IEC 62303:2008

(Main)Radiation protection instrumentation - Equipment for monitoring airborne tritium

Radiation protection instrumentation - Equipment for monitoring airborne tritium

IEC 62303:2008 is applicable to equipment used for sampling and continuous measurement of tritium in the workplace, in gaseous effluents discharged into the environment as well as in the environment itself and it is applicable to installed, portable and transportable equipment. The object is to establish mandatory general requirements and to present examples of acceptable methods and equipment for continuously monitoring and/or sampling airborne tritium. Complements IEC 60761-5.

Instrumentation pour la radioprotection - Matériel pour la surveillance du tritium atmosphérique

La CEI 62303:2008 est applicable au matériel utilisé pour les mesures par prélèvement ou en continu du tritium sur les lieux de travail, dans les effluents gazeux rejetés dans l'environnement et dans l'environnement lui-même, et elle est applicable aux matériels installés, portables et transportables. L'objet est d'établir des exigences générales impératives et de présenter des exemples de méthodes acceptables et de matériels de surveillance en continu ou par prélèvement du tritium atmosphérique. Complète la norme CEI 60761-5.

General Information

- Status

- Published

- Publication Date

- 10-Dec-2008

- Technical Committee

- SC 45B - Radiation protection instrumentation

- Drafting Committee

- WG 13 - TC 45/SC 45B/WG 13

- Current Stage

- PPUB - Publication issued

- Start Date

- 11-Dec-2008

- Completion Date

- 15-Jan-2009

Overview

IEC 62303:2008 is an international standard published by the International Electrotechnical Commission (IEC) that establishes general requirements and acceptable methods for equipment used to monitor airborne tritium. This standard applies to various types of monitoring devices including installed, portable, and transportable equipment designed for sampling and continuous measurement of tritium in workplaces, gaseous effluents, and the environment. The objective of IEC 62303 is to ensure reliable and consistent radiation protection instrumentation focused on airborne tritium detection.

As a radiation protection instrumentation guideline, IEC 62303 complements related standards such as IEC 60761-5 by providing a specialized framework for airborne tritium monitoring systems. It includes requirements covering design considerations, performance testing, environmental resistance, and operational features to facilitate accurate, safe, and regulatory-compliant tritium measurement.

Key Topics

- Scope of Equipment – Covers installed, portable, and transportable instruments for continuous or sampling-based tritium monitoring.

- Design Considerations – Emphasizes reliability, corrosion resistance, explosive mixture safety, decontamination ease, and electromagnetic compatibility.

- Detection Methods – Describes various accepted tritium detection technologies and the importance of measurement characteristics such as range, response time, and sensitivity.

- Equipment Components – Details key assemblies including sampling, detection, control, indication, alarm, and power supply modules.

- Testing Protocols – Specifies rigorous testing for radiation detection performance, electrical and mechanical robustness, air circuit functionality, and environmental endurance under various conditions.

- Calibration and Metrological Confirmation – Includes guidelines for calibration loops, reference sources, and quality assurance to maintain measurement accuracy.

- Operational and Maintenance Guidance – Addresses requirements for manuals, routine testing, and maintenance to ensure long-term reliability.

Applications

IEC 62303 applies widely in nuclear power plants, research laboratories, environmental monitoring agencies, and industrial facilities where tritium gas is present or produced. Key applications include:

- Workplace Air Monitoring – Continuous tritium concentration measurement to protect personnel from radiological exposure.

- Effluent Monitoring – Ensures gaseous emissions containing tritium comply with regulatory limits before discharge to the environment.

- Environmental Surveillance – Detects and samples airborne tritium to monitor environmental contamination and safety.

- Portable Safety Instruments – Enables field measurements and emergency response monitoring for rapid detection of tritium leaks or releases.

The standard supports safety management systems designed to minimize tritium exposure risks and optimize radiation protection activities.

Related Standards

IEC 62303 operates in conjunction with several other IEC and international standards focused on radiation protection and nuclear instrumentation, including:

- IEC 60761-1 and IEC 60761-5 – Provide complementary guidelines for radiation protection instrumentation.

- ISO/IEC Directives – Guide standard preparation and quality management applicable to IEC publications.

- Radiation Source Calibration Standards – Support proper calibration and traceability of radiation detection equipment.

- Environmental Monitoring Standards – Facilitate broader ecosystem protection from radioactive substances.

By leveraging IEC 62303 alongside these related standards, organizations ensure industry-conforming, high-integrity measurement solutions for airborne tritium monitoring and radiation protection worldwide.

For more information or to access IEC 62303:2008, contact the IEC Central Office or visit www.iec.ch. This standard remains essential for professionals managing radiological safety where tritium is present in gaseous forms.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

IEC 62303:2008 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Radiation protection instrumentation - Equipment for monitoring airborne tritium". This standard covers: IEC 62303:2008 is applicable to equipment used for sampling and continuous measurement of tritium in the workplace, in gaseous effluents discharged into the environment as well as in the environment itself and it is applicable to installed, portable and transportable equipment. The object is to establish mandatory general requirements and to present examples of acceptable methods and equipment for continuously monitoring and/or sampling airborne tritium. Complements IEC 60761-5.

IEC 62303:2008 is applicable to equipment used for sampling and continuous measurement of tritium in the workplace, in gaseous effluents discharged into the environment as well as in the environment itself and it is applicable to installed, portable and transportable equipment. The object is to establish mandatory general requirements and to present examples of acceptable methods and equipment for continuously monitoring and/or sampling airborne tritium. Complements IEC 60761-5.

IEC 62303:2008 is classified under the following ICS (International Classification for Standards) categories: 13.280 - Radiation protection. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62303:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62303

Edition 1.0 2008-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Radiation protection instrumentation – Equipment for monitoring airborne

tritium

Instrumentation pour la radioprotection – Matériel pour la surveillance du tritium

atmosphérique

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 62303

Edition 1.0 2008-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Radiation protection instrumentation – Equipment for monitoring airborne

tritium

Instrumentation pour la radioprotection – Matériel pour la surveillance du tritium

atmosphérique

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

X

CODE PRIX

ICS 13.280 ISBN 978-2-88910-666-0

– 2 – 62303 © IEC:2008

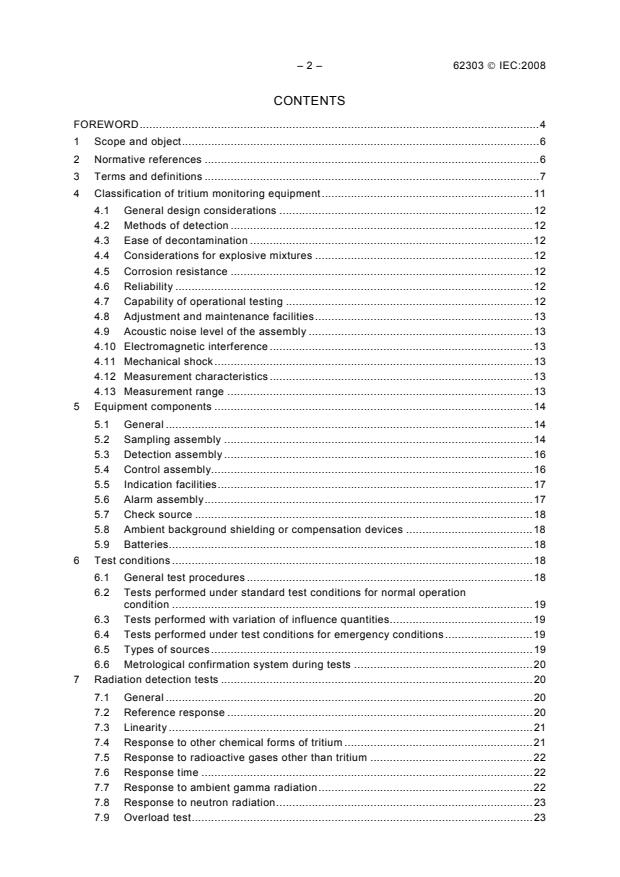

CONTENTS

FOREWORD.4

1 Scope and object.6

2 Normative references .6

3 Terms and definitions .7

4 Classification of tritium monitoring equipment.11

4.1 General design considerations .12

4.2 Methods of detection .12

4.3 Ease of decontamination .12

4.4 Considerations for explosive mixtures .12

4.5 Corrosion resistance .12

4.6 Reliability .12

4.7 Capability of operational testing .12

4.8 Adjustment and maintenance facilities.13

4.9 Acoustic noise level of the assembly .13

4.10 Electromagnetic interference .13

4.11 Mechanical shock.13

4.12 Measurement characteristics .13

4.13 Measurement range .13

5 Equipment components .14

5.1 General .14

5.2 Sampling assembly .14

5.3 Detection assembly .16

5.4 Control assembly.16

5.5 Indication facilities.17

5.6 Alarm assembly.17

5.7 Check source .18

5.8 Ambient background shielding or compensation devices .18

5.9 Batteries.18

6 Test conditions .18

6.1 General test procedures .18

6.2 Tests performed under standard test conditions for normal operation

condition .19

6.3 Tests performed with variation of influence quantities.19

6.4 Tests performed under test conditions for emergency conditions .19

6.5 Types of sources.19

6.6 Metrological confirmation system during tests .20

7 Radiation detection tests .20

7.1 General .20

7.2 Reference response .20

7.3 Linearity .21

7.4 Response to other chemical forms of tritium .21

7.5 Response to radioactive gases other than tritium .22

7.6 Response time .22

7.7 Response to ambient gamma radiation.22

7.8 Response to neutron radiation.23

7.9 Overload test.23

62303 © IEC:2008 – 3 –

7.10 Repeatability .24

7.11 Stability of background indication .24

7.12 Reproducibility of the indication.24

8 Electrical and mechanical tests .25

8.1 Alarm trip range .25

8.2 Alarm trip stability .25

8.3 Equipment fault alarms.25

8.4 Warm-up time — detection and measurement assembly.25

8.5 Power supply variations.26

8.6 Battery test.26

8.7 Power supply transient effects.27

9 Air circuit performance test.27

9.1 General .27

9.2 Susceptibility to gaseous retention .28

9.3 Accuracy of the volume and flow rate measurement .28

9.4 Flow rate stability .29

9.5 Effect of filter pressure drop .29

9.6 Effect of power supply voltage on the flow rate.30

9.7 Effect of power supply frequency on flow rate.30

10 Environmental performance tests .30

10.1 Ambient temperature .30

10.2 Temperature shock.31

10.3 Relative humidity.31

10.4 Atmospheric pressure.32

10.5 Sealing.32

10.6 Mechanical shock.32

10.7 External electromagnetic immunity and electrostatic discharge .33

10.8 Electromagnetic emission.33

11 Type test report and certificate .33

12 Operation and maintenance manual .34

Annex A (informative) General information on conditions of operation.40

Annex B (informative) Preparation of tritiated radioactive reference sources.43

Figure B.1 – Calibration loop .44

Figure B.2 – Calibration loop with tritiated water vapours.45

Table 1 – Reference conditions and standard test conditions for normal operation

condition.35

Table 2 – Tests performed under standard test conditions for normal operation

condition.36

Table 3 – Tests performed with variation of influence quantities for normal operation

condition.37

Table 4 – Tests of air circuit.39

– 4 – 62303 © IEC:2008

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

RADIATION PROTECTION INSTRUMENTATION –

EQUIPMENT FOR MONITORING

AIRBORNE TRITIUM

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62303 has been prepared by subcommittee 45B: Radiation

protection instrumentation, of IEC technical committee 45: Nuclear instrumentation.

This standard cancels and replaces the first edition of IEC 60710, published in 1981.

This standard directly complements IEC 60761-1 (2002) and IEC 60761-5 (2002).

The text of this standard is based on the following documents:

FDIS Report on voting

45B/593/FDIS 45B/599/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

62303 © IEC:2008 – 5 –

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 62303 © IEC:2008

RADIATION PROTECTION INSTRUMENTATION –

EQUIPMENT FOR MONITORING

AIRBORNE TRITIUM

1 Scope and object

This International Standard is applicable to equipment used for sampling and continuous

measurement of tritium in the workplace, in gaseous effluents discharged into the

environment as well as in the environment itself and it is applicable to installed, portable and

transportable equipment.

The object of this International Standard is to establish mandatory general requirements and

to present examples of acceptable methods and equipment for continuously monitoring and/or

sampling airborne tritium. The current standard IEC 60761-5 which is complemented by this

standard, is applicable to equipment for sampling and monitoring tritium only in gaseous

effluents, while this standard expands coverage to include monitoring all possible locations

where tritium could present a radiological hazard. The equipment is designed to be in

operation during normal operation conditions as well as under emergency conditions, both

during and following an accident. Depending of the emergency conditions, it might be

necessary to install specially designed equipment for normal operation conditions and other

equipment for emergency conditions.

This International Standard is applicable to tritium samplers and tritium monitors intended to

provide the following functions:

– the measurement of the volumetric activity of tritium and its variation with time in the

workplace, in gaseous effluents at the discharge point and in the environment;

– the actuation of an alarm when a predetermined volumetric tritium activity or tritium

concentration or a predetermined total activity of released tritium is exceeded;

– the determination of the total tritium activity discharged over a given time;

– the sampling and analysis of air or gas containing tritium.

This standard specifies the general characteristics, general testing procedures, mechanical,

electrical and electronic, radiological, safety and environmental characteristics, and the

proper identification and certification of the equipment. If this equipment is part of a

centralized system for continuous radiation monitoring in a nuclear facility, there may be

additional requirements from other standards related to those systems.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60050-393:2003, International Electrotechnical Vocabulary (IEV) – Part 393: Nuclear

instrumentation – Physical phenomena and basic concepts

IEC 60050-394:2007, International Electrotechnical Vocabulary (IEV) – Part 394: Nuclear

instrumentation – Instruments , systems, equipment and detectors

IEC 60068 (all parts), Environmental testing

62303 © IEC:2008 – 7 –

IEC 60068-2-27, Environmental testing – Part 2-27: Tests – Test Ea and guidance: Shock

(Basic safety publication)

IEC 60068-2-38, Environmental testing – Part 2-38: Tests – Test Z/AD:Composite

temperature/humidity cyclic test

IEC 60761-1, Equipment for continuous monitoring of radioactivity in gaseous effluents –

Part 1: General requirements

IEC 60761-5, Equipment for continuous monitoring of radioactivity in gaseous effluents –

Part 5: Specific requirements for tritium monitors

IEC 61000 (all parts), Electromagnetic compatibility (EMC)

IEC 61000-4-2, Electromagnetic compatibility (EMC) – Part 4-2: Testing and measurement

techniques – Electrostatic discharge immunity test

IEC 61000-4-3, Electromagnetic compatibility (EMC) – Part 4-3: Testing and measurement

techniques – Radiated, radio-frequency, electromagnetic field immunity test

IEC 61000-4-4, Electromagnetic compatibility (EMC) – Part 4-4: Testing and measurement

techniques – Electrical fast transient/burst immunity test

IEC 61000-4-5, Electromagnetic compatibility (EMC – Part 4-5: Testing and measurement

techniques – Surge immunity test

IEC 61000-4-11, Electromagnetic compatibility (EMC) – Part 4-11: Testing and measurement

techniques – Voltage dips, short interruptions and voltage variations immunity tests

IEC 61000-4-12, Electromagnetic compatibility (EMC) – Part 4-12: Testing and measurement

techniques – Ring wave immunity test

IEC 61000-6-4, Electromagnetic compatibility (EMC) – Part 6-4: Generic standards –

Emission standard for industrial environments

IEC 61000-6-6, Electromagnetic compatibility (EMC) – Part 6-6: Generic standards – HEMP

immunity for indoor equipment

IEC 61187:1993,Electrical and electronic measuring equipment – Documentation

ISO 2889 General principles for sampling airborne radioactive materials

ISO 10012:2003, Measurement management systems – Requirements for measurement

processes and measuring equipment

Guide to the expression of uncertainty in measurement (GUM), ISO, 1995

3 Terms and definitions

For the purposes of this document, the terms and definitions concerning detection and

measurement of ionizing radiation and nuclear instrumentation given in IEC 60050-393,

IEC 60050-394, as well as the following, apply.

– 8 – 62303 © IEC:2008

3.1

accident conditions

substantial deviations from operational states that are expected to be infrequent and which

could lead to release of unacceptable quantities of radioactive materials if the relevant

engineered safety features did not function as per design intent

3.2

alarm assembly

assembly or a combination of assemblies that provides audible or visual alarm output in the

event of an alarm threshold being exceeded or a malfunction being detected

3.3

anticipated operational occurrence

all operational processes deviating from normal operation which are expected to occur once

or several times during the operating life of the plant and which, in view of appropriate design

provisions, do not cause any significant damage to items important to nuclear safety nor lead

to accident conditions

3.4

coefficient of variation

the ratio V of the standard deviation s to the arithmetic mean x of a set of n measurements x

i

given by the following formula:

n

s 1 1

V = = ()x − x

∑ i

x x n − 1

i=1

3.5

control assembly

the assembly used to process the output of the detection assembly and provide indication and

power supply for the whole system

3.6

conventionally true activity

the best estimate of the activity of a radioactive source

NOTE Conventionally true activities are, in general, regarded as sufficiently close to the true value for the

difference to be insignificant for the given purpose. For example, a value and its uncertainty determined from a

primary or a secondary standard, or by a reference instrument which has been calibrated against a primary or

secondary standard, may be taken as the conventionally true value.

3.7

coverage factor

numerical factor (k) used as a multiplier of the combined standard uncertainty in order to

obtain an expanded uncertainty (GUM)

3.8

decision quantity

random variable for the decision whether the physical effect to be measured is present or not

3.9

decision threshold

fixed value of the decision quantity by which, when exceeded by the result of an actual

measurement of an measurand quantifying a physical effect, one decides that the physical

effect is present

NOTE The statistical test should be designed such that the probability of wrongly rejecting the hypothesis (error

of the first kind) is equal to a given value α. For this standard, α equals 5 %.

62303 © IEC:2008 – 9 –

3.10

design basis accident

set of accident conditions against which a facility is designed according to established design

criteria, and for which the damage to the nuclear fuel and the release of radioactive material

are kept within authorized limits

3.11

detection limit

smallest true value of the measurand which is detectable by the measuring method

NOTE The detection limit is the smallest true value of the measurand which is associated with the statistical test

and hypotheses (see decision threshold) by the following characteristics: if in reality the true value is equal or

exceeds the detection limit, the probability of wrongly not rejecting the hypothesis (error of the second kind) will be

at most equal to a given value β. For this standard, ß equals 5 %.

3.12

dynamic range

quotient of the signal from the maximum measurable indication of a quantity by the signal

from the decision threshold of that quantity

3.13

effective range of measurement

range of the values of the activity to be measured over which the performance of a piece of

equipment or an assembly meets the requirements of its specifications

3.14

error of indication

difference between the indicated value v of a quantity and the conventionally true value v of

c

that quantity at the point of measurement

Δν =ν −ν

c

where

ν is the value of the quantity indicated by the equipment or assembly under test;

ν is the conventionally true value of the quantity

c

3.15

manufacturer

the term "manufacturer" includes the designer and the seller of the equipment

3.16

measurement assembly

this assembly includes functional units designed to measure quantities related to ionizing

radiation (activity, volumetric activity, etc.)

3.17

measurement uncertainty

parameter, associated with the result of a measurement, that characterises the dispersion of

the values that could reasonably be attributed to the measurand. Any result of a measurement

should be given with the associated uncertainty calculated following the method

recommended in the GUM

3.18

normal operation

operation of a nuclear facility within specified operational limits and conditions

3.19

purchaser

the term "purchaser" includes the user

– 10 – 62303 © IEC:2008

3.20

radiation detection assembly

assembly designed to produce a signal in response to incident ionising radiation

NOTE 1 This signal carries information about physical properties of the radiation.

NOTE 2 One or more sub-assemblies may be included in the same unit.

3.21

reference response

response of the assembly under reference conditions to a reference volumetric activity. This

reference response is expressed as:

V

R =

ref

V

c

where

ν is the value measured by the the equipment or assembly under test; and

ν is the conventionally true value of the reference source.

c

NOTE The background value may be automatically taken in account by an algorithm included in the measuring

system.

3.22

relative error

error of the measurement divided by a true value of the measurand

NOTE Since a true value cannot be determined, in practise a conventionally true value is used.

3.23

response time (of a measuring assembly)

duration between the instant of a step change in the measured quantity and the instant when

the output signal reaches for the first time as specified percentage of its final value, that

percentage being usually taken as 90 %

NOTE For this standard, 90 % is used.

3.24

retention capacity

the maximum quantity of a defined substance which can be retained at equilibrium in the

medium considered

3.25

sampling assembly

set of connected devices used to collect a representative sample

3.26

sampling collection efficiency

for a given quantity of radioactive material, ratio of the collected activity to the supplied

activity, for a specified time interval

3.27

sensitivity

for a given value of the measured quantity, ratio of the variation of the observed variable to

the corresponding variation of the measured quantity

62303 © IEC:2008 – 11 –

3.28

severe accident

set of accident conditions more severe than those of a design basis accident and involving

significant core degradation

3.29

tritium

unless otherwise stated, ”tritium”, in this standard, covers tritium in gaseous or vapour forms,

whether chemically combined or not

3.30

tritium monitor

equipment designed for the monitoring of airborne tritium in gaseous effluent discharged to

the environment, in the environment and in the atmosphere of a workplace.

3.31

tritium sampler

equipment designed to collect a sample of tritium in any form for subsequent analysis.

3.32

volumetric activity

quotient of the activity by the total volume of the sample

NOTE 1 For a gas, it is necessary to indicate the temperature and pressure conditions for which the volumetric

activity, expressed in becquerels per cubic metre, is measured, for example standard temperature and pressure

(STP).

NOTE 2 This quantity is expressed in becquerels per cubic metre (Bq/m ).

4 Classification of tritium monitoring equipment

Various tritium monitor designs are available to meet the specific needs of the user. This

standard classifies tritium monitors based on the following operational and usage

requirements:

• Selectivity for the chemical form of tritium:

– gross tritium monitors respond to all gaseous or vapour forms of tritium;

– selective tritium monitors are designed to detect a specific chemical form of airborne

tritium, for example tritiated water vapour.

• Method of sampling and analysis:

– flow-through methods in which air is drawn through a measuring device with

simultaneous detection;

– batch (sequential) methods in which tritium is collected on an adsorber or trap to allow

detection.

• Measurement range:

– low range tritium monitors include those monitors that can be used to measure

volumetric activity up to 10 MBq/m ;

– high range monitors are those monitors that can be used to measure volumetric

activity in excess of 10 MBq/m .

• Working condition:

– normal operation conditions;

– emergency conditions.

• System interface:

– local readout and alarm only;

– 12 – 62303 © IEC:2008

– interfaced with a centralized system to initiate alarms or indicate operating faults in

addition to the local readout and alarm indications.

• Type of installation and/or power source:

– installed or transportable tritium monitors primarily operate using mains power, and

may have battery backup. Installed monitors typically have outputs that interface the

monitor with a centralized radiation monitoring system;

– portable monitors primarily use battery power and are typically carried from location to

location for use. They can also use line power through an internal or external

converter, and can also have the ability to interface with a centralized system.

4.1 General design considerations

4.2 Methods of detection

This standard does not specify what type or types of radiation detectors may be used to

accomplish the performance required.

4.3 Ease of decontamination

Surfaces that are designed to come in contact with radioactivity (e.g., the sampling and

detection assemblies) shall be constructed in such a manner that the build-up of

contamination is minimized and shall be designed to facilitate decontamination or to make

components easily replaceable.

4.4 Considerations for explosive mixtures

In some circumstances, the measured sample may contain an explosive mixture of gases.

Where an explosive mixture may exist, the assembly shall be designed to prevent the ignition

of the sample.

4.5 Corrosion resistance

Special system designs shall be required to protect sampling and measuring systems from

noxious and/or corrosive substances.

4.6 Reliability

All equipment shall be designed to provide reliable performance with unexplained failures kept

to a practical minimum.

The manufacturer should provide documentation on the expected operational lifetime of

critical components such as, the air pump, the detector, the flow rate measuring device, the

batteries etc.

The manufacturer shall specify the frequency of routine maintenance, and fully describe each

maintenance procedure. These maintenance requirements should be kept to a practical

minimum.

4.7 Capability of operational testing

The purchaser should be provided with the capability to carry out periodic checks for

satisfactory operations of the assembly, including calibration and verification of the

measurement linearity. These testing components should normally be installed so as to allow

the checks to be carried out with the control and measurement assembly.

It shall be possible to check the calibration of the assembly at two representative points on

the measurement range.

62303 © IEC:2008 – 13 –

This check shall be carried out using one or more suitable radioactive sources, as necessary.

The measurement linearity may be checked electronically.

4.8 Adjustment and maintenance facilities

All electronic equipment shall have a sufficient number of easily accessible identified test

points to facilitate adjustments and fault location. Any special maintenance tools, together

with an appropriate maintenance manual shall be supplied.

The design of all equipment shall be such as to facilitate ease of repair and maintenance.

Self-diagnostic features should be available with a display.

4.9 Acoustic noise level of the assembly

Acoustic noise level of the assembly mainly arises from the sampling assembly and more

particularly from the operation of the fluid duct system and the resultant vibration.

The manufacturer shall select the components and shall design the assembly so that the

acoustic noise level is minimized and consistent with the type of environment for which the

assembly is intended.

4.10 Electromagnetic interference

All necessary precautions shall be taken to protect the equipment from the effects of

electromagnetic interference either received or emitted by the equipment.

The severity level 3 shall be applied for immunity (IEC 61000 series).

The manufacturer shall specify the electromagnetic emission of the equipment. The emission

limits for apparatus covered by this standard are given in Table 1 of the IEC 61000-6-6.

4.11 Mechanical shock

The monitor should be designed to minimize the effects of mechanical shock.

4.12 Measurement characteristics

The electronic assembly should indicate the measured activity in Bq/m . Other methods of

indication shall be used by agreement between the manufacturer and the purchaser

The manufacturer shall indicate the decision threshold and the effective range of

measurement of the equipment. These characteristics shall be described taking into account

the reference background level (0,2 μGy/h) and volumetric activity of radon.

4.13 Measurement range

The effective range of the measurement shall be appropriate to the particular application. The

lowest detectable concentration for emergency condition tritium monitors shall at least overlap

the highest decade of a tritium monitor designed for normal operation conditions.

The highest detectable concentration shall be at least 0,5 decade above the concentration

expected during emergency conditions.

The values of the lowest and highest concentration to be monitored shall be agreed upon

between the purchaser and the manufacturer.

– 14 – 62303 © IEC:2008

5 Equipment components

5.1 General

The equipment comprises several components. The main components and their functions are

mentioned and described in the following subclauses.

5.2 Sampling assembly

5.2.1 General

The sampling assembly includes essentially one or more of the following assemblies and

functional units:

– sampling and exhaust pipes;

– facility for drawing samples for laboratory analysis and for calibration tests with tritium;

– air/counting gas mixing device (for proportional counters);

– air/liquid scintillation mixing device (for liquid scintillation counters);

– measuring chamber and/or sample cell;

– ambient gamma radiation protection device and/or compensation device or adequate

shielding;

– airborne particulate retention device, where appropriate;

– individual air pump or centralized pumping station;

– air flow rate monitoring and/or control devices, where appropriate;

– pressure monitoring and/or control device, where appropriate;

– humidity monitoring and/or control device, where appropriate;

– temperature measuring device, where appropriate;

– batteries, where appropriate.

5.2.2 Sampling and exhaust pipes

The following characteristics shall be considered and shall be agreed upon between the

manufacturer and the purchaser:

– the material being used, with particular attention being given to chemical corrosion,

surface adsorption, memory effects, etc.;

– the minimum distance between inlet and outlet to avoid recirculation;

– the prevention of condensation in the pipe by control of temperature and/or pressure;

– the impacts of flow rate and pressure drop on the measurement;

– the delay time to detector (flow rate, pipe diameter, length of the sampling pipes);

– the ease of decontamination.

5.2.3 Inlet filter

A filter shall be placed in a filter-holder at the sampling circuit inlet to remove any dust and

aerosols from the air. In order to maintain the specified performance of the equipment, such a

filter shall not trap, or even temporarily retain tritium. To ensure that the inlet filter does not

retain tritium or to observe the retained tritium by the calculation of the tritium activity the

filter-holder shall be removable without loss of radioactive material sticking to the filter.

All necessary arrangements shall be made to control the pressure drop in the filter. The

system should be designed with an alarm facility indicating a significant pressure change

which may have resulted from a faulty filter. It shall be possible to change the filter easily.

62303 © IEC:2008 – 15 –

5.2.4 Collection medium

If the detection assembly includes a collection medium intended to collect a specific chemical

form of tritium or to concentrate the activity, its characteristics efficiency, retention capacity

and delay time constant - shall be known for the appropriate form of tritium.

The manufacturer shall specify how the collection efficiency and the collection capability are

influenced by the chemical form of tritium, the sampling flow rate, the tritium concentration,

atmospheric conditions and the presence of chemical products and other gases in air

sampled. The manufacturer shall indicate how a purchaser can recognise that the collection

efficiency or the collection capacity have deteriorated to become unacceptable. The

manufacturer shall specify the conditions of storage of the collection medium.

5.2.5 Air pump

Where a pump is an integral part of any assembly, the following requirements shall be met:

– the pump shall be placed downstream of the detection assembly. An exception is when the

measurement is made by collecting the tritium in a pressurised chamber;

– the design shall provide for ease of access to the pump and its replaceable parts;

– the nominal flow rate shall be stated by the manufacturer;

– the model of pump and its replaceable parts shall be specified;

– the pump and its replaceable parts shall be easily replaceable;

– the pump shall provide an air flow at a rate that is adequate for the measurement method;

– where the measurement technique of volumetric activity is sensitive to pressure, care

should be taken to ensure that the pressure in the measuring volume is only slightly

affected by the variation of pressure drop across the inlet filter;

– care shall be taken to prevent radioactive gases from leaking into the breathing zone of

workers;

– the pumps of a monitoring system and the sampling units designed to be operational

during and after an accident shall be gas tight. The acceptable leak rate depends on the

accident conditions. The manufacturer and the purchaser shall agree upon the leak rate of

a pump of a measuring device to be in operation during and after a design basis accident

or a severe accident and upon the conditions to be used whilst the monitors are in

operation;

– the pump shall be capable of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...