IEC 60127-7:2013

(Main)Miniature fuses - Part 7: Miniature fuse-links for special applications

Miniature fuses - Part 7: Miniature fuse-links for special applications

IEC 60127-7:2013 covers requirements for miniature fuse-links for special applications. It does not apply to fuses completely covered by the subsequent parts of IEC 60269-1. It does not apply to miniature fuse-links for appliances intended to be used under special conditions, such as in corrosive or explosive atmospheres. This standard applies in addition to the requirements of IEC 60127-1. This standard is applicable to fuse-links with a rated voltage not exceeding 1000 V, a rated current not exceeding 20 A and a rated breaking capacity not exceeding 50 kA. Miniature fuse-links for special applications are not intended to be replaced by the end-user of an electrical/electronic appliance. The object of this standard is to establish uniform test methods for miniature fuse-links for special applications, so as to allow verification of the values (for example melting time and breaking capacity values) specified by the manufacturer. Keywords: requirements for miniature fuse-links

This publication is to be read in conjunction with IEC 60127-1:2006.

Coupe-circuit miniatures - Partie 7: Eléments de remplacement miniatures pour applications spéciales

La CEI 60127-7:2013 couvre des exigences pour éléments de remplacement miniatures destinés à des applications spéciales. Elle ne s'applique pas aux coupe-circuits complètement couverts par les autres parties de la CEI 60269-1. Elle n'est pas applicable aux éléments de remplacement miniatures placés dans des appareils destinés à être employés dans des conditions particulières, telles qu'atmosphères corrosives ou explosives. La présente norme s'applique en complément des exigences présentées dans la CEI 60127-1. La présente norme est applicable aux éléments de remplacement de tension assignée ne dépassant pas 1 000 V, de courant assigné ne dépassant pas 20 A et de pouvoir de coupure assigné ne dépassant pas 50 kA. Les éléments de remplacement miniatures pour applications spéciales ne sont pas destinés à être remplacés par l'utilisateur final d'un appareil électronique ou électrique. La présente norme a pour objet d'établir des méthodes d'essai uniformes pour des éléments de remplacement miniatures pour applications spéciales, pour permettre de vérifier les valeurs (par exemple la durée de fusion et le pouvoir de coupure) spécifiées par le fabricant. Mots clés: exigences pour éléments de remplacement miniatures

Cette publication doit être lue conjointement avec la CEI 60127-1:2006.

General Information

- Status

- Published

- Publication Date

- 19-Mar-2013

- Technical Committee

- SC 32C - Miniature fuses

- Drafting Committee

- WG 12 - TC 32/SC 32C/WG 12

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 22-Sep-2015

- Completion Date

- 26-Oct-2025

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60127-7:2013 is an international standard developed by the International Electrotechnical Commission (IEC) that specifies the requirements for miniature fuse-links designed for special applications. This standard complements IEC 60127-1 and applies to fuse-links with rated voltages up to 1000 V, rated currents up to 20 A, and breaking capacities not exceeding 50 kA. Importantly, it excludes fuse-links intended for use in corrosive or explosive atmospheres and those fully covered by IEC 60269-1. The focus of IEC 60127-7 is to standardize test methods to verify manufacturer specifications such as melting time and breaking capacity, ensuring reliable protection in specialized electrical and electronic equipment.

Key Topics

Scope and Applicability

IEC 60127-7 applies to miniature fuse-links with dimensions up to 12 mm in width and height, and a length not exceeding 50 mm. These fuse-links are intended for applications that require specific design and performance considerations beyond standard fuse requirements.Uniform Test Procedures

The standard establishes uniform test methods including:- Melting time verification to confirm rapid and reliable fuse action

- Breaking capacity tests to ensure safe interruption of overcurrents up to 50 kA

- Voltage drop and time/current characteristics at normal and elevated temperatures

- Endurance and pulse tests to assess the durability and performance under stress conditions

- Temperature measurements, particularly for fuse-links mounted on printed circuit boards or in fuse-holders

Ratings and Marking

Fuse-link ratings such as rated current, rated voltage, and breaking capacity are standardized. Marking requirements ensure clear identification of fuse specifications, supporting correct fuse selection and replacement.Additional Normative References

IEC 60127-7 relies on related standards for testing environmental robustness (IEC 60068-2-21), insulation coordination (IEC 60664-1), and fire hazard tests (IEC 60695 series), ensuring comprehensive safety and performance validation.

Applications

IEC 60127-7 miniature fuse-links are integral in electrical and electronic devices requiring precise, reliable circuit protection in specialized environments. These include:

- Industrial control systems

- Electronic instrumentation and measurement equipment

- Communication devices with unique electrical requirements

- Appliances where fuse replacement is performed only by authorized service personnel due to safety concerns

- Equipment operating under normal environmental conditions but requiring specialized fuse characteristics to prevent damage or hazards

By adhering to this standard, manufacturers and design engineers can ensure miniature fuse-links provide consistent performance, promote user safety, and facilitate interoperability in global markets.

Related Standards

- IEC 60127-1: Definitions and general requirements for miniature fuse-links, serving as the foundational document complementing Part 7.

- IEC 60127-2, -3, -4: Cover cartridge, sub-miniature, and universal modular fuse-links respectively, which define other categories of miniature fuses not included in Part 7.

- IEC 60269-1: Standards covering low-voltage fuses where this part does not apply.

- IEC 60068-2-21: Environmental testing procedures to validate robustness of fuse terminations.

- IEC 60664-1: Principles and tests for insulation coordination critical to fuse safety.

- IEC 60695 series: Fire hazard testing standards evaluating flammability and glow-wire ignition resistance relevant to fuse materials.

These interconnected standards ensure comprehensive coverage for the testing, performance, and safety of miniature fuses across applications.

Keywords: IEC 60127-7 standard, miniature fuse-links, special applications, miniature fuses, fuse-link testing, rated voltage 1000 V, rated current 20 A, breaking capacity 50 kA, fuse specifications, electrical safety, fuse standards compliance, miniature fuse requirements, fuse-link endurance tests, fuse time/current characteristics.

Frequently Asked Questions

IEC 60127-7:2013 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Miniature fuses - Part 7: Miniature fuse-links for special applications". This standard covers: IEC 60127-7:2013 covers requirements for miniature fuse-links for special applications. It does not apply to fuses completely covered by the subsequent parts of IEC 60269-1. It does not apply to miniature fuse-links for appliances intended to be used under special conditions, such as in corrosive or explosive atmospheres. This standard applies in addition to the requirements of IEC 60127-1. This standard is applicable to fuse-links with a rated voltage not exceeding 1000 V, a rated current not exceeding 20 A and a rated breaking capacity not exceeding 50 kA. Miniature fuse-links for special applications are not intended to be replaced by the end-user of an electrical/electronic appliance. The object of this standard is to establish uniform test methods for miniature fuse-links for special applications, so as to allow verification of the values (for example melting time and breaking capacity values) specified by the manufacturer. Keywords: requirements for miniature fuse-links This publication is to be read in conjunction with IEC 60127-1:2006.

IEC 60127-7:2013 covers requirements for miniature fuse-links for special applications. It does not apply to fuses completely covered by the subsequent parts of IEC 60269-1. It does not apply to miniature fuse-links for appliances intended to be used under special conditions, such as in corrosive or explosive atmospheres. This standard applies in addition to the requirements of IEC 60127-1. This standard is applicable to fuse-links with a rated voltage not exceeding 1000 V, a rated current not exceeding 20 A and a rated breaking capacity not exceeding 50 kA. Miniature fuse-links for special applications are not intended to be replaced by the end-user of an electrical/electronic appliance. The object of this standard is to establish uniform test methods for miniature fuse-links for special applications, so as to allow verification of the values (for example melting time and breaking capacity values) specified by the manufacturer. Keywords: requirements for miniature fuse-links This publication is to be read in conjunction with IEC 60127-1:2006.

IEC 60127-7:2013 is classified under the following ICS (International Classification for Standards) categories: 29.120.50 - Fuses and other overcurrent protection devices. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60127-7:2013 has the following relationships with other standards: It is inter standard links to IEC 60127-7:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60127-7:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60127-7 ®

Edition 1.0 2013-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Miniature fuses –

Part 7: Miniature fuse-links for special applications

Coupe-circuits miniatures –

Partie 7: Eléments de remplacement miniatures pour applications spéciales

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 60127-7 ®

Edition 1.0 2013-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Miniature fuses –

Part 7: Miniature fuse-links for special applications

Coupe-circuits miniatures –

Partie 7: Eléments de remplacement miniatures pour applications spéciales

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX S

ICS 29.120.50 ISBN 978-2-83220-670-6

– 2 – 60127-7 IEC:2013

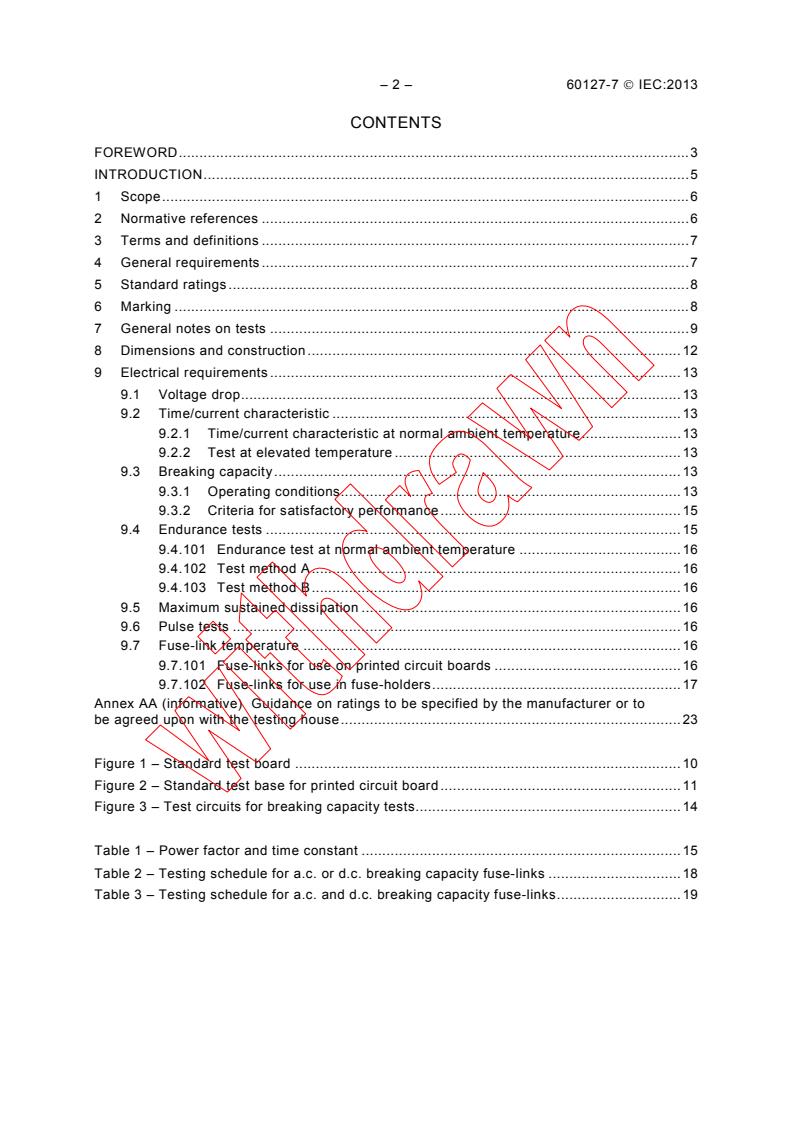

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 General requirements . 7

5 Standard ratings . 8

6 Marking . 8

7 General notes on tests . 9

8 Dimensions and construction . 12

9 Electrical requirements . 13

9.1 Voltage drop . 13

9.2 Time/current characteristic . 13

9.2.1 Time/current characteristic at normal ambient temperature . 13

9.2.2 Test at elevated temperature . 13

9.3 Breaking capacity . 13

9.3.1 Operating conditions . 13

9.3.2 Criteria for satisfactory performance . 15

9.4 Endurance tests . 15

9.4.101 Endurance test at normal ambient temperature . 16

9.4.102 Test method A . 16

9.4.103 Test method B . 16

9.5 Maximum sustained dissipation . 16

9.6 Pulse tests . 16

9.7 Fuse-link temperature . 16

9.7.101 Fuse-links for use on printed circuit boards . 16

9.7.102 Fuse-links for use in fuse-holders . 17

Annex AA (informative) Guidance on ratings to be specified by the manufacturer or to

be agreed upon with the testing house . 23

Figure 1 – Standard test board . 10

Figure 2 – Standard test base for printed circuit board . 11

Figure 3 – Test circuits for breaking capacity tests . 14

Table 1 – Power factor and time constant . 15

Table 2 – Testing schedule for a.c. or d.c. breaking capacity fuse-links . 18

Table 3 – Testing schedule for a.c. and d.c. breaking capacity fuse-links . 19

60127-7 IEC:2013 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MINIATURE FUSES –

Part 7: Miniature fuse-links for special applications

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60127-7 has been prepared by subcommittee 32C: Miniature fuses,

of IEC technical committee 32: Fuses.

The text of this standard is based on the following documents:

CDV Report on voting

32C/458/CDV 32C/467/RVC

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

This International Standard is to be used in conjunction with IEC 60127-1:2006, Miniature

fuses – Part 1: Definitions for miniature fuses and general requirements for miniature fuse-

links and its Amendment 1 (2011).

– 4 – 60127-7 IEC:2013

The clauses of this standard supplement, modify or replace the corresponding clauses in

IEC 60127-1.

Where there is no corresponding clause or subclause in this standard, the clause or

subclause of IEC 60127-1 applies without modification as far as is reasonable. When this

standard states “addition” or “replacement”, the relevant text in IEC 60127-1 is to be adapted

accordingly.

Subclauses which are additional to those in Part 1 are numbered starting from 101. Additional

annexes are numbered AA, BB, etc.

A list of all parts in the IEC 60127 series, published under the general title Miniature fuses,

can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

60127-7 IEC:2013 – 5 –

INTRODUCTION

According to the wish expressed by the users of miniature fuses, all standards,

recommendations and other documents relating to miniature fuses should have the same

publication number in order to facilitate reference to fuses in other specifications, for example,

equipment specifications.

Furthermore, a single publication number and subdivision into parts would facilitate the

establishment of new standards, because clauses containing general requirements need not

be repeated.

The IEC 60127 series, under the general heading Miniature fuses, is thus subdivided as

follows:

IEC 60127-1, Miniature fuses – Part 1: Definitions for miniature fuses and general

requirements for miniature fuse-links

IEC 60127-2, Miniature fuses – Part 2: Cartridge fuse-links

IEC 60127-3, Miniature fuses – Part 3: Sub-miniature fuse-links

IEC 60127-4, Miniature fuses – Part 4: Universal modular fuse-links (UMF) – Through-hole

and surface mount types

IEC 60127-5, Miniature fuses – Part 5: Guidelines for quality assessment of miniature fuse-

links

IEC 60127-6, Miniature fuses – Part 6: Fuse-holders for miniature fuse-links

IEC 60127-7, Miniature fuses – Part 7: Miniature fuse-links for special applications

IEC 60127-8, (Free for further documents)

IEC 60127-9, (Free for further documents)

IEC 60127-10, Miniature fuses – Part 10: User guide for miniature fuses

– 6 – 60127-7 IEC:2013

MINIATURE FUSES –

Part 7: Miniature fuse-links for special applications

1 Scope

This part of IEC 60127 covers requirements for miniature fuse-links for special applications.

It does not apply to fuses completely covered by the subsequent parts of IEC 60269-1.

It does not apply to miniature fuse-links for appliances intended to be used under special

conditions, such as in corrosive or explosive atmospheres.

This standard applies in addition to the requirements of IEC 60127-1.

This standard is applicable to fuse-links with a rated voltage not exceeding 1000 V, a rated

current not exceeding 20 A and a rated breaking capacity not exceeding 50 kA.

Miniature fuse-links for special applications are not intended to be replaced by the end-user of

an electrical / electronic appliance.

The object of this standard is to establish uniform test methods for miniature fuse-links for

special applications, so as to allow verification of the values (for example melting time and

breaking capacity values) specified by the manufacturer.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60068-2-21:2006, Environmental testing – Part 2-21: Tests – Test U: Robustness of

terminations and integral mounting devices

IEC 60127-1:2006, Miniature fuses – Part 1: Definitions for miniature fuses and general

requirements for miniature fuse-links

IEC 60127-6:1994, Miniature fuses – Part 6: Fuse-holders for miniature cartridge fuse-links

Amendment 1:1996

Amendment 2:2002

IEC 60664-1:2007, Insulation coordination for equipment within low-voltage systems – Part 1:

Principles, requirements and tests

IEC 60695-2-12:2010, Fire hazard testing – Part 2-12: Glowing/hot-wire based test methods –

Glow-wire flammability index (GWFI) test method for materials

IEC 60695-2-13:2010, Fire hazard testing – Part 2-13: Glowing/hot-wire based test methods –

Glow-wire ignition temperature (GWIT) test method for materials

IEC 60695-4:2012, Fire hazard testing – Part 4: Terminology concerning fire tests for

electrotechnical products

60127-7 IEC:2013 – 7 –

IEC 61249-2-7:2002, Materials for printed boards and other interconnecting structures –

Part 2-7: Reinforced base materials clad and unclad – Epoxide woven E-glass laminated

sheet of defined flammability (vertical burning test), copper-clad

ISO 3:1973, Preferred numbers – Series of preferred numbers

3 Terms and definitions

For the purposes of this document, the terms and definitions given in Clause 3 of IEC 60127-

1:2006, except 3.5, as well as the following apply.

3.1

miniature fuse-link for special applications

enclosed fuse-link which is not covered in IEC 60127-2, IEC 60127-3 or IEC 60127-4 and of

rated breaking capacity not exceeding 50 kA, with a width and height not exceeding 12 mm

and a length not exceeding 50 mm

Note 1 to entry: Special precautions may be necessary to ensure that the fuse-links will be replaced by a fuse-link

with the same technical parameters.

3.2

t to t

1 8

limit values for time/current characteristic

3.3

I

test current for testing at elevated temperature of 70 °C

Note 1 to entry: Preferred values are 0,8 I or 1,0 I or 1,1 I .

N N N

3.4

I (A)

test

test current for endurance testing according to method A

Note 1 to entry: Preferred values are 1,0 I or 1,05 I or 1,2 I .

N N N

3.5

I (B)

test

test current for endurance testing according to method B

Note 1 to entry: Preferred values are 0,8 I or 1,0 I .

N N

3.6

I (A)

OVL

test current for measuring the maximum sustained dissipation according to method A

Note 1 to entry: Preferred values are 1,25 I or 1,35 I or 1,5 I .

N N N

3.7

I (B)

OVL

test current for measuring the maximum sustained dissipation according to method B

Note 1 to entry: Preferred values are 1,0 I or 1,25 I .

N N

4 General requirements

Clause 4 of IEC 60127-1:2006 applies.

– 8 – 60127-7 IEC:2013

5 Standard ratings

Clause 5 of IEC 60127-1:2006 does not apply.

Replacement:

The following ratings shall be agreed upon between the testing house and the manufacturer:

– rated voltage;

– rated current (see standard sheet 1 for preferred ratings);

– rated breaking capacity (a.c. and/or d.c.);

– time/current characteristic (at least at 2,0 I or 2,1 I and 10 I ).

N N N

The following may be agreed upon on an optional basis:

– test at elevated temperature;

– time/current characteristic (additionally at 2,75 I and 4 I ).

N N

Any additional specified values are given in standard sheet 1.

6 Marking

Clause 6 of IEC 60127-1:2006 applies except as follows.

6.1

Replacement:

d) Not applicable.

NOTE A symbol denoting the time/current characteristic cannot be stated, because this part of IEC 60127 does

not specify any values for this parameter.

Addition:

e) Type designation.

f) Rated breaking capacity in amperes (A) or in kilo amperes (kA).

6.2

Deletion of NOTE 2.

6.3

Addition after first paragraph:

Furthermore the rated breaking capacity in amperes (A) or in kilo amperes (kA) shall be

marked on the package label.

6.4

Addition of heading title and replacement of text:

6.4 Colour coding for miniature fuse-links for special applications

Marking of fuse-links by means of colour bands according to IEC 60127-1:2006, Annex A, is

not permitted. It is, however, possible to use colour markings that clearly differ from this

colour band system. In this case, the manufacturer shall provide the relevant information, for

example colour key.

60127-7 IEC:2013 – 9 –

Additional subclause:

6.101 Where marking is impracticable due to space limitations, the relevant information

should appear on the smallest package and in the manufacturer’s technical literature.

7 General notes on tests

Clause 7 of IEC 60127-1:2006 applies except as follows.

7.2 Type tests

7.2.1

Replacement:

For testing the individual current ratings of fuses with a.c. or d.c. breaking capacity, the

number of fuse-links required is 51, of which 12 are kept as spares.

The testing schedule is shown in Table 2.

For testing the individual current ratings of fuses with a.c. and d.c. breaking capacity, the

number of fuse-links required is 63, of which 9 are kept as spares.

The testing schedule is shown in Table 3.

7.3 Fuse-bases for tests

Addition:

For fuse-links designed for use in a special type of fuse-holder, testing shall be performed in

that fuse-holder.

For tests that require a printed circuit board for mounting and connection of the fuse-links, a

test board according to Figure 1 shall be used.

NOTE Fuse-bases for surface-mounted fuse-links are under consideration.

– 10 – 60127-7 IEC:2013

Dimensions in millimetres

∅4,2

O U

U

n × e

n × e

Figure 1A

∅1,0

n × e

Radius =

IEC 492/13

Key

O copper layer

U connection for voltage drop measurement

e 2,5 mm

n 1, 2, 3, 4

n 1, 2, 3 … (to be adapted depending on the length of the fuse-link)

Figure 1 – Standard test board

This test board shall be mounted on the fuse-base according to Figure 2.

16,5

60127-7 IEC:2013 – 11 –

Dimensions in millimetres

D

F C

E

B A

G

IEC 493/13

Key

A base of low heat conducting material, thickness 10 mm

B brass electrodes 10 mm × 10 mm

C fuse-link soldered in place

D fixing screws

E contact screws holding solder terminal

F printed circuit board according to Figure 1

G top view of base with brass electrodes 10 mm × 10 mm

Figure 2 – Standard test base for printed circuit board

The test board shall be made of epoxide woven glass fabric copper-clad laminated sheet, as

defined in IEC 61249-2-7.

The nominal sheet thickness shall be 1,6 mm.

The nominal thickness of copper layer may be 0,035 mm or 0,070 mm.

The nominal width of copper layer may be 2,5 mm, 5 mm, 7,5 mm or 10 mm.

The nominal thickness and nominal width of applied copper layer shall be stated in the test

report.

Metal parts of the fuse-base shall be made of brass with a copper content between 58 % and

70 %. Contact parts shall be silver-plated.

7.4 Nature of supply

Addition:

Schedule for testing fuse-links with a.c. or d.c. breaking capacity according to Standard

Sheet 1, see Table 2.

– 12 – 60127-7 IEC:2013

Schedule for testing fuse-links with a.c. and d.c. breaking capacity according to Standard

Sheet 1, see Table 3.

8 Dimensions and construction

Clause 8 of IEC 60127-1:2006 applies except as follows.

8.2 Construction

Replacement:

The fuse-element shall be completely enclosed.

The fuse-links shall be resistant to heat according to 9.7, and to fire according to

IEC 60695-2-12 and IEC 60695-2-13.

Compliance is checked by inspection. This is not applicable for fuse-links which represent

small parts according to IEC 60695-4:2012, 3.78.

For fuse bodies made of plastic material or of material containing organic substances the

following minimum requirements apply:

– Glow-wire ignition temperature (GWIT) = 775 °C

– Glow-wire flammability index (GWFI) = 850 °C

NOTE 1 For the glow wire tests it is necessary to use material plates with dimensions according to IEC 60695-2-

12:2010, 4.2 and/or IEC 60695-2-13:2010,, 4.2.

NOTE 2 For materials such as glass and ceramic whose GWIT and GWFI are thought to be higher than 775 °C

and respectively 850 °C the glow-wire tests do not apply.

8.3 Fuse-link terminations

Replacement:

Subclause 8.3 applies only to fuse-links with wire terminations.

Fuse-link contacts shall be made of non-corroding material or of material suitably protected

against corrosion, and shall be effectively free from flux or other non-conducting substance on

their outer surfaces.

Nickel or silver plating is deemed to be adequate protection for brass end caps.

The fuse-link terminations shall be reliably attached.

The samples shall be immersed in water for 24 h at a temperature of between 15 °C and

35 °C.

Terminations shall withstand the mechanical forces likely to be encountered during normal

use. With the fuse-link held in a fixed position, each terminal in turn is subjected at ambient

temperature to the forces laid down in this standard. The test samples shall be equally divided

among the specific termination tests.

Present test methods are to be performed in accordance with IEC 60068-2-21.

– For the tensile test (Ua ), the force applied shall be 10 N.

– For the thrust test (Ua ), the force applied shall be 2 N.

60127-7 IEC:2013 – 13 –

– For the bending test (Ub), if applicable, the force applied shall be 5 N and the number of

bends shall be one.

After the conclusion of testing, the fuse-link terminations shall remain firmly attached and the

voltage drop shall not exceed the maximum allowed value in standard sheet 1.

9 Electrical requirements

Clause 9 of IEC 60127-1:2006 applies except as follows.

9.1 Voltage drop

Addition:

The use of a high impedance voltmeter is recommended for measuring the voltage drop. The

voltage drop shall be measured directly at the fuse-link terminations or, where this is not

possible, in the immediate vicinity of the fuse body.

If the test board according to Figure 1 is used, the voltage drop may be measured at the

points marked with U.

9.2 Time/current characteristic

9.2.1 Time/current characteristic at normal ambient temperature

Addition:

Limit values t to t given in standard sheet 1 shall be defined by the manufacturer.

Limit values t (maximum value at 2,1 I or 2,0 I ) and t (maximum value at 10 I ) are

2 N N 8 N

required to be specified. Limit values t , t , t , t , t and t are optional.

1 3 4 5 6 7

The value t shall be not more than 1 h.

The value t shall be not more than 1 s.

9.2.2 Test at elevated temperature

Replacement:

If declared by the manufacturer, this test shall be carried out according to IEC 60127-1:2006,

9.2.2, using the test current (I ) specified by the manufacturer.

9.3 Breaking capacity

9.3.1 Operating conditions

Method A of IEC 60127-1:2006, 9.3.1, applies.

Addition:

In the case of fuse-links in which any component is organic (such as with a moulded body),

the recovery voltage shall be maintained for 5 min after the fuse has operated.

Typical test circuits for a.c. and d.c. are given in Figure 3.

– 14 – 60127-7 IEC:2013

Figure 3a – Typical test circuit for breaking capacity tests for fuse-links

with breaking capacity greater than 100 A

Figure 3b – Typical test circuit for breaking capacity tests for fuse-links

with breaking capacity less or equal than 100 A

Components

A removable link used for calibration S source of supply, impedance less than 10 % of the

total impedance of the circuit

C contactor that makes the circuit

L air-cored inductance

D switch to disconnect the source of supply

R series resistor, adjusted to obtain correct

F fuse-link under test

prospective current

Figure 3 – Test circuits for breaking capacity tests

60127-7 IEC:2013 – 15 –

In principle, the rated breaking capacity (a.c. and/or d.c.) and associated power factor or time

constant, respectively, shall be specified by the manufacturer. The values given in the table

below are reference values only.

The specified rated breaking capacity shall not be less than 35 A or 10 times the rated current,

whichever is greater.

Unless otherwise stated by the manufacturer, the power factor and time constant of the test

circuit shall be chosen from Table 1.

Table 1 – Power factor and time constant

Test current Power factor Time constant

up to 100 A

>0,95 <1 ms

above 100 A up to 500 A 0,8 to 0,9 1 ms to 1,7 ms

above 500 A up to 1 500 A 0,7 to 0,8 2 ms to 2,5 ms

above 1 500 A up to 10 000 A 0,5 to 0,6 4,5 ms to 5 ms

above 10 000 A up to 25 000 A 0,3 to 0,4 9 ms to 10 ms

above 25 000 A up to 50 000 A 0,2 to 0,3 12,5 ms to 15 ms

For tests at lower prospective currents (5 I , 10 I , 50 I , 250 I ), the inductance of the circuit

N N N N

shall remain constant and the current shall be adjusted by changing the resistance only.

9.3.2 Criteria for satisfactory performance

Addition:

In addition to the failure criteria described in IEC 60127-1, the fuse-link shall operate

satisfactorily in all tests without any of the following phenomena:

– fusing together of the contacts;

– illegibility of marking after test;

– piercing of end caps (if applicable), visible to the naked eye;

– piercing of the external surfaces, visible to the naked eye;

– scorching or melting of organic substances on the external surfaces.

The following phenomena are neglected:

– black spots or other marks on the fuse-link terminations;

– small deformations of the fuse-link;

– cracking of the fuse-link, unless it causes the fuse-link to fall apart during replacement.

9.4 Endurance tests

a) Replacement of the first sentence as follows:

The test current I (A) is passed through the fuse-link for a period of 1 h. The minimum

test

value for I (A) is 1,0 I .

test N

b) Replacement of the first sentence as follows:

The test current I (A) is then passed through the fuse-link for a period of 1 h.

OVL

c) Addition:

The voltage drop shall not exceed the maximum value specified in standard sheet 1.

– 16 – 60127-7 IEC:2013

Additional subclauses:

9.4.101 Endurance test at normal ambient temperature

Compliance is checked by subjecting the fuse-links to test method A or test method B.

Choice of either method A or method B shall be as agreed upon with the manufacturer. This

also applies to the test currents to be selected among I (A), I (B), I (A) and I (B).

test test OVL OVL

9.4.102 Test method A

As specified in IEC 60127-1:2006, 9.4 a) to d), with test current I (A) for 9.4 a) and I (A)

test OVL

for 9.4 b).

9.4.103 Test method B

The test sequence has to be as follows:

a) The d.c. current I (B) is passed through the fuse-link for a period of 100 h. The

test

minimum value for I (B) is 0,8 I .

test N

The current stability during the test shall be maintained within ±1 % of the adjusted value.

The d.c. current I (B) is then passed through the fuse-link for a period of 1 h.

OVL

b) At the end of this test the voltage drop across the fuse-link is measured and used for the

calculation of the maximum sustained dissipation.

c) Finally, the voltage drop across the fuse-link is measured again according to 9.1. The

voltage drop shall not have increased by more than 10 % of the value measured before

the test and shall not exceed the maximum value specified in standard sheet 1.

d) After the test, the marking shall still be legible and soldered joints on the fuse-link

terminations shall not show any appreciable changes.

NOTE Changes in colour are not considered a failure.

9.5 Maximum sustained dissipation

Subclause 9.5 of IEC 60127-1:2006 applies.

9.6 Pulse tests

Replacement:

None specified.

9.7 Fuse-link temperature

Additional subclauses:

9.7.101 Fuse-links for use on printed circuit boards

For fuse-links designed to be mounted on circuit boards, compliance is checked by subjecting

the fuse-links to test method I or method II as requested by the manufacturer.

Test method I

As specified in IEC 60127-1:2006, 9.7, with replacement of the maximum temperature rise of

135 K by 150 K for terminals and 135 K for plastic body materials. The initial current shall be

I (A) or I (B) depending on which test method of 9.4 has been chosen.

OVL OVL

The temperature during the last 30 s prior to opening shall be ignored.

60127-7 IEC:2013 – 17 –

Test method II

The temperature rise above ambient temperature shall be measured on the terminals of the

fuse-links soldered to the relevant test board, using a fine-wire thermocouple not larger than

0,21 mm .

The measurement shall be done during the final 5 min of the endurance test at I (A) or

OVL

I (B) depending on which test method of 9.4 has been chosen. The temperature rise shall

OVL

not exceed 95 K.

Fuse-link numbers 1, 2, 3, 4, 5 and 6 shall be used for this test and fuse-link numbers 43, 44

and 45 in Table 2, or 58, 59 and 60 in Table 3, shall be kept as additional spares.

9.7.102 Fuse-links for use in fuse-holders

For fuse-links intended to be inserted in specifically designed fuse-holders, the test according

to IEC 60127-6:1994, Clause 14, shall be carried out using the fuse-links to be tested instead

of the required dummy fuse-links.

After the test in 14.1 of IEC 60127-6:1994, the inspection according to IEC 60127-6:1994,

12.2, shall not be performed.

– 18 – 60127-7 CEI:2013

Table 2 – Testing schedule for a.c. or d.c. breaking capacity fuse-links

Fuse-link number

1 4 7 10 13 16 19 22 25 28 31 34 37 40 43 46 49

Subclause Description

2 5 8 11 14 17 20 23 26 29 32 35 38 41 44 47 50

3 6 9 12 15 18 21 24 27 30 33 36 39 42 45 48 51

9.7 Fuse-link temperature X

9.4 Endurance tests X X

9.2.2 Test at elevated temperature X

9.2.1 Time/current characteristic 10 I X

N

at normal ambient temperature

4,0 I X

N

2,75 I X

N

2,0 I or 2,1 I X

N N

9.3 Breaking capacity

Rated breaking capacity X

5 times the rated current 5 I X

N

10 times the rated current 10 I X

N

a

50 times the rated current 50 I X

N

a

250 times the rated current 250 I X

N

9.3.3 Insulation resistance X X X X X

8.3 Fuse-link terminations X X

8.5 Soldered joints X X X X X X X

6.2 Legibility and indelibility of marking X X X X X

a

Applicable only when the rated breaking capacity is not exceeded.

60127-7 IEC:2013 – 19 –

Table 3 – Testing schedule for a.c. and d.c. breaking capacity fuse-links

Fuse-link number

1 4 7 10 13 16 19 22 25 28 31 34 37 40 43 46 49 52 55 58 61

Subclause Description

2 5 8 11 14 17 20 23 26 29 32 35 38 41 44 47 50 53 56 59 62

3 6 9 12 15 18 21 24 27 30 33 36 39 42 45 48 51 54 57 60 63

9.7 Fuse-link temperature X

9.4 Endurance tests X X

9.2.2 Test at elevated temperature X

9.2.1 Time/current characteristic 10 I X

N

at normal ambient temperature

4,0 I X

N

2,75 I X

N

2,0 I or 2,1 I X

N N

9.3 Breaking capacity

Rated breaking capacity a.c. X

Rated breaking capacity d.c. X

5 times the rated current 5 I – a.c. X

N

5 times the rated current 5 I – d.c. X

N

10 times the rated current 10 I – a.c. X

N

10 times the rated current 10 I – d.c. X

N

a

50 times the rated current 50 I – a.c. X

N

a

50 times the rated current 50 I – d.c. X

N

a

250 times the rated current 250 I – a.c. X

N

a

250 times the rated current 250 I – d.c. X

N

9.3.3 Insulation resistance X X X X X X X X X X

8.3 Fuse-link terminations X X

8.5 Soldered joints X X X X X X X

6.2 Legibility and indelibility of marking X X X X X

a

Applicable only when the rated breaking capacity is not exceeded.

– 20 – 60127-7 CEI:2013

Standard

sheet

Fuse-links for special applications

Page 1

a

Minimum Maximum dimensions

Rated voltage

terminal spacing mm

P W H L

V mm (width) (height) (length)

12,5 0,4 12 12 50

25 0,45 12 12 50

32 0,48 12 12 50

50 0,53 12 12 50

63 1,1 12 12 50

125 1,3 12 12 50

250 2,5 12 12 50

500 to be determined 12 12 50

1 000 to be determined 12 12 50

a

Intermediate values are possible. The respective minimum terminal spacing P

shall be chosen according to IEC 60664-1.

Any shape is allowed; the point at which the terminations protrude from the body is optional and

the termination may vary.

Some alternative shapes are shown below:

Remark: The terminal spacing P has been chosen according to IEC 60664-1 taking into account pollution

degree 2 and overvoltage category II (stress less than 1 500 h).

60127-7 CEI:2013 – 21 –

Standard

sheet

Fuse-links for special applications

Page 2

Maximum values of voltage drop and sustained dissipation

Rated current Maximum voltage drop Maximum sustained

dissipation

mV mW

32 mA 7 000 1 600

50 mA 5 000 1 600

63 mA 4 400 1 600

80 mA 3 800 1 600

100 mA 3 500 1 600

125 mA 2 500 1 600

160 mA 2 200 1 600

200 mA 1 800 1 600

250 mA 1 400 1 600

315 mA 1 300 1 600

400 mA 1 000 1 600

500 mA 900 1 600

630 mA 800 1 600

800 mA 600 1 600

1,0 A 500 2 500

1,25 A 400 2 500

1,6 A 300 2 500

2,0 A 300 2 500

2,5 A 300 2 500

3,15 A 300 4 000

4,0 A 300 4 000

5,0 A 300 4 000

6,3 A 300 4 000

8,0 A 220 4 000

10,0 A 220 4 000

12,5 A 180 4 000

16 A 140 4 000

20 A 100 4 000

If intermediate rated currents are required, they shall be chosen from the series R20 or R40

according to ISO 3.

If lower values are stated by the manufacturer, these values shall be used.

Marking

Fuse-links shall be marked according to the requirements of Clause 6.

Pre-arcing time/current characteristic

The pre-arcing time shall be within the following limits:

2,0 I or 2,1 I 2,75 I 4 I 10 I

N N N N N

min. max. min. max. min. max. min. max.

t t t t t t t t

1 2 3 4 5 6 7 8

– 22 – 60127-7 CEI:2013

Standard

sheet

Fuse-links for special applications

Page 3

Test at a temperature of (70 ± 2)°C (if requested by the manufacturer)

A test current I shall be passed through the fuse-links for 1 hour and they shall not operate.

NOTE The manufacturer can additionally specify a higher test temperature than 70 °C or a longer test

duration than 1 h.

Breaking capacity

Fuse-links shall be tested as appropriate to their a.c., d.c or a.c./d.c. rating as specified in 9.3.

Endurance test

Fuse-links shall be tested according to either method A or method B as specified in 9.4.

Maximum sustained dissipation

The maximum sustained dissipation shall be measured at test current I (A) or I (B) during the last

OVL OVL

10 min of the endurance test and shall not exceed the values specified in this standard sheet.

Temperature rise test

Fuse-links shall be tested according to method I or method II of 9.7.101, as specified by the manufacturer, or

according to 9.7.102.

9.7.101 Method I

The temperature rise shall not exceed 150 K (except 135 K for plastic body materials).

(The temperature during the last 30 s prior to opening shall be ignored).

9.7.101 Method II

The temperature rise shall not exceed 95 K.

9.7.102

If a fuse-holder is used, the temperature rise of the plastic material shall not exceed the respective RTI value.

60127-7 CEI:2013 – 23 –

Annex AA

(informative)

Guidance on ratings to be specified by the manufacturer

or to be agreed upon with the testing house

Subclause Rating Remark

9.2 t to t t and t are mandatory;

1 8 2 8

the values t and t shall be not more

2 8

than 1 h (t = 1 h) and 1 s (t =

2max 8max

1,00 s) respectively

t , t , t , t , t and t are optional

1 3 4 5 6 7

2,0 I or 2,1 I to be chosen for t and t

N N 1 2

9.2.2 I test current for an optional test at 70 °C

preferred values: 0,8 I or 1,0 I or 1,1 I

N N N

NOTE The manufacturer can additionally specify

a higher test temperature than 70 °C or a longer

test duration than 1 hour.

9.3 Breaking capacity may be specified for a.c. or d.c or

a.c./d.c.;

the specified rated breaking capacity

shall be not less than 35 A or 10 times

the rated current whichever is greater

I (A) or I (B)

9.4and 9.5 specification of cyclic test current

test test

according to test method A;

(A) is 1,0 I

the minimum value for I

test N

(I (A)min = 1,0 I )

test N

or of continuous current according to

method B;

the minimum value for I (B) is 0,8 I

test N

(I (B)min = 0,8 I )

test N

I (A) or I (B)

specification of overload current for

OVL OVL

endurance test

9.7.101 Method I: for fuse-links for use on printed circuit

boards:

initial current is

I (A) or I (B) test method I (step test) or test method II

OVL OVL

(1 hour overload) as determined by the

Method II:

manufacturer

test current is

(A) or I (B)

I

OVL OVL

9.7.102

test current is for fuse-links for use in fuse-holders

I

N

_____________

– 24 – 60127-7 CEI:2013

SOMMAIRE

AVANT-PROPOS . 25

INTRODUCTION . 27

1 Domaine d’application . 28

2 Références normatives .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...