ISO/TR 19402:2018

(Main)Paints and varnishes — Adhesion of coatings

Paints and varnishes — Adhesion of coatings

This document summarises the common methods for evaluating the adhesive strength of coatings on a substrate, which can be another coating beneath or the substrate itself. The test methods and evaluation methods are described in Clauses 4, 5, and 6. In the case of standardized test methods the respective standard is referenced in regard to procedure and evaluation. Annex A compares the methods in the synoptic Tables A.1, A.2, and A.3. Often the adhesive strength cannot be sufficiently evaluated by means of a single method. The purely physical methods for measuring the adhesive strength are such in which mechanical quantities (e.g. force or torsion moment) are measured directly. All other methods are based on the evaluation of behaviour under mechanic stress according to practical conditions. For these methods the viscoelastic properties have a wide influence on the evaluation of the adhesive strength, so that it can only be tested comparatively within one method. Each method has its specific application. An unsuitable method can lead to false information. All of the test methods for the evaluation of the adhesive strength require a certain routine of the test person, especially in regard to identifying the separation line. For most of the test methods the test results, among other things, depend on the film thickness of the coating to be tested. In addition, for several methods differences between tests on a test sheet and in practice can occur, due to different roughness of the substrate. Effects of delamination caused by weathering or corrosion influences are not subject of this document. In case cohesion failures predominantly occur during an adhesive strength test, this is no measure for the adhesive strength. However, information can be given on the protective effect of the coating against corrosion.

Peintures et vernis — Adhérence des revêtements

General Information

- Status

- Published

- Publication Date

- 18-Jul-2018

- Technical Committee

- ISO/TC 35/SC 9 - General test methods for paints and varnishes

- Drafting Committee

- ISO/TC 35/SC 9/WG 31 - Properties after application

- Current Stage

- 6060 - International Standard published

- Start Date

- 19-Jul-2018

- Due Date

- 10-Feb-2017

- Completion Date

- 10-Feb-2017

Overview

ISO/TR 19402:2018 - "Paints and varnishes - Adhesion of coatings" is a technical report that summarizes common test methods and evaluation methods for assessing the adhesive strength of coatings on substrates (including underlying coatings). Rather than prescribing a single procedure, it surveys a wide range of methods, explains their scope and limitations, and provides synoptic comparisons (Annex A) to help users select the most suitable approach.

Key topics

- Scope and definition of adhesion, cohesion, adhesive strength and failure types (references ISO 4618 terminology).

- Test-method categories described in Clauses 4 and 5:

- Mechanical stress tests (e.g., pull-off, twist-off, peel-off)

- Continuous-deformation tests (e.g., bend, cupping, three-point bending, T-bend)

- Impact tests (single- and multi-impact, falling-weight)

- Scratch/cut tests (single-scratch, cross-cut, scribe, pressure-water jetting)

- Evaluation methods (Clause 6):

- Auxiliary and contrasting techniques

- Visual failure pattern analysis and area comparison

- Instrumental and digital image evaluation for quantitative assessment

- Practical influences and limitations:

- Many methods are affected by viscoelastic properties, film thickness and substrate roughness

- Some methods provide purely physical measurements (force, torque); others are comparative and mimic practical stress

- Cohesion failures do not measure adhesion but can inform on coating integrity or corrosion protection

- Effects of weathering or corrosion-induced delamination are outside this document

Practical applications

ISO/TR 19402:2018 is intended to guide the selection and interpretation of coating adhesion tests across multiple use cases:

- Quality control and laboratory testing of paints and varnishes

- Coating formulation development and comparative performance screening

- Surface treatment and pretreatment verification (assessing adhesion to substrates)

- Specification writing and test selection by engineers, inspectors and coating consultants

- Test laboratories seeking to understand method applicability, limitations and assessment techniques

Who should use it

- Coating manufacturers and formulators

- Independent testing laboratories and QC teams

- Corrosion engineers, asset owners and specifiers

- Surface preparation and application contractors

Related standards

- ISO 4618 (Paints and varnishes - Terms and definitions) is referenced for terminology.

ISO/TR 19402:2018 also cross-references existing standardized test methods where those procedures apply; users should consult the specific referenced standards for detailed test procedures.

This technical report helps users choose the appropriate adhesion test method, understand practical constraints (film thickness, operator routine, substrate roughness), and interpret results accurately for reliable evaluation of coating adhesion.

Frequently Asked Questions

ISO/TR 19402:2018 is a technical report published by the International Organization for Standardization (ISO). Its full title is "Paints and varnishes — Adhesion of coatings". This standard covers: This document summarises the common methods for evaluating the adhesive strength of coatings on a substrate, which can be another coating beneath or the substrate itself. The test methods and evaluation methods are described in Clauses 4, 5, and 6. In the case of standardized test methods the respective standard is referenced in regard to procedure and evaluation. Annex A compares the methods in the synoptic Tables A.1, A.2, and A.3. Often the adhesive strength cannot be sufficiently evaluated by means of a single method. The purely physical methods for measuring the adhesive strength are such in which mechanical quantities (e.g. force or torsion moment) are measured directly. All other methods are based on the evaluation of behaviour under mechanic stress according to practical conditions. For these methods the viscoelastic properties have a wide influence on the evaluation of the adhesive strength, so that it can only be tested comparatively within one method. Each method has its specific application. An unsuitable method can lead to false information. All of the test methods for the evaluation of the adhesive strength require a certain routine of the test person, especially in regard to identifying the separation line. For most of the test methods the test results, among other things, depend on the film thickness of the coating to be tested. In addition, for several methods differences between tests on a test sheet and in practice can occur, due to different roughness of the substrate. Effects of delamination caused by weathering or corrosion influences are not subject of this document. In case cohesion failures predominantly occur during an adhesive strength test, this is no measure for the adhesive strength. However, information can be given on the protective effect of the coating against corrosion.

This document summarises the common methods for evaluating the adhesive strength of coatings on a substrate, which can be another coating beneath or the substrate itself. The test methods and evaluation methods are described in Clauses 4, 5, and 6. In the case of standardized test methods the respective standard is referenced in regard to procedure and evaluation. Annex A compares the methods in the synoptic Tables A.1, A.2, and A.3. Often the adhesive strength cannot be sufficiently evaluated by means of a single method. The purely physical methods for measuring the adhesive strength are such in which mechanical quantities (e.g. force or torsion moment) are measured directly. All other methods are based on the evaluation of behaviour under mechanic stress according to practical conditions. For these methods the viscoelastic properties have a wide influence on the evaluation of the adhesive strength, so that it can only be tested comparatively within one method. Each method has its specific application. An unsuitable method can lead to false information. All of the test methods for the evaluation of the adhesive strength require a certain routine of the test person, especially in regard to identifying the separation line. For most of the test methods the test results, among other things, depend on the film thickness of the coating to be tested. In addition, for several methods differences between tests on a test sheet and in practice can occur, due to different roughness of the substrate. Effects of delamination caused by weathering or corrosion influences are not subject of this document. In case cohesion failures predominantly occur during an adhesive strength test, this is no measure for the adhesive strength. However, information can be given on the protective effect of the coating against corrosion.

ISO/TR 19402:2018 is classified under the following ICS (International Classification for Standards) categories: 87.040 - Paints and varnishes. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/TR 19402:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

TECHNICAL ISO/TR

REPORT 19402

First edition

2018-08

Paints and varnishes — Adhesion of

coatings

Peintures et vernis — Adhérence des revêtements

Reference number

©

ISO 2018

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

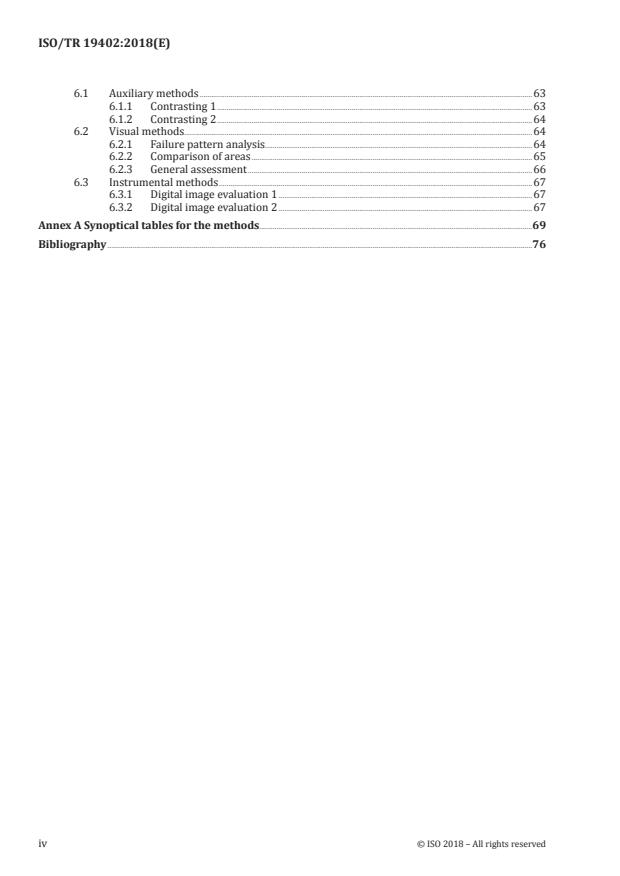

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Adhesive strength tests without scratch/cut . 3

4.1 Tests with mechanical stress application on the coating . 3

4.1.1 Pull-off test . 3

4.1.2 Twist-off test . 5

4.1.3 Peel-off test 1 . 6

4.1.4 Peel-off test 2 . 8

4.2 Tests with continuous deformation of test specimens . 9

4.2.1 Bend test with a wedge-shaped conical mandrel . 9

4.2.2 Bend test with a conical mandrel .11

4.2.3 Bend test with a cylindrical mandrel 1 .12

4.2.4 Bend test with a cylindrical mandrel 2 .14

4.2.5 Three point bending method .15

4.2.6 T-bend test 1 .17

4.2.7 T-bend test 2 .19

4.2.8 Cupping test 1 .20

4.3 Test with impact stress application .22

4.3.1 Single-impact test 1 .22

4.3.2 Single-impact test 2 .25

4.3.3 Single-impact test 3 .27

4.3.4 Single-impact test 4 .28

4.3.5 Falling-weight test 1 .30

4.3.6 Falling-weight test 2 .33

4.3.7 Falling-weight test 3 .35

4.3.8 Multi-impact test 1 .36

4.3.9 Multi-impact test 2 .38

4.3.10 Multi-impact test 3 .41

4.3.11 Multi-impact test 4 .43

4.3.12 Impact-bend test .44

5 Adhesive strength tests with scratch/cut .45

5.1 Tests with single scratch .45

5.1.1 Scratch test 1 .45

5.1.2 Scratch test 2 .46

5.1.3 Scratch test 3 (Scrape-adhesion test) .47

5.2 Test with multiple scratch (without deformation of test specimens) .49

5.2.1 Pressure-water jetting test .49

5.2.2 Cross-cut test 1 .53

5.2.3 Cross-cut test 2 .56

5.2.4 Cross-cut test 3 .57

5.2.5 X-cut test 1 .58

5.2.6 X-cut test 2 .58

5.2.7 X-cut test 3 .59

5.2.8 X-cut test 4 .59

5.2.9 Scribe test with a square-diagonal grid .60

5.2.10 Scribe test with a rhombus grid .61

5.3 Test with multiple scratch (with deformation of test specimens) .62

5.3.1 Cupping test 2 .62

6 Evaluation methods for adhesive strength .63

6.1 Auxiliary methods .63

6.1.1 Contrasting 1 .63

6.1.2 Contrasting 2 .64

6.2 Visual methods.64

6.2.1 Failure pattern analysis.64

6.2.2 Comparison of areas .65

6.2.3 General assessment .66

6.3 Instrumental methods .67

6.3.1 Digital image evaluation 1 .67

6.3.2 Digital image evaluation 2 .67

Annex A Synoptical tables for the methods.69

Bibliography .76

iv © ISO 2018 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www .iso .org/iso/foreword .html.

This document was prepared by Technical Committee ISO/TC 35, Paints and varnishes, Subcommittee

SC 9, General test methods for paints and varnishes.

Introduction

The determination of the adhesive strength is one of the most important preconditions for evaluating

the protective function of coatings.

This document offers a helpful overview for the selection of the test method most suitable for each

individual case in regard to the evaluation of the adhesive strength.

vi © ISO 2018 – All rights reserved

TECHNICAL REPORT ISO/TR 19402:2018(E)

Paints and varnishes — Adhesion of coatings

1 Scope

This document summarises the common methods for evaluating the adhesive strength of coatings on a

substrate, which can be another coating beneath or the substrate itself. The test methods and evaluation

methods are described in Clauses 4, 5, and 6. In the case of standardized test methods the respective

standard is referenced in regard to procedure and evaluation. Annex A compares the methods in the

synoptic Tables A.1, A.2, and A.3.

Often the adhesive strength cannot be sufficiently evaluated by means of a single method.

The purely physical methods for measuring the adhesive strength are such in which mechanical

quantities (e.g. force or torsion moment) are measured directly.

All other methods are based on the evaluation of behaviour under mechanic stress according to practical

conditions. For these methods the viscoelastic properties have a wide influence on the evaluation of the

adhesive strength, so that it can only be tested comparatively within one method.

Each method has its specific application. An unsuitable method can lead to false information. All of the

test methods for the evaluation of the adhesive strength require a certain routine of the test person,

especially in regard to identifying the separation line. For most of the test methods the test results,

among other things, depend on the film thickness of the coating to be tested. In addition, for several

methods differences between tests on a test sheet and in practice can occur, due to different roughness

of the substrate.

Effects of delamination caused by weathering or corrosion influences are not subject of this document.

In case cohesion failures predominantly occur during an adhesive strength test, this is no measure for

the adhesive strength. However, information can be given on the protective effect of the coating against

corrosion.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 4618, Paints and varnishes — Terms and definitions

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 4618 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https: //www .iso .org/obp

— IEC Electropedia: available at http: //www .electropedia .org/

3.1

adhesion

phenomenon of attachment at the interface between a solid surface and another material caused by

molecular forces

Note 1 to entry: Adhesion should not be confused with cohesion.

[SOURCE: ISO 4618:2014, 2.7]

3.2

cohesion

forces that bind a film or coat into an integral entity

Note 1 to entry: Cohesion should not be confused with adhesion.

[SOURCE: ISO 4618:2014, 2.55]

3.3

adhesion failure

detachment of a coating from the substrate caused by external forces

Note 1 to entry: The substrate can be another coating beneath or the working material.

3.4

cohesion failure

loss of coherence within a coating caused by external forces

3.5

adhesive strength

force required to detach a coating from a substrate or another coating

[SOURCE: ISO 4618:2014, 2.8]

3.6

wet adhesive strength

adhesive strength (3.5) immediately after previous exposure to moisture

3.7

separation line

interface in which adhesion failure (3.3) occurs

3.8

failure pattern

entirety of the visual coating defects, which are caused by an adhesive strength (3.5) test

3.9

failure pattern assessment

classification of a failure pattern (3.8) by means of criteria or reference patterns

3.10

failure pattern analysis

quantitative evaluation of a failure pattern (3.8) with specification of the relative percentages of area

for adhesion failure (3.3) and cohesion failure (3.4) as well as the separation line(s)

3.11

main separation line

separation line with the largest area

3.12

repeatability conditions

conditions where independent test results are obtained with the same method on identical test items

in the same laboratory by the same operator using the same equipment within short intervals of time

[SOURCE: ISO 5725-1:1994, 3.14]

2 © ISO 2018 – All rights reserved

3.13

repeatability limit

r

the value less than or equal to which the absolute difference between two test results obtained under

repeatability conditions (3.12) may be expected to be with a probability of 95 %

[SOURCE: ISO 5725-1:1994, 3.16]

3.14

reproducibility conditions

conditions where independent test results are obtained with the same method on identical test items in

different laboratories with different operators using different equipment

[SOURCE: ISO 5725-1:1994, 3.18]

3.15

reproducibility limit

R

the value less than or equal to which the absolute difference between two test results obtained under

reproducibility conditions (3.14) may be expected to be with a probability of 95 %

[SOURCE: ISO 5725-1:1994, 3.20]

4 Adhesive strength tests without scratch/cut

4.1 Tests with mechanical stress application on the coating

4.1.1 Pull-off test

— Principle

A uniformly increasing tensile force is applied to a test cylinder (metal cylinder of diameter

20 mm), which is adhered to the coating, until the test cylinder is pulled off. The pull-off strength

is determined by calculating the tensile force to pull off the test cylinder and the area of the test

cylinder.

The principle of the pull-off test is illustrated schematically in Figure 1.

Key

1 substrate

2 coating

3 adhesive film

4 free punch

5 test cylinder

6 outer ring to support the test panel

a

The pull-off direction.

Figure 1 — Principle of the pull-off test

— Application

The pull-off test is generally applicable.

— Procedure

— Attach the test cylinder to the coating by means of a previously tested adhesive.

— Cut the coating around the circumference of the test cylinder using a suitable tool through to

the substrate (see Figure 1).

— Attach the test specimen to the test apparatus so that it is supported and the test cylinder is

connected to the pulling unit, centred and without being wedged.

— Carry out the pull-off process with a uniformly increasing tensile force and measure when the

test cylinder is pulled off.

— Evaluation

The test result is the pull-off strength (MPa) = the tensile force when pulling off the test cylinder

divided by the area of the test cylinder.

Specify the result of the failure pattern analysis (see the procedure specified in 6.2.1).

— Precision

Precision data are not available at present.

— Reference

The pull-off test is specified in ISO 4624 and ISO 16276-1.

4 © ISO 2018 – All rights reserved

4.1.2 Twist-off test

— Principle

By means of a motor-driven test apparatus a uniformly increasing torsion moment is introduced to

a test cylinder (a metal cylinder of a 12 mm or 15 mm diameter and a 6 mm drill), which is adhered

to the coating, until it is twisted off. The adhesive strength (“shear strength”) can be read directly

from the test apparatus as shear stress (N/mm = MPa).

Figure 2 illustrates the principle of the twist-off test in a schematic diagram. Figure 3 shows the

minimum distance between the test cylinders for repeated tests.

Key

1 substrate

2 coating

3 adhesive

4 test cylinder

a

The axis of rotation.

Figure 2 — Principle of the twist-off test

Figure 3 — Minimum distance between the test cylinders

— Application

The twist-off test is generally applicable.

— Procedure

— Use a sufficiently thick substrate (minimum 0,7 mm) or a substrate with reinforcement adhered

to the backside in order to avoid deformation during testing.

— Adhere the test cylinder to the coating using a previously tested adhesive. For repeated tests

observe a minimum distance between the test cylinders (see Figure 3).

— Attach the test apparatus at the hexagon bolt of the test cylinder (see Figure 2) and secure the

test panel against twisting.

— Start torsional stress and read the shear stress from the apparatus when the test cylinder is

twisted off.

— Evaluation

The test result is the shear stress (N/mm = MPa), which is read from the apparatus and interpreted

as the twist-off strength.

Specify the result of the failure pattern analysis (see the procedure specified in 6.2.1).

— Precision

Precision data are not available at present.

— Reference

The twist-off test is specified in Reference [50].

4.1.3 Peel-off test 1

— Principle

A fabric specified by material, thread size, and mesh size is bedded into a newly applied coating

material. After curing of the coating a tensile tester grabs the overlapping fabric, and due to

continuous tensile force at 90° the coating is peeled off from the substrate. The peel strength is

determined as the force required for peeling off and referring to the width of the test specimen.

Figure 4 schematically shows the peel-off process and the function of a 90°-peel-off apparatus.

6 © ISO 2018 – All rights reserved

Key

1 substrate

2 coating

3 fabric

4 tape (uncoated end of the test panel)

a

The direction of movement of the test panel.

b

The direction of rotation of the pressing roller on the coating.

c

The direction of rotation of the pressing roller on the uncoated test panel.

d

The direction of peel-off (tensile tester).

Figure 4 — Principle of the peel-off test 1

— Application

The peel-off test 1 is preferably carried out on automotive coatings.

— Procedure

— Coat the test panel (dimensions 15 mm × 100 mm) sparing a 10 mm wide strip at the edge of

the narrow side. Subsequently bed the fabric so that it remains for about 50 mm uncoated and

overlaps at the uncoated end of the test panel (see Figure 5).

Key

1 substrate

2 coating

3 fabric

4 tape (uncoated end of the test panel)

Figure 5 — Test panel with coating and fabric

— After drying/hardening of the coating mount the test panel into a tensile tester equipped with

a 90°-peel-off apparatus (see Figure 4) and clamp the free end of the fabric.

— Start the peel-off process and record the tensile force (peel strength) required for peeling off.

— Evaluation

Determine the mean peel strength over a peel-off distance of at least 50 mm for five test specimens,

disregard the beginning and the end of the test.

The test result is the mean value (with standard deviation) from the five individual determinations,

which is designated as the peel strength (N/15 mm width of test specimen).

Specify the result of the failure pattern analysis (see the procedure specified in 6.2.1).

— Precision

Precision data are not available at present.

— Reference

The peel-off test 1 is specified in Reference [47].

4.1.4 Peel-off test 2

— Principle

The coating is peeled off from the substrate under specified conditions by means of an electrically

driven test apparatus. The force is determined which is required for peeling off and which refers to

the width of peeling off. Figure 6 illustrates the peel-off process in a schematic diagram.

8 © ISO 2018 – All rights reserved

Key

1 substrate

2 coating

3 peel-off tool

a

The peel strength.

Figure 6 — Principle of the peel-off test 2

— Application

The peel-off test 2 is generally applicable.

— Procedure

— Specify the peel-off tool (cutting angle/width), setting angle, peel-off speed and peel-off

distance.

— Mount the test panel into the peel-off apparatus and start the peel-off process.

— During testing record the force (peel strength) required for peeling off.

— Evaluation

Determine the mean peel strength over the peel-off distance, disregard the beginning and the end

of the peel-off process.

The test result is the mean peel strength divided by the width of the peel-off tool (N/mm).

— Precision

Precision data are not available at present.

— Reference

The peel-off test 2 is specified in Reference [35].

4.2 Tests with continuous deformation of test specimens

4.2.1 Bend test with a wedge-shaped conical mandrel

— Principle

The test panel is deformed from the direction of the substrate side by pressing in a wedge-shaped

conical mandrel of specified geometry. The smallest radius of the mandrel is determined for which

no defect of delamination in the deformed area is detectable.

Figure 7 shows the test principle in a schematic diagram. Figure 8 illustrates the dimensions of the

wedge-shaped conical mandrel.

Key

1 wedge-shaped conical mandrel

2 test panel (after deformation)

3 elastic pad

Figure 7 — Principle of the bend test with a wedge-shaped conical mandrel

Key

R radius – the number specifies the bending radius in mm

Figure 8 — Measures of the wedge-shaped conical mandrel

— Application

The bend test with a wedge-shaped conical mandrel is preferably carried out on coil coatings.

— Procedure

— Put the test panel with the coated side onto an elastomer panel.

— From the direction of the substrate side press the mandrel by hand (with lever transmission)

or by means of a pneumatic apparatus into the panel until the deformation results in a V-shape.

10 © ISO 2018 – All rights reserved

Doing so, the longitudinal axis of the mandrel shall be parallel to the direction of rolling of the

substrate.

— Evaluation

Examine the coating in the deformed area for delamination using a magnifier and determine the

smallest bending radius for which no defect can be detected.

The test result is this bend radius (mm) divided by the thickness of the substrate (mm).

— Precision

Precision data are not available at present.

— Reference

The bend test with a wedge-shaped conical mandrel is specified in EN 13523-7.

4.2.2 Bend test with a conical mandrel

— Principle

The test panel is bent around a conical mandrel of specified dimensions and is deformed accordingly.

The length (mm) of the produced defect is determined.

Figure 9 shows the principle of the bend test with a conical mandrel. Figure 10 shows the bent

test panel.

Key

1 conical mandrel

2 test panel

3 clamping element

l length of the mandrel (203 mm)

d smallest diameter of the mandrel (3,1 mm)

d largest diameter of the mandrel (38 mm)

Figure 9 — Test arrangement of the bend test with a conical mandrel

Key

1 test panel

2 end of the crack in the coating

a

The small radius of the bent test panel.

b

The large radius of the bent test panel.

Figure 10 — Bent test panel with delamination

— Application

The bend test with a conical mandrel is generally applicable for coatings on deformable substrates.

— Procedure

— Mount the test panel into the test apparatus, coating facing outwards, and bend uniformly

around the mandrel.

— Evaluation

Visually examine the delaminated area of the coating (10× magnifier).

The test result is the length (mm) of the delamination (the mean value rounded to whole numbers

of the three single values).

— Precision

The repeatability limit r is 23 mm.

The reproducibility limit R is 46 mm.

— Reference

The bend test with a conical mandrel is specified in ISO 6860.

4.2.3 Bend test with a cylindrical mandrel 1

— Principle

The test panel is bent around a cylindrical mandrel and is deformed accordingly. The exchangeable

mandrels in the bending apparatus have diameters of 2 mm, 3 mm, 4 mm, 5 mm, 6 mm, 8 mm,

10 mm, 12 mm, 16 mm, 20 mm, 25 mm, and 32 mm. The largest diameter of the mandrel (mm)

is determined for which a defect of the coating is visible after bending around that mandrel. The

method can also be carried out as a “pass/fail” test.

12 © ISO 2018 – All rights reserved

Figure 11 shows the principle of bending around a cylindrical mandrel. Figure 12 shows the bent

test panel.

Key

1 cylindrical mandrel

2 test panel

3 clamping element

Figure 11 — Test arrangement of the bend test with a cylindrical mandrel 1

Key

1 test panel

2 crack in the coating

a

The radius of the bent test panel.

Figure 12 — Bent test panel with delamination

— Application

The bend test with a cylindrical mandrel 1 is generally applicable for coatings on deformable

substrates.

— Procedure

— Insert a mandrel of medium diameter into the bending apparatus.

— Mount the test panel into the test apparatus, coating facing outwards, and bend uniformly

around the mandrel.

— Visually examine the coating on the deformed test panel for defects and specify the diameter of

the mandrel for the next bend test:

a) when the coating has been damaged select the next larger mandrel;

b) when the coating has not been damaged select the next smaller mandrel.

— Continue bend tests until the final result has been determined.

— When carrying out the test as a “pass/fail” test bend the test specimen around the mandrel of

the agreed diameter and visually examine the coating for defects.

— Evaluation

The test result is the largest diameter of the mandrel (mm) for which a defect of the coating is

visible after bending around that mandrel or the information that for all mandrels no defect can be

detected after bending.

When carried out as a “pass/fail” test specify if the coating has been damaged (“fail”) or not (“pass”)

for the agreed diameter of the mandrel.

— Precision

The method should only be considered as an approximation test and not as one giving precise

results. The reproducibility limit R, determined in a round-robin test with six participants and

two coating systems, has been set at 50 %, and is only specified here in order to convey a rough

impression of the precision.

— Reference

The bend test with a cylindrical mandrel 1 is specified in ISO 1519.

4.2.4 Bend test with a cylindrical mandrel 2

— Principle

The test panel is bent around a cylindrical mandrel and deformed accordingly. The exchangeable

mandrels in the bending apparatus have diameters in the range of 0,5 mm to 5,0 mm, in steps

of 0,5 mm. The smallest diameter of the mandrel (mm) is determined for which no defect of the

coating is visible after bending around that mandrel.

Figure 13 shows a typical mandrel bending apparatus for exchangeable cylindrical mandrels.

Figure 13 — Mandrel bending apparatus for exchangeable cylindrical mandrels

— Application

The bend test with a cylindrical mandrel 2 is preferably carried out on coil coatings.

14 © ISO 2018 – All rights reserved

— Procedure

— Insert a mandrel of medium diameter into the bending apparatus.

— Mount the test panel into the test apparatus so that the uncoated side faces the mandrel.

— Bend the test panel uniformly around the mandrel.

— Examine the coating on the deformed test panel for defects and specify the diameter of the

mandrel for the next bend test:

a) when the coating has been damaged select the next larger mandrel;

b) when the coating has not been damaged select the next smaller mandrel.

— Continue bend tests until the final result has been determined.

— Evaluation

Visually examine the delaminated area of the coating using a magnifier and determine the smallest

bending radius for which delamination is not yet detectable.

The test result is the bending radius (mm) divided by the thickness of the substrate (mm).

— Precision

Precision data are not available at present.

— Reference

The bend test with a cylindrical mandrel 2 is specified in EN 13523-7.

4.2.5 Three point bending method

— Principle

The coating is applied as specified to a substrate of specified dimensions. The test specimen is

continuously bent by means of a bending apparatus at a speed of 0,5 mm/s. From the recorded

force-distance graph information in regard to the adhesion of the coating is taken.

Figure 14 illustrates the test principle.

a) Test specimen prior to stress application b) Test specimen after stress application

Key

1 struts (diameter 6 mm, length >15 mm, centre distance 33 mm)

2 coating (25 mm × 5 mm)

3 substrate (30 mm × 10 mm)

4 compression bar (diameter 12 mm, length >15 mm)

a

The direction of stress application.

Figure 14 — Principle of the three point bending test

— Application

The three point bending method is applicable for coatings on flexible substrates.

— Procedure

— Coat the substrate panels by means of a template.

— Dry/harden the coating and determine the dry film thickness.

— Mount the specimen in accordance with Figure 14 into the test apparatus and start the bending

process.

— During the bending process record the force-distance graph (see Figure 15).

16 © ISO 2018 – All rights reserved

Key

X bending distance

Y bending force

1 maximum bending distance

2 maximum bending force

3 linear range

4 failure extent

Figure 15 — Force-distance graph

— Evaluation

Read from the force-distance graph (see Figure 15):

— the gradient of the curve (N/mm) in the linear range,

— the maximum bending force (N) and the maximum bending distance (mm), and

— a qualitative description of the failure extent.

— Precision

Precision data are not available at present.

— Reference

The three point bending method is specified in NF T 30-010.

A similar method is specified in EN 1966.

4.2.6 T-bend test 1

— Principle

The test panel is successively bent around itself. Doing so the coating shall be facing outwards. The

smallest radius is determined around which the test panel can be bent without any loss of adhesion.

Figure 16 shows a common bending apparatus and explains the bending process. Figure 17

illustrates the individual stages of the bending process.

Figure 16 — Common bending apparatus

1 1

0 T T 1 T 1 T 2 T

2 2

Figure 17 — Stages of the bending process from 0 T to 2 T

— Application

The T-bend test 1 is preferably carried out on coil coatings.

— Procedure

— Mount the test panel into the bending test apparatus with the coated side facing down and

swivel the bending plate as far as it goes.

— Take out the bent test panel and then complete the 180° bending by means of the bending

apparatus, resulting in the bent condition illustrated in Figure 16.

— Continue bending the bent test panel in the same way.

— After each bending examine the bent area for delamination using a magnifier.

— The test is completed when no delamination is detectable for the first time.

— Evaluation

The smallest radius is determined around which the test panel can be bent without delamination,

expressed in “T units” (see Figure 17).

— Precision

Precision data are not available at present.

18 © ISO 2018 – All rights reserved

— Reference

The T-bend test 1 is specified in EN 13523-7.

4.2.7 T-bend test 2

— Principle

The test panel is bent around a distance piece with the coating facing outwards. The distance piece

can be a solid bending piece or consist of a pile of substrate panels. Alternatively, the test panel

can also be bent around itself. The smallest bending distance is determined for which no loss of

adhesion is detectable. The method can also be carried out as a “pass/fail” test.

Figure 18 shows the process of the T-bend test around a solid bending piece using a bench vice.

Figure 19 illustrates representative examples for both of the other types of the process.

Figure 18 — Bending around a bending piece

a) Bending with panels as distance pieces (ex- b) Bending method with a bench vice (exam-

ample 2T) ple 2T)

Figure 19 — Further types of the process

— Application

The T-bend test 2 is generally applicable for coatings on deformable metal substrates.

— Procedure

— Specify the type of the process:

a) bending around solid bending pieces,

b) bending around bending pieces consisting of substrate panels,

c) bending procedure.

— Carry out the bend test in accordance with Figure 18 or Figure 19 and examine the bent area for

delamination using a magnifier.

— Carry out further bend tests with increasing bending distance until no loss of adhesion is

detected.

— When carrying out the test as a “pass/fail” test carry out the T-bend test with the agreed bending

distance and examine for delamination.

— Evaluation

The test result is the smallest bending distance for which no loss of adhesion is detectable,

expressed by the equivalent number of substrate panels in T units.

When carried out as a “pass/fail” test specify if the coating has been damaged (“fail”) or not (“pass”)

after bending with the agreed bending distance.

— Precision

The repeatability limit r is 0,7 T.

The reproducibility limit R is 1,2 T.

— Reference

The T-bend test 2 is specified in ISO 17132.

4.2.8 Cupping test 1

— Principle

The test panel is clamped between a die (inner diameter 27 mm) and a retaining ring. From the

direction of the uncoated side a ball indenter (diameter 20 mm) deforms the test panel at a constant

speed. The distance of the indenter (cupping) is determined until defects are visually detectable.

The method can also be carried out as a “pass/fail” test.

Figure 20 illustrates the test arrangement of a cupping apparatus in a schematic diagram.

20 © ISO 2018 – All rights reserved

Key

1 test panel

2 die

3 retaining ring

4 ball indenter

5 cupping

a

The direction of movement of the indenter.

Figure 20 — Principle of the cupping test 1

— Application

The cupping test 1 is generally applicable for coatings on deformable substrates.

— Procedure

— Mount the test panel into the cupping apparatus with the coated side facing outwards.

— Press the indenter at a constant speed (0,1 mm/s to 0,3 mm/s) from the backside into the test

panel. Observe the coating in the indented area using optical tools.

— When the first defects of the coating are visible stop the indenter movement and read the

distance (cupping) from the apparatus.

— When carrying out the test as a “pass/fail” test indent the test specimen until the agreed

distance (cupping) is reached and examine for defects of the coating.

— Evaluation

The test result is the mean value (mm) of a double determination, which is then referred to as the

cupping value.

When carried out as a “pass/fail” test specify if the coating has been damaged (“fail”) or not (“pass”)

until the agreed cupping value had been reached.

— Precision

The repeatability limit r is 2 mm.

The reproducibility limit R is 4 mm.

— Reference

The cupping test 1 is specified in ISO 1520.

4.3 Test with impact stress application

4.3.1 Single-impact test 1

— Principle

A single guided impact body (a wedge-shaped steel plunger), which receives its impact impulse

from a steel ball, which is also guided and accelerated by pressurised air, impacts the coating.

The impact energy is specified by a calibration method. The width (mm) of the damaged area is

determined.

Figure 21 illustrates the test principle. Figure 22 shows details and the measures of the impact body.

22 © ISO 2018 – All rights reserved

Key

1 counter weight

2 test panel

3 impact body

4 spring

5 casing

6 steel ball

7 tube

8 pressurised air

Figure 21 — Principle of the single-impact test 1

Dimensions in millimetres

Figure 22 — Impact body

— Application

The single-impact test 1 is preferably carried out on automotive coatings in order to determine the

stone-chip resistance.

— Procedure

— Put the test panel on the test apparatus with the coating facing down and load with the counter

weight (see Figure 21).

— Introduce the single impact.

— Remove parts of the coating, which have not been detached completely, e.g. by using a tape.

— Evaluation

The defect can be visually captured or by means of the digital image evaluation (see the procedure

specified

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...