ISO 7240-17:2020

(Main)Fire detection and fire alarm systems — Part 17: Transmission path isolators

Fire detection and fire alarm systems — Part 17: Transmission path isolators

This document specifies the requirements, test methods and performance criteria for transmission path isolators for use in fire detection and fire alarm systems for buildings (for general requirements and definitions, see ISO 7240‑1). Means of isolation or protection incorporated within control and indicating equipment are not covered by this document.

Systèmes de détection d'incendie et d'alarme — Partie 17: Isolateurs de court-circuit

General Information

- Status

- Published

- Publication Date

- 06-Feb-2020

- Technical Committee

- ISO/TC 21/SC 3 - Fire detection and alarm systems

- Drafting Committee

- ISO/TC 21/SC 3/WG 6 - Smoke detectors

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 15-Sep-2025

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 05-Nov-2015

Overview

ISO 7240-17:2020 specifies requirements, test methods and performance criteria for transmission path isolators used in building fire detection and fire alarm systems. Formerly called short-circuit isolators, these devices are intended to limit the consequences of wiring faults on detection and alarm transmission paths. The standard applies to standalone isolators; isolation features built into control and indicating equipment are excluded. For general definitions and system-level requirements see ISO 7240‑1.

Key topics and requirements

ISO 7240-17 covers the full lifecycle of transmission path isolators, from design expectations to laboratory verification:

- General requirements: compliance obligations, integral status indication, connection of ancillary devices, monitoring of detachable isolators, manufacturer and on‑site adjustment controls.

- Software-controlled isolators: requirements on software design, storage of programs and data, and associated documentation.

- Comprehensive test program: functional testing and environmental/mechanical/electromagnetic tests, including:

- Variation in supply voltage, dry heat, cold, damp heat (cyclic and steady state)

- Corrosion (sulfur dioxide), shock, impact, vibration (sinusoidal operational and endurance)

- Electromagnetic compatibility (EMC) immunity tests

- Test reproducibility and detailed test procedures and schedules to ensure consistent verification.

- Documentation and marking: requirements for test reports, product marking, technical installation documentation and software documentation.

The standard provides informative annexes with examples for functional test procedures and apparatus for impact tests.

Practical applications and who uses it

ISO 7240-17 is relevant to professionals concerned with the reliable operation of fire detection signalling paths:

- Manufacturers of transmission path isolators - to design, test and certify products to international performance criteria.

- Test laboratories and certification bodies - to perform standardized environmental, mechanical and EMC tests and produce test reports.

- System designers and installers - to select compliant isolators, understand monitoring and installation requirements, and ensure correct integration with fire alarm control and indicating equipment.

- Facilities managers and specifiers - to verify that installed devices meet recognized safety and performance standards for building fire systems.

Using compliant isolators reduces risk of circuit failure propagation, improves system resilience and supports regulatory approvals.

Related standards

- ISO 7240‑1 (general requirements and definitions for fire detection and alarm systems)

- IEC 62599-2 (referenced in the latest edition for related technical aspects)

- The ISO 7240 series (other parts for detectors, alarms and system components)

Keywords: ISO 7240-17, transmission path isolators, fire detection, fire alarm systems, short-circuit isolators, test methods, EMC, environmental testing, fire safety standards.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

ISO 7240-17:2020 is a standard published by the International Organization for Standardization (ISO). Its full title is "Fire detection and fire alarm systems — Part 17: Transmission path isolators". This standard covers: This document specifies the requirements, test methods and performance criteria for transmission path isolators for use in fire detection and fire alarm systems for buildings (for general requirements and definitions, see ISO 7240‑1). Means of isolation or protection incorporated within control and indicating equipment are not covered by this document.

This document specifies the requirements, test methods and performance criteria for transmission path isolators for use in fire detection and fire alarm systems for buildings (for general requirements and definitions, see ISO 7240‑1). Means of isolation or protection incorporated within control and indicating equipment are not covered by this document.

ISO 7240-17:2020 is classified under the following ICS (International Classification for Standards) categories: 13.220.20 - Fire protection. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 7240-17:2020 has the following relationships with other standards: It is inter standard links to ISO 7240-17:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 7240-17:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 7240-17

Second edition

2020-02

Fire detection and fire alarm

systems —

Part 17:

Transmission path isolators

Systèmes de détection d'incendie et d'alarme —

Partie 17: Isolateurs de court-circuit

Reference number

©

ISO 2020

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

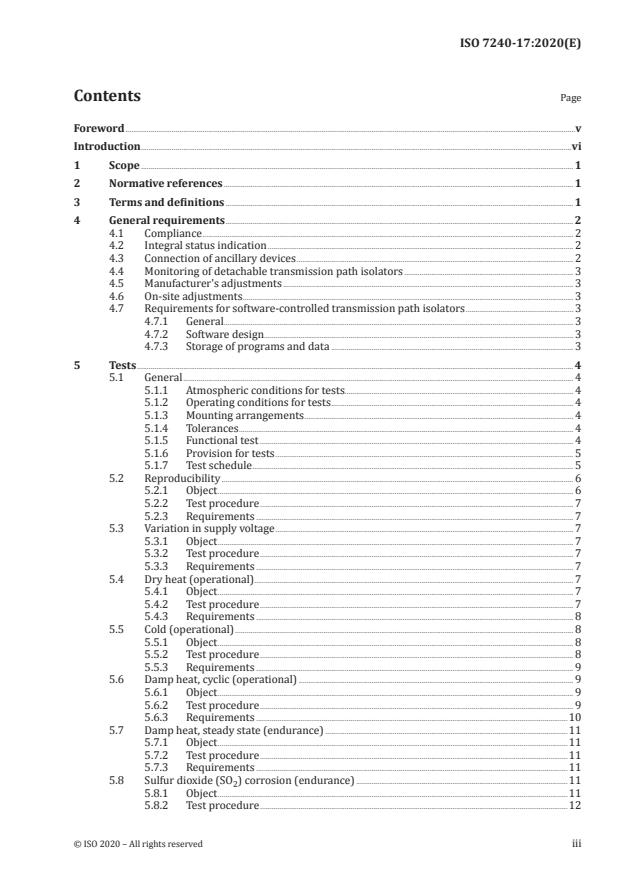

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 General requirements . 2

4.1 Compliance . 2

4.2 Integral status indication . 2

4.3 Connection of ancillary devices . 2

4.4 Monitoring of detachable transmission path isolators . 3

4.5 Manufacturer's adjustments . 3

4.6 On-site adjustments . 3

4.7 Requirements for software-controlled transmission path isolators . 3

4.7.1 General. 3

4.7.2 Software design. 3

4.7.3 Storage of programs and data . 3

5 Tests . 4

5.1 General . 4

5.1.1 Atmospheric conditions for tests. 4

5.1.2 Operating conditions for tests . 4

5.1.3 Mounting arrangements . 4

5.1.4 Tolerances . 4

5.1.5 Functional test . 4

5.1.6 Provision for tests . 5

5.1.7 Test schedule . 5

5.2 Reproducibility . 6

5.2.1 Object . 6

5.2.2 Test procedure . 7

5.2.3 Requirements . 7

5.3 Variation in supply voltage . 7

5.3.1 Object . 7

5.3.2 Test procedure . 7

5.3.3 Requirements . 7

5.4 Dry heat (operational) . 7

5.4.1 Object . 7

5.4.2 Test procedure . 7

5.4.3 Requirements . 8

5.5 Cold (operational) . 8

5.5.1 Object . 8

5.5.2 Test procedure . 8

5.5.3 Requirements . 9

5.6 Damp heat, cyclic (operational) . 9

5.6.1 Object . 9

5.6.2 Test procedure . 9

5.6.3 Requirements .10

5.7 Damp heat, steady state (endurance) .11

5.7.1 Object .11

5.7.2 Test procedure .11

5.7.3 Requirements .11

5.8 Sulfur dioxide (SO ) corrosion (endurance) .11

5.8.1 Object .11

5.8.2 Test procedure .12

5.8.3 Requirements .12

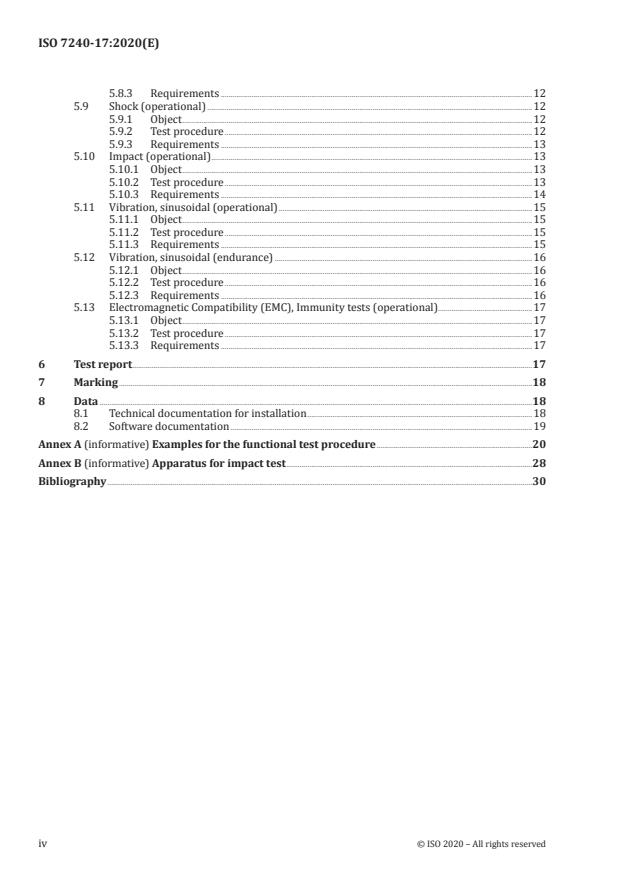

5.9 Shock (operational) .12

5.9.1 Object .12

5.9.2 Test procedure .12

5.9.3 Requirements .13

5.10 Impact (operational) .13

5.10.1 Object .13

5.10.2 Test procedure .13

5.10.3 Requirements .14

5.11 Vibration, sinusoidal (operational) .15

5.11.1 Object .15

5.11.2 Test procedure .15

5.11.3 Requirements .15

5.12 Vibration, sinusoidal (endurance) .16

5.12.1 Object .16

5.12.2 Test procedure .16

5.12.3 Requirements .16

5.13 Electromagnetic Compatibility (EMC), Immunity tests (operational) .17

5.13.1 Object .17

5.13.2 Test procedure .17

5.13.3 Requirements .17

6 Test report .17

7 Marking .18

8 Data .18

8.1 Technical documentation for installation .18

8.2 Software documentation .19

Annex A (informative) Examples for the functional test procedure .20

Annex B (informative) Apparatus for impact test .28

Bibliography .30

iv © ISO 2020 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see

www .iso .org/ iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 21, Equipment for fire protection and fire

fighting, Subcommittee SC 3, Fire detection and alarm systems.

The second edition cancels and replaces the first edition (ISO 7240-17:2009), which has been technically

revised. The main changes compared to the previous edition are as follows:

— the title of the document has been changed to “Transmission path isolators” which better reflects

the functionality of the product;

— the whole document has been updated to the latest ISO standard template;

— IEC 62599-2 has been included and replaces the reference to EN 50130-4;

— a new Clause 6 on test report, Clause 7 on marking and Clause 8 on data have been included.

A list of all parts in the ISO 7240 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

Introduction

Short-circuit isolators have been renamed transmission path isolators reflecting that the isolators

considered are intended to limit the consequences of low parallel resistance faults between the

lines of the transmission path(s) of a fire detection and fire alarm system. This is normally achieved

by connecting the transmission path in a loop configuration, separating sections of the loop with

transmission path isolators and introducing a means of detecting the presence of a fault if its

consequences (e.g. reduction in the line voltage) jeopardises the correct operation of components

on the transmission path. The faulty section of the loop can then be switched out, between a pair of

transmission path isolators, allowing the rest of the loop to continue to function correctly.

It is recognised that it is not possible for this component standard to specify all of the requirements

for the function of a transmission path isolator in a system. The requirements for the functioning of a

transmission path isolator are dependent on the system operation, the other components associated

with the transmission path (e.g. the control and indicating equipment and detectors) and the

transmission path parameters (e.g. line impedance and line loads), and they will have to be verified in a

system test.

However, this document includes:

— a requirement that the manufacturer gives all of the specifications, for the transmission path

isolator, needed by system designers to use the device correctly, in accordance with the system

requirements;

NOTE It is recognized that the system designer needs to ensure that only those transmission path isolators

having the necessary performance are chosen to meet the specific requirements of a given system design.

— the tests to verify that the transmission path isolator functions in accordance with these

manufacturer’s specifications;

— the tests to verify the stability of the transmission path isolator with respect to environmental and

electromagnetic compatibility (EMC) conditions.

Due to the many different concepts that can be used for the operation of transmission path isolators, it is

not possible to define a precise functional test procedure applicable to all types. Instead, this document

requires that a functional test procedure is developed to verify the manufacturer’s specification and

lists the most important points that have to be verified. To assist in developing such test procedures,

some example procedures are given in an informative annex (Annex A).

In view of the above, it is important that, in addition to meeting the requirements of this document,

transmission path isolators are shown to operate correctly within the types of systems with which

they are intended to be used.

vi © ISO 2020 – All rights reserved

INTERNATIONAL STANDARD ISO 7240-17:2020(E)

Fire detection and fire alarm systems —

Part 17:

Transmission path isolators

1 Scope

This document specifies the requirements, test methods and performance criteria for transmission

path isolators for use in fire detection and fire alarm systems for buildings (for general requirements

and definitions, see ISO 7240-1).

Means of isolation or protection incorporated within control and indicating equipment are not covered

by this document.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 209, Aluminium and aluminium alloys — Chemical composition

ISO 7240-1, Fire detection and alarm systems — Part 1: General and definitions

IEC 60068-1, Environmental testing — Part 1: General and guidance

IEC 60068-2-1, Environmental testing — Part 2-1: Tests. Tests A: Cold

IEC 60068-2-6, Environmental testing — Part 2-6: Tests — Test Fc: Vibration (sinusoidal)

IEC 60068-2-27, Environmental testing — Part 2-27: Tests. Test Ea and guidance: Shock

IEC 60068-2-30, Environmental testing — Part 2-30: Tests. Test Db and guidance: Damp heat, cyclic

(12 + 12-hour cycle)

IEC 60068-2-42, Environmental testing — Part 2-42: Tests — Test Kc: Sulphur dioxide test for contacts and

connections

IEC 62599-2, Alarm systems — Part 2: Electromagnetic compatibility — Immunity requirements for

components of fire and security alarm systems

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 7240-1 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1

transmission path isolator

device, which may be inserted into a transmission path of a fire detection and fire alarm system, to

limit the consequences of low parallel resistance faults between the lines of this transmission path

Note 1 to entry: A transmission path isolator may be a physically separate device or it may be incorporated into

another device (e.g. integrated into a smoke detector or detector base).

3.2

closed condition

condition of the transmission path isolator which allows the normal signals and the supply currents to

pass through the transmission path isolator

Note 1 to entry: This is the correct condition for the transmission path isolator when there is no short circuit.

3.3

open condition

condition of the transmission path isolator which prevents the passage of short circuit currents through

the transmission path isolator

Note 1 to entry: This is the correct condition for the transmission path isolator when it is protecting part of a

circuit from the effects of a short circuit.

3.4

field device

device, which is located remotely from the CIE and may be subject to a more severe environmental

condition

Note 1 to entry: Detectors, MCP, and alarm devices are always considered as field devices whereas PSE, input/

output module, and routing equipment may be field devices.

3.5

non-field device

device which is specified to be located in the same conditions as the CIE

4 General requirements

4.1 Compliance

In order to comply with this document, the transmission path isolator shall meet the requirements of:

a) Clause 4, which shall be verified by visual inspection or engineering assessment, shall be tested as

described in Clause 5 and shall meet the requirements of the tests;

b) Clauses 7 and 8, which shall be verified by visual inspection.

4.2 Integral status indication

If the transmission path isolator incorporates an integral visual indication of its status, then this

indication shall not be red.

4.3 Connection of ancillary devices

Where the transmission path isolator provides for connections to ancillary devices (e.g. remote

indicators), open or short circuit failures of these connections shall not prevent the correct operation of

the transmission path isolator.

2 © ISO 2020 – All rights reserved

4.4 Monitoring of detachable transmission path isolators

If a transmission path isolator is detachable (i.e. it is attached to a mounting base), then a means shall

be provided for a remote monitoring system (e.g. the control and indicating equipment) to detect the

removal of the device from the base, in order to give a fault signal.

4.5 Manufacturer's adjustments

It shall not be possible to change the manufacturer's settings except by special means (e.g. the use of a

special code or tool) or by breaking or removing a seal.

4.6 On-site adjustments

If there is provision for on-site adjustment of the transmission path isolator, then for each setting, the

transmission path isolator shall comply with the requirements of this document. Access to the means of

adjustment shall only be possible using a code or special tool.

4.7 Requirements for software-controlled transmission path isolators

4.7.1 General

The requirements of 4.7.2 and 4.7.3 shall apply to transmission path isolators that rely on software

control in order to fulfil the requirements of this document.

4.7.2 Software design

To ensure the reliability of the transmission path isolator, the following requirements for software

design shall apply.

— The software shall have a modular structure.

— The design of the interfaces for manually and automatically generated data shall not permit invalid

data to cause error in the program operation.

— The software shall be designed to avoid the occurrence of deadlock of the program flow.

4.7.3 Storage of programs and data

The program necessary to comply with this document and any pre-set data, such as manufacturer's

settings, shall be held in non-volatile memory. Writing to areas of memory containing this program

and data shall be possible only using some special tool or code and shall not be possible during normal

operation of the transmission path isolator.

Site-specific data shall be held in memory that will retain data for at least two weeks without external

power to the transmission path isolator, unless provision is made for the automatic renewal of such

data, following loss of power, within 1 h of power being restored.

5 Tests

5.1 General

5.1.1 Atmospheric conditions for tests

Unless otherwise stated in a test procedure, carry out the testing after the test specimen has been

allowed to stabilize in the standard atmospheric conditions for testing as described in IEC 60068-1 as

follows:

a) temperature: (15 to 35) °C;

b) relative humidity: (25 to 75) %;

c) air pressure: (86 to 106) kPa.

If variations in these parameters have a significant effect on a measurement, then such variations

need to be kept to a minimum during a series of measurements carried out as part of one test on one

specimen.

5.1.2 Operating conditions for tests

If a test method requires a specimen to be operational, then connect the specimen to suitable supply and

monitoring equipment with characteristics as required by the manufacturer's data. Unless otherwise

specified in the test method, apply the supply parameters to the specimen within the manufacturer's

specified range(s) so that it remains substantially constant throughout the tests. For each parameter,

choose the value that is normally the nominal value, or the mean of the specified range. If a test

procedure requires a specimen to be monitored to detect any alarm or fault signals, then connect it to

any necessary ancillary devices.

EXAMPLE To an end-of-line device for conventional detectors to allow a fault signal to be recognised.

5.1.3 Mounting arrangements

Mount the specimen by its normal means of attachment in accordance with the manufacturer's

instructions. If these instructions describe more than one method of mounting, then choose the method

considered to be most unfavourable for each test.

5.1.4 Tolerances

Unless otherwise stated, use the tolerances for the environmental test parameters as given in the basic

reference standards for the test (e.g. the relevant part of IEC 60068).

If a specific tolerance or deviation limit is not specified in a requirement or test procedure, then use a

deviation limit of ±5 %.

5.1.5 Functional test

5.1.5.1 Object

The object is to confirm the correct operation of the transmission path isolator, in accordance with

the manufacturer’s specification, and to verify their stability after and, where required, during the

environmental and EMC tests.

4 © ISO 2020 – All rights reserved

5.1.5.2 Test procedure

The functional test is intended to verify that the isolator operates within the manufacturer’s

specification, including the parameters that characterise the transmission path isolator. The functional

test verifies at least the following parameters:

a) each stimulus, which the manufacturer claims will cause the isolator to change from the closed to

the open condition;

EXAMPLE Stimulus such as current, voltage, and protocol.

b) each stimulus, which the manufacturer claims will cause the isolator to change from the open to

the closed condition;

c) the response to a direct short circuit applied to the isolator.

NOTE Some examples of functional tests are given in Annex A but these are not exhaustive.

5.1.6 Provision for tests

Provide the following for testing compliance with this document:

a) 14 specimens required to conduct the tests as indicated in the test schedule (see 5.1.7) and number

these specimens 1 to 14 arbitrarily;

b) the technical data required in Clause 8.

NOTE The specimens submitted are expected to be representative of the manufacturer's normal production

regarding their construction and calibration.

5.1.7 Test schedule

Test the specimen according to the following test schedule (see Table 1):

Table 1 — Test schedule

Subclause

Stand-alone Combined with

Test of this Remarks

isolator other functions

document

Specimen Specimen

number(s) number(s)

Reproducibility 5.2 all specimens all specimens

Variation in supply voltage 5.3 1 1

a,b,d

Dry heat (operational) 5.4 2 2

c

Dry heat (endurance) N/A N/A 5 refer to other

applicable part(s)

a

Cold (operational) 5.5 3 3

a,b

Damp heat, cyclic (operational) 5.6 4 4

a,b

Damp heat, steady state (endurance) 5.7 5 5

c

Damp heat, steady state (operational) N/A N/A 5 refer to other

applicable part(s)

a,d

Sulfur dioxide, SO , corrosion 5.8 6 6

(endurance)

a,d

Shock (operational) 5.9 7 7

Impact (operational) 5.10 8 8

c

Vibration, sinusoidal (operational) 5.11 9 9

c

Vibration, sinusoidal (endurance) 5.12 9 9

Enclosure protection (IP test) N/A N/A 7

e

Electrostatic discharge (operational) 5.13 10

e

Radiated electromagnetic fields 5.13 11

(operational)

e

Conducted disturbances induced by 5.13 12

electromagnetic fields (operational)

e

Fast-transient bursts (operational) 5.13 13

e

Slow, high-energy voltage surge 5.13 14

(operational)

a

If the other parts of ISO 7240 do not call up this test, then the test in this document shall be applied.

b

If the other function reacts to its normal operation due to the conditioning, then this is acceptable (e.g. [1] heat detector

class A1 may alarm at a temperature of 55 ± 2 °C, [2] smoke detector may go into alarm or fault due to condensation).

c

If the other parts of ISO 7240 call up these tests, then it shall be applied, and the functional test of the isolator shall be

applied before, after, and during where applicable.

d

If the other function is exclusively installed as a non-field device as specified in the manufacturer’s data sheet, then

this test will not be applicable (e.g. if a routing equipment is installed as a field device on a loop, the test will apply but if it is

installed in the same condition as CIE then the test will not apply).

e

In the interests of test economy, it is permitted to use the same specimen for more than one EMC test. In this case,

intermediate functional test(s) on the specimen(s) used for more than one test may be deleted, and the functional test

may conducted at the end of the sequence of tests. However, it should be noted that in the event of a failure, it might not be

possible to identify which test exposure caused the failure; see IEC 62599-2.

5.2 Reproducibility

5.2.1 Object

The object is to show that each specimen meets the manufacturer’s specification.

6 © ISO 2020 – All rights reserved

5.2.2 Test procedure

Conduct the functional test as described in 5.1.5 on each specimen.

5.2.3 Requirements

Each specimen shall function correctly within the manufacturer’s specification.

5.3 Variation in supply voltage

5.3.1 Object

The object is to show that the transmission path isolator meets the manufacturer’s specification for the

specified range of supply voltage.

5.3.2 Test procedure

Conduct the functional test as described in 5.1.5 at the upper and lower limits of the supply voltage

range specified by the manufacturer.

NOTE In the examples given in Annex A, this would mean replacing V by V and V .

nom max min

5.3.3 Requirements

The specimen shall function correctly within the manufacturer’s specification.

5.4 Dry heat (operational)

5.4.1 Object

The object is to demonstrate the ability of the transmission path isolator to function correctly at high

ambient temperatures appropriate to the anticipated service environment.

5.4.2 Test procedure

5.4.2.1 Reference

Use the test apparatus and procedure as described in IEC 60068-2-2, test Bb and the procedure

indicated below.

Where the isolator is combined with other parts of ISO 7240 functions in a component, apply the

apparatus and test procedure described in the part of ISO 7240 for that other function.

Where the isolator is combined with other function(s) in a component and the test is not in other parts

of the ISO 7240 series, then apply the test, in this document, unless the other function(s) is exclusively a

non-field device as specified in the manufacturer’s data sheet., in which case, no test needs to be applied.

The dry heat (operational) clause in ISO 7240-7 is not equivalent to this test, hence a combined

transmission path isolator and smoke detection component shall be tested in accordance with this

procedure.

5.4.2.2 State of the specimen during conditioning

Mount the specimen as described in 5.1.3 and connect it to the supply and monitoring equipment as

described in 5.1.2.

5.4.2.3 Conditioning

Apply the following conditioning unless the transmission path isolator is combined with other

function(s) in a component that specifies different conditioning in which case, apply the conditioning

specified in the part of ISO 7240 for that other function:

a) indoor environmental type

— temperature: (55 ± 2) °C, and

— duration: 16 h;

b) outdoor environmental type

— temperature: (70 ± 2) °C, and

— duration: 16 h.

5.4.2.4 Measurements during conditioning

During the conditioning period, monitor the specimen to detect any change from the transmission path

isolator closed condition.

During the last hour of the conditioning period, conduct the functional test as described in 5.1.5.

5.4.2.5 Final measurements

After a recovery period of at least 1 h at the standard laboratory conditions, conduct the functional test

as described in 5.1.5.

5.4.3 Requirements

The specimen shall remain in the closed condition during the conditioning period except when required

to change during the functional test.

The specimen shall function correctly within the manufacturer’s specification during the functional tests.

5.5 Cold (operational)

5.5.1 Object

The object is to demonstrate the ability of the transmission path isolator to function correctly at low

ambient temperatures appropriate to the anticipated service environment.

5.5.2 Test procedure

5.5.2.1 Reference

Use the test apparatus and procedure as described in IEC 60068-2-1, Test Ab and the procedure

described below.

Where the isolator is combined with other ISO 7240 function(s) in a component, use the apparatus and

test procedure specified in the part of ISO 7240 for that other function(s).

Where the isolator is combined with other function(s) in a component and the test is not in any other

part of ISO 7240, then apply the test in this document.

8 © ISO 2020 – All rights reserved

5.5.2.2 State of the specimen during conditioning

Mount the specimen as described in 5.1.3 and connect it to the supply and monitoring equipment as

described in 5.1.2.

5.5.2.3 Conditioning

Apply the following conditioning unless the transmission path isolator is combined with other

function(s) in a component that specifies different conditioning in which case, apply the conditioning

specified in the part of ISO 7240 for that other function:

a) indoor environmental type

— temperature: (−10 ± 3) °C, and

— duration: 16 h;

b) outdoor environmental type

— temperature: (−25 ± 3) °C, and

— duration: 16 h.

NOTE In countries with very cold temperatures, specific requirements can apply.

5.5.2.4 Measurements during conditioning

During the conditioning period, monitor the specimen to detect any change from the transmission path

isolator closed condition.

During the last hour of the conditioning period, conduct the functional test as described in 5.1.5.

5.5.2.5 Final measurements

After a recovery period of at least 1 h at the standard laboratory conditions, conduct the functional test

as described in 5.1.5.

5.5.3 Requirements

The specimen shall remain in the closed condition during the conditioning period except when required

to change during the functional test.

The specimen shall function correctly within the manufacturer’s specification during the functional tests.

5.6 Damp heat, cyclic (operational)

5.6.1 Object

The object is to demonstrate the ability of the transmission path isolator to function correctly at high

relative humidity (with condensation), which can occur for short periods in the anticipated service

environment.

5.6.2 Test procedure

5.6.2.1 Reference

Use the test apparatus and procedure as described in IEC 60068-2-30, Test Db using the Variant 1 test

cycle and controlled recovery conditions and the procedure described below.

Where the isolator is combined with other ISO 7240 function(s) in a component, use the apparatus and

test procedure specified in the part of ISO 7240 for that other function(s).

Where the isolator is combined with other function(s) in a component and the test is not in any other

part of ISO 7240, then apply the test in this document.

5.6.2.2 State of the specimen during conditioning

Mount the specimen as described in 5.1.3 and connect it to the supply and monitoring equipment as

described in 5.1.2.

5.6.2.3 Conditioning

Apply the following conditioning unless the transmission path isolator is combined with other

function(s) in a component that specifies different conditioning in which case, apply the conditioning

specified in the part of ISO 7240 for that other function:

a) indoor environmental type

— lower temperature: (25 ± 3) °C,

— relative humidity (lower temperature): ≥95 %,

— upper temperature: (40 ± 3) °C,

— relative humidity (upper temperature): (93 ± 3) %, and

— number of cycles: 2;

b) outdoor environmental type

— lower temperature: (25 ± 3) °C,

— relative humidity (lower temperature): ≥95 %,

— upper temperature: (55 ± 3) °C,

— relative humidity (upper temperature): (93 ± 3) %, and

— number of cycles: 2.

5.6.2.4 Measurements during conditioning

During the conditioning period, monitor the specimen to detect any change from the transmission path

isolator closed condition.

During the last hour of the conditioning period, conduct the functional test as described in 5.1.5.2 c).

5.6.2.5 Final measurements

After the recovery period, conduct the functional test as described in 5.1.5.

5.6.3 Requirements

The specimen shall remain in the closed condition during the conditioning period.

The specimen shall function correctly within the manufacturer’s specification during the functional test.

10 © ISO 2020 – All rights reserved

5.7 Damp heat, steady state (endurance)

5.7.1 Object

The object is to demonstrate the ability of the transmission path isolator to withstand the long-term

effects of humidity in the service environment (e.g. changes in electrical properties of materials,

chemical reactions involving moisture or galvanic corrosion).

5.7.2 Test procedure

5.7.2.1 Reference

Use the test apparatus and procedure as described in IEC 60068-2-30, Test Db using the Variant 1 test

cycle and controlled recovery conditions and as described below.

Where the isolator is combined with other ISO 7240 function(s) in a component, use the apparatus and

test procedure described in the part of ISO 7240 for that other function(s).

Where the isolator is combined with other function(s) in a component and the test is not in any other

part of ISO 7240, then apply the test in this document.

5.7.2.2 State of the specimen during conditioning

Mount the specimen as described in 5.1.3 but do not supply it with power during the conditioning.

5.7.2.3 Conditioning

Apply the following conditioning unless the transmission path isolator is combined with other

function(s) in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...