IEC TS 61244-3:2005

(Main)Long-term radiation ageing in polymers - Part 3: Procedures for in-service monitoring of low-voltage cable materials

Long-term radiation ageing in polymers - Part 3: Procedures for in-service monitoring of low-voltage cable materials

Summarizes the main cable monitoring techniques which are currently being assessed worldwide. These techniques are primarily aimed at monitoring degradation of low-voltage cables. Most of the methods are at the development stage and require more in-plant evaluation before they could be recommended as standard techniques. The advantages and disadvantages of each method, and its current state of development, are outlined in the following clauses. The main technical changes with regard to the previous edition are as follows: a) as there have been technical advances in established test methods and newer methods have become available, several additions have been made to the techniques available in Clause 5; b) some of the techniques listed in the previous edition were found to be either unsuitable for use as cable monitoring methods in plants, or less sensitive to radiation ageing than other methods; these techniques have now been removed; c) a list of abbreviations and their meanings has been added.

General Information

- Status

- Withdrawn

- Publication Date

- 15-Nov-2005

- Withdrawal Date

- 30-Dec-2013

- Technical Committee

- TC 112 - Evaluation and qualification of electrical insulating materials and systems

- Drafting Committee

- WG 2 - TC 112/WG 2

- Current Stage

- WPUB - Publication withdrawn

- Start Date

- 31-Dec-2013

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC TS 61244-3:2005 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Long-term radiation ageing in polymers - Part 3: Procedures for in-service monitoring of low-voltage cable materials". This standard covers: Summarizes the main cable monitoring techniques which are currently being assessed worldwide. These techniques are primarily aimed at monitoring degradation of low-voltage cables. Most of the methods are at the development stage and require more in-plant evaluation before they could be recommended as standard techniques. The advantages and disadvantages of each method, and its current state of development, are outlined in the following clauses. The main technical changes with regard to the previous edition are as follows: a) as there have been technical advances in established test methods and newer methods have become available, several additions have been made to the techniques available in Clause 5; b) some of the techniques listed in the previous edition were found to be either unsuitable for use as cable monitoring methods in plants, or less sensitive to radiation ageing than other methods; these techniques have now been removed; c) a list of abbreviations and their meanings has been added.

Summarizes the main cable monitoring techniques which are currently being assessed worldwide. These techniques are primarily aimed at monitoring degradation of low-voltage cables. Most of the methods are at the development stage and require more in-plant evaluation before they could be recommended as standard techniques. The advantages and disadvantages of each method, and its current state of development, are outlined in the following clauses. The main technical changes with regard to the previous edition are as follows: a) as there have been technical advances in established test methods and newer methods have become available, several additions have been made to the techniques available in Clause 5; b) some of the techniques listed in the previous edition were found to be either unsuitable for use as cable monitoring methods in plants, or less sensitive to radiation ageing than other methods; these techniques have now been removed; c) a list of abbreviations and their meanings has been added.

IEC TS 61244-3:2005 is classified under the following ICS (International Classification for Standards) categories: 17.240 - Radiation measurements; 29.035.01 - Insulating materials in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 61244-3:2005 has the following relationships with other standards: It is inter standard links to IEC TS 61244-3:1998. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC TS 61244-3:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

TECHNICAL IEC

SPECIFICATION TS 61244-3

Second edition

2005-11

Long-term radiation ageing in polymers –

Part 3:

Procedures for in-service monitoring

of low-voltage cable materials

Reference number

IEC/TS 61244-3:2005(E)

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/searchpub) enables you to

search by a variety of criteria including text searches, technical committees

and date of publication. On-line information is also available on recently issued

publications, withdrawn and replaced publications, as well as corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/online_news/ justpub)

is also available by email. Please contact the Customer Service Centre (see

below) for further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

TECHNICAL IEC

SPECIFICATION TS 61244-3

Second edition

2005-11

Long-term radiation ageing in polymers –

Part 3:

Procedures for in-service monitoring

of low-voltage cable materials

IEC 2005 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

Commission Electrotechnique Internationale U

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

For price, see current catalogue

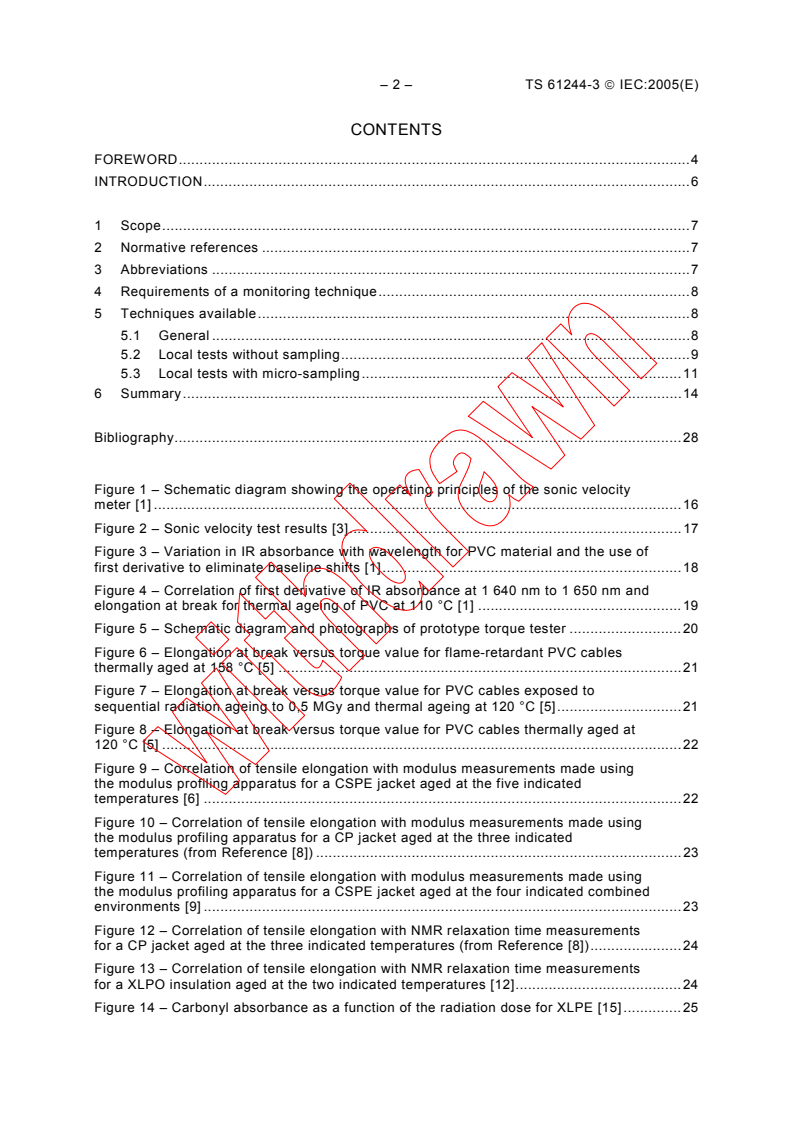

– 2 – TS 61244-3 IEC:2005(E)

CONTENTS

FOREWORD.4

INTRODUCTION.6

1 Scope.7

2 Normative references .7

3 Abbreviations .7

4 Requirements of a monitoring technique.8

5 Techniques available.8

5.1 General .8

5.2 Local tests without sampling.9

5.3 Local tests with micro-sampling.11

6 Summary.14

Bibliography.28

Figure 1 – Schematic diagram showing the operating principles of the sonic velocity

meter [1] .16

Figure 2 – Sonic velocity test results [3].17

Figure 3 – Variation in IR absorbance with wavelength for PVC material and the use of

first derivative to eliminate baseline shifts [1].18

Figure 4 – Correlation of first derivative of IR absorbance at 1 640 nm to 1 650 nm and

elongation at break for thermal ageing of PVC at 110 °C [1] .19

Figure 5 – Schematic diagram and photographs of prototype torque tester .20

Figure 6 – Elongation at break versus torque value for flame-retardant PVC cables

thermally aged at 158 °C [5] .21

Figure 7 – Elongation at break versus torque value for PVC cables exposed to

sequential radiation ageing to 0,5 MGy and thermal ageing at 120 °C [5].21

Figure 8 – Elongation at break versus torque value for PVC cables thermally aged at

120 °C [5] .22

Figure 9 – Correlation of tensile elongation with modulus measurements made using

the modulus profiling apparatus for a CSPE jacket aged at the five indicated

temperatures [6] .22

Figure 10 – Correlation of tensile elongation with modulus measurements made using

the modulus profiling apparatus for a CP jacket aged at the three indicated

temperatures (from Reference [8]) .23

Figure 11 – Correlation of tensile elongation with modulus measurements made using

the modulus profiling apparatus for a CSPE jacket aged at the four indicated combined

environments [9] .23

Figure 12 – Correlation of tensile elongation with NMR relaxation time measurements

for a CP jacket aged at the three indicated temperatures (from Reference [8]).24

Figure 13 – Correlation of tensile elongation with NMR relaxation time measurements

for a XLPO insulation aged at the two indicated temperatures [12].24

Figure 14 – Carbonyl absorbance as a function of the radiation dose for XLPE [15].25

TS 61244-3 IEC:2005(E) – 3 –

Figure 15 – Carbonyl absorbance as a function of thermal ageing for XLPE [14].25

Figure 16 – Correlation of tensile elongation with solvent uptake factor for a CP jacket

aged at the three indicated temperatures [8] .26

Figure 17 – Elongation results compared to uptake and gel results for XLPE insulation

aged at 130 °C [18].26

Figure 18 – Elongation results compared to uptake and gel results for an XLPO

insulation aged at 125 °C [18].27

Table 1 – Summary of currently available techniques for cable condition monitoring.15

– 4 – TS 61244-3 IEC:2005(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

LONG-TERM RADIATION AGEING IN POLYMERS –

Part 3: Procedures for in-service monitoring

of low-voltage cable materials

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. In

exceptional circumstances, a technical committee may propose the publication of a technical

specification when

• the required support cannot be obtained for the publication of an International Standard,

despite repeated efforts, or

• the subject is still under technical development or where, for any other reason, there is the

future but no immediate possibility of an agreement on an International Standard.

Technical specifications are subject to review within three years of publication to decide

whether they can be transformed into International Standards.

IEC 61244-3, which is a technical specification, was prepared by subcommittee 15E: Methods

of test, of IEC technical committee 15: Insulating materials, which has now been merged with

IEC technical committee 98: Electrical insulation systems into IEC technical committee 112:

Evaluation and qualification of electrical insulating materials and systems (provisional title).

TS 61244-3 IEC:2005(E) – 5 –

This second edition cancels and replaces the first edition, published in 1998, and constitutes

a technical revision. The main technical changes with regard to the previous edition are as

follows:

a) as there have been technical advances in established test methods and newer methods

have become available, several additions have been made to the techniques available in

Clause 5;

b) some of the techniques listed in the previous edition were found to be either unsuitable for

use as cable monitoring methods in plants, or less sensitive to radiation ageing than other

methods; these techniques have now been removed;

c) a list of abbreviations and their meanings has been added.

The text of this technical specification is based on the following documents:

Enquiry draft Report on voting

15E/252/DTS 15E/258/RVC

Full information on the voting for the approval of this technical specification can be found in

the report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

IEC 61244 consists of the following parts, under the general title Long-term radiation ageing

in polymers:

Part 1 Techniques for monitoring diffusion-limited oxidation

Part 2: Procedures for predicting ageing at low dose rates

Part 3: Procedures for in-service monitoring of low-voltage cable materials

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result dateindicated on the IEC web site under "http://webstore.iec.ch" in the

data related to the specific publication. At this date, the publication will be

• transformed into an International standard,

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

– 6 – TS 61244-3 IEC:2005(E)

INTRODUCTION

Polymers are widely used as electric insulating materials (e.g. in cables for control,

instrumentation and power) in environments in which they are exposed to radiation. In such

applications, these materials may well be required to survive the full working life of the plant,

which may be more than 40 years, and possibly accident conditions up to and at the end of

their working life. Although considerable data are available on the behaviour of polymeric

insulating materials under irradiation, there is still some uncertainty on the effects of long-

term, low-dose rate irradiation such as would be experienced by cables. There is, therefore, a

requirement for techniques for monitoring the state of degradation of cable materials in situ

throughout the lifetime of the plant. Suitable cable monitoring techniques would also be

important to surveillance programmes in support of plant life extension and licence renewal.

Although this technical specification is primarily aimed at cable condition monitoring in

radiation environments, it can also be applied to other polymeric components. Many of the

techniques are equally applicable to thermal-only ageing of polymeric components.

TS 61244-3 IEC:2005(E) – 7 –

LONG-TERM RADIATION AGEING IN POLYMERS −

Part 3: Procedures for in-service monitoring

of low-voltage cable materials

1 Scope

This part of IEC 61244, which is a technical specification, summarizes the main cable

monitoring techniques which are currently being assessed worldwide. These techniques are

primarily aimed at monitoring degradation of low-voltage cables. Most of the methods are at

the development stage and require more in-plant evaluation before they could be

recommended as standard techniques. The advantages and disadvantages of each method,

and its current state of development, are outlined in the following clauses.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60544-5:2003, Electrical insulating materials – Determination of the effect of ionizing

radiation – Part 5: Procedures for assessment of ageing in service

3 Abbreviations

BR Butyl rubber

CM Condition monitoring

CSPE Chlorosulphonated polyethylene

CP Chloroprene

DLO Diffusion limited oxidation

DSC Differential scanning calorimetry

EPR Ethylene propylene rubber

EVA Ethylene vinyl acetate

IR Infrared

OIT Oxidation induction time

OITP Oxidation induction temperature

NIR Near infra-red reflectance

NMR Nuclear magnetic resonance

PE Polyethylene

PVC Polyvinyl chloride

PEEK Polyetheretherketone

SBR Styrene butadiene rubber

TGA Thermo-gravimetric analysis

XLPE Cross-linked polyethylene

XLPO Cross-linked polyolefin

– 8 – TS 61244-3 IEC:2005(E)

4 Requirements of a monitoring technique

There is a range of requirements which the ideal cable monitoring technique would need to

satisfy. In practice, no one technique can currently satisfy all of the requirements and a range

of techniques is likely to be needed. In each case, baseline data (i.e. data on unaged material

of the same formulation and manufacturer) are needed to make full use of the techniques.

The ideal monitoring technique would have the following attributes:

– non-intrusive, causing minimal cable disturbance;

– capable of use during normal operation;

– not require disconnection of equipment;

– related to an identifiable degradation criterion;

– applicable to a wide range of cable materials and configuration;

– applicable at accessible locations;

– capable of measuring degradation at hot-spots;

– reproducible and capable of compensating for environmental conditions (temperature,

humidity);

– less expensive to implement than periodic cable replacement;

– readily available reference data.

5 Techniques available

5.1 General

There is a wide range of possible techniques which are being considered for cable monitoring.

A few are already in use in-plant, whilst others are only at the laboratory evaluation stage.

Those methods for which there is most experience have been published in IEC 60544-5. Such

methods consist of:

– indenter;

– oxidation induction time and oxidation induction temperature;

– thermo-gravimetric analysis;

– density measurements;

– equipment deposit.

The monitoring methods which have been evaluated can be grouped together under generic

types, as follows:

a) Local tests without sampling

– indenter;

– sonic velocity;

– near infrared reflectance;

– torque testing;

b) Local tests with micro-sampling

– modulus profiling;

– NMR relaxation;

– infrared spectroscopy;

– oxidation induction time (OIT) and temperature (OITP);

TS 61244-3 IEC:2005(E) – 9 –

– thermogravimetric analysis (TGA);

– density measurements;

– gel fraction and solvent uptake.

Each of these types of test is described in more detail in the following subclauses.

5.2 Local tests without sampling

5.2.1 General

The term "local" refers to techniques which give information on the state of the cable at the

measuring point only and are thus likely to miss localized degraded areas. These methods

can only be applied in man-accessible areas and are generally limited to tests of the cable

jacket material except at terminations where the insulation is exposed. Where the techniques

have been cross-correlated with changes in elongation at break, which is a consistent

indicator of degradation, these methods have a predictive capability. This type of test will

provide immediate data in-plant on the state of the cable. Where the cable jacket is more

likely to degrade than the insulation (which is often true), the methods provide early warning

of cable failure. Local bend tests by manipulation of the cable by hand can give qualitative

information when carried out by experienced personnel.

5.2.2 Indenter

The indenter is an instrument that determines a parameter related to the compressive

modulus of a polymer. By driving an instrumented probe of known shape into the surface of

the polymer, the load exerted is measured. Details of the method are given in IEC 60544-5.

5.2.3 Sonic velocity

This technique is under development and at present (2005), has only been tested on PVC

based cables [1-3] . Sonic velocity testing is based on the fact that the velocity of sound in a

solid medium is dependent on both the density and the elastic modulus and is given by:

E

C =

ρ

where

C is the sonic velocity;

E is the elastic modulus;

ρ is the polymer density.

Since both modulus and density can change during ageing of cable materials, changes in

sonic velocity would be expected to occur on ageing.

The tester uses piezoelectric transducers to transmit and receive a series of pulses as shown

schematically in Figure 1. The signal transit times can be plotted as a function of transducer

separation distance (up to a few centimetres) to obtain the slope which represents velocity.

Sonic velocity measurements have been made at 20 kHz on a series of PVC jacketed cables

and on strips of jacket material cut from the cables. Comparison between the data obtained

on the test strips and the complete cables has shown that the technique is dependent on the

cable geometry and adjacent shielding and insulation components. The magnitude of the

sonic velocity at this frequency also varies considerably with different formulations of PVC,

therefore baseline data would be required for each type of cable used in a plant if the

technique was to be of practical use [1]. Other work, using 1MHz pulses [2][3], found the

sonic velocity to be strongly dependent on the degradation of PVC jacket materials but

independent of cable geometry and PVC formulation (Figure 2).

—————————

Figures in square brackets refer to the bibliography.

– 10 – TS 61244-3 IEC:2005(E)

Limitations

The sonic velocity tester measures properties of the cable jacket over a small volume

between the transducer probes. The measurements obtained can be strongly dependent on

the cable construction and the specific formulation of the jacket material. Therefore, extensive

baseline data may be required. The technique is still under development and has so far only

been tested on PVC jacketed cables. At present, a prototype portable tester has been

developed but it has not been used for field use. Its high sensitivity to ageing degradation

indicates that it may well be worth further development.

5.2.4 Near infrared reflectance

Changes in the infrared spectrum of polymers are known to occur with ageing, primarily in

functional groups such as carbonyl (C=O), hydroxyl (O-H) and carboxyl (COOH). These

functional groups are normally observed in the infrared spectrum in transmission, but for use

in-plant a portable unit based on near-IR reflectance (NIR) using a fibre optic probe would be

more suitable. NIR is also being used as a method for identifying cable materials and

compounds [4].

NIR reflectance measurements have been carried out on PVC jacketed cables in the

–1 -1

wavelength range 1 300 nm to 2 100 nm (7 692 cm to 4 762 cm ) [1] using a fibre optic

probe pressed against the cable jacket. Baseline shifts arising from small changes in optical

path length are often seen in the absorbance spectra. These small baseline shifts can be

eliminated by using the first derivative of the absorbance spectra (Figure 3), since the first

derivative is the slope of the absorbance spectrum at each wavelength. Various regions of the

IR spectrum were found to correlate well with changes in the elongation at break of the PVC

–1

material tested; for example, changes in the spectrum at 1 640 nm to 1 650 nm (6 098 cm to

–

6 060 cm ) are shown in Figure 4 for thermal ageing of PVC. This technique using fibre optic

probes for reflectance measurements is at an early stage of development.

Limitations

The NIR reflectance spectrum obtained is only from a thin surface layer of the cable material

being tested. This surface may not be representative of the state of degradation of the bulk of

the material. As in the other techniques in this category, data are limited to the immediate

area of the probe. Care must also be taken in interpreting the data as some stabilizing

additives in polymers have peaks in the same range of wavelengths. The technique is not

sensitive to the cable geometry or construction but calibration curves would be required for

each cable material. NIR is not applicable to carbon-filled materials.

5.2.5 Torque tester

The degradation of cable jacket materials can also be determined using a torque-strain

response method [5]. A pair of chucks are used to grip the outside of the cable and a small

angle torque, in the range 5° to 10°, is applied to one of the chucks at up to 2 Hz. A schematic

diagram of the apparatus for such measurements is shown in Figure 5a; Figures 5b and 5c

show prototype benchtop and portable versions of the torque tester. Preliminary data on the

behaviour of PVC cables have been used to optimize the test conditions for the torque

method.

The effect of torsion frequency on the torque values obtained is small in the frequency range

0 Hz to 2 Hz; for PVC the optimum frequency is 0,8 Hz. In both as-received and aged cables

the torque values measured increase linearly with the applied torque angle up to 10°. At

higher torque angles, components other than the jacket material will significantly contribute to

the values obtained. For a non-destructive technique, a maximum torque angle of 10° is

recommended. The effect of the length of cable between the chucks has also been

investigated. At shorter cable lengths, the measured response will be strongly dependent on

the insulation, conductors and any shielding components, whereas as the cable length

increases, the sensitivity of the torque-strain response will decrease. The optimum cable

length between chucks is 50 mm for PVC cables.

TS 61244-3 IEC:2005(E) – 11 –

There is a strong correlation between the torque values measured using the prototype tester

and elongation at break, both for thermally aged material and for cables subjected to

sequential radiation and thermal chemical ageing (Figures 6 and 7). A linear relationship

between elongation and torque is found over a wide range of elongation values. Deviations

from this linear rela

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...