ISO 11336-2:2020

(Main)Large yachts — Strength, weathertightness and watertightness of glazed openings — Part 2: Glazed opening integrated into adjacent structure (elastically bonded to bulkhead or shell) design criteria, structural support, installation and testing

Large yachts — Strength, weathertightness and watertightness of glazed openings — Part 2: Glazed opening integrated into adjacent structure (elastically bonded to bulkhead or shell) design criteria, structural support, installation and testing

This document specifies technical requirements for direct adhesive bonding of glazing materials into recesses forming part of the structure of the ship and into frames that are fastened to the structure of the ship. It is applicable to large yachts as defined in ISO 11336-1. This document is limited to the bonding of independent glazed openings, where the bonded joint is designed to withstand local loads (from external loads coming from weather and sea conditions, internal impact loads from accidental passenger or cargo shifting, wind suction and accelerations due to ship motions). Bonding of glazed openings where the glazing material is subjected to loads from global ship motions (bending, shear force and torsion), which are considered as structural glazed openings, are outside the scope of this document. Quantitative identification of the global deflection is also outside the scope. Additionally, this document is limited to bonding that exhibits elastic behaviour, and excludes rigid bonding and nonlinear elastic bonding. The design of the bonding for the following installation types is outside the scope of this document: — fire protected areas; — glazed bulwarks; — underwater glazing; — pool glazing; — glazing for use in polar areas; — unstepped IGUs.

Grands yachts — Résistance, imperméabilité au mauvais temps et étanchéité des ouvertures vitrées — Partie 2: Critères de conception, support structurel, installation et essais des ouvertures vitrées faisant partie intégrale de la structure adjacente (directement collées sur la cloison ou le bordé)

General Information

- Status

- Published

- Publication Date

- 11-Aug-2020

- Technical Committee

- ISO/TC 8/SC 12 - Ships and marine technology - Large yachts

- Drafting Committee

- ISO/TC 8/SC 12/WG 2 - Safety and hull integrity

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 11-Dec-2025

- Completion Date

- 12-Feb-2026

Overview

ISO 11336-2:2020 specifies technical requirements for the direct adhesive bonding of glazing into recesses or frames that form part of a large yacht’s structure. Focused on elastically bonded (not rigid) glazed openings, the standard applies to independent glazed openings integrated into adjacent structure and addresses design criteria, structural support, installation and testing to assure strength, weathertightness and watertightness. It complements ISO 11336-1 and is limited to local loads (weather, wind suction, accidental internal impacts and ship motion accelerations), excluding structural glazing that carries global ship loads.

Key topics and technical requirements

- Bonding materials: Requirements for adhesives, including physical characteristics (flexural and shear modulus, elongation, tensile strength, Shore hardness), environmental resistance and long‑term properties.

- Bonding arrangements: Configurations for glazing bonded to bulkheads or shell, limitations for sloped/overhead glazing and guidance on insulated glazed units (IGUs).

- Bonded joint design: Design loads and load cases (static, dynamic, fatigue and accidental internal loads), bondline parameter limitations and calculation guidance (worked examples in annexes).

- Installation and procedures: Surface preparation, bonding application guidelines, installation sequencing and laboratory/onsite curing practices.

- Testing and verification: Material testing, proof testing of bonded joints and acceptance criteria; includes personnel qualification and survey guidance.

- Scope exclusions: Fire-protected areas, glazed bulwarks, underwater glazing, pool glazing, polar-area glazing, unstepped IGUs and bonding that behaves non‑elastically.

Practical applications and intended users

ISO 11336-2 is essential for professionals involved in yacht design, construction and certification who need to ensure glazed openings perform reliably under marine service conditions. Typical users include:

- Naval architects and yacht designers specifying bonded glazing solutions

- Shipyards and fit-out yards installing bonded windows and deckhouse glazing

- Glazing and insulated glazed unit (IGU) manufacturers designing bondlines

- Adhesive suppliers qualifying materials for marine glazing applications

- Surveyors, certification bodies and QA/QC inspectors performing proof testing and acceptance checks

Benefits include consistent weathertight/watertight performance, predictable elastic behaviour under local loads, reduced leak and failure risk and clear testing and installation requirements for regulatory compliance.

Related standards

- ISO 11336-1 (Design criteria, materials, framing and testing of independent glazed openings)

- Normative test references cited in the document (examples): ISO 37, ISO 527 series, ISO 8339, ISO 11003 series, DIN 6701-3

Keywords: ISO 11336-2, large yachts, glazed openings, adhesive bonding, elastic bonding, weathertightness, watertightness, IGU, bondline design, installation, testing.

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Sponsored listings

Frequently Asked Questions

ISO 11336-2:2020 is a standard published by the International Organization for Standardization (ISO). Its full title is "Large yachts — Strength, weathertightness and watertightness of glazed openings — Part 2: Glazed opening integrated into adjacent structure (elastically bonded to bulkhead or shell) design criteria, structural support, installation and testing". This standard covers: This document specifies technical requirements for direct adhesive bonding of glazing materials into recesses forming part of the structure of the ship and into frames that are fastened to the structure of the ship. It is applicable to large yachts as defined in ISO 11336-1. This document is limited to the bonding of independent glazed openings, where the bonded joint is designed to withstand local loads (from external loads coming from weather and sea conditions, internal impact loads from accidental passenger or cargo shifting, wind suction and accelerations due to ship motions). Bonding of glazed openings where the glazing material is subjected to loads from global ship motions (bending, shear force and torsion), which are considered as structural glazed openings, are outside the scope of this document. Quantitative identification of the global deflection is also outside the scope. Additionally, this document is limited to bonding that exhibits elastic behaviour, and excludes rigid bonding and nonlinear elastic bonding. The design of the bonding for the following installation types is outside the scope of this document: — fire protected areas; — glazed bulwarks; — underwater glazing; — pool glazing; — glazing for use in polar areas; — unstepped IGUs.

This document specifies technical requirements for direct adhesive bonding of glazing materials into recesses forming part of the structure of the ship and into frames that are fastened to the structure of the ship. It is applicable to large yachts as defined in ISO 11336-1. This document is limited to the bonding of independent glazed openings, where the bonded joint is designed to withstand local loads (from external loads coming from weather and sea conditions, internal impact loads from accidental passenger or cargo shifting, wind suction and accelerations due to ship motions). Bonding of glazed openings where the glazing material is subjected to loads from global ship motions (bending, shear force and torsion), which are considered as structural glazed openings, are outside the scope of this document. Quantitative identification of the global deflection is also outside the scope. Additionally, this document is limited to bonding that exhibits elastic behaviour, and excludes rigid bonding and nonlinear elastic bonding. The design of the bonding for the following installation types is outside the scope of this document: — fire protected areas; — glazed bulwarks; — underwater glazing; — pool glazing; — glazing for use in polar areas; — unstepped IGUs.

ISO 11336-2:2020 is classified under the following ICS (International Classification for Standards) categories: 47.040 - Seagoing vessels. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 11336-2:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 11336-2

First edition

2020-08

Large yachts — Strength,

weathertightness and watertightness

of glazed openings —

Part 2:

Glazed opening integrated into

adjacent structure (elastically

bonded to bulkhead or shell)

design criteria, structural support,

installation and testing

Grands yachts — Résistance, imperméabilité au mauvais temps et

étanchéité des ouvertures vitrées —

Partie 2: Critères de conception, support structurel, installation et

essais des ouvertures vitrées faisant partie intégrale de la structure

adjacente (directement collées sur la cloison ou le bordé)

Reference number

©

ISO 2020

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

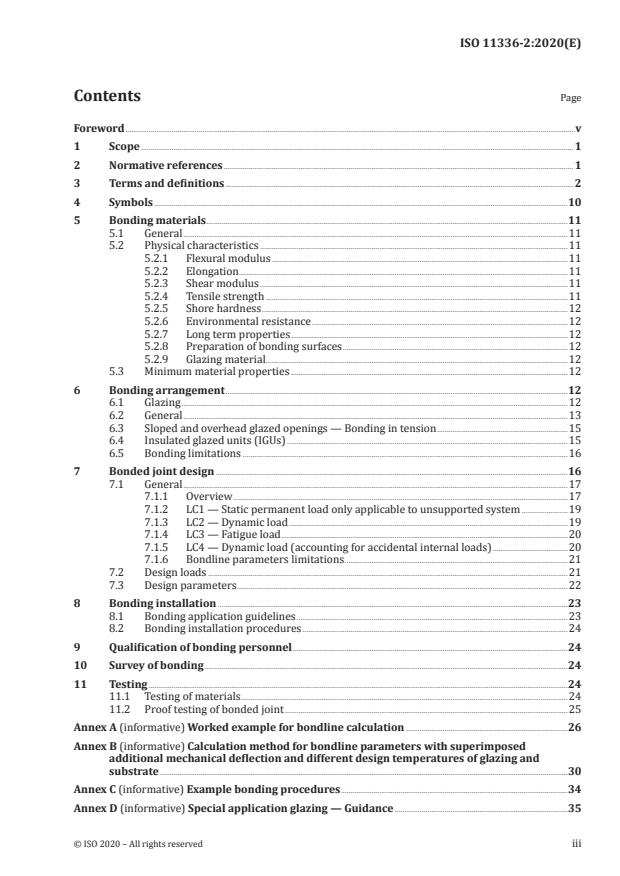

Contents Page

Foreword .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Symbols .10

5 Bonding materials .11

5.1 General .11

5.2 Physical characteristics .11

5.2.1 Flexural modulus .11

5.2.2 Elongation .11

5.2.3 Shear modulus .11

5.2.4 Tensile strength .11

5.2.5 Shore hardness .12

5.2.6 Environmental resistance .12

5.2.7 Long term properties .12

5.2.8 Preparation of bonding surfaces .12

5.2.9 Glazing material .12

5.3 Minimum material properties .12

6 Bonding arrangement .12

6.1 Glazing .12

6.2 General .13

6.3 Sloped and overhead glazed openings — Bonding in tension .15

6.4 Insulated glazed units (IGUs) .15

6.5 Bonding limitations .16

7 Bonded joint design .16

7.1 General .17

7.1.1 Overview .17

7.1.2 LC1 — Static permanent load only applicable to unsupported system .19

7.1.3 LC2 — Dynamic load .19

7.1.4 LC3 — Fatigue load .20

7.1.5 LC4 — Dynamic load (accounting for accidental internal loads) .20

7.1.6 Bondline parameters limitations .21

7.2 Design loads .21

7.3 Design parameters .22

8 Bonding installation .23

8.1 Bonding application guidelines .23

8.2 Bonding installation procedures .24

9 Qualification of bonding personnel .24

10 Survey of bonding .24

11 Testing .24

11.1 Testing of materials .24

11.2 Proof testing of bonded joint .25

Annex A (informative) Worked example for bondline calculation .26

Annex B (informative) Calculation method for bondline parameters with superimposed

additional mechanical deflection and different design temperatures of glazing and

substrate .30

Annex C (informative) Example bonding procedures .34

Annex D (informative) Special application glazing — Guidance .35

Bibliography .36

iv © ISO 2020 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www .iso .org/ iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 8, Ships and marine technology,

Subcommittee SC 12, Large yachts.

A list of all parts in the ISO 11336 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

INTERNATIONAL STANDARD ISO 11336-2:2020(E)

Large yachts — Strength, weathertightness and

watertightness of glazed openings —

Part 2:

Glazed opening integrated into adjacent structure

(elastically bonded to bulkhead or shell) design criteria,

structural support, installation and testing

1 Scope

This document specifies technical requirements for direct adhesive bonding of glazing materials into

recesses forming part of the structure of the ship and into frames that are fastened to the structure of

the ship.

It is applicable to large yachts as defined in ISO 11336-1.

This document is limited to the bonding of independent glazed openings, where the bonded joint is

designed to withstand local loads (from external loads coming from weather and sea conditions,

internal impact loads from accidental passenger or cargo shifting, wind suction and accelerations due

to ship motions).

Bonding of glazed openings where the glazing material is subjected to loads from global ship motions

(bending, shear force and torsion), which are considered as structural glazed openings, are outside the

scope of this document. Quantitative identification of the global deflection is also outside the scope.

Additionally, this document is limited to bonding that exhibits elastic behaviour, and excludes rigid

bonding and nonlinear elastic bonding.

The design of the bonding for the following installation types is outside the scope of this document:

— fire protected areas;

— glazed bulwarks;

— underwater glazing;

— pool glazing;

— glazing for use in polar areas;

— unstepped IGUs.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 37, Rubber, vulcanized or thermoplastic — Determination of tensile stress-strain properties

ISO 48-5, Rubber, vulcanized or thermoplastic — Determination of hardness — Part 5: Indentation

hardness by IRHD pocket meter method

ISO 527-1, Plastics — Determination of tensile properties — Part 1: General principles

ISO 527-2, Plastics — Determination of tensile properties — Part 2: Test conditions for moulding and

extrusion plastics

ISO 8339, Building construction — Sealants — Determination of tensile properties (Extension to break)

ISO 11003-1, Adhesives — Determination of shear behaviour of structural adhesives — Part 1: Torsion test

method using butt-bonded hollow cylinders

ISO 11003-2, Adhesives — Determination of shear behaviour of structural adhesives — Part 2: Tensile test

method using thick adherends

ISO 11336-1:2012Large yachts — Strength, weathertightness and watertightness of glazed openings —

Part 1: Design criteria, materials, framing and testing of independent glazed openings

DIN 53504, Testing of rubber — Determination of tensile strength at break, tensile stress at yield, elongation

at break and stress values in a tensile test

DIN 6701-3:2015, Adhesive bonding of railway vehicles and parts. Part 3 Guideline for construction design

and verification of bonds on railway vehicles

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1

bonding material

adhesive material that is used to adhere or bond items together

3.2

bonding process

process to join two materials with an adhesive

3.3

bonded joint

joint between the glazing (3.6) and substrate, consisting of a bonding material (3.1) and a sealing

material (3.4) if required

3.4

sealing material

material used to cover and protect (where necessary) the bonding material (3.1)

Note 1 to entry: The sealing itself is not considered to be part of the adhesive bond.

Note 2 to entry: The following items can have a negative effect on bonding materials:

— UV Light,

— seawater,

— chemicals (from cleaning compounds and or biological degradation).

Unless the bonding is specifically designed to be resistant to the above items, it must be protected by a seal

or sealing material (3.4). The sealing material (if present) combines with the bonding to form a weather or

watertight seal.

2 © ISO 2020 – All rights reserved

3.5

elastic bonding

bonding where the bonded joints (3.3) are capable of transferring forces and distributing stresses

evenly and show a high degree of flexibility (ability to return to its original shape after deformation)

Note 1 to entry: Its purpose is to hold the glazing (3.6) in place, and to maintain its attachment to the structure

(transmitting loads from the glazing to the ships structure). Additionally, it provides the watertight/weathertight

boundary, whilst allowing rotational deflection and expansion/contraction of the glazing and/or the supporting

structure.

3.6

glazing

transparent or translucent pane

3.7

glazed opening

opening in the hull, superstructure or deckhouse of a ship structure fitted with glazing (3.6)

3.8

independent glazed opening

glazed opening (3.7) where the mechanical behaviour of the pane can be considered independent from

adjacent structures

EXAMPLE Framed appliance (3.9).

3.9

framed appliance

independent glazed opening (3.8) where the glass is clamped into a frame structure consisting of a frame

and a mechanical retainer

Note 1 to entry: For a framed appliance, the weight of the glass is mainly kept by the frame and the retainer. A

rubber gasket or an adhesive is used in this construction to prevent the direct contact between glass and frame

and to achieve watertightness or weathertightness.

3.10

appliance

device made of glazing (3.6) and adhesive or frame, used to cover and protect an opening in the hull,

superstructure or deckhouse

3.11

glazed opening integrated into adjacent structure

glazed opening (3.7) where the mechanical behaviour of the pane cannot be considered independent

from adjacent structures

EXAMPLE Pane bonded directly into a frame.

3.12

insulated glazing unit

IGU

glazing (3.6) made of multiple panes, either monolithic or laminated, separated by sealed gaps filled

with gas (air, argon, etc.)

3.13

stepped IGU

IGU (3.12) where one of the panes is fixed to the framing while the other pane is not supported by the

framing structure

Note 1 to entry: The bonding of stepped IGUs can be designed using the approach defined in this document.

Note 2 to entry: See Figure 1.

3.14

unstepped IGU

IGU (3.12) where both panes are supported by the framing structure

Note 1 to entry: See Figure 1.

Key

1 stepped IGU

2 unstepped IGU

Figure 1 — Stepped and unstepped IGU glazing

3.15

bonded window

glazed opening (3.7) where the glass is attached to the adjacent structure by an adhesive

Note 1 to entry: For a bonded window, the adhesive holds the weight of the glass and keeps the glass in its position

under load. Bonded windows can be used like a framed window in any position on board of a large yacht.

3.16

substrate

material from which the frame, hull or superstructure is constructed, which can include filler, primer,

and paint systems

EXAMPLE Steel, aluminium, fibre reinforced plastic (FRP), or wood.

3.17

surface preparation

process of treating the surface of a substance in order to increase its adhesion, which includes applying

components such as activators, cleaners and primers

3.18

UV protection

UV light blocking border, applied to the surface or within the laminate of the glazing, designed to

protect the bond from UV light

3.19

spacer

element used to support the glass weight and to secure positioning during installation and bond cure,

that is removed prior to the application of the sealing

3.20

setting block

element used to support the glass weight and to secure positioning during installation and bond cure,

left in place throughout the lifetime of the bonding but considered not to take any load

Note 1 to entry: The setting block must be chemically compatible and must have a shore hardness less than the

surrounding bonding and sealing.

4 © ISO 2020 – All rights reserved

3.21

resting pad

element designed to support the glass weight and to secure positioning during installation, bond cure

and during the lifetime of the bonding

Note 1 to entry: A resting pad is left in place throughout the lifetime of the bonding, and must be chemically

compatible. It must have a shore hardness greater than the surrounding bonding and sealing, so as to support the

glass weight throughout the lifetime of the bonding.

3.22

bonding width

distance along the mating faces of the substrate and adhesive, and the adhesive and glazing (3.6)

Note 1 to entry: See Figures 2 to 4 for illustrative sketches.

3.23

bonding thickness

distance between the mating faces of the substrate and the glazing

Note 1 to entry: See Figures 2 to 4 for illustrative sketches.

3.24

sealing gap

in case of flush or recessed glazing, distance between the edge of the glazing and substrate and/or

adjacent glazing, measured in the plane of the glazing

Note 1 to entry: See Figures 2 to 4 for illustrative sketches.

Key

1 glazing

2 UV protection

3 bonding material

4 sealing material

5 substrate

6 outside

7 inside

A bonding thickness, see 3.23

B bonding width, see 3.22

C sealing gap, see 3.24

Figure 2 — Bonding from outside — Glazing to substrate

6 © ISO 2020 – All rights reserved

Key

1 glazing

2 UV protection

3 bonding material

4 sealing material

5 substrate

6 outside

7 inside

A bonding thickness, see 3.23

B bonding width, see 3.22

C sealing gap, see 3.24 (note that for a glass to glass bonding, the seal gap is 2 × C)

Figure 3 — Bonding from outside — Glazing to glazing and substrate

Key

1 glazing

2 UV protection

3 bonding material

4 sealing material

5 substrate

6 outside

7 inside

A bonding thickness, see 3.23

B bonding width, see 3.22

C sealing gap, see 3.24

Note For limits of the use of windows bonded from the inside, see ISO 11336-1:2012, 6.2.2.

Figure 4 — Bonding from inside (see Note) — Glazing to substrate

3.25

bonding manufacturer

competent entity that provides the bonding material (3.1) and sealing material (3.4), the technical

documentation and the application guidance for its use by the bonding installer

3.26

bonding installer

company, organisation, or person responsible for the installation of the glazing (3.6), bonding, and sealing

3.27

sloped glazed opening

glazed opening (3.7) where the installation is such that the plane of the glazing (3.6) of the appliance is

orientated at an angle to vertical

3.28

overhead glazed opening

glazed opening (3.7) where the installation of the appliance is located where persons on board can be

underneath

8 © ISO 2020 – All rights reserved

3.29

walkable glazed opening

glazed opening (3.7) where the installation of the appliance is located in a position where persons can

walk or stand on the opening during normal operations

3.30

retainer

structural or mechanical device that is fastened to the substrate and that prevents the glazing from

falling out of the recess in the event of failure of the bonding material

3.31

filler

substance used to fill or fair the structure of a yacht prior to painting

3.32

reduction factor

factor used to take into account the effect of the reduced performance of an adhesive when exposed to a

particular load (environmental) situation

Note 1 to entry: See 7.1 and 11.1.

3.33

temperature exposure

temperature range considered for the bonding likely to be experienced during the lifetime of the yacht

3.34

permanent static load

long duration load that does not change in magnitude

EXAMPLE Self weight (3.36).

3.35

dynamic cyclic load

short duration load that varies in cycles

EXAMPLE Wave or wind pressure, accelerations due to ship motions.

3.36

self weight

force exerted by gravity on a body

3.37

aging conditions

long term exposure to environmental conditions that can reduce the performance of a bonding

material (3.1)

EXAMPLE UV, temperature.

3.38

design pressure

pressure acting on the glazing (3.6) due to the independent or combined actions of the wave impact and

head of water

3.39

wind load

pressure or wind suction loads acting on the glazing (3.6) due to the movement of air

3.40

linear thermal expansion

change in linear dimension of a material in response to a change in temperature

3.41

bonding application guidance

guidance information, provided by the bonding manufacturer, for use of the bonding material (3.1) or

materials during installation

3.42

bonding installation procedures

operational procedures, provided by the bonding installer, to detail and control the bonding process

(3.2) during installation

4 Symbols

σ Allowable strength, N/mm

A

σ Equivalent stress, N/mm

v

σ Characteristic strength value at laboratory condition (95 % confidence), N/mm

lab

σ Stress along bonding thickness direction (compression or tensile stress), N/mm

f Reduction factor for temperature exposure

redT

f Reduction factor for permanent static load

redS

f Reduction factor for dynamic cyclic load

redD

f Reduction factor for fatigue cyclic load

redF

f Reduction factor for aging conditions

redA

S Material factor

R Ratio compression strength to tensile strength of adhesive

c Maximum allowable adhesive elongation, decimal fraction or percentage

γ Shear strain

P Design pressure, kN/m

D

P Maximum wind load (dynamic load), kN/m

wind,max

P Medium wind load (fatigue load), kN/m

wind,med

T Maximum/minimum design temperature of the window, °C

design

T Temperature of joint application, °C

application

a Maximum acceleration due to sea swell, m/s

max

a Medium acceleration due to sea swell, m/s

med

α Linear thermal expansion coefficient of glazing material

g

α Linear thermal expansion coefficient of substrate material

s

τ Stress perpendicular to glass plane applied at the bonding surface - shear stress, N/mm

τ Supported shear stress, N/mm

Supp

10 © ISO 2020 – All rights reserved

τ Unsupported shear stress, N/mm

Unsupp

β Glazing angle, °

d Bonding thickness, mm

w Bonding width, mm

C Sealing gap, mm

gap

5 Bonding materials

5.1 General

A record of the bonding application guidance (see 8.1) and bonding installation procedures (see 8.2)

shall be provided and kept on board (see ISO 11336-3).

Where no previous information on the installed bonding is available and it is required to install new

bonding, compatibility tests shall be made (see ISO 11336-3).

The bonding material shall meet the minimum requirements specified in 5.3.

The simplified and approximated structural model of the bonding, considered in this document, is

made of two stress components: a uniaxial tensile or compressive component (σ) perpendicular to the

glass plane, and a shear component (τ) whose plane is perpendicular to the glass plane and applied at

the bonding surface. This is shown in Figure 5.

Figure 5 — Tensile or compressive (σ) and shear (τ) stress components

5.2 Physical characteristics

5.2.1 Flexural modulus

Tests according to ISO 37, ISO 527-1, ISO 527-2 and DIN 53504.

5.2.2 Elongation

Tests according to ISO 37, ISO 527-1, ISO 527-2 and DIN 53504.

5.2.3 Shear modulus

Tests according to ISO 11003-1 and ISO 11003-2, DIN 6701-3.

5.2.4 Tensile strength

Tests according to ISO 37 and DIN 53504.

5.2.5 Shore hardness

Tests according to ISO 48-5.

5.2.6 Environmental resistance

The resistance of the bonding material shall be tested and documented by

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...