ISO 2394:1998

(Main)General principles on reliability for structures

General principles on reliability for structures

Principes généraux de la fiabilité des constructions

General Information

- Status

- Withdrawn

- Publication Date

- 10-Jun-1998

- Withdrawal Date

- 10-Jun-1998

- Technical Committee

- ISO/TC 98/SC 2 - Reliability of structures

- Drafting Committee

- ISO/TC 98/SC 2 - Reliability of structures

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 04-Mar-2015

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 15-Jan-2011

- Effective Date

- 15-Apr-2008

- Effective Date

- 15-Apr-2008

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

ISO 2394:1998 is a standard published by the International Organization for Standardization (ISO). Its full title is "General principles on reliability for structures". This standard covers: General principles on reliability for structures

General principles on reliability for structures

ISO 2394:1998 is classified under the following ICS (International Classification for Standards) categories: 91.080.01 - Structures of buildings in general. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 2394:1998 has the following relationships with other standards: It is inter standard links to ISO 2394:2015, ISO 2394:1986/Add 1:1988, ISO 2394:1986. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 2394:1998 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 2394

Second edition

1998-06-01

General principles on reliability for structures

Principes généraux de la fiabilité des constructions

A

Reference number

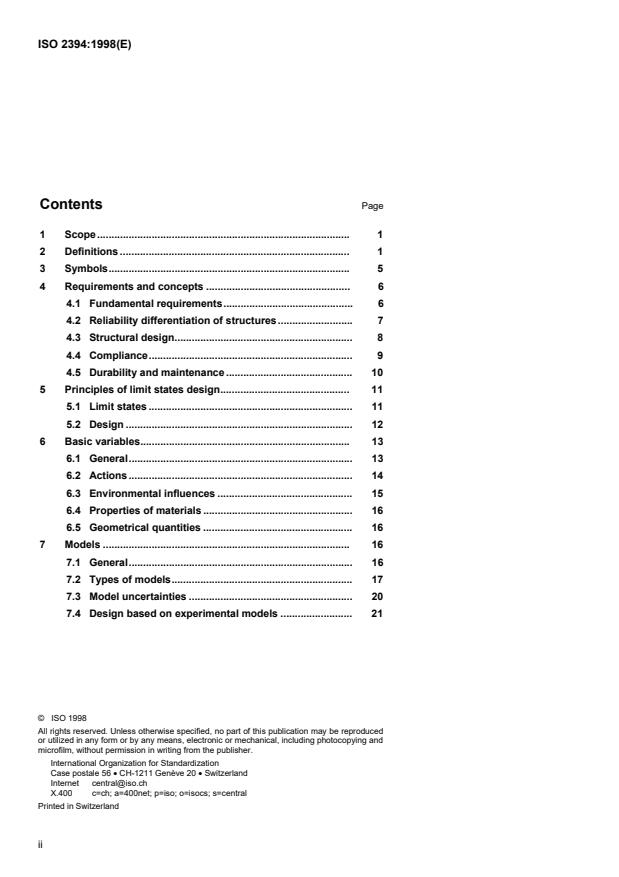

Contents Page

1 Scope. 1

2 Definitions . 1

3 Symbols. 5

4 Requirements and concepts . 6

4.1 Fundamental requirements. 6

4.2 Reliability differentiation of structures. 7

4.3 Structural design. 8

4.4 Compliance. 9

4.5 Durability and maintenance . 10

5 Principles of limit states design. 11

5.1 Limit states . 11

5.2 Design . 12

6 Basic variables. 13

6.1 General. 13

6.2 Actions. 14

6.3 Environmental influences . 15

6.4 Properties of materials . 16

6.5 Geometrical quantities . 16

7 Models . 16

7.1 General. 16

7.2 Types of models. 17

7.3 Model uncertainties . 20

7.4 Design based on experimental models . 21

© ISO 1998

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced

or utilized in any form or by any means, electronic or mechanical, including photocopying and

microfilm, without permission in writing from the publisher.

International Organization for Standardization

Case postale 56 • CH-1211 Genève 20 • Switzerland

Internet central@iso.ch

X.400 c=ch; a=400net; p=iso; o=isocs; s=central

Printed in Switzerland

ii

©

ISO ISO 2394:1998(E)

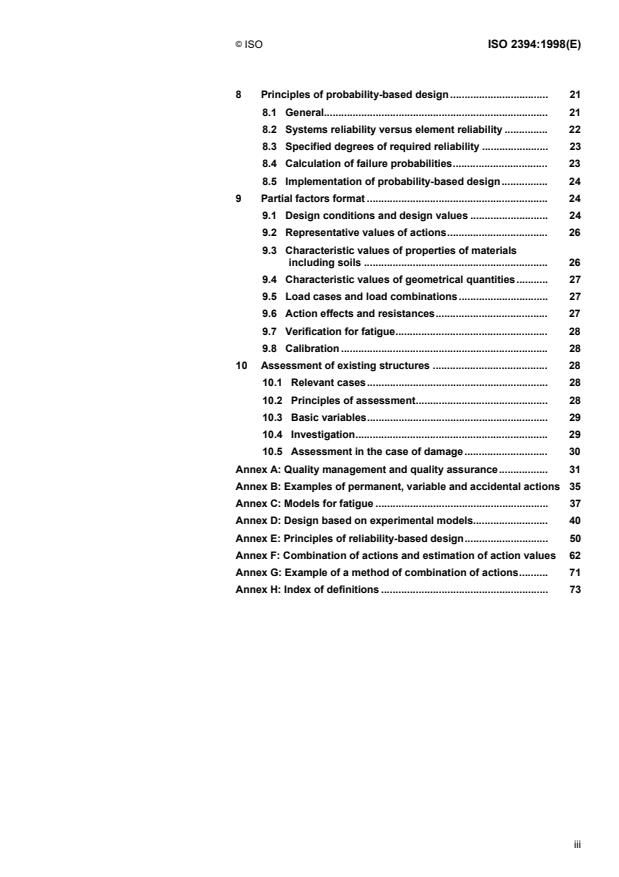

8 Principles of probability-based design . 21

8.1 General. 21

8.2 Systems reliability versus element reliability . 22

8.3 Specified degrees of required reliability . 23

8.4 Calculation of failure probabilities. 23

8.5 Implementation of probability-based design. 24

9 Partial factors format . 24

9.1 Design conditions and design values . 24

9.2 Representative values of actions. 26

9.3 Characteristic values of properties of materials

including soils . 26

9.4 Characteristic values of geometrical quantities. 27

9.5 Load cases and load combinations. 27

9.6 Action effects and resistances. 27

9.7 Verification for fatigue. 28

9.8 Calibration . 28

10 Assessment of existing structures . 28

10.1 Relevant cases. 28

10.2 Principles of assessment. 28

10.3 Basic variables. 29

10.4 Investigation. 29

10.5 Assessment in the case of damage. 30

Annex A: Quality management and quality assurance. 31

Annex B: Examples of permanent, variable and accidental actions 35

Annex C: Models for fatigue . 37

Annex D: Design based on experimental models. 40

Annex E: Principles of reliability-based design. 50

Annex F: Combination of actions and estimation of action values 62

Annex G: Example of a method of combination of actions. 71

Annex H: Index of definitions . 73

iii

©

Foreword

ISO (the International Organization for Standardization) is a worldwide

federation of national standards bodies (ISO member bodies). The work of

preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which

a technical committee has been established has the right to be represented

on that committee. International organizations, governmental and non-

governmental, in liaison with ISO, also take part in the work. ISO

collaborates closely with the International Electrotechnical Commission

(IEC) on all matters of electrotechnical standardization.

Draft International Standards adopted by the technical committees are

circulated to the member bodies for voting. Publication as an International

Standard requires approval by at least 75 % of the member bodies casting

a vote.

International Standard ISO 2394 was prepared by Technical Committee

ISO/TC 98, Bases for design of structures, Subcommittee SC 2, Reliability

of structures.

This second edition cancels and replaces the first edition (ISO 2394:1986),

which has been technically revised.

Annexes A to F of this International Standard are for information only.

iv

©

ISO ISO 2394:1998(E)

Introduction

This International Standard constitutes a common basis for defining design

rules relevant to the construction and use of the wide majority of buildings

and civil engineering works, whatever the nature or combination of the

materials used. However, their application to each type of material

(concrete, steel, timber, masonry, etc.) will require specific adaptation to

ensure a degree of reliability which, as far as possible, is consistent with

the objectives of the code drafting committees for each material.

This International Standard is intended to serve as a basis for those

committees responsible for the task of preparing national standards or

codes of practice in accordance with the technical and economic conditions

in a particular country, and which take into account the nature, type and

conditions of use of the structure and the properties of the materials during

its design working life. It will also provide a common basis for other

International Standards (e.g. ENV 1991-1 EC1) dealing with load-bearing

structures. Thus it has a conceptual character and it is of a fairly general

nature.

It is important to recognize that structural reliability is an overall concept

comprising models for describing actions, design rules, reliability elements,

structural response and resistance, workmanship, quality control

procedures and national requirements, all of which are mutually dependent.

The modification of one factor in isolation could therefore disturb the

balance of reliability inherent in the overall concept.

It is therefore important that the modification of any one factor should be

accompanied by a study of the implications relating to the overall reliability

concept.

v

©

INTERNATIONAL STANDARD ISO ISO 2394:1998(E)

General principles on reliability for structures

1 Scope

This International Standard specifies general principles for the verification of the reliability of structures subjected to

known or foreseeable types of action. Reliability is considered in relation to the performance of the structure

throughout its design working life.

The general principles are applicable to the design of complete structures (buildings, bridges, industrial structures,

etc.), the structural elements making up the structure and the foundations.

This International Standard is also applicable to the successive stages in construction, namely the fabrication of

structural elements, the transport and handling of the structural elements, their erection and all work on site, as well

as the use of the structure during its design working life, including maintenance and repair.

To allow for the differences in design practice between different countries, the national standards or codes of

practice may be simpler or more detailed in comparison with this International Standard.

Generally the principles are also applicable to the structural appraisal of existing constructions or assessing

changes of use. However in some respects this is associated with special aspects of the basic variables and

calculation models. Such aspects are considered in clause 10.

NOTE — When this International Standard is applied in a particular country for the development of its standards, it is

admissible not to use those clauses which are not in accordance with the regulations of that particular country.

2 Definitions

For the purposes of this International Standard, the following definitions apply.

NOTE — An alphabetical index of the definitions is given in annex H.

2.1 General terms

2.1.1 structure: Organized combination of connected parts designed to provide some measure of rigidity.

2.1.2 structural element: Physically distinguishable part of a structure.

EXAMPLES: Column, beam, plate.

2.1.3 structural system: Load-bearing elements of a building or civil engineering works and the way in which

these elements function together.

2.1.4 compliance: Fulfilment of specified requirements.

©

ISO

2.1.5 life cycle: Total period of time during which the planning, execution and use of a construction works takes

place. The life cycle begins with identification of needs and ends with demolition.

2.2 Terms relating to design in general

2.2.1 design situation: Set of physical conditions representing a certain time interval for which the design

demonstrates that relevant limit states are not exceeded.

2.2.2 persistent situation: Normal condition of use for the structure, generally related to its design working life.

NOTE — "Normal use" includes possible extreme loading conditions due to wind, snow, imposed loads, earthquakes in areas of

high seismicity, etc.

2.2.3 transient situation: Provisional condition of use or exposure for the structure.

EXAMPLE: During its construction or repair, which represents a time period much shorter than the design working life.

2.2.4 accidental situation: Exceptional condition of use or exposure for the structure.

EXAMPLES: Flood, land slip, fire, explosion, impact or local failure, which represent in most cases a very short time period

(apart from situations where a local failure may remain undetected during a longer period).

2.2.5 serviceability: Ability of a structure or structural element to perform adequately for normal use under all

expected actions.

2.2.6 failure: Insufficient load-bearing capacity or inadequate serviceability of a structure or structural element.

2.2.7 reliability: Ability of a structure or structural element to fulfil the specified requirements, including the working

life, for which it has been designed.

2.2.8 reference period: A chosen period of time which is used as a basis for assessing values of variable actions,

time-dependent material properties, etc.

2.2.9 limit state: A state beyond which the structure no longer satisfies the design performance requirements.

NOTE — Limit states separate desired states (no failure) from undesired states (failure).

2.2.10 ultimate limit state: A state associated with collapse, or with other similar forms of structural failure.

NOTE — This generally corresponds to the maximum load-carrying resistance of a structure or structural element but in some

cases to the maximum applicable strain or deformation.

2.2.11 serviceability limit state: A state which corresponds to conditions beyond which specified service

requirements for a structure or structural element are no longer met.

2.2.12 irreversible limit state: A limit state which will remain permanently exceeded when the actions which

caused the excess are removed.

2.2.13 reversible limit state: A limit state which will not be exceeded when the actions which caused the excess

are removed.

2.2.14 structural integrity (structural robustness) : Ability of a structure not to be damaged by events like fire,

explosions, impact or consequences of human errors, to an extent disproportionate to the original cause.

2.2.15 design working life: Assumed period for which a structure or a structural element is to be used for its

intended purpose without major repair being necessary.

2.2.16 maintenance: Total set of activities performed during the design working life of a structure to enable it to

fulfil the requirements for reliability.

©

ISO

2.2.17 reliability class of structures: Class of structures or structural elements for which a particular specified

degree of reliability is required.

2.2.18 basic variable: Part of a specified set of variables representing physical quantities which characterize

actions and environmental influences, material properties including soil properties, and geometrical quantities.

2.2.19 primary basic variable: Variable whose value is of primary importance to the design results.

2.2.20 limit state function: A function g of the basic variables, which characterizes a limit state when

g(X , X ,., X ) = 0: g > 0 identifies with the desired state and g < 0 with the undesired state.

1 2 n

-1 -1

2.2.21 reliability index, b: A substitute for the failure probability p , defined by b = - F (p ), where F is the

f f

inverse standardized normal distribution.

2.2.22 partial factors format: Calculation format in which allowance is made for the uncertainties and variabilities

assigned to the basic variables by means of representative values, partial factors and, if relevant, additive

quantities.

2.2.23 reliability element: Numerical quantity used in the partial factors format, by which the specified degree of

reliability is assumed to be reached.

2.2.24 element reliability: Reliability of a single structural element which has one single dominating failure mode.

2.2.25 system reliability: Reliability of a structural element which has more than one relevant failure mode or the

reliability of a system of more than one relevant structural element.

2.2.26 model: Simplified mathematical description or experimental set-up simulating actions, material properties,

the behaviour of a structure, etc.

NOTE — Models should generally take account of decisive factors and neglect the less important ones.

2.2.27 model uncertainty: Related to the accuracy of models, physical or statistical.

NOTE — Further information is given in annexes D and E.

2.2.28 statistical uncertainty: Uncertainty related to the accuracy of the distribution and estimation of

parameters.

2.2.29 assessment: Total set of activities performed in order to find out if the reliability of a structure is acceptable

or not.

2.3 Terms relating to actions, action effects and environmental influences

2.3.1 action

1) An assembly of concentrated or distributed mechanical forces acting on a structure (direct actions).

2) The cause of deformations imposed on the structure or constrained in it (indirect action).

2.3.2 permanent action:

1) Action which is likely to act continuously throughout a given reference period and for which variations in

magnitude with time are small compared with the mean value.

2) Action whose variation is only in one sense and can lead to some limiting value.

2.3.3 variable action: Action for which the variation in magnitude with time is neither negligible in relation to the

mean value nor monotonic.

©

ISO

2.3.4 accidental action: Action that is unlikely to occur with a significant value on a given structure over a given

reference period.

NOTE — Accidental actions are in most cases of short duration.

2.3.5 fixed action: Action which has a fixed distribution on a structure, such as its magnitude and direction are

determined unambiguously for the whole structure when determined at one point on the structure.

2.3.6 free action: Action which may have an arbitrary spatial distribution over the structure within given limits.

2.3.7 static action: Action which will not cause significant acceleration of the structure or structural elements.

2.3.8 dynamic action: Action which may cause significant acceleration of the structure or structural elements.

2.3.9 bounded action: Action which has a limiting value which cannot be exceeded and which is exactly or

approximately known.

2.3.10 unbounded action: Action which has no known limiting values.

2.3.11 representative value of an action: A value used for the verification of a limit state.

NOTE — Representative values consist of characteristic values, combination values, frequent values and quasi-permanent

values, but may also consist of other values.

2.3.12 characteristic value of an action: Principal representative value.

NOTE — It is chosen either on a statistical basis, so that it can be considered to have a specified probability of not being

exceeded towards unfavourable values during a reference period, or on acquired experience, or on physical constraints.

2.3.13 combination value: Value chosen, in so far as it can be fixed on statistical bases, so that the probability

that the action effect values caused by the combination will be exceeded is approximately the same as when a

single action is considered.

2.3.14 frequent value: Value determined, in so far as it can be fixed on statistical bases, so that:

— the total time, within a chosen period of time, during which it is exceeded is only a small given part of the

chosen period of time; or

— the frequency of its exceedance is limited to a given value.

2.3.15 quasi-permanent value: Value determined, in so far as it can be fixed on statistical bases, so that the total

time, within a chosen period of time, during which it is exceeded is of the magnitude of half the period.

2.3.16 design value of an action, F : Value obtained by multiplying the representative value by the partial

d

factor g .

F

2.3.17 load arrangement: Identification of the position, magnitude and direction of a free action.

2.3.18 load case: Compatible load arrangements, set of deformations and imperfections considered for a

particular verification.

2.3.19 load combination: Set of design values used for the verification of the structural reliability for a limit state

under the simultaneous influence of different actions.

2.3.20 environmental influence: Mechanical, physical, chemical or biological influence which may cause

deterioration of the materials constituting a structure, which in turn may affect its serviceability and safety in an

unfavourable way.

©

ISO

2.4 Terms relating to structural response, resistance, material properties and geometrical

quantities

2.4.1 characteristic value of a material property: An a priori specified fractile of the statistical distribution of the

material property in the supply produced within the scope of the relevant material standard.

2.4.2 characteristic value of a geometrical quantity: A quantity usually corresponding to dimensions specified

by the designer.

2.4.3 design value of a material property: Value obtained by dividing the characteristic value by a partial factor

g or, in special circumstances, by direct assessment.

M

2.4.4 design value of a geometrical quantity: Characteristic value plus or minus an additive geometrical

quantity.

2.4.5 conversion factor: Factor which converts properties obtained from test specimens to properties

corresponding to the assumptions made in calculation models.

2.4.6 conversion function: Function which converts properties obtained from test specimens to properties

corresponding to the assumptions made in calculation models.

3 Symbols

NOTE — The symbols used generally are listed below. Those which are not general and which are used only in one clause

(and are explained there) are not listed.

3.1 Main letters

A Accidental action

C Serviceability constraint

F Action in general

F Basic action variable

F Representative value of an action

r

G Permanent action

Q Variable action

R Resistance

S Action effect

W Action model variable

X Basic variable

Y Model output variable

a Geometrical quantity

Additive geometrical quantity

Da

f Material property

©

ISO

p Probability of failure

f

p Specified value of p

fs f

Time

t

b Reliability index

g Partial factor

g Partial factor for actions

f

g Generalized partial factor for actions taking account of model and geometric uncertainties

F

g Partial factor for permanent actions

G

g Partial factor for variable actions

Q

g Partial factor for material properties

m

g Generalized partial factor for resistance properties taking account of material, model and geometric

M

uncertainties

g Partial factor for model uncertainties

D

g Factor by which the importance of the structure and the consequences of failure are taken into account

n

q Parameter which contains model uncertainties

q Value for action effects

s

q Value for resistance

R

j Function of action variables

Y Factor for determining combination values of actions

Y Factor for determining frequent values of actions

Y Factor for determining quasi-permanent values of actions

g(X,t) Limit state function

3.2 Subscripts

i Basic variable (mainly action) number i

j Action number j

k Characteristic value

d Design value

4 Requirements and concepts

4.1 Fundamental requirements

Structures and structural elements shall be designed, constructed and maintained in such a way that they are suited

for their use during the design working life and in an economic way.

©

ISO

In particular they shall, with appropriate degrees of reliability, fulfil the following requirements:

— they shall perform adequately under all expected actions (serviceability limit state requirement);

— they shall withstand extreme and/or frequently repeated actions occurring during their construction and

anticipated use (ultimate limit state requirement);

— they shall not be damaged by events like flood, land slip, fire, explosions, impact or consequences of human

errors, to an extent disproportionate to the original cause (structural integrity requirement).

The appropriate degree of reliability should be judged with due regard to the possible consequences of failure and

the expense, level of effort and procedures necessary to reduce the risk of failure (see 4.2).

The measures that can be taken to achieve the appropriate degree of reliability include:

— choice of structural system, proper design and analysis;

— implementation of a quality policy;

— design for durability and maintenance;

— protective measures.

These items will be treated in 4.3 to 4.5.

4.2 Reliability differentiation of structures

The expression "with appropriate degrees of reliability" used in 4.1 means that the degree of reliability should be

adopted taking account of:

— the cause and mode of failure implying that a structure or structural element which would be likely to collapse

suddenly without warning should be designed for a higher degree of reliability than one for which a collapse is

preceded by some kind of warning in such a way that measures can be taken to limit the consequences;

— the possible consequences of failure in terms of risk to life, injury, potential economic losses and the level of

social inconvenience;

— the expense, level of effort and procedures necessary to reduce the risk of failure;

— the social and environmental conditions in a particular location.

Differentiation of the required degrees of reliability may be obtained by the classification of whole structures or by

the classification of structural elements. Thus, as an example, degrees of reliability may be selected according to

the consequences of failure as follows:

a) risk to life low, economic, social and environmental consequences small or negligible;

b) risk to life medium, economic, social or environmental consequences considerable;

c) risk to life high, economic, social or environmental consequences very great.

The required reliability related to structural safety or serviceability may be achieved by suitable combinations of the

following measures.

a) Measures relating to design:

— serviceability requirements;

— the choice of the values of action variables;

©

ISO

— the choice of the degree of reliability for the design calculations;

— consideration of durability;

— consideration of the degree of structural integrity (robustness), see 4.3;

— the amount and quality of preliminary investigations of soils and possible environmental influences;

— the accuracy of the mechanical models used;

— the stringency of the detailing rules.

b) Measures relating to quality assurance to reduce the risk of hazards in:

— gross human errors;

— design;

— execution.

4.3 Structural design

A failure of a structure or part of it may occur due to:

— an extremely unfavourable combination of actions, material properties, geometrical quantities, etc., all of which

are associated with ordinary use and other ordinary circumstances;

— effects of exceptional but foreseeable actions or environmental influences, for example, collision or extreme

climatic influences;

— consequences of an error, such as lack of information, omission, misunderstanding and lack of communication,

negligence, misuse, etc.;

— influences that are not foreseen.

NOTE — The term "exceptional" refers to circumstances and/or actions that are present only during a small portion of the life

and/or with a low probability. Depending on the type of structure, these actions may or may not be considered explicitly in

design.

No structure can be expected to function adequately in all cases if exceptional actions or exceptionally low

resistance occur, but the foreseeable scope of damage should be limited to an extent not disproportionate to the

original cause. Thus measures should be taken to counter such events. The measures would basically consist of

one or more of the following.

a) Designing and maintaining the structure according to the rules given in the following clauses for conditions

associated with ordinary use and other ordinary circumstances.

b) Design of the essential load-bearing members of a structure for specified exceptional actions which may be

caused by accidents or similar occurrences.

NOTE — The intention of such design criteria is that they should also cover the effect of the majority of unforeseen

events.

The structural layout should be checked to identify "key" structural elements, whose failure would cause the

collapse of more than a limited portion of the structure close to the element in question. Where such structural

elements are identified and the structural layout cannot be revised to avoid them, the design should take their

importance into account.

c) Protection against foreseeable actions and elimination of errors.

A careful check should be made and appropriate action taken to ensure that there is no inherent weakness in

the structural layout and that adequate means exist to transmit all loads safely to the foundations.

©

ISO

Protective measures should be introduced, for example, safeguarding against vehicular impact by the provision

of additional protection such as bollards.

The probability of gross design and construction errors should be reduced by appropriate quality assurance

and/or quality control measures, as described in 4.4.

d) Design of the structure in such a way that local damage does not lead to immediate collapse of the whole structure

or a significant part of it.

As a design assumption, the following may be chosen to represent local damage. The structure shall be

designed and detailed so that any load-bearing elements other than the "key" structural elements can be

removed without causing the collapse of more than a limited portion close to the element in question. In the

event of the removal of a non-key structural element, a less than normal reliability for the remaining structure

will be considered acceptable provided that the structure is repaired to normal reliability standard within a

reasonably short period of time after damage.

4.4 Compliance

To achieve adequate confidence that the completed construction works fulfil the specified requirements for quality

and, in particular, the fundamental requirements (4.1), an appropriate quality policy should be adopted and

implemented by parties involved in the management of all stages of the life cycle of the construction works.

NOTE — For further details, see annex A and ISO 9000, ISO 9001, ISO 9002, ISO 9003 and ISO 9004.

This quality policy should comprise:

a) definition of quality requirements;

b) organization measures and controls at the stages of design and execution and during the use and the

maintenance of the structure.

The quality management selected for implementing the quality policy should include consideration of:

— the type and use of the structure;

— the consequences of quality deficiencies (e.g. accidents resulting from structural failures); and

— the management culture of the involved parties.

In the structural design of the construction works, reliability is the most important aspect to consider to achieve

quality. Standards for structural design should provide a framework to achieve structural reliability as follows:

— by providing requirements for reliability;

— by specifying the rules to verify the fulfilment of the requirements for reliability;

— by specifying the rules for structural design and associated conditions.

The conditions to be fulfilled concern, for example, the choice of structural system, level of workmanship and

maintenance regime, and are normally detailed in the structural design standards. The conditions should also take

into account the variability of material properties, the quality control and the criteria for material acceptance. They

also include consideration of the use of information technology with regard to the design and the execution process

including supply chains with regard to delivering of material and testing of material.

NOTES

1 For example the conditions are given as "assumptions" in Eurocode 1: Part 1, Basis of Design.

2 See also annex A.

©

ISO

4.5 Durability and maintenance

Durability is a necessary condition for the fulfillment of the requirements for reliability. The durability of the structure

and the structural elements in their environment shall be such that they remain fit for use during their design working

lives, given appropriate maintenance. This is also applicable to fatigue. Examples of design working life are given in

table 1.

Table 1 — Notional classification of design working life

Class Notional design working life Examples

(years)

1 1 to 5 Temporary structures

2 25 Replacement structural parts, e.g. gantry girders, bearings

3 50 Buildings and other common structures, other than those listed below

4 100 or more Monumental buildings, and other special or important structures.

Large bridges

Maintenance is the total set of activities performed during the life of the structure to enable it to fulfil the

requirements for durability. Maintenance includes the performance of regular inspections, inspections on special

occasions (e.g. after an earthquake), the upgrading of protection systems and repair of structural elements.

Durability shall be secured by:

— either a maintenance programme, or

— design such that deterioration will not lead to the failure of the structure, in those cases when the structure

cannot or is not expected to be subjected to maintenance.

In the first case above, the structure shall be designed and constructed in such a way, or provided with protection

so that no significant deterioration is likely to occur within the period between successive inspections. The need for

relevant parts of the structure being available for inspection — without complicated dismantling — shall be

considered in the design.

To ensure an adequately durable structure, the following inter-related factors shall be considered:

— the intended use of the structure;

— the required performance criteria (e.g. appearance);

— the expected environmental conditions;

— the composition, properties and performance of the materials;

— the structural system;

— the shape of members and the structural detailing;

— the quality of workmanship, and level of control;

— the particular protective measures;

— the maintenance during the design working life.

The rate of deterioration may be estimated on the basis of theoretical or experimental investigation and experience.

©

ISO

5 Principles of limit states design

5.1 Limit states

5.1.1 General

The structural performance of a whole structure or part of it should generally be described with reference to a

specified set of limit states which separate desired states of the structure from undesired states.

The limit states are divided into the following two categories:

a) ultimate limit states, which correspond to the maximum load-carrying capacity or, in some cases, to the

maximum applicable strain or deformation;

b) serviceability limit states, which concern the normal use.

The effect of exceeding a limit state may be irreversible or reversible. In the irreversible case, the damage or

malfunction associated with the limit state being exceeded will remain until the structure has been repaired. In the

reversible case, the damage or malfunction will remain only as long as the cause of the limit state being exceeded is

present. As soon as this cause ceases to act, a transition from the undesired state back to the desired state

occurs.

5.1.2 Ultimate limit states

Ultimate limit states include:

a) loss of equilibrium of the structure or of a part of the structure, considered as a rigid body (e.g. overturning);

b) attainment of the maximum resistance capacity of sections, members or connections by rupture (in some cases

affected by fatigue, corrosion, etc.) or excessive deformations;

c) transformation of the structure or part of it into a mechanism;

d) instability of the structure or part of it;

e) sudden change of the assumed structural system to a new system (e.g. snap through).

The effect of exceeding an ultimate limit state is almost always irreversible and the first time that this occurs it

causes failure.

NOTE — For simplicity, a state prior to structural collapse may be considered as an ultimate limit state, e.g. reduced structural

system following an accidental action.

5.1.3 Serviceability limit states

Serviceability limit states include:

a) local damage (including cracking) which may reduce the working life of the structure or affect the efficiency or

appearance of structural or non-structural elements; repeated loading may affect the local damage, e.g. by

fatigue;

b) unacceptable deformations which affect the efficient use or appearance of structural or non-structural elements

or the functioning of equipment;

c) excessive vibrations which cause discomfort to people or affect non-structural elements or the functioning of

equipment.

In the cases of permanent local damage or permanent unacceptable deformations, exceeding a serviceability limit

state is irreversible and the first time that this occurs it causes failure.

©

ISO

In other cases, exceeding a serviceability limit state may be reversible and then failure occurs as follows:

a) the first time the serviceability limit state is exceeded, if no excess is considered as acceptable;

b) if the excess is acceptable but the time when the structure is in the undesired state is longer than specified;

c) if the excess is acceptable but the number of times that the serviceability limit state is exceeded is larger than

specified;

d) if a combination of the above criteria or of some other relevant criteria occur.

These cases may involve temporary local damage (e.g. temporarily wide cracks), temporary large deformations and

vibrations.

Design criteria for serviceability limit states are generally expressed in terms of limits for acceptable deformations,

accelerations, crack widths, etc.

NOTE — These limits should generally be considered random and may be described by statistical methods. They are,

however, normally introduced into codes with specified limiting values.

5.2 Design

5.2.1 Design procedure

All relevant limit states should be considered in the design.

For each specific limit state, the relevant basic variables should be identified, i.e. the variables which characterize:

— actions and environmental influences;

— properties of materials and soils;

— geometrical parameters.

Models which describe the behaviour of a structure should be established for each limit state. These models

include mechanical models which describe the structural behaviour, as well as other physical or chemical models

which describe the effects of environmental influences on the properties of the materials.

Where calculation models are available, the limit state can be described with aid of a function, g, of the basic

variables X = X , X ,., X so that

1 2 n

g(X , X ,., X ,t ) = 0 . . . (1)

1 2 n

Equation (1) is called the limit state equation, and

g(X ,X ,., X ,t ) > 0 . . . (2)

1 2 n

identifies the desired state.

In principle, the purpose of design calculations (or prototype testing) is to ensure an adequate degree of reliability.

To verify this, calculations are performed according to a chosen design format. In this International Standard two

possible design formats are treated:

— a probabilistic format (clause 8), and

— a partial factors format (clause 9).

The partial factors format is the format which is intended to be used for design calculations in normal cases. The

probabilistic format may be convenient for special design problems and may be used for the calibration of partial

factors.

©

ISO

In addition to design calculations, detailing is an important part of the design procedure. Thus assumptions made in

the calculation models must be incorporated in the workshop drawings, instructions, etc., by appropriate structural

provisions and detailing.

5.2.2 Design situations

Actions, environmental influences and, in many cases, the expected properties of a structure vary with time. These

variations, which occur throughout the life of the structure, should be considered by selected design situations, each

one representing a certain time interval with associated hazards, conditions and relevant structural limit states.

Separate reliability checking is required for each design situation with due regard to the different consequences of

failure.

The design situations are classified as:

— persistent situations;

— transient situations;

— accidental situations.

Persistent and transient situations are considered to act with certainty. Accidental situations by definition occur with

a relatively low probability during the design working life.

Whether loads, such as snow loads, earthquakes, etc., are associated with other transient or accidental situations

will depend on local conditions.

6 Basic variables

6.1 General

The calculation model for each limit state considered should contain a specified set of basic variables, representing

physical quantities which characterize actions and environmental influences, material and soil properties, and

geometrical quantities.

If the uncertainty of a basic variable is judged to be important, e.g. by experience or by a sensitivity study, it shall be

represented as a random variable.

The uncertainties generally consist of a systematic part (bias) and a random part.

The uncertainties are caused by:

— inherent random variability, which is the unpredictable variability in time or among the typical structures and

geographical regions under consideration;

— insufficient data and/or imprecise knowledge.

Random variables should be described by probability distributions, which often should be considered as conditional.

In many cases these distributions are characterized by main parameters such as mean, standard deviation,

skewness and coefficient of correlation in the case of multi-dimensional distribution. A probabilistic model should be

based on a statistical analysis of available data. It is important to separate and identify the different statistical

populations in order not to use erroneous types of distributions. The data should, when possible, be examined to

eliminate measurement errors, scale effects, etc.

Probabilistic models for basic variables can be used directly within the probabilistic format (see clause 8). Within the

partial factors format, basic variables are represented by their design values (see clause 9), which, where possible,

should be derived from the probabilistic models.

NOTE — Further details are given in annex E.

©

ISO

6.2 Actions

6.2.1 General

An action is:

— an assembly of concentrated or distributed mechanical forces acting on the structure (direct actions), or

— the cause of deformations imposed on the structure or constrained in it (indirect actions).

An action is considered to be one single action if it can be assumed to be statistically independent, in time and

space, of any other action acting on the structure.

NOTE — In reality, actions that are introduced simultaneously are often statistically dependent to a certain extent, for

example, climatic actions (wind, snow, temperature). This dependency is usually taken into account by specific provisions.

An action is often characterized by two or more basic variables. For example, the magnitude and direction of an

action can both be basic variables.

Sometimes an action may be introduced as a function of basic variables, each of which represents some underlying

physical property. Such a function is called an action model. An example is earth pressure, which may depend on

the vertical pressure from the earth and the angle of friction; both are random variables.

Variables of natural actions are determined by environmental conditions. Variables of actions due to human activity

are determined by normal human behaviour, gross human errors, etc.

6.2.2 Classification of actions according to the variation of their magnitude with time

Actions are classified according to their variation in time as

— permanent actions (G),

— variable actions (Q),

— accidental actions (A).

Permanent actions are those which are likely to act continuously throughout a given reference period and for which

variations in magnitude with time are small compared with the mean value; or the variation of which is only in one

sense and can lead to some limiting values.

Variable actions are those for which the variation in magnitude with time is neither negligible in relation to the mean

value nor monotonic.

Accidental actions are those that are unlikely to occur with

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...