IEC 62922:2016/AMD1:2021

(Amendment)Amendment 1 - Organic light emitting diode (OLED) panels for general lighting - Performance requirements

Amendment 1 - Organic light emitting diode (OLED) panels for general lighting - Performance requirements

Amendement 1 - Panneaux à diodes électroluminescentes organiques (OLED) destinés à l'éclairage général - Exigences de performance

General Information

- Status

- Published

- Publication Date

- 25-Aug-2021

- Technical Committee

- SC 34A - Electric light sources

- Drafting Committee

- WG 3 - TC 34/SC 34A/WG 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 26-Aug-2021

- Completion Date

- 17-Sep-2021

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 62922:2016/AMD1:2021 is the first amendment to the International Electrotechnical Commission (IEC) standard IEC 62922:2016, which defines performance requirements for organic light emitting diode (OLED) panels used in general lighting applications. This amendment, published in August 2021, updates and refines elements relating to photometric characteristics, lifetime, uniformity, and operational parameters of OLED lighting panels to ensure consistent performance and reliability in line with evolving industry practices.

Developed by IEC Technical Committee 34, Subcommittee 34A (Electric light sources), the amendment aims to support manufacturers, designers, and certification bodies by offering clear, internationally accepted guidelines for OLED panel evaluation, facilitating global market compatibility and product transparency.

Key Topics

Performance Criteria for OLED Panels

The amendment introduces detailed definitions such as median useful life, maintained operating voltage, and maintained chromaticity coordinate, which are critical for assessing OLED panel durability and color stability during their service life.Marking and Documentation Requirements

Updated marking requirements mandate that key parameters be indicated clearly on product packaging or documentation, including:- Rated luminous flux and average luminance

- Chromaticity coordinates and allowable color range

- Correlated color temperature (CCT)

- Colour rendering index (CRI)

- Operating temperature range

- Luminous efficacy and luminance uniformity

- Median useful life and luminous flux maintenance

- Maintained operating voltage and chromaticity after aging

Photometric Measurement Updates

Chromaticity coordinates measurement aligns with ISO 11664-5/CIE S 014-5/E:2016 standards, enhancing consistency and accuracy in color metrics. The average luminance measurement methods are clarified with two prescribed approaches - imaging luminance measuring device (ILMD) and spot luminance meter techniques - including specific spatial and angular considerations.Lifetime and Reliability Testing

The amendment refines the evaluation of luminous flux maintenance, requiring that the flux at rated life (e.g., 2000 hours) be no less than 90% of the initial rated value. Accelerated life testing protocols and associated manufacturer declarations on maintained operating voltage limits ensure transparency in OLED panel aging behavior.Environmental Durability

New test conditions for high temperature and high humidity storage environments are introduced to simulate real-world stress, requiring OLED panels withstand 500 hours at 60 ±2°C and 90% relative humidity without condensation, confirming stable luminous flux and chromaticity thereafter.Controlgear Design Guidance

Essential information for driver and controlgear compatibility is highlighted, pointing users to Annex E for operational guidelines that ensure optimal electrical and thermal management of OLED lighting panels.

Applications

General Lighting Solutions

These standardized performance requirements streamline the adoption of OLED technology in residential, commercial, and industrial lighting products by guaranteeing consistent luminance, efficiency, and lifespan metrics.Quality Assurance and Certification

OEMs, testing laboratories, and certification bodies rely on IEC 62922:2016/AMD1:2021 for conformity assessment of OLED panels, helping manufacturers meet market regulatory demands and consumer expectations on durability and performance.Design and Engineering

Lighting designers and engineers utilize this standard to specify OLED panels with verified color accuracy, luminance uniformity, and thermal performance, ensuring that devices function reliably within specified conditions.Environmental Stress Testing

The inclusion of rigorous high humidity and temperature endurance tests allows industry players to predict and mitigate product degradation in harsh environments, enhancing product lifespan.

Related Standards

IEC 62922:2016

The base edition detailing original photometric and electrical requirements for OLED general lighting panels.ISO 11664-5 / CIE S 014-5/E:2016

Defines uniform color space and chromaticity measurement methodologies, referenced for color performance evaluations in OLED panels.IEC 62717

Addresses LED modules for general lighting, offering complementary insights on lifetime metrics and luminous flux maintenance applicable to OLED devices.IEC TR 62732

Previously referenced photometric code standard, removed in this amendment to streamline marking requirements.IEC 34 Technical Committee Publications

Covers electric light sources, including LED and OLED lighting technologies, providing broader context and development direction.

Keywords: IEC 62922 amendment, OLED panels, OLED lighting performance, median useful life, luminous flux maintenance, chromaticity coordinates, luminance uniformity, high humidity test, maintained operating voltage, general lighting standards, OLED quality assurance, OLED reliability.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 62922:2016/AMD1:2021 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Amendment 1 - Organic light emitting diode (OLED) panels for general lighting - Performance requirements". This standard covers: Amendment 1 - Organic light emitting diode (OLED) panels for general lighting - Performance requirements

Amendment 1 - Organic light emitting diode (OLED) panels for general lighting - Performance requirements

IEC 62922:2016/AMD1:2021 is classified under the following ICS (International Classification for Standards) categories: 29.140.99 - Other standards related to lamps. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62922:2016/AMD1:2021 has the following relationships with other standards: It is inter standard links to IEC 62922:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62922:2016/AMD1:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62922 ®

Edition 1.0 2021-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

AM ENDMENT 1

AM ENDEMENT 1

Organic light emitting diode (OLED) panels for general lighting – Performance

requirements

Panneaux à diodes électroluminescentes organiques (OLED) destinés à

l'éclairage général – Exigences de performance

IEC 62922:2016-11/AMD1:2021-08(en-fr)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 18 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC online collection - oc.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications. Avec un

en utilisant différents critères (numéro de référence, texte, abonnement, vous aurez toujours accès à un contenu à jour

comité d’études, …). Elle donne aussi des informations sur adapté à vos besoins.

les projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au

Restez informé sur les nouvelles publications IEC. Just

monde, avec plus de 22 000 articles terminologiques en

Published détaille les nouvelles publications parues.

anglais et en français, ainsi que les termes équivalents dans

Disponible en ligne et une fois par mois par email.

16 langues additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 62922 ®

Edition 1.0 2021-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

AM ENDMENT 1

AM ENDEMENT 1

Organic light emitting diode (OLED) panels for general lighting – Performance

requirements

Panneaux à diodes électroluminescentes organiques (OLED) destinés à

l'éclairage général – Exigences de performance

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.140.99 ISBN 978-2-8322-1013-9

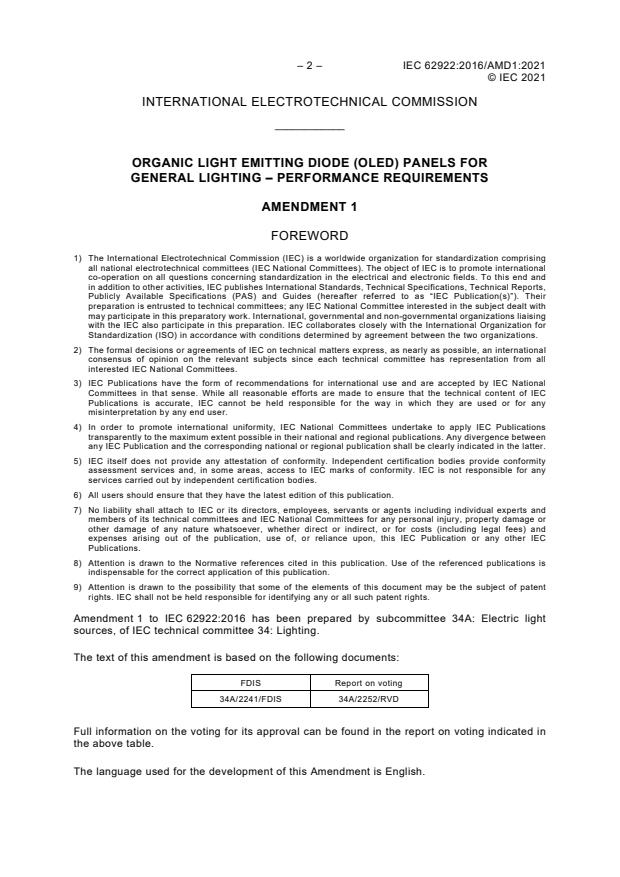

– 2 – IEC 62922:2016/AMD1:2021

© IEC 2021

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ORGANIC LIGHT EMITTING DIODE (OLED) PANELS FOR

GENERAL LIGHTING – PERFORMANCE REQUIREMENTS

AMENDMENT 1

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

Amendment 1 to IEC 62922:2016 has been prepared by subcommittee 34A: Electric light

sources, of IEC technical committee 34: Lighting.

The text of this amendment is based on the following documents:

FDIS Report on voting

34A/2241/FDIS 34A/2252/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this Amendment is English.

© IEC 2021

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications/.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 4 – IEC 62922:2016/AMD1:2021

© IEC 2021

2 Normative references

Delete the reference to IEC TR 62732.

Replace "ISO 11664-5/CIE S 014-5/E:2009" with "ISO 11664-5/CIE S 014-5/E:2016".

3 Terms and definitions

Add, at the end of 3.5, the following new entries 3.6, 3.7 and 3.8:

3.6

median useful life

L

x

length of operating time during which a total of 50 % of a population

of operating OLED tiles or panels of the same type have flux degraded to the luminous flux

maintenance factor x

Note 1 to entry: The median useful life includes operating OLED tiles and panels only.

Note 2 to entry: By convention, the expression "life of OLED tiles" or "life of OLED panels" without any modifiers is

understood to be the median useful life.

3.7

maintained operating voltage

operating voltage measured at an operational time, the OLED tiles

or panels operating under specified conditions

Note 1 to entry: Specified conditions are described either in this document or the manufacturer’s document.

3.8

maintained chromaticity coordinate

chromaticity coordinate measured at an operational time, the OLED

tiles or panels operating under specified conditions

Note 1 to entry: Specified conditions are described either in this document, or the manufacturer’s document.

Note 2 to entry: Details are given in 8.2.2.

5 Marking

5.1 Contents and location

Table 1

Delete the row "Photometric code" and add four new rows before the NOTE, as follows:

© IEC 2021

Table 1 – Contents and location of marking

Parameters Location

Rated luminous flux (lm) Mandatory on packaging or product information

Mandatory on packaging or product information

Average luminance (cd/m )

Photometric code (according to IEC TR 62732) Mandatory on packaging or product information

Rated chromaticity coordinates (in u’v’ coordinates) and Mandatory on packaging or product information

chromaticity coordinate range (expressed by Δu’v’, a

u’v’ circle or a u’v’ quadrangle)

Correlated colour temperature (K) Mandatory on packaging or product information

Rated colour rendering index Mandatory on packaging or product information

Operating temperature range (°C) Mandatory on packaging or product information

Rated luminous efficacy (lm/W) Mandatory on packaging or product information

Luminance uniformity (%) Mandatory on packaging or product information

a

Mandatory on packaging or product information

Luminous intensity distribution

Surface chromaticity uniformity and location of Mandatory on packaging or product information

measurement spots (if applicable)

Angular chromaticity uniformity Mandatory on packaging or product information

Rated location and dimensions of the light output Mandatory on packaging or product information

surface

Rated median useful life (h) Mandatory on packaging or product information

Luminous flux maintenance (%) Mandatory on packaging or product information

Maintained operating voltage (V) Mandatory on packaging or product information

Maintained chromaticity coordinate Mandatory on packaging or product information

NOTE The operating temperature range specifies maximum and minimum temperatures of the OLED panel at

which the OLED panel will function as intended. The operating temperatures are measured according to Annex F.

a

This requirement is fulfilled if the data file is made available electronically.

7.4 Chromaticity coordinates

Replace the existing text with the following new text:

The chromaticity coordinates shall be determined from the spectral distribution obtained from

the measurement specified in 7.2, in accordance with ISO 11664-5/CIE S 014-5/E:2016.

7.7 Luminance uniformity

Replace the existing title of 7.7 with the following new title:

7.7 Luminance

7.7.1 Average luminance (L )

av

Replace the existing subclauses 7.7.1.1 to 7.7.1.3 with the following new text:

The initial average luminance is measured in accordance with Annex G.

– 6 – IEC 62922:2016/AMD1:2021

© IEC 2021

Compliance:

The initial average luminance shall not deviate from the rated average luminance by more than

10 %.

8 Maintained photometric characteristics

Replace the existing text with the following new Subclauses 8.1 to 8.3:

8.1 Luminous flux maintenance

The luminous flux maintenance factor is obtained from the value at rated life expressed as a

percentage of the initial value.

For the measurement method of luminous flux, Annex C applies.

Information on lifetime estimation is given in Annex H.

An accelerated life test can be used to estimate the lifetime of an OLED light source. If an

accelerated life test is used to estimate the lifetime, then the estimation method with detailed

measurement conditions shall be provided by the manufacturer.

NOTE 1 The luminous flux at the rated life can be evaluated by the direct measurement or estimation.

NOTE 2 For general guidance on LED product lifetime metrics, see Annex C of IEC 62717:2014 and Annex C of

IEC 62717:2014/AMD2:2019.

Compliance:

The evaluated luminous flux maintenance factor at rated life time shall not be less than 90 %

of the rated luminous flux maintenance factor.

8.2 Maintained operating voltage

The manufacturer shall declare the maintained operating voltage values for 2 000 h and the

maximum operating voltage value for OLED light sources during their lifetime.

An OLED panel shall not exceed the maintained operating voltage rise, which is defined by its

manufacturer.

Compliance:

The maintained operating voltage of the OLED panels measured at 2 000 h shall not exceed

the declared value.

8.3 Maintained chromaticity coordinates

The initial chromaticity coordinates of the OLED panel and the chromaticity coordinates at

2 000 h are measured.

NOTE The maintained chromaticity coordinate shift can be expressed by Δ(u’,v’).

Compliance:

The OLED panel shall not exceed the rated maintained chromaticity coordinate shift.

© IEC 2021

9.2 High temperature – high humidity storage

Replace the existing text with the following new text:

An OLED panel shall be kept in a humidity cabinet having a relative humidity of (90 ± 5) % for

500 h. The temperature of internal air shall be maintained at (60 ± 2) °C. The OLED panel shall

be placed in the humidity cabinet where humidity and temperature are maintained without

supplying electricity. The test shall be conducted so that no condensation or water droplets

appear on any part of the OLED panel. After the high temperature – high humidity storage test,

the luminous flux and chromaticity of the OLED panel are measured in accordance with 7.2 and

7.4 respectively. The mounting position shall be declared in the test report.

10 Information for controlgear design

Replace the existing text with the following new text:

Information for controlgear design is given in Annex E. This should be followed for proper

operation of OLED panels.

– 8 – IEC 62922:2016/AMD1:2021

© IEC 2021

At the end of Annex F, add the following new Annex G and Annex H:

Annex G

(normative)

Measuring method for average luminance

G.1 General

Measurement of the average luminance of an OLED panel shall use one of the two methods

described below.

1) imaging luminance measuring device (ILMD) method;

2) spot luminance meter method.

The actual method used for measurement shall be recorded in the test report.

G.2 Setting

Depending on the method adopted, it may be necessary to install the panel vertically to keep

an adequate distance between the panel and the instrument. In this case, the vertical mounting

position shall be recorded in the test report.

G.3 Imaging luminance measuring device (ILMD) method

The average luminance shall be calculated from an image of the entire light output surface with

a maximum exclusion zone of 3 mm from the edge.

G.4 Spot luminance meter method

The measurement of average luminance (L ) shall be carried out in perpendicular direction to

av

the light output surface of an OLED panel. The distance from the edge of the light output surface

to the closest measurement spot perimeter shall be a maximum of 3 mm.

The remaining lighting area shall then be subdivided into quadrilateral areas with a side length

corresponding to a viewing angle of not more than 1° at a viewing distance of 1 m. The spot

size shall fit into the quadrilateral area with a clearance of at least 1 mm.

EXAMPLE For a 1° viewing angle, the side length l of a subdivision is given by

l = tan (0,5°) × 2 × 1 m = 0,017 m = 1,7 cm. So a 10 cm × 10 cm lighting area would have to be divided into

10/1,7 ≈ 5,8, i. e. 5 × 5 segments.

The arithmetic average of all luminance values of the measured areas is taken as the initial

average luminance.

© IEC 2021

Annex H

(informative)

Information on lifetime estimation

H.1 General

A direct measurement of the median useful life, L , of an OLED light source operating at rated

x

electrical conditions can take tens of thousands of hours. Therefore, accelerated life tests are

used to reduce the necessary testing time for an estimation of the median useful life.

The physical mechanisms for luminous flux degradation differ substantially between OLED

products from different designs and manufacturing processes. Thus, a single standardized

mathematical model for the luminous flux degradation is not known or expected for OLED

technology today.

This annex gives guidance on various tests for OLED lifetime estimation that do not require

testing to the full median useful life.

H.2 Extrapolation through the deterioration curve fitting

The objective of this method is to use degradation measurements taken under the rated

electrical conditions and before reaching L to determine the functional parameters.

x

The majority part of the degradation curve of OLED panels can be expressed in a Weibull

degradation mode (Equation (H.1)).

The luminous flux maintenance can be represented over elapsed time t by the Weibull reliability

function, R(t),

β

R(t) = exp(−(t/t ) ) (H.1)

where t is the time scaling factor and β is the shape factor.

Some of the degradation curves of OLED panels can be expressed with the combination of the

initial degradation (first term) and the normal degradation (second term).

β

R(t) = a∙exp(−(t/t )) + (1 − a)exp(−(t/t ) ) (H.2)

1 0

0 ≦ a < 1

where t is the time scaling factor of the initial degradation and 𝑎𝑎 is the proportion factor of the

initial degradation.

NOTE In 2014, the group who proposed this Annex H (Chemical Materials Evaluation and Research Base) reported

that about 3 % of data cannot be fitted by stretched-exponential decay (SED) function (Weibull reliability function)

(Equation (1)) [T. Yoshioka et al. SID Symposium Digest, 45, 642 (2014)]. And there is a document which expresses

that stretched-exponential decay (SED) function does not have a reaction kinetics meaning and is expressed by

several Arrhenius equations [T. Yoshioka et al. SID Symposium Digest, 46, 1650 (2015)]. Therefore, the fitting

equations are not restricted to one form in order to express OLED degradation data in the current situation.

Most OLED panels are fitted by Equation (H.1). Some panels with fair initial degradation are

fitted by Equation (H.2).

– 10 – IEC 62922:2016/AMD1:2021

© IEC 2021

EXAMPLE

In this example degradation data was collected frequently over a period of 500 h. The data was fitted using

Equation (H.1). A best fit to the parameters was obtained for β = 0,8 and t = 8 000 h. An estimation of the median

useful life for 70 % luminous flux maintenance is calculated using the fitted function as 2 200 h (see Figure H.1).

NOTE The extrapolation value (□) of L is obtained by using the deterioration curve data (○) and the extrapolation

curve (dashed line). The time is 2 200 h when the luminous flux maintenance ratio becomes 70 % (L ).

Figure H.1 – Typical degradation curve of acceleration test

The estimation accuracy of the median useful life, L , improves considerably as more data is

x

taken over a longer period.

H.3 Lifetime estimation using accelerated testing

The time required for lifetime estimation may be shortened by conducting an accelerated test,

which speeds up the degradation process of an OLED product by subjecting it to higher stress

conditions of temperature or drive current or both. Extrapolation to normal operating conditions

of temperature and drive current is used to estimate the median useful life.

Test samples for an accelerated test should be selected from a population of OLED products

having the same degradation characteristics. Normally this will be from a normal manufacturing

production run. At least three test samples should be tested for each selected stress condition.

The accelerated test should be designed so as to avoid changing the failure or degradation

mode at all levels of stress conditions, especially high temperature and high drive current for

OLED panels. A lack of fit to the same degradation function at all stress levels may be evidence

of a changing degradation physics. Test samples should maintain uniform current density at all

stress levels. Heating characteristics may differ due to self-heating either by conduction (joule

heating) or radiation from the test piece resulting in a non-uniform current density distribution.

If evidence of an altered degradation mode is observed, either by visual inspection of test

samples or by lack of fit analysis, then the results should not be used to estimate the median

useful life.

The time required for significant degradation of the test samples subjected to the lowest stress

level will normally be longer than for the higher stress levels. However, estimates of the median

useful life are possible as soon as the data fits the accelerated life test model reasonably well.

© IEC 2021

H.4 Life estimation using the acceleration factor

This method uses complete acceleration test data for a shorter time (e.g. L or L ) to estimate

99 90

an acceleration factor which is then applied to complete data at the high stress level lifetime

(L ) to estimate the median useful life (L ) in normal operation. Either acceleration stress,

70 70

drive current or temperature, can be used. However, the same acceleration stress, type and

level, should be used for all test pieces. If the data at the same acceleration stress is not

available, then this method should not be used.

The estimated acceleration factor is calculated by dividing the measured lifetime (e.g. L ) at

normal operation by the same measured lifetime (e.g. L ) with accelerated stress.

EXAMPLE

Normal: L = 100 h, Accelerated: L = 10 h

99 99

Normal: L = 500 h, Accelerated: L = 50 h

90 90

Acceleration factor = 100/10 = 500/50 = 10 for each lifetime.

When the test pieces at the accelerated stress level reach the rated median useful life, L

,

then the acceleration factor can be used to estimate the L life in normal operation. Continuing

the example, if L at the accelerated condition is 200 h and the accelerated factor is 10, then

L in normal operation is 2 000 h.

H.5 Extrapolation of lifetime using current acceleration data

This method uses complete acceleration test data at two or more acceleration stress levels of

drive current and fits a power function, Equation (H.3), for the measured median useful life, L ,

x

as a function of the stress drive current, I ,

d

α

L = L · (I /I ) (H.3)

x 0 d 0

where I is the rated drive current in normal operation, and the fitted parameters are L and α.

0 0

The current multiplication factor is defined as the ratio, I /I , for convenience when plotting the

d 0

data on a double logarithmic plot and fitting with a straight line. The median useful life for

operation at the rated drive current is estimated at a current multiplication factor equal to

1 (I = I ).

d 0

As an example, consider accelerated test data in which L is measured at three accelerated

drive currents with current multiplication factors as follows:

L = 80 h; at I /I = 5

70 d 0

L = 125 h; at I /I = 4

70 d 0

L = 222 h; at I /I = 3

70 d 0

The data of this example is plotted in Figure H.2. The fitted function parameters are α = 2 and

L = 2 000 h. Thus, the estimated median useful life at rated drive current is L = 2 000 h

0 70

shown as the open square symbol in Figure H.2.

– 12 – IEC 62922:2016/AMD1:2021

© IEC 2021

Figure H.2 – Dependence of L on the driving current

H.6 Extrapolation of lifetime using current and temperature acceleration data

This method uses complete acceleration test data at two or more acceleration stress levels of

drive current and temperature. A full or half fraction factorial test design at three levels of drive

current and temperature with replication is recommended. Then the degradation data collected

at each stress condition is fitted to a Weibull reliability function, R(t), using Equation (H.1).

The fitted shape parameters, β, should have nearly the same value indicating a consistent

physical degradation mode. An average β value should be used in the equation for estimating

median useful life, see Equation (H.6). If the shape parameter, β, varies significantly between

stress conditions, then this method should not be used. The fitted time scale parameters, t ,

should vary with stress conditions and are subsequently fitted to a power function for the drive

current, I , and an Arrhenius function for the OLED panel temperature, T , using

d EL

Equation (H.4),

α

t (T ,I ) = A∙(I /I ) ∙exp(E /(k ∙T ) (H.4)

0 EL d d 0 a B EL

where I is the rated drive current in normal operation, A and α are the fitted time parameter

and power function exponent respectively, E is the fitted activation energy parameter, and k

a B

−5

is the Boltzmann constant (8,617 × 10 eV/K).

The OLED panel temperature, T , is related to the ambient temperature, T , and the

EL amb

temperature rise, ΔT , due to self-heating of the OLED device by Equation (H.5),

sh

T = T + ΔT (H.5)

EL amb sh

Temperature values for Equations (H.3) and (H.4) are in Kelvin.

© IEC 2021

The median useful life for normal operation at rated drive current, I , and OLED device

temperature, T , is estimated using the calculated time scale parameter, t (T ,I ), and

stack 0 stack 0

the average shape value, β, using Equation (H.6),

(1.β)

L = t · (ln(100/x)) (H.6)

x 0

where x is the luminous flux maintenance factor.

The following illustrated example of this method is provided for additional guidance. Five

acceleration stress conditions are tested.

Condition 1: I /I = 10, T = 298 K

d 0 amb

Condition 2: I /I = 10, T = 313 K

d 0 amb

Condition 3: I /I = 10, T = 328 K

d 0 amb

Condition 4: I /I = 7, T = 328 K

d 0 amb

Condition 5: I /I = 5, T = 328 K

d 0 amb

NOTE The recommendation for a factorial test design has not been followed in this example.

Luminous flux degradation data for each condition is fitted to the Weibull reliability function, R(t),

using Equation (H.1). The following fitted parameter values are calculated.

Condition 1: t = 718 h, β = 0,71

Condition 2: t = 411 h, β = 0,70

Condition 3: t = 229 h, β = 0,71

Condition 4: t = 387 h, β = 0,69

Condition 5: t = 646 h, β = 0,69

The variation in the fitted shape parameters is small indicating a consistent physical degradation

mode, thus the average β = 0,70 will be used in the median useful life estimation.

The time scale parameter, t , is fitted using Equation (H.3), the drive currents, I , and the OLED

0 d

device temperatures, T , adjusted for self-heating (not presented) by Equation (H.5). The fitted

EL

parameters for this example were as follows:

E = 0,36 eV

a

α = 1,24

A = 0,022 h

Figure H.3 a) shows an Arrhenius plot of the time scale (t ) data versus reciprocal temperature

(1/(k · T )) for conditions 1, 2 and 3. The slope of the line estimates the activation energy, E .

B EL a

Figure H.3 b) shows a plot of the time scale data adjusted for temperature (t /exp(E /k · T ))

0 a B EL

versus the current multiplication factor (I /I ) for conditions 3, 4 and 5. The slope of this line

d 0

estimates the power function exponent, α.

For normal operation at rated drive current, ambient temperature, T = 298 K and OLED

amb

device temperature, T = 306 K, the time scale parameter is estimated to be t = 18 485 h.

EL 0

Using this t , the average shape parameter, β = 0,7, and a luminous flux maintenance factor,

x = 70, in Equation (H.6), the median useful life at 70 % maintained luminous flux is estimated

as L = 4 167 h for normal operating conditions.

– 14 – IEC 62922:2016/AMD1:2021

© IEC 2021

a) Arrhenius plot of t b) Current dependence of t

0 0

Figure H.3 – Arrhenius plot and power function

Figure H.4 shows the fitted functions for the time scale parameter, t , and median useful life at

70 % maintained luminous flux, L overlaid on the data for each stress condition.

a) Current dependence of t b) Current dependence of L

0 70

Figure H.4 – Current dependence of t and L

0 70

By using the accelerated data (plots symbolled with O), t and L for any operation condition

0 70

by using Equations (H.3) and (H.4), T = 298 K (solid line), T = 313 K (dotted line) and

amb amb

T = 328 K (slashed line). T and L at rated operation condition are shown by Figure H.4.

amb 0 70

© IEC 2021

Bibliography

Add the following new references:

IEC 62717:2014, LED modules for general lighting – Performance requirements

IEC 62717:2014/AMD1:2015

IEC 62717:2014/AMD2:2019

T. Yoshioka, K. Sugimoto, K. Katagi, Y. Kitago, M. Tajima, S. Miyaguchi, T. Tsutsui, R. Iwasaki,

Y. Furukawa, "An

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...