IEC TS 61400-13:2001

(Main)Wind turbine generator systems - Part 13: Measurement of mechanical loads

Wind turbine generator systems - Part 13: Measurement of mechanical loads

Acts as a guide for carrying out measurements used for verification of codes and for direct determination of the structural loading. Focuses mainly on large electricity generating horizontal axis wind turbines.

This publication is of high relevance for Smart Grid.

General Information

- Status

- Replaced

- Publication Date

- 27-Jun-2001

- Technical Committee

- TC 88 - Wind energy generation systems

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 21-Dec-2015

- Completion Date

- 13-Feb-2026

Relations

- Replaced By

IEC 61400-13:2015/AMD1:2021 - Amendment 1 - Wind turbines - Part 13: Measurement of mechanical loads - Effective Date

- 31-May-2024

- Effective Date

- 31-May-2024

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC TS 61400-13:2001 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Wind turbine generator systems - Part 13: Measurement of mechanical loads". This standard covers: Acts as a guide for carrying out measurements used for verification of codes and for direct determination of the structural loading. Focuses mainly on large electricity generating horizontal axis wind turbines. This publication is of high relevance for Smart Grid.

Acts as a guide for carrying out measurements used for verification of codes and for direct determination of the structural loading. Focuses mainly on large electricity generating horizontal axis wind turbines. This publication is of high relevance for Smart Grid.

IEC TS 61400-13:2001 is classified under the following ICS (International Classification for Standards) categories: 27.180 - Wind turbine energy systems. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 61400-13:2001 has the following relationships with other standards: It is inter standard links to IEC 61400-13:2015/AMD1:2021, IEC 61400-13:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC TS 61400-13:2001 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

TECHNICAL IEC

SPECIFICATION

TS 61400-13

First edition

2001-06

Wind turbine generator systems –

Part 13:

Measurement of mechanical loads

Aérogénérateurs –

Partie 13: Mesure des charges mécaniques

Reference number

IEC/TS 61400-13:2001(E)

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/catlg-e.htm) enables

you to search by a variety of criteria including text searches, technical

committees and date of publication. On-line information is also available on

recently issued publications, withdrawn and replaced publications, as well as

corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/JP.htm) is also

available by email. Please contact the Customer Service Centre (see below) for

further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

TECHNICAL IEC

SPECIFICATION

TS 61400-13

First edition

2001-06

Wind turbine generator systems –

Part 13:

Measurement of mechanical loads

Aérogénérateurs –

Partie 13: Mesure des charges mécaniques

IEC 2001 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission 3, rue de Varembé Geneva, Switzerland

Telefax: +41 22 919 0300 e-mail: inmail@iec.ch IEC web site http://www.iec.ch

Commission Electrotechnique Internationale

PRICE CODE

XB

International Electrotechnical Commission

For price, see current catalogue

– 2 – TS 61400-13 © IEC:2001(E)

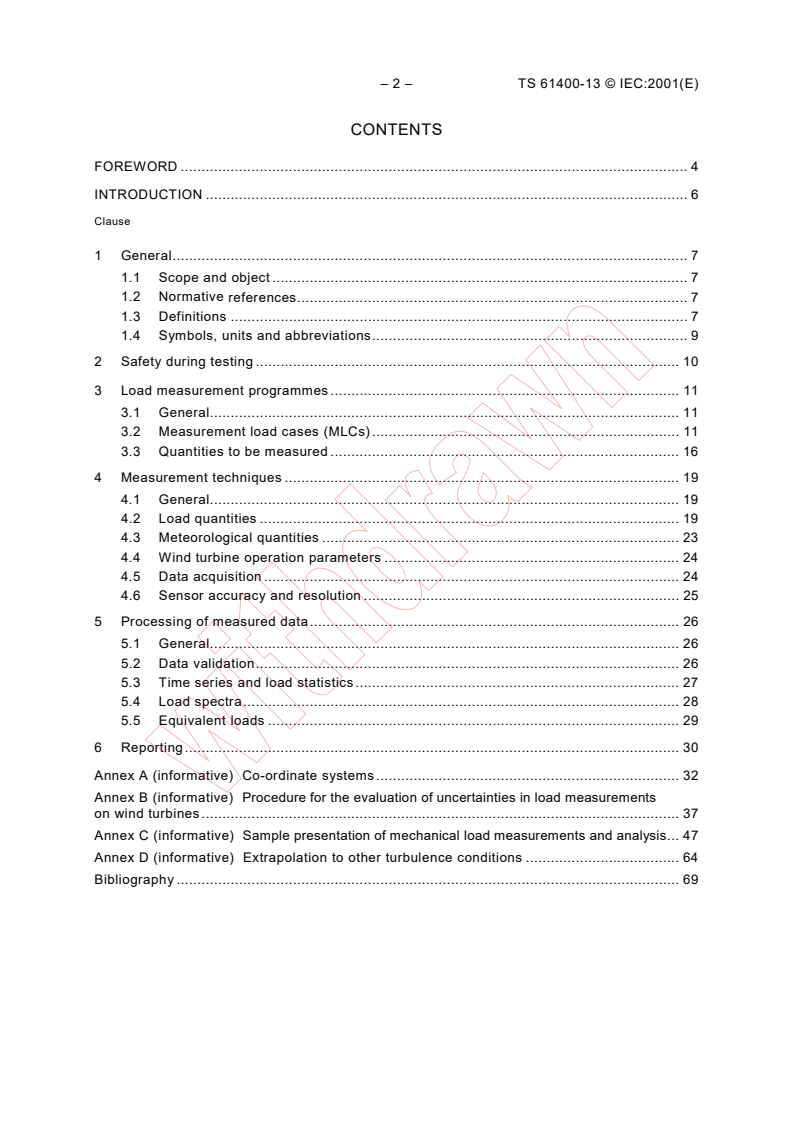

CONTENTS

FOREWORD . 4

INTRODUCTION .6

Clause

1 General. 7

1.1 Scope and object . 7

1.2 Normative references. 7

1.3 Definitions . 7

1.4 Symbols, units and abbreviations. 9

2 Safety during testing . 10

3 Load measurement programmes . 11

3.1 General. 11

3.2 Measurement load cases (MLCs). 11

3.3 Quantities to be measured . 16

4 Measurement techniques . 19

4.1 General. 19

4.2 Load quantities . 19

4.3 Meteorological quantities . 23

4.4 Wind turbine operation parameters . 24

4.5 Data acquisition . 24

4.6 Sensor accuracy and resolution . 25

5 Processing of measured data. 26

5.1 General. 26

5.2 Data validation. 26

5.3 Time series and load statistics . 27

5.4 Load spectra. 28

5.5 Equivalent loads . 29

6 Reporting. 30

Annex A (informative) Co-ordinate systems. 32

Annex B (informative) Procedure for the evaluation of uncertainties in load measurements

on wind turbines . 37

Annex C (informative) Sample presentation of mechanical load measurements and analysis. 47

Annex D (informative) Extrapolation to other turbulence conditions . 64

Bibliography . 69

TS 61400-13 © IEC:2001(E) – 3 –

Figure 1 – Fundamental wind turbine loads: tower base, tower top, rotor and blades. 18

Figure A.1 – Blade co-ordinate system . 32

Figure A.2 – Hub co-ordinate system. 33

Figure A.3 – Nacelle co-ordinate system . 33

Figure A.4 – Tower co-ordinate system . 34

Figure A.5 – Yaw misalignment . 35

Figure A.6 – Cone angle and tilt angle. 35

Figure C.1 – Meteorological quantities record time series. 49

Figure C.2 – Wind turbine operational quantities record time series . 50

Figure C.3 – Wind turbine mechanical load time series (first minute of record) . 51

Figure C.4 – Wind turbine mechanical load time series (first minute of record) . 52

Figure C.5 – Azimuthal variation of blade and shaft loads . 53

Figure C.6 – Frequency spectral density functions for blade, rotor and tower loads . 54

Figure C.7 – Fatigue spectra for blade, rotor and tower loads. 55

Figure C.8 – Meteorological quantities statistics. 56

Figure C.9 – Wind turbine operational quantities statistics

.................................................... 57

Figure C.10 – Blade-root flapwise and lead-lag bending-moment statistics. 58

Figure C.11 – Rotor mechanical load statistics . 59

Figure C.12 – Tower load statistics

...................................................................................... 60

Figure C.13 – Fatigue equivalent loads for blade root bending moments and shaft torque . 61

Figure C.14 – Fatigue equivalent loads for rotor yaw and tilt moments and tower torsion

...... 62

Figure C.15 – Fatigue equivalent loads for tower base bending moment

............................... 63

Figure D.1 – Linear extrapolation of fatigue spectra to higher turbulence intensity levels. 65

Figure D.2 – Turbulence intensity versus wind speed . 67

Figure D.3 – Mean amplitude (1st statistical moment) of flap-bending moment

versus wind speed. 67

Figure D.4 – Coefficient of variation (2nd statistical moment) of flap-bending moment

versus wind speed. 68

Figure D.5 – Skewness (3rd statistical moment) of flap-bending moment versus wind speed . 68

Figure D.6 – Measured and extrapolated spectra of flap-bending moment ranges . 68

Table 1 – MLCs during steady-state operation related to the DLCs defined in IEC 61400-1. 12

Table 2 – Measurement of transient load cases related to the DLCs defined in IEC 61400-1. 13

Table 3 – Capture matrix for normal power production. 14

Table 4 – Capture matrix for power production plus occurrence of fault . 15

Table 5 – Capture matrix for parked condition . 15

Table 6 – Capture matrix for normal transient events. 15

Table 7 – Capture matrix for other than normal transient events. 16

Table 8 – Wind turbine fundamental load quantities. 16

Table 9 – Meteorological quantities . 17

Table 10 – Wind turbine operation quantities. 17

Table 11 – Target standard uncertainties for the various non-load quantities. 25

Table C.1 – Capture matrix. 47

Table C.2 – Record brief statistical description. 48

– 4 – TS 61400-13 © IEC:2001(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

WIND TURBINE GENERATOR SYSTEMS –

Part 13: Measurement of mechanical loads

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International

Organization for Standardization (ISO) in accordance with conditions determined by agreement between the

two organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical specifications, technical reports or guides and they are accepted by the National

Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this technical specification may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. In

exceptional circumstances, a technical committee may propose the publication of a technical

specification when

the required support cannot be obtained for the publication of an International Standard,

despite repeated efforts, or

the subject is still under technical development or where, for any other reason, there is the

future but no immediate possibility of an agreement on an International Standard.

Technical specifications are subject to review within three years of publication to decide

whether they can be transformed into International Standards.

IEC 61400-13, which is a technical specification, has been prepared by IEC technical

committee 88: Wind turbine systems.

The text of this technical specification is based on the following documents:

Enquiry draft Report on voting

88/120/CDV 88/132/RVC

Full information on the voting for the approval of this technical specification can be found in

the report on voting indicated in the above table.

TS 61400-13 © IEC:2001(E) – 5 –

This publication has been drafted in accordance with the ISO/IEC Directives, Part 3.

The committee has decided that the contents of this publication will remain unchanged

until 2004. At this date, the publication will be

reconfirmed;

withdrawn;

replaced by a revised edition, or

amended.

A bilingual version of this technical specification may be issued at a later date.

– 6 – TS 61400-13 © IEC:2001(E)

INTRODUCTION

In the process of structural design of a wind turbine, thorough understanding about, and

accurate quantification of, the loading is of utmost importance.

In the design stage, loads can be predicted with aeroelastic models and codes. However,

such models have their shortcomings and uncertainties, and they always need to be validated

by measurement. Furthermore, measurements can be used for the direct determination of

structural loads in specific conditions.

Mechanical load measurements can be used both as the basis for design and as the basis for

certification. Design aspects for wind turbines are covered by IEC 61400-1 whilst certification

*

procedures are described in IEC WT 01 . This technical specification is aimed at the test

engineer who will design and implement the test programme to meet the specific design or

certification needs. The specification provides specific guidance on load measurements on

key structural components and load paths. Data analysis procedures are also outlined.

The specification describes how to collect various types of time-series or statistical load

information. Two types of situation are considered – steady-state operation and transient

operation. The prescribed measurement load cases mirror the design load cases within

IEC 61400-1, the wind turbine safety standard.

___________

*

IEC WT 01:2001, IEC System for Conformity Testing and Certification of Wind Turbines – Rules and

procedures

TS 61400-13 © IEC:2001(E) – 7 –

WIND TURBINE GENERATOR SYSTEMS –

Part 13: Measurement of mechanical loads

1 General

1.1 Scope and object

This part of IEC 61400 deals with mechanical load measurements on wind turbines. It mainly

focuses on large (>40 m ) electricity generating horizontal axis wind turbines. However, the

methods described might be applicable to other wind turbines as well (for example,

mechanical water pumpers, vertical axis turbines).

The object of this specification is to describe the methodology and corresponding techniques

for the experimental determination of the mechanical loading on wind turbines. This technical

specification is intended to act as a guide for carrying out measurements used for verification

of codes and/or for direct determination of the structural loading. This specification is not only

intended as one coherent measurement specification but can also be used for more limited

measurement campaigns.

1.2 Normative references

The following normative documents contain provisions which, through reference in this text,

constitute provisions of this part of IEC 61400. For dated references, subsequent

amendments to, or revisions of, any of these publications do not apply. However, parties to

agreements based on this part of IEC 61400 are encouraged to investigate the possibility of

applying the most recent editions of the normative documents indicated below. For undated

references, the latest edition of the normative document referred to applies. Members of IEC

and ISO maintain registers of currently valid International Standards.

IEC 60050(415):1999, International Electrotechnical Vocabulary (IEV) – Part 415: Wind turbine

generator systems

IEC 61400-1:1999, Wind turbine generator systems – Part 1: Safety requirements

IEC 61400-12:1998, Wind turbine generator systems – Part 12: Wind turbine power performance

testing

ISO 1995, Guide to the expression of uncertainty in measurement

ISO 2394:1998, General principles on reliability for structures

1.3 Definitions

For the purpose of this technical specification, the definitions related to wind turbine systems

or wind energy in general of IEC 60050(415) and the following definitions apply.

1.3.1

blade

rotating aerodynamically active part of the rotor

1.3.2

blade root

that part of the rotor blade that is connected to the hub of the rotor

– 8 – TS 61400-13 © IEC:2001(E)

1.3.3

calibration load

forces and moments applied during calibration

1.3.4

capture matrix

organization of the measured time series according to mean wind speeds and turbulence

intensities

1.3.5

chord

length of a reference straight line (the chord line) that joins, by certain defined conventions,

the leading and trailing edges of a blade airfoil cross-section

1.3.6

chord line

reference straight line that joins, by certain defined conventions, the leading and trailing

edges of a blade airfoil cross-section

1.3.7

design loads

loads that the turbine is designed to withstand. They are obtained by applying the appropriate

partial load factors to the characteristic values

1.3.8

flap

direction which is perpendicular to the swept surface of the undeformed rotor blade axis

1.3.9

hub

fixture for attaching the blades or blade assembly to the rotor shaft

1.3.10

lead-lag

direction which is parallel to the plane of the swept surface and perpendicular to the

longitudinal axis of the undeformed rotor blade

1.3.11

nacelle

housing which contains the drive train and other equipment on the top of a HAWT tower

1.3.12

natural frequency (eigenfrequency)

frequency at which a structure will choose to vibrate when perturbed and allowed to vibrate freely

1.3.13

outboard

towards the blade tip

1.3.14

partial safety factors

factors that are applied to loads and material strengths to account for uncertainties in the

representative (characteristic) values

1.3.15

radial position

distance from the rotor centre in a plane perpendicular to the rotor axis

TS 61400-13 © IEC:2001(E) – 9 –

1.3.16

rotor centre

point on the main shaft in the plane perpendicular to the main shaft that contains the blade

co-ordinate origin of the reference blade

1.3.17

rotor plane

plane perpendicular to the main shaft and which includes the rotor centre

1.3.18

spanwise

direction parallel to the longitudinal axis of a rotor blade

1.3.19

steady-state operation

state of operation of the turbine during which it remains in a steady state such as during

power production, power production + fault condition and when parked or idling and for which

the external conditions also remain essentially steady or characterized by stationary random

processes for the duration of the measurement

1.3.20

transient event

event during which the state of operation of the wind turbine changes, such as during shut-down

1.3.21

test load

forces and moments applied during a test

1.3.22

turbulence intensity

turbulence intensity is the ratio of the standard deviation of the wind speed in a given time

interval to the mean wind speed in the same time interval

1.3.23

yaw position

angle between the vertical projection of the centre line of the main shaft on the tower base

and the X-axis of the tower co-ordinate system (which is to be defined as appropriate

according to the site and the shape of the tower cross-section). The yaw position is positive

rotating counter-clockwise (top view)

1.4 Symbols, units and abbreviations

1.4.1 Symbols and units

ε strain –

ϕ angle for yaw misalignment [°]

F

B number of blades –

f frequency [Hz]

F forces [N]

I turbulence intensity –

I index for wind speed bin –

j index for accumulated number of alternating load cycles –

k index for specific load –

M blade-root lead-lag bending moment [Nm]

be

M blade-root flap-bending moment [Nm]

bf

M equivalent load [Nm, N]

eq

– 10 – TS 61400-13 © IEC:2001(E)

M tower base normal bending moment [Nm]

tm

M tower base lateral bending moment [Nm]

tl

M rotor tilt moment [Nm]

tilt

M tower top normal moment [Nm]

ttm

M tower top lateral moment [Nm]

ttl

M tower top torsion moment [Nm]

ttt

m slope of S-N curve –

n number of measurements/results –

N number of cycles to failure –

R rotor radius [m]

e

R extrapolated load range [Nm, N]

ijk

m

R measured load range [Nm, N]

ijk

S load amplitude [Nm, N]

s type A standard uncertainty –

I

T rotor torque [Nm]

rotor

u measured value for uncertainty assessment –

u type B standard uncertainty –

I

x , y , z blade co-ordinates (see figure A.1) –

b b b

x , y , z hub co-ordinates (see figure A.2) –

h h h

x input quantity –

I

x , y , z nacelle co-ordinates (see figure A.3) –

n n n

x , y , z tower co-ordinates (see figure A.4) –

t t t

y quantity to be measured –

v extreme wind speed with return period of one year [m/s]

e1

v wind speed at hub height [m/s]

hub

v cut-in wind speed [m/s]

in

v rated wind speed [m/s]

r

v cut-out wind speed [m/s]

out

1.4.2 Abbreviations

MLC measurement load case

DLC design load case

SO steady-state operation

TE transient event

TI turbulence intensity

2 Safety during testing

Certain measurement load cases involve deliberate operation of the turbine in extreme and/or

emergency fault conditions (for example, grid loss). As the purpose of the tests and

measurements in most cases is to verify loads on a prototype turbine, it shall not be assumed

that the turbine will behave and respond as intended. Therefore, such tests shall always be

assumed to be dangerous and due regard shall be taken for personnel safety. On this basis,

such tests shall be initiated and observed from a safe position, usually at a certain distance

upwind the rotor plane and they shall not be carried out with personnel inside or on the nacelle or

tower or within the rotor plane. All tests and test procedures shall be agreed with the turbine

manufacturer before implementation to ensure that the turbine integrity, and hence that personnel

safety, is not compromised. Requirements from existing applicable safety standards shall be

followed.

TS 61400-13 © IEC:2001(E) – 11 –

3 Load measurement programmes

3.1 General

The measurement programme involves collecting both a comprehensive statistical database

and a set of time series, which define the behaviour of the turbine in certain specific

situations. In this clause, a system of measurement load cases (MLCs) is defined to

determine the wind turbine loads in conditions corresponding to a selection of design load

cases (DLCs) of IEC 61400-1. The MLCs may directly be used for documentation of the load

in relation to the DLCs, or the MLCs may provide a basis for the validation of calculation

models at specific and well-defined external conditions. Subsequently, the models can be

used to estimate the loads at the design conditions. This clause also provides specifications

for the quantities to be measured.

3.2 Measurement load cases (MLCs)

3.2.1 General

This subclause describes how to build up load measurement campaigns from a number of

well-defined MLCs. The MLCs are defined in relation to the DLCs, described in IEC 61400-1.

Hence, not all DLCs can be reasonably verified by measurement.

The MLCs define the main external conditions and the operational conditions of the turbine

during the measurement campaigns. The external conditions include meteorological para-

meters such as wind speed, turbulence intensity and air density. The operational conditions

include operational parameters such as rotational speed, yaw error, electrical power and

blade pitch angle. The operational conditions depend on the wind turbine configuration and

shall be specified for each particular case.

Due to the stochastic character of the external conditions, measurements of each MLC have

to be repeated several times in order to reduce the statistical uncertainty. The minimum

number of measurements at each MLC is specified in this subclause.

Some of the DLCs of IEC 61400-1 and covered by MLCs defined in this specification are

specified at external conditions that are difficult to achieve during a measurement campaign.

In particular, the high wind speeds for those DLCs are difficult to obtain during the

measurement campaign or at a specific site. For example, it is not possible to forcefully apply

the extreme coherent gust to the turbine. In such cases, these load cases shall be assessed

at wind speeds which are as high as possible.

The measured time histories are classified in two ways: one considering steady-state

operation (SO) and one considering transient events (TE). In this way, all measurements can

be classified in measurement load cases which relate to the IEC 61400-1 DLCs.

Tables 1 and 2 show the MLCs that are recommended to be recorded. The MLCs defined in

the tables may not be complete. Additional MLCs may be necessary depending on the wind

turbine concept and control and safety strategy.

3.2.2 MLCs during steady-state operation

Power production

During power production, measurements shall be performed in the wind speed range from

cut-in to cut-out and in a range of turbulence intensity levels described in the following

subclause.

– 12 – TS 61400-13 © IEC:2001(E)

Power production with occurrence of fault

According to IEC 61400-1 any fault in the control or protection systems, or any internal fault in

the electrical systems being significant for the wind turbine loading, shall be considered to

occur during power production. The occurrence of a fault in the control system, which is

considered as a normal event, shall be analysed. A typical fault condition could be the

operation at extreme yaw misalignment due to a faulty wind vane, which might not be relevant

for a free yaw wind turbine. Faults in the protection system or in the internal electrical system,

not causing an immediate shut-down of the wind turbine and consequently leading to higher

fatigue loading, shall be considered. An example could be operation with one tip brake

activated. The possible fault conditions shall be considered for each wind turbine and

application in order to define the measurement campaigns.

Parked, idling

The loads on the parked wind turbine, which may be either in a standstill or idling condition,

shall be measured. It is recommended that measurements be performed at wind speeds as

high as possible.

Table 1 – MLCs during steady-state operation related to the DLCs defined in IEC 61400-1

MLC Measurement load DLC number Wind condition Remarks

number case MLC (IEC 61400-1) at DLC

1.1 Power production 1.2 v < v < v * In this mode of operation, the wind

in hub out

turbine is running and connected to

the grid

1.2 Power production 2.3 v < v < v * Any fault in the control or protection

in hub out

plus occurrence of system, which does not cause an

fault immediate shut-down of the turbine

1.3 Parked, idling 6.2 v < v < 0,75 v * When the wind turbine is parked,

in hub e1

the rotor may either be stopped or

idling

* Has to be divided further into wind speed bins and turbulence bins.

3.2.3 MLCs during transient events

Start-up

This design situation includes all events resulting in loads on the wind turbine during the

transients from standstill or idling to power production. The normal start-up of the turbine shall

be performed slightly below cut-out wind speed and at cut-in wind speed. If the turbine

operates at more than one fixed speed, cut-in on the different rotational speeds shall be

evaluated too.

Normal shut-down

This design situation includes all events resulting in loads on a wind turbine during the normal

transient caused by going from a power production situation to a standstill or idling condition.

The normal shut-down is recommended to be performed at cut-in wind speed, at rated power

and at cut-out wind speed.

Emergency shut-down

The loads arising from emergency shut-down shall be considered. It is recommended to

perform the emergency shut-down near cut-in wind speed and above rated wind speed.

TS 61400-13 © IEC:2001(E) – 13 –

Grid failure

The loads arising from grid failure shall be considered. It is recommended to perform the

simulation of grid disconnection above rated wind speed and near cut-out wind speed.

Overspeed activation of the protection system

The loads during activation of the protection system due to turbine overspeed shall be

measured. All combinations of braking procedures and activation methods shall be

considered. It is recommended to perform this test above rated wind speed.

Table 2 – Measurement of transient load cases related to the DLCs defined in IEC 61400-1

MLC Measurement load case MLC DLC Target wind speed

and > + 2 m/s

2.1 Start-up 3.1 v v

in r

2.2. Normal shut-down 4.1 v , v and > v + 2 m/s

in r r

2.3 Emergency shut-down 5.1 v and > v + 2 m/s

in r

2.4 Grid failure 1.5 v and > v + 2 m/s

r r

2.5 Overspeed activation of the protection system 5.1 > v + 2 m/s

r

Ideally the measurements should be taken at v . As this is impractical, the measurements are

out

taken at wind speeds higher than v + 2 m/s.

r

3.2.4 Capture matrix

The capture matrix is used to organize the measured time series. The capture matrix has two

objectives: it can be used as a guideline for programming the data acquisition system for

automatic and unattended operation and it can be used as a tool to decide when the

measurement requirements are fulfilled.

For steady-state operation, the operational condition is defined and the mean wind speed and

turbulence intensity are calculated. If it is decided to store the time series, the relevant matrix

element is updated. Consequently, it is simple to decide when the recommended number of time

series is reached. For a transient event the actual wind speed is written in the capture matrix.

The bin sizes of the matrix and the number of data sets in each matrix element have to be adapted

for each specific measurement campaign. If the relevant status parameters from the control

system are recorded, capturing the measurements during some of the transient events can be

recorded automatically too. The scheme of the complete capture matrix is given in table 3.

If the measurement site terrain characteristics differ significantly in the various wind direction

sectors, the capture matrix can additionally be divided into pre-selected wind directions

sectors. The overall requirements on the database remain the same.

Power production

During the measurement campaign the data should be classified according to the wind speed

and turbulence intensity. Even though there is no requirement on the turbulence intensity at

high wind speeds, the recorded data shall be classified according to the turbulence bins.

It is recommended that the wind speed be divided into bin intervals of 1 m/s and the

turbulence intensity into 2 % bin intervals. The accumulated number of 10-min time series at

each wind speed bin up to v shall be at least 30. This corresponds to 5 h of raw data in total

r

at each wind speed bin from v to v . In addition to the totally required amount of data, the

in r

measurements shall be recorded at different turbulence intensities. As a minimum four

turbulence bins at each wind speed bin should include at least three time series.

– 14 – TS 61400-13 © IEC:2001(E)

In the wind speed range from v to v minus 5 m/s the accumulated number of 10-min time

r out

series at each wind speed bin shall be at least eight. No further conditions are put on

the turbulence intensity in the same range of v to v minus 5 m/s. In the wind speed bin

r out

from v minus 5 m/s up to v , the duration of the time series to be recorded may be

out out

reduced to 2 min. At least three time series at each wind speed bin from v minus 5 m/s to

out

v minus 1 m/s should be recorded. At least one time series shall be recorded at v .

out out

No conditions are put on the turbulence intensity in the range from v minus 5 m/s to v .

out out

The 2-min time series may be derived from the 10-min time series, on condition that there is

no overlap in the resulting 2-min series.

Power production and occurrence of fault

The wind speed is divided into three intervals, from v minus 6 m/s to v minus 2 m/s, from

r r

v minus 2 m/s to v plus 2 m/s, and for wind speeds larger than v plus 2 m/s. The duration of

r r r

each time series shall be more than 2 min. The relevant fault conditions shall be evaluated for

each particular case.

Parked (standstill or idling)

The wind speed bin size for standstill or idling MLCs is recommended to be 4 m/s. The

duration of the time series is recommended to be 10 min. Measurements at parked conditions

should be made at a variety of yaw misalignment angles, including the most unfavourable

inflow angles.

Table 3 – Capture matrix for normal power production

Normal power production

Wind speed bin size: 1 m/s

Turbulence bin size: 2 %

Time series

10 min At least 2 min

length

Wind (m/s) ⇒ v - … 4,5 …… v……… v …… v

in r m out

I (%) ⇓ 5,5

<3

3-5

5-7

7-9

…

…

27-29

>29

Minimum 4 4 4 4 4 4 4 4 – – – – – –

number of

turbulence bins

with at least

three time series

Minimum 30 30 30 30 30 30 30 8 8 8 3 3 3 1

recommended

number of time

series for

empirical load

determination

Minimum

ν − 2 to ν + 2 (ν + 2) +ν

v to v − 2

r r ( v + 2 ) + v

in r r out

r out

ν + 2 to

recommended r to v

out

measurement

hours for model

3 h

3 h

3 h

1 h

validation

NOTE The recommended number of time series at each wind speed bin is given in the last but one row. The actual number of

measurements can be updated in the white cells.

TS 61400-13 © IEC:2001(E) – 15 –

Table 4 – Capture matrix for power production plus occurrence of fault

Power production plus occurrence of fault

Time series length 2 min 2 min 2 min

Wind (m/s) v < v < v – 2 m/s v – 2 m/s < v < v + 2 m/s v + 2 m/s < v

in r r r r

Fault condition

Fault No. 1 2 2 2

Fault No. 2 2 2 2

………….

Fault No. n 2 2 2

NOTE The recommended number of time series at each fault condition is shown in the grey elements. The

actual number of measurements can be filled in the white cells.

Table 5 – Capture matrix for parked condition

Parked (standing still and/or idling)

Time series record

Minimum 2 min

length

Parking modes All design driving parking modes

(for example, idling, standstill)

Yaw angles At least the two most unfavourable angles

Record mean wind

(v to v – 2 m/s) (v – 2 m/s to v + 2 m/s) above v + 2 m/s

in r r r r

speed ranges

Minimum total time 20 min 20 min 20 min

Actual number of

measurements

Table 6 – Capture matrix for normal transient events

Normal start-up and shut-down events

Event (v to v – 2) (v – 2 to v + 2) above v + 2

in r r r r

Start-up Recommended

3 – 3

number

Actual measured

wind speed (m/s)

Normal shut- Recommended

3 3 3

down number

Actual measured

wind speed (m/s)

NOTE 1 The actual measured wind speed is the average over the duration of the transient event.

NOTE 2 The actual wind speed measured during the transient event shall be filled in the white cells.

– 16 – TS 61400-13 © IEC:2001(E)

Table 7 – Capture matrix for other than normal transient events

Other transient events

Event Most critical wind speed

Grid failure Recommended number 3

Actual measured wind speed (m/s)

Emergency shut down Recommended number 3

Actual measured wind speed (m/s)

Overspeed combinations Recommended number 3

Actual measured wind speed (m/s)

Other design critical transients Recommended number 3

Actual measured wind speed (m/s)

NOTE 1 The actual measured wind speed is the average over the duration of the transient event.

NOTE 2 The actual wind speed measured during the transient event shall be filled in the white

cells.

3.3 Quantities to be measured

3.3.1 General

The relevant physical quantities to be measured in order to characterize the loading of wind

turbines can be classified into

– load quantities (for example, blade loads, rotor loads and tower loads);

– meteorological parameters (for example, wind speed and direction, ambient temperature

and air pressure and other);

– operational parameters (for example, power, rotational speed, pitch angles, yaw position,

azimuth angle).

In the following subclause, a more detailed specification is given for the various categories of

measurement quantities.

3.3.2 Load quantities

The measurements aim at the determination of the fundamental loads on the wind turbine.

These are the basic loads on crucial locations of the wind turbine construction from which the

loading in all the relevant wind turbine structural components can be derived. The

fundamental loads to be measured are listed in table 8. Figure 1 indicates the load vectors on

the wind turbine structure. The co-ordinate systems to use for the description of the load

quantities are given in annex A. If specific loads such as actuator loads (for example, yaw and

pitch) are critical to safe operation then they should also be measured.

Table 8 – Wind turbine fundamental load quantities

Load quantities Specification Comments

Blade root loads Flap bending Blade 1: mandatory

Lead-lag bending Other blades: recommended

Rotor loads Tilt moment The tilt and yaw moment can be measured in

the rotating frame of reference or on the fixed

Yaw moment

system (for example, on the tower)

Rotor torque

Tower loads Bottom bending in two directions

TS 61400-13 © IEC:2001(E) – 17 –

3.3.3 Meteorological parameters

Table 9 lists the meteorological quantities to be measured in load measuring programmes.

Table 9 – Meteorological quantities

Quantity Importance level Comments

Wind speed Mandatory At hub height

Wind shear Recommended

Wind direction Mandatory At hub height

Air temperature Mandatory Influences material properties

Temperature gradient Recommended

Air density Mandatory Derived from air temperature and air pressure

(which may be derived from the altitude taking

into account ISO atmosphere)

3.3.4 Wind turbine operation quantities

Table 10 lists the operation quantities which are or may be required.

Table 10 – Wind turbine operation quantities

Quantity Importance level Comments

Electrical power Mandatory

Rotor speed Mandatory

Pitch angle Mandatory Only for variable pitch turbines

Yaw position Mandatory

Rotor azimuth Mandatory If yaw and tilt moment are measured on the

rotor shaft

Grid connection Recommended

Brake status Recommended

Wind turbine status Useful Relevant parameters may be derived from

control panel of wind turbine

– 18 – TS 61400-13 © IEC:2001(E)

Blade loads

M

yaw

M

ttt

M

bf

M

bll

M

tilt M

T ttn

Rotor

M

ttl

Rotor loads

Wind Tower top loads

Wind

M

tn

M

tl

Tower loads

IEC 801/01

Figure 1 – Fundamental wind turbine loads: tower base, tower top, rotor and blades

TS 61400-13 © IEC:2001(E) – 19 –

4 Measurement techniques

4.1 General

In this clause, the measurement techniques for the various types of quantities in load

measurement programmes are described. These techniques include

− instrumentation;

− calibration;

− signal conditioning (where relevant).

If, with respect to calibration, for a particular type of sensor, nothing is specifically mentioned,

sensor calibrations should be performed and documented.

Furthermore, this clause gives recommendations with respect to the data-acquisition methods

in load measurement programmes.

4.2 Load quantities

4.2.1 Sensors

This subclause deals with load sensors, selection of suitable locations and recommended

deployment procedures. Before dealing with the specifics of measuring loads on wind

turbines, the following points will be highlighted:

− recommended types of load sensors;

− general considerations for sensor location;

− calibration procedures to ensure accurate and reliable performance of the instrumentation.

4.2.1.1 Types of sensors

A load sensor is a device that directly or indirectly measures the load experienced by a

system or component. Typical devices include, but are not limited to

− strain gauge bridges;

− load cells/torque tubes (including piezoelectric cells);

− accelerometers, velocity, rotation and displacement transducers.

For wind turbines, it will seldom be possible to place a load cell in a main load path. For this

reason, strain gauges applied to the structure are selected as the recommended type of

sensor. It is recommended that the strain gauge output be related direct to an applied load

level. This is achieved by establishing static calibration relationships. It is important to realize

that dynamic behaviour of the structure or component can modify this relationship so that the

strain gauge will indicate gross internal loads rather than externally applied loads. In strain

gauge application, it is particularly important to avoid wire temperature effects and cross-

sensitivity and to ensure proper temperature compensation. Cross-sensitivity is the

undesirab

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...