ISO 2415:1973

(Main)Shackles — General characteristics

Shackles — General characteristics

Manilles — Caractéristiques générales

General Information

- Status

- Withdrawn

- Publication Date

- 31-Aug-1973

- Withdrawal Date

- 31-Aug-1973

- Technical Committee

- ISO/TC 111/SC 3 - Components and accessories

- Drafting Committee

- ISO/TC 111/SC 3 - Components and accessories

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 01-Apr-1987

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 15-Apr-2008

Frequently Asked Questions

ISO 2415:1973 is a standard published by the International Organization for Standardization (ISO). Its full title is "Shackles — General characteristics". This standard covers: Shackles — General characteristics

Shackles — General characteristics

ISO 2415:1973 is classified under the following ICS (International Classification for Standards) categories: 53.020.30 - Accessories for lifting equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 2415:1973 has the following relationships with other standards: It is inter standard links to ISO 2415:1987. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 2415:1973 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

I

~~

@ 2415

INTERNATIONAL STANDARD

‘ai&

~~ ~ ~ ~~~~~~~~ ~~

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION *MEXAYHAPOAHAR OPrAHHJAUHR II0 CTAHflAPTM3AUHH.ORGANISATION INTERNATIONALE DE NORMALISATION

1 Shackles - General characteristics

First edition - 1973-09-01

w UDC 672.611 : 621.86.06 Ref. No. IS0 2415-1973 (E)

I

? Descriptors : chains, accessories, shackles, characteristics, mechanical properties, dimensional tolerances, proof loads, vocabulary.

ÙI

Price based on 7 pages

FOREWORD

IS0 (the International Organization for Standardization) is a worldwide federation

of national standards institutes (IS0 Member Bodies). The work of developing

International Standards is carried out through IS0 Technical Committees. Every

Member Body interested in a subject for which a Technical Committee has been set

up has the right to be represented on that Committee. International organizations,

governmental and nongovernmental, in liaison with ISO, also take part in the work.

Draft International Standards adopted by the Technical Committees are circulated

to the Member Bodies for approval before their acceptance as International

Standards by the IS0 Council.

International Standard IS0 2415 was drawn UD by Technical Committee

lSO/TC 11 1, Round steel link chains, chain wheels, lifting hooks and accessories,

and circulated to the Member Bodies in August 1971.

It has been approved by the Member Bodies of the following countries :

Austria I re land South Africa, Rep. of

Canada Italy Sweden

Egypt, Arab Rep. of Netherlands Thailand

France New Zealand Turkey

India Romania United Kingdom

The Member Bodies of the following countries expressed disapproval of the

document on technical grounds :

Austr a I ia

Belgium

Japan

U.S.A.

O International Organization for Standardization, 1973 0

Printed in Switzerland

IS0 2415-1973 (E)

INTERNATIONAL STANDARD

Shackles - General characteristics

O INTRODUCTION 3.2 body : One of the two parts of the shackle, consisting

a bar of circular section bent through 180' terminating

of

The characteristics described in this International Standard

in coaxial eyes.

are applicable to shackles of any form or dimension. Other

International Standards have been prepared for shackles of

3.3 crown : The bent part of the shackle body.

particular forms and dimensions.' )

Lifting tackle is made in more than one type of material. 3.4 eyes: Bosses on the end of the body, pierced by

The variations of the material impart variations of mechanical coaxial holes through which the pin passes.

characteristics. A shackle having the same working load

as another may have smaller body and pin diameters, owing

3.5 pin : A straight bar of circular section which closes the

to the greater strength which results from the material

shackle body, arranged so as to be secure when in position

used and its subsequent treatment, especially heat treatment.

and readily demountable. (See Figure 2.)

In order to give an indication as to the grade of chain

hook, shackle, etc. relative to others, a system of grade

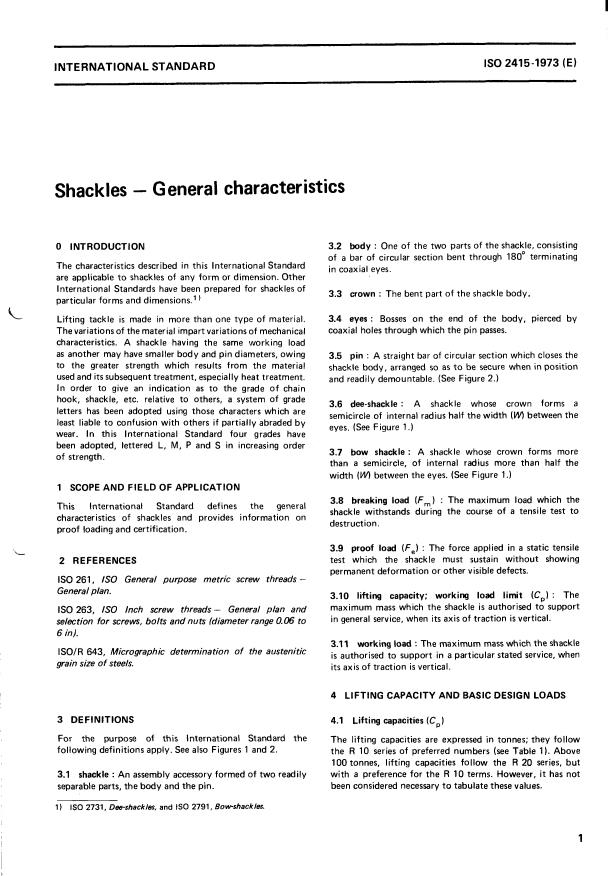

3.6 dee-shackle : A shackle whose crown forms a

letters has been adopted using those characters which are

semicircle of internal radius half the width (w) between the

least liable to confusion with others if partially abraded by

eyes. (See Figure 1.)

wear. In this International Standard four grades have

been adopted, lettered L, M, P and S in increasing order

3.7 bow shackle: A shackle whose crown forms more

of strength.

than a semicircle, of internal radius more than half the

width (W between the eyes. (See Figure 1.)

1 SCOPE AND FIELD OF APPLICATION

3.8 breaking load (F,) : The maximum load which the

This International Standard defines the general

shackle withstands during the course of a tensile test to

characteristics of shackles and provides information on

destruct ion.

proof loading and certification.

3.9 proof load (Fe) : The force applied in a static tensile

k-

test which the shackle must sustain without showing

2 REFERENCES

permanent deformation or other visible defects.

IS0 261, IS0 General purpose metric screw threads -

General pian.

3.10 lifting capacity; working load limit (C,) : The

is authorised to support

maximum mass which the shackle

IS0 263, IS0 inch screw threads - General plan and

in general service, when its axis of traction is vertical.

selection for screws, bolts and nuts (diameter range 0.06 to

6 in).

3.1 1 working load : The maximum mass which the shackle

ISO/R 643, Micrographic determination of the austenitic

is authorised to support in a particular stated service, when

grain size of steels.

its axis of traction is vertical.

4 LIFTING CAPACITY AND BASIC DESIGN LOADS

3 DEFINITIONS

4.1 Lifting capacities (C,)

For the purpose of this International Standard the

The lifting capacities are expressed in tonnes; they follow

following definitions apply. See also Figures 1 and 2.

the R 10 series of preferred numbers (see Table 1). Above

100 tonnes, lifting capacities follow the R 20 series, but

3.1 shackle : An assembly accessory formed of two readily with a preference for the R 10 terms. However, it has not

separable parts, the body and the pin.

been considered necessary to tabulate these values.

IS0 2731, Dee-shackles, and IS0 2791, Bow-shackles.

1 )

IS0 2415-1973 (E)

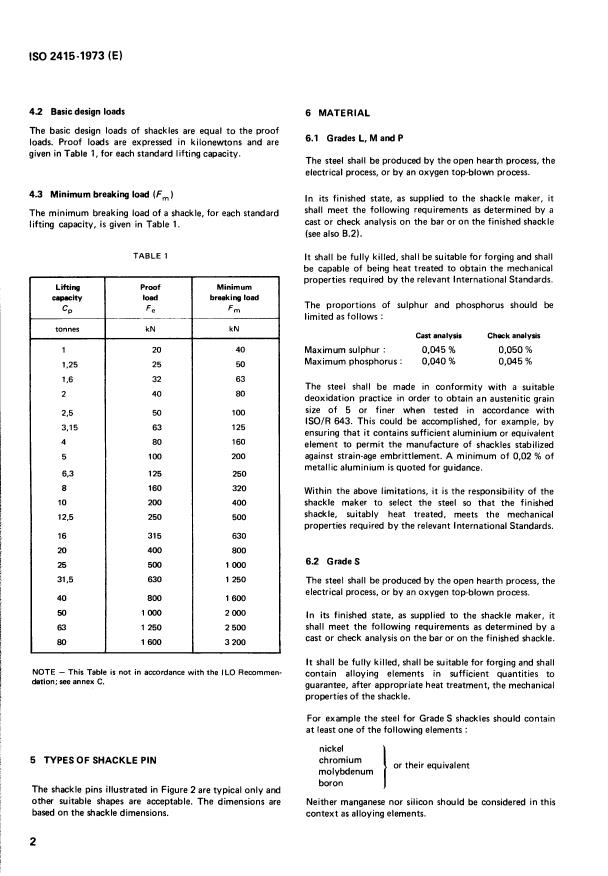

4.2 Basic design loads

6 MATERIAL

The basic design loads of shackles are equal to the proof

6.1 Grades L, M and P

loads. Proof loads are expressed in kilonewtons and are

given in Table 1, for each standard lifting capacity.

The steel shall be produced by the open hearth process, the

electrical process, or by an oxygen top-blown process.

4.3 Minimum breaking load (F,)

In its finished state, as supplied to the shackle maker, it

shall meet the following requirements as determined by a

The minimum breaking load of a shackle, for each standard

cast or check analysis on the bar or on the finished shackle

lifting capacity, is given in Table 1.

(see also 8.2).

TABLE 1

It shall be fully killed, shall be suitable for forging and shall

be capable of being heat treated to obtain the mechanical

properties required by the relevant International Standards.

Proof Minimum

load breaking load

The proportions of sulphur and phosphorus should be

Fe Fm

limited as follows :

tonnes kN kN

Cast analysis Check analysis

20 40

1 Maximum sulphur : 0,045 % 0,050 %

Maximum phosphorus : 0,040 % 0,045 %

1.25 25

1.6

The steel shall be made in conformity with a suitable

2 40 80

deoxidation practice in order to obtain an austenitic grain

size of 5 or finer when tested in accordance with

50 1 O0

2.5

ISO/R 643. This could be accomplished, for example, by

3.1 5 63 125

ensuring that it contains sufficient aluminium or equivalent

4 80 160

element to permit the manufacture of shackles stabilized

A minimum of 0.02 % of

5 100 200 against strain-age embrittlement.

metallic aluminium is quoted for guidance.

6,s

8 320

Within the above limitations, it is the responsibility of the

10 200 shackle maker to select the steel so that the finished

shackle, suitably heat treated, meets the mechanical

12.5 250 500

properties required by the relevant International Standards.

16 31 5 630

20 400 800

6.2 Grade S

500 1 000

31.5 630 1 250

The steel shall be produced by the open hearth process, the

electrical process, or by an oxygen top-blown process.

40 800 1600

1 O00 2 O00

In its finished state, as supplied to the shackle maker, it

1 250 2 500 shall meet the following requirements as determined by a

cast or check analysis on the bar or on the finished shackle.

1 600 3 200

It shall be fully killed, shall be suitable for forging and shall

NOTE - This Table is not in accordance with the IL0 Recornmen-

contain alloying elements in sufficient quantities to

dation; see annex C.

guarantee, after appropriate heat treatment, the mechanical

properties of the shackle.

For example the steel for Grade S shackles should contain

at least one of the following elements :

nickel

5 TYPES OF SHACKLE PIN chromium

or their equivalent

molybdenum

I

boron J

The shackle pins illustrated in Figure 2 are typical only and

other suitable shapes are acceptable. The dimensions are

Neither manganese nor silicon should be considered in this

based on the shackle dimensions. context as alloying elements.

IS0 2415-1973 (E)

e

t

Dee-shackle Bow shackle

FIGURE 1 - Forms of shackle

I

Countersunk with slotted head

c

.

W + 2 d + 0.8 O

L

W+2d

,

I

I I

I

Screwed with eye and collar

Q

Lo-- Q

c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...