page: 7 ----------------------

ISO 18921:2002(E)

5.3 Test specimen

A test specimen is any disc that meets ISO/IEC 10149 specifications and contains representative data extending to

within 2mm of the maximum recording diameter.

6 Accelerated stress test plan

6.1 General

A CD-ROM of good manufacture should last several years or even decades. Consequently, it is necessary to conduct

accelerated ageing studies in order to develop a life expectancy estimate. The key is conducting and evaluating a test

plan that will provide the information necessary to satisfactorily evaluate the particular product.

Many accelerated life test plans follow a rather traditional approach in sampling, experimentation and data

evaluation. These “traditional plans” share the following characteristics:

— the total number of specimens is evenly divided amongst all the accelerated stresses;

— each stress is evaluated at the same time increments;

— the Arrhenius relationship is used as the acceleration model;

— the Least Squares method is used for all regressions;

— the calculated life expectancy is for the mean or median life rather than for the first few failure percentiles.

On the other hand, “optimum test plans” have been proposed which differ in significant aspects from traditional plans.

These plans have the following characteristics:

— two and only two acceleration levels for each stress;

— a large number of specimens distributed mostly in the lowest stress levels;

— the need to know the failure distribution, a priori, in order to develop the plan.

The maximum effectiveness of a plan can either be estimated before the test starts or determined after the results

have been obtained. As each CD-ROM system has different characteristics, a specific, detailed optimum plan is

impossible to forecast.

This test plan borrows from the optimum plan, the traditional plan, previous experience with the systems, test

equipment and accelerated test stresses to put together a “compromise test plan”. Modifications of this plan will be

required to design the best plan for other applications. The methodology shall be applicable to all CD-ROM media

assessments.

6.2 Stress conditions

6.2.1 Levels

As mentioned in 6.1, an optimum test plan utilizes only two stress levels for each parameter evaluated, since in an

ideal case the relationship between changes in the parameter investigated and changes in stress is known. The

compromise test plan documented in this International Standard does not make such an assumption; therefore, three

different stress levels per parameter shall be used so that the linearity of the parameter function versus the stress

level may be demonstrated.

The test plan shall have the majority of test specimens placed at the lowest stress condition. This minimizes the

estimation error at this condition and results in the best estimate of the degradation rate at a level close to the usage

condition. The greater number of specimens at the lower stress also tends to equalize the number of failures

observed by test completion.

©

4 ISO 2002 – All rights reserved

---------------------- Page: 8 ----------------------

ISO 18921:2002(E)

6.2.2 Conditions

For implementing the test plan documented in this International Standard, five stress conditions shall be used. The

minimum distribution of specimens among the stress points that shall be used is shown in Table 1. For improved

precision, additional specimens and conditions may be used if desired.

Table 1 — Summary of stress conditions

Minimum

Test cell Number of Incubation Minimum total Intermediate

Test stress equilibrium

number specimens duration time RH

duration

hh RH h

T /RH

int

inc inc

◦

80 C/85 % 31 %

1 RH 10 500 2 000 6

◦

80 C/70 % 31 %

2 RH 10 500 2 000 8

◦

80 C/55 % 31 %

3 RH 15 500 2 000 4

◦

70 C/85 % 33 %

4 RH 15 750 3 000 8

◦

60 C/85 % 36 %

5 RH 30 1 000 4 000 11

6.2.3 Temperature (T)

The temperature levels chosen for this test plan are based on the following:

— there shall be no change of phase within the test system over the test temperature range. This restricts the

◦ ◦

0 C 100 C

temperature to greater than and less than ;

— the temperature level shall not be so high that plastic deformation occurs.

◦

The typical substrate material for CD-ROMs is polycarbonate (glass transition temperature ∼ 150 C). The glass

transition temperature of other layers may be lower. Experience with high temperature testing of CD-ROMs indicates

◦

that an upper limit of 80 C is practical for most applications.

6.2.4 Relative humidity (RH)

Practical experience shows that 85 % RH is the upper limit within most accelerated test cells. This is due to the

tendency for condensation to occur on cool sections of the chamber, e.g., observation windows, cable ports, wiper

handles, etc. Droplets may become dislodged and entrained in the circulating air within the chamber. If these droplets

fall on the test specimen, false error signals could be produced.

6.2.5 Rate of stress change

The process described in this International Standard requires that discs be ramped from the test conditions to stress

conditions and back again a number of times during the course of testing. The ramp duration and conditions shall be

chosen to allow sufficient equilibration of absorbed substrate moisture.

Large departures from equilibrium conditions may result in the formation of liquid water droplets inside the substrate

or at its interface with the reflecting layer. Gradients in the water concentration through the thickness of the substrate

shall also be limited. These gradients drive expansion gradients which can cause significant disc deflection.

In order to minimize moisture concentration gradients, the ramp profile specified in Table 2 shall be used. The objects

of the profile are:

— to avoid any situation that may cause moisture condensation within the substrate;

— to minimize the time during which substantial moisture gradients exist in the substrate;

— to produce, at the end of the specified profile, a disc that is sufficiently equilibrated to proceed directly to testing

without delay.

©

ISO 2002 – All rights reserved 5

---------------------- Page: 9 ----------------------

ISO 18921:2002(E)

The profile accomplishes this by varying the moisture content of the disc only at the stress incubation temperature,

and allowing sufficient time for equilibration during ramp-down based on the diffusion coefficient of water in

polycarbonate.

Table 2 — Temperature and relative humidity transition (ramp) profile

Temperature Relative humidity Duration

Process step

◦

C% RH h

Start at T at RH —

amb

amb

T, RH ramp to T to RH 1,5± 0,5

inc int

RH ramp at T to RH 1,5± 0,5

inc inc

Incubation at T at RH See Table 1

inc inc

RH ramp at T to RH 1,5± 0,5

inc int

Equilibration at T at RH See Table 1

inc int

T, RH ramp to T to RH 1,5± 0,5

amb amb

End at T at RH

amb amb

NOTE 1 T and RH are room ambient temperature and relative humidity; T and RH are the stress incubation

amb amb inc inc

temperature and relative humidity; and RH is the intermediate relative humidity that at T supports the same equilibrium

int inc

moisture absorption in polycarbonate as that supported at T and RH (see Table 1).

amb amb

◦

NOTE 2 Transitions should not deviate from a linear change over the chosen duration by more than ± 2 C and ±3% RH.

Ramp transitions may be controlled automatically or manually.

Figure 1 graphically portrays the temperature and relative humidity changes that would occur during one cycle of

◦

incubation at 80C8 and 5% RH, as per Tables 1 and 2.

Key

____ Temperature (T)

........ Relative humidity (RH)

1 T, RH ramp

2 RH ramp

3 Incubation

4 RH ramp

5 Equilibration

6 T, RH ramp

◦

Figure 1 — Graph of nominal 80 C/85 % RH transition (ramp) profile

©

6 ISO 2002 – All rights reserved

---------------------- Page: 10 ----------------------

ISO 18921:2002(E)

6.2.6 Independent verification of chamber conditions

A system independent of the chamber control system shall be used to monitor temperature and humidity conditions

in the test chamber during the stress test.

6.2.7 Specimen placement

Disc specimens shall be placed uncovered, either vertically or horizontally, within the test chamber. Discs shall be

aligned so that their surface is parallel to the chamber airflow, and a space of at least 2mm shall be maintained

between them.

6.2.8 Other influences

During the course of the test, the discs shall be shielded from excessive illumination and potentially corrosive fumes,

gases and liquids.

6.3 Accelerated test cell specimen population

In order to estimate the shape and scale parameters of a Weibull distribution, at least ten failures shall be observed.

◦

Observing at least ten failures is generally not a problem for a realistic test time at 80 C/85 % RH, but becomes

more difficult at milder stress temperature and relative humidity combinations. Assigning a larger percentage of the

specimens at the lower stresses increases the chance of observing the necessary number of failures within a

practical time interval.

Specimens that have not failed at the end of the test duration shall be time censored. This is also known as Type I

censoring (see [3] in the Bibliography).

To compute the estimated failure time for each disc, it is necessary to first determine a transformation of the

maximum BLER, such as log (max. BLER), that results in a linear time dependence. Standard li

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.