IEC 62246-1:2002

(Main)Reed contact units - Part 1: Generic specification

Reed contact units - Part 1: Generic specification

Is a generic specification applying to dry and mercury wetted reed contact units of assessed quality. Lists the tests and measurement procedures which may be selected for use in detail specifications for such units. Specifies the quality assessment procedures to be followed.

General Information

- Status

- Published

- Publication Date

- 29-Apr-2002

- Technical Committee

- TC 94 - Electrical relays

- Drafting Committee

- MT 2 - TC 2/MT 2

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 10-Feb-2011

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 62246-1:2002 - Reed contact units: Part 1, Generic specification is the International Electrotechnical Commission’s generic standard for dry and mercury-wetted reed contact units of assessed quality. It defines the scope, terminology, quality assessment procedures, and a comprehensive menu of tests and measurement procedures that manufacturers, test laboratories and specifiers can select when preparing detail specifications for reed contact units operated by an externally applied magnetic field (for example via a coil).

Key topics and requirements

The standard is a generic framework rather than a product-by-product spec. Key technical topics covered include:

- Scope and terminology: Definitions for reed contact unit types (dry vs. mercury-wetted), contact blades, biasing/applied magnetic fields, and units/symbols.

- Quality assessment procedures: Qualification approval, quality conformance inspection and sampling guidance.

- Extensive test and measurement procedures, including:

- Visual inspection and dimensional checks

- Functional tests and remanence testing

- Contact circuit resistance and time-parameter measurements (operate, release, transfer, bounce)

- Dielectric and insulation resistance tests

- Contact sticking, robustness of terminals and solderability/soldering-heat resistance

- Environmental and mechanical tests: climatic sequence, damp heat, rapid temperature change, salt mist, vibration, bump and shock

- Electrical and mechanical endurance tests, maximum cycling frequency

- Mercury-specific considerations: precautions, mounting position and drain time tests

- Voltage surge and sealing tests

- Reference test coils and test systems (annexes) and normative references to environmental test standards (IEC 60068 series).

- Marking, preferred values, and order of precedence for detail specifications.

Practical applications and users

IEC 62246-1 is used to:

- Guide manufacturers in preparing product and test specifications for reed contact units.

- Help component test laboratories and QA teams select and perform appropriate tests for conformity and life‑cycle assessment.

- Support design engineers who integrate reed units into relays, sensors or switching devices and need standardized test methods.

- Aid purchasing agents and specifiers to request consistent test regimes and quality evidence from suppliers.

- Be used together with relay standards (e.g., IEC 61810-1, IEC 61811-1) for elementary relays containing reed contacts.

Related standards

- IEC 61810-1 - Electromechanical non-specified time relays: general requirements

- IEC 61811-1 - Electromechanical relays of assessed quality: generic specification

- Environmental testing standards: IEC 60068 series

IEC 62246-1 is essential for anyone specifying, testing or qualifying reed contact units, ensuring consistent performance assessment and traceable quality for both dry and mercury-wetted types.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 62246-1:2002 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Reed contact units - Part 1: Generic specification". This standard covers: Is a generic specification applying to dry and mercury wetted reed contact units of assessed quality. Lists the tests and measurement procedures which may be selected for use in detail specifications for such units. Specifies the quality assessment procedures to be followed.

Is a generic specification applying to dry and mercury wetted reed contact units of assessed quality. Lists the tests and measurement procedures which may be selected for use in detail specifications for such units. Specifies the quality assessment procedures to be followed.

IEC 62246-1:2002 is classified under the following ICS (International Classification for Standards) categories: 29.120.70 - Relays. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62246-1:2002 has the following relationships with other standards: It is inter standard links to IEC 62246-1:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62246-1:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD

62246-1

First edition

2002-04

Reed contact units –

Part 1:

Generic specification

Contacts à lames souples en enceinte scellée –

Partie 1:

Spécification générique

Reference number

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/catlg-e.htm) enables

you to search by a variety of criteria including text searches, technical

committees and date of publication. On-line information is also available on

recently issued publications, withdrawn and replaced publications, as well as

corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/JP.htm) is also

available by email. Please contact the Customer Service Centre (see below) for

further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD

62246-1

First edition

2002-04

Reed contact units –

Part 1:

Generic specification

Contacts à lames souples en enceinte scellée –

Partie 1:

Spécification générique

IEC 2002 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

Commission Electrotechnique Internationale

XA

International Electrotechnical Commission

Международная Электротехническая Комиссия

For price, see current catalogue

– 2 – 62246-1 IEC:2002(E)

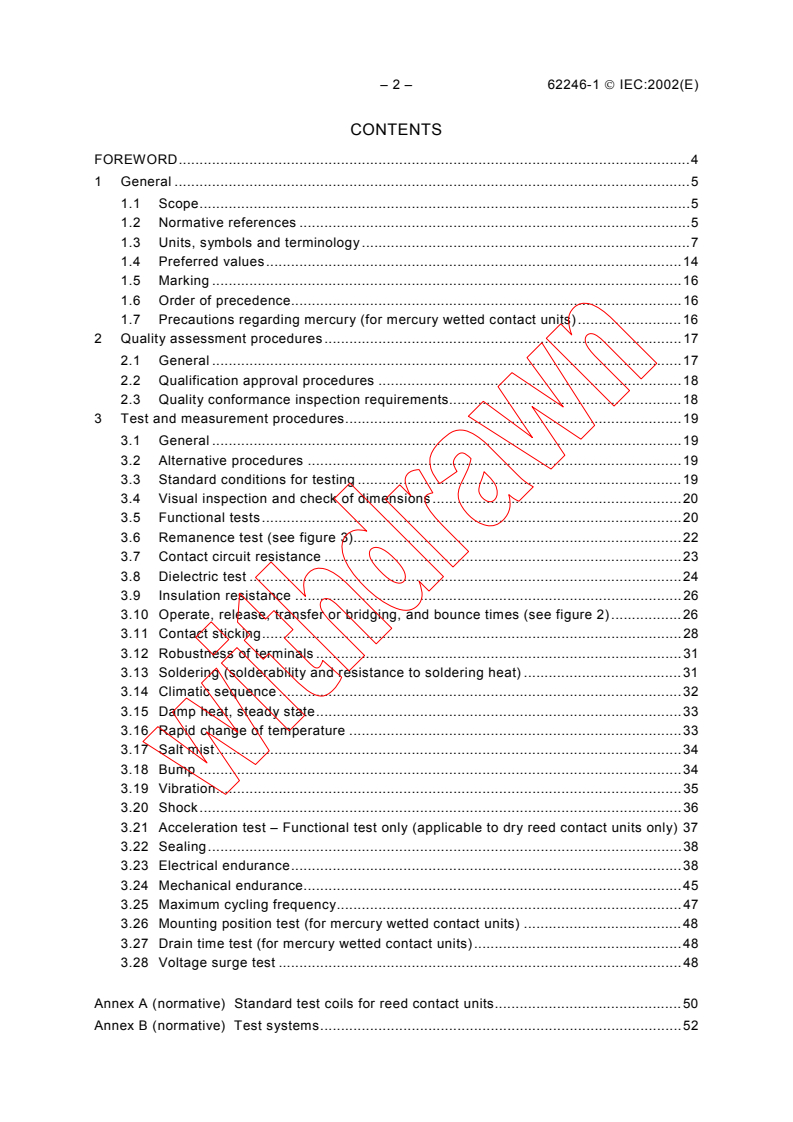

CONTENTS

FOREWORD.4

1 General .5

1.1 Scope.5

1.2 Normative references .5

1.3 Units, symbols and terminology .7

1.4 Preferred values.14

1.5 Marking .16

1.6 Order of precedence.16

1.7 Precautions regarding mercury (for mercury wetted contact units).16

2 Quality assessment procedures.17

2.1 General .17

2.2 Qualification approval procedures .18

2.3 Quality conformance inspection requirements.18

3 Test and measurement procedures.19

3.1 General .19

3.2 Alternative procedures .19

3.3 Standard conditions for testing .19

3.4 Visual inspection and check of dimensions .20

3.5 Functional tests.20

3.6 Remanence test (see figure 3).22

3.7 Contact circuit resistance .23

3.8 Dielectric test .24

3.9 Insulation resistance .26

3.10 Operate, release, transfer or bridging, and bounce times (see figure 2).26

3.11 Contact sticking.28

3.12 Robustness of terminals .31

3.13 Soldering (solderability and resistance to soldering heat) .31

3.14 Climatic sequence .32

3.15 Damp heat, steady state.33

3.16 Rapid change of temperature .33

3.17 Salt mist.34

3.18 Bump .34

3.19 Vibration.35

3.20 Shock.36

3.21 Acceleration test – Functional test only (applicable to dry reed contact units only) 37

3.22 Sealing.38

3.23 Electrical endurance.38

3.24 Mechanical endurance.45

3.25 Maximum cycling frequency.47

3.26 Mounting position test (for mercury wetted contact units) .48

3.27 Drain time test (for mercury wetted contact units).48

3.28 Voltage surge test .48

Annex A (normative) Standard test coils for reed contact units.50

Annex B (normative) Test systems.52

62246-1 IEC:2002(E) – 3 –

Figure 1 – Functional characteristics.9

Figure 2 – Time definitions.11

Figure 3 – Remanence test sequence .23

Figure 4 – Sequence of contact circuit resistance measurement .24

Figure 5 – Test circuit for the measurement of release and bounce time of a make

contact unit.27

Figure 6 – Test circuit for the measurement of time parameters of a change-over

contact unit.28

Figure 7 – Electrical endurance test arrangement .39

Figure A.1 – Configuration of test coils .50

Figure B.1 – Test system 1 .52

Figure B.2 – Test system 2 .52

Table 1 – Resistive loads.42

Table 2 – Loads .43

Table 3 – Cables.43

Table A.1 – List of standard test coils .50

– 4 – 62246-1 IEC:2002(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

REED CONTACT UNITS –

Part 1: Generic specification

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International

Organization for Standardization (ISO) in accordance with conditions determined by agreement between the

two organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical specifications, technical reports or guides and they are accepted by the National

Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62246-1 has been prepared by IEC technical committee 94: All-or-

nothing electrical relays.

The text of this standard is based on the following documents:

FDIS Report on voting

94/156/FDIS 94/164/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This standard cancels and replaces IEC 60255-9 (1979).

The detail specifications (DS), the sectional specifications (SS) and the blank detail

specifications (BDS) are not yet available and will be developed as the need arises.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

2005. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

62246-1 IEC:2002(E) – 5 –

REED CONTACT UNITS –

Part 1: Generic specification

1 General

1.1 Scope

This part of IEC 62246 which is the generic specification applies to dry and mercury wetted

reed contact units of assessed quality. It lists the tests and measurement procedures which

may be selected for use in detail specifications for such units. This standard also specifies the

quality assessment procedures to be followed.

This standard applies to those reed contact units which are operated by an applied magnetic

field; it is not restricted to any particular type of contact load.

NOTE 1 Since tests using a standard coil and standard resistive loads are the easiest to specify and to define,

this standard is currently restricted to tests of this type.

NOTE 2 For elementary relays with reed contact units, this standard is recommended to be used together with the

standards IEC 61810-1 and IEC 61811-1 as applicable.

Where in this part of IEC 62246 the term “detail specification” is used, this either has the

meaning defined in A.7 of QC 001001 for application within the IECQ system, or it means any

appropriate document, for example manufacturer’s data sheet, test specification, customer

detail specification.

1.2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60027, Letter symbols to be used in electrical terminology

IEC 60050, International Electrotechnical Vocabulary (IEV)

IEC 60068-1:1988, Environmental testing – Part 1: General and guidance

Amendment 1(1992)

IEC 60068-2-1:1990, Environmental testing – Part 2: Tests – Tests A: Cold

Amendment 1(1993)

Amendment 2(1994)

IEC 60068-2-2:1974, Environmental testing – Part 2: Tests – Tests B: Dry heat

Amendment 1(1993)

Amendment 2(1994)

IEC 60068-2-3:1969, Environmental testing – Part 2: Tests – Test Ca: Damp heat, steady

state

IEC 60068-2-6:1995, Environmental testing – Part 2: Tests – Test Fc: Vibration (sinusoidal)

– 6 – 62246-1 IEC:2002(E)

IEC 60068-2-7:1983, Environmental testing – Part 2: Tests – Test Ga: Acceleration, steady state

Amendment 1(1986)

IEC 60068-2-11:1981, Environmental testing – Part 2: Tests – Test Ka: Salt mist

IEC 60068-2-13:1983, Environmental testing – Part 2: Tests – Test M: Low air pressure

IEC 60068-2-14:1984, Environmental testing – Part 2: Tests – Test N: Change of temperature

Amendment 1(1986)

IEC 60068-2-17:1994, Basic environmental testing procedures – Part 2: Tests – Test Q:

Sealing

IEC 60068-2-20:1979, Environmental testing – Part 2: Tests – Test T: Soldering

Amendment 2(1987)

IEC 60068-2-21:1999, Environmental testing – Part 2-21: Tests – Test U: Robustness of

terminations and integral mounting devices

IEC 60068-2-27:1987, Environmental testing – Part 2: Tests – Test Ea and guidance: Shock

IEC 60068-2-29:1987, Environmental testing – Part 2: Tests – Test Eb and guidance: Bump

IEC 60068-2-30:1980, Environmental testing – Part 2: Tests – Test Db and guidance: Damp

heat, cyclic (12 + 12 hour cycle)

Amendment 1(1985)

IEC 60096 (series), Radio-frequency cables

IEC 60317-1:1990, Specifications for particular types of winding wires – Part 1: Polyvinyl

acetal enamelled round copper wire, class 105

Amendment 1(1997)

Amendment 2(1997)

IEC 60410:1973, Sampling plans and procedures for inspection by attributes

IEC 60617, Graphical symbols for diagrams

IEC 61810-1:1998, Electromechanical non-specified time all-or-nothing relays – Part 1:

General requirements

IEC 61811-1:1999, Electromechanical non-specified time all-or-nothing relays of assessed

quality – Part 1: Generic specification

ISO 1000, SI units and recommendation for the use of their multiples and of certain other

units

ITU-T Recommendation K.17:1988, Tests on power-fed repeaters using solid-state devices in

order to check the arrangements for protection from external interference

QC 001002, IEC Quality Assessment System for Electronic Components (IECQ) – Rules of

Procedure

62246-1 IEC:2002(E) – 7 –

1.3 Units, symbols and terminology

Units, graphical symbols, letter symbols and terminology shall, whenever possible, be taken

from the following documents:

ISO 1000, SI units and recommendations for the use of their multiples and of certain other units

IEC 60027, Letter symbols to be used in electrical technology

IEC 60050, International electrotechnical vocabulary

IEC 60617, Graphical symbols for diagrams

Any other units, symbols and terminology specific to one of the components covered by the

generic specification, shall be taken from the relevant IEC or ISO documents, listed under 1.2.

The following additional terminology is also applicable.

1.3.1

reed contact unit

assembly containing contact blades, some or all of magnetic material, hermetically sealed in

an envelope and controlled by means of externally generated magnetic field (e.g. an

energizing quantity applied to a coil)

1.3.2

mercury wetted contact unit

assembly containing contact blades, some or all of magnetic material, some or all mercury

wetted, hermetically sealed in an envelope and controlled by means of an externally

generated magnetic field (e.g. an energizing quantity applied to a coil)

1.3.3

contact blade

metal blade providing either the functions of the electric or magnetic circuit or both functions

combined as in the case of dry and wetted reed contact units.

For mercury wetted contact units: metal blade providing either the functions of the electric

circuit through mercury or the magnetic circuit, or both functions combined

1.3.4

biasing magnetic field

continuous magnetic field intended to determine the operate and the release position of the

contact, which can be adjusted to form a monostable or bistable contact unit

NOTE For bistable contact units, operate and release conditions have to be defined by the manufacturer in the

detail specification with reference to applied magnetic field polarity.

1.3.5

applied magnetic field

externally generated field (for example by a test coil) intended to change the position of the

contact

1.3.6

contact unit, mechanically biased

contact unit where the biasing, to determine the operate and release positions, is achieved

mechanically

1.3.7

magnetically biased contact unit

contact unit to which a biasing magnetic field is applied, determining the functional

characteristics and the operate and release position

– 8 – 62246-1 IEC:2002(E)

1.3.8

make contact (Form A contact)

means that a reed contact unit is open when there is no applied magnetic field. This is a

normally open contact

1.3.9

break contact (Form B contact)

means that a reed contact unit is closed when there is no applied magnetic field. This is a

normally closed contact

1.3.10

change-over reed contact unit

contains a make contact and a break contact within its envelope, one contact blade being

common

a) change-over break-before-make reed contact unit (Form C contact)

Change-over reed contact unit, one contact circuit of which breaks before the other

makes.

b) change-over make-before-break reed contact unit (Form D contact)

Change-over reed contact unit, one contact circuit of which makes before the other

breaks.

c) change-over reed contact unit with unspecified switching sequence (Form A and Form B

contacts)

Change-over reed contact unit where the switching sequence can be either make-

before-break or break-before-make.

1.3.11

type

type comprises products having similar design features manufactured by the same techniques

and falling within the manufacturer's usual range of ratings for these products

NOTE Mounting accessories are ignored, provided they have no significant effect on the test results.

1.3.12

variant

variation within a type having specific nominal dimensions and characteristics

1.3.13

rated value

value assigned by the manufacturer to a given characteristic of the reed contact unit

1.3.14

operate position

position where the make contact is closed and the break contact is open.

1.3.15

release position

position where the make contact is open and the break contact is closed

1.3.16

to operate

reed contact unit operates when it changes from the release position to the operate position

1.3.17

to release

reed contact unit releases when it changes from the operate position to the release position

62246-1 IEC:2002(E) – 9 –

1.3.18

just-operate value

value of the magnetic field at which the released reed contact unit just operates (see figure 1)

Magnetic field

Saturate value

Characteristic

non-release value

Must-operate value

Must-not-release value

Just-operate value

(specific to each

contact unit)

Just-release value

(specific to each

contact unit)

Must-not-operate value

Must-release value

t

IEC 1093/02

Figure 1 – Functional characteristics

1.3.19

must-operate value

stated limit of the applied magnetic field at which the reed contact unit operates (see figure 1)

1.3.20

just-release value

value of the applied magnetic field at which the operated reed contact unit just releases (see

figure 1)

1.3.21

must-release value

stated limit of the applied magnetic field at which the operated reed contact unit releases (see

figure 1)

1.3.22

must-not-operate value

stated limit of the applied magnetic field at which the reed contact unit does not operate (see

figure 1)

1.3.23

must-not-release value

stated limit of the applied magnetic field at which the operated reed contact unit remains

operated (see figure 1)

1.3.24

characteristic non-release value

stated value of the applied magnetic field above which the operated reed contact unit fulfils

specified qualities, for example contact resistance, noise characteristics, etc. (see figure 1)

– 10 – 62246-1 IEC:2002(E)

1.3.25

saturate value

arbitrarily defined value of the applied magnetic field at which the reed contact unit is

unaffected by further increase of the applied magnetic field (see figure 1)

1.3.26

bounce

momentary re-opening of a contact after initial closing, or a momentary closing after initial

opening

1.3.27

magnetic dwell (only for change-over contact units)

difference in the values of applied magnetic field when the break contact just opens and the

make contact just closes, or vice versa

NOTE For time definitions, see figure 2, for test conditions, see 3.10.

1.3.28

bounce time

interval of time between the instant of the first closing (or opening) and the instant of the final

closing (or opening) of the reed contact unit

1.3.29

operate time

time between the instant of the application of a magnetic field to a reed contact unit and the

instant the contact is in the operate position. It does not include bounce time

1.3.30

release time

time between the instant of the removal of the applied magnetic field to a reed contact unit,

and the instant the contact is in the release position. It does not include bounce time

62246-1 IEC:2002(E) – 11 –

Oscilloscope diagram

V

V

B

0,62

0,35

0,25

t t t t t t t t

1 5 3 6 10 11 15 13 16

t ms

min.

t

t

IEC 1094/02

a) Break-before-make

V

V

B

0,62

0,50

0,35

0,25

t ms

t t t t

t t t t

10 min. 12 15 14 16

2 5 4 6

t t

1 11

IEC 1095/02

b) Make-before-break

Energization of the test coil De-energization of the test coil

t : operate break time t : release break time

1 11

t : operate make time t : release make time

2 12

t : operate transfer time t : release transfer time

3 13

t : operate bridging time t : release bridging time

4 14

t

and t : bounce times t and t : bounce times

5 6 15 16

Refer to figures 5 and 6 for key to V .

B

Figure 2 – Time definitions

– 12 – 62246-1 IEC:2002(E)

1.3.31

transfer time (Form C contact)

time interval during which both contact circuits are open (not including bounce time)

1.3.32

bridging time (Form D contact)

time interval during which both contact circuits are closed (not including bounce time)

1.3.33

operate make time

time interval between the instant of the application of a magnetic field to the contact unit and

the instant of the first closing of the make contact

1.3.34

operate break time

time interval between the instant of the application of a magnetic field to the contact unit and

the instant of the first opening of the break contact

1.3.35

release make time

time interval between the instant of the removal of an applied magnetic field from the reed

contact unit and the instant of the first closing of the break contact

1.3.36

release break time

time interval between the instant of the removal of an applied magnetic field from the reed

contact unit and the instant of the first opening of the make contact

1.3.37

operate transfer time (Form C contact)

transfer time measured when the break-before-make reed contact unit moves from the release

position to the operate position

1.3.38

release transfer time (Form C contact)

transfer time measured when the break-before-make reed contact unit moves from the

operate position to the release position

1.3.39

operate bridging time (Form D contact)

bridging time during which the make-before-break reed contact unit moves from the release to

the operate position

1.3.40

release bridging time (Form D contact)

bridging time during which the make-before-break reed contact unit moves from the operate to

the release position

1.3.41

minimum time of operate energization

minimum time between the instant of the first application of a magnetic field (at a stated

value), and the instant of reduction of that field to the characteristic non release value to

ensure that the reed contact unit is maintained in the operate condition

62246-1 IEC:2002(E) – 13 –

1.3.42

time to stable closed position

time between the instant of application of a specified magnetic field to the instant at which the

reed contact unit fulfils specified qualities, for example contact resistance, noise character-

istics, etc.

1.3.43

maximum cycling frequency

maximum number of cycles per second, at and below which, the contact unit still meets the

specifications

1.3.44

failure-to-make

fault condition of the contacts, indicated by the contact circuit resistance of the unit exceeding

a specified value, for a specified applied magnetic field, within a specified period

1.3.45

failure-to-break

fault condition of the contacts, indicated by the contact circuit resistance of the unit failing to

exceed a specified value, for a specified applied magnetic field, within a specified period

1.3.46

contact sticking

failure-to-break of a reed contact unit due to residual magnetic, physical or chemical effects

1.3.47

maximum contact current

maximum allowed switched d.c. or peak current in correlation to a given number and

frequency of operations and load, under specified conditions

1.3.48

limiting continuous current

highest value of the current (r.m.s. if a.c.) which a previously closed contact is capable of

carrying continuously, in specified conditions

1.3.49

maximum contact voltage

maximum allowed switched d.c. or peak voltage, in correlation to a given number of

operations and load, under specified conditions

1.3.50

contact noise

spurious peak-to-peak voltage which is generated across the reed contact unit terminations,

in specified conditions

1.3.51

thermal e.m.f.

e.m.f. generated by the reed contact unit, when connected to an external circuit in an operate

position and subjected to a temperature differential

1.3.52

duty cycle

ratio, expressed as a percentage, of the duration of energization to the interval between

commencements of successive energizations

– 14 – 62246-1 IEC:2002(E)

1.3.53

drain-time

time taken for the contacts to become electrically open after they have been flooded with

mercury by inversion and then returned to the preferred position

NOTE In the case of change-over mercury wetted contact units there are two drain-times; one for each position of

the contact.

1.3.54

preferred position

position recommended for use and in which tests are normally performed, unless otherwise

specified

1.3.55

mounting position restriction

maximum angle from the preferred position at which the device may be mounted and still

meet the specifications

1.4 Preferred values

The following preferred values shall be used, unless otherwise stated in the detail

specification.

1.4.1 Frequency of operation

1; 2; 5; 8; 10; 12,5; 16; 20; 25; 30; 50; 60; 100; 500 operations per second.

1.4.2 Duty cycle

50 %.

1.4.3 Open-circuit voltage across contacts

a) 0,01; 0,1; 5; 12; 24, 50; 100; 110; 127; 150; 220; 250; 380; 500; 1 000; 1 500; 2 000 V a.c.

(r.m.s.).

b) 0,01; 0,03; 0,05; 0,1; 1; 1,5; 4,5; 5; 6; 6,3; 10; 12; 15; 17; 20; 24; 30; 36; 48; 50; 60; 80;

100; 110; 150; 175; 200; 250; 440; 500; 600; 800; 1 200; 1 500 V d.c.

1.4.4 Current rating

1; 1,25; 1,6; 2; 2,5; 3; 3,15; 4; 5; 6,3; 8 A or the decimal multiples or submultiples of these

figures in amps; 1, 2 and 5 are preferred.

1.4.5 Load ratings

1; 2; 5; 10; 15; 30; 50; 100; 150; 250; 500 VA.

1.4.6 Number of operations

5 000, 10 000, 20 000, 50 000

5 5 6 6 6 7 7 7 8 8 8 9 10

1⋅10 , 2⋅10 , 1⋅10 , 2⋅10 , 5⋅10 , 1⋅10 , 2⋅10 , 5⋅10 , 1⋅10 , 2⋅10 , 5⋅10 , 1⋅10 , 1⋅10 .

1.4.7 Climatic category

The climatic category (see appendix A of IEC 60068-1) of a reed contact unit, both steady

state and cyclic shall be established by a selection from the following preferred standard

values of lower and upper ambient temperatures and damp heat values.

62246-1 IEC:2002(E) – 15 –

a) The preferred values of lower ambient temperature are:

− 65, – 50, – 40, – 25, −10 °C

b) The preferred values of upper ambient temperature are:

40, 55, 70, 85, 100, 125, 200 °C

c) The preferred times of exposure to damp heat, steady state are:

4, 10, 21, 56 days

d) The preferred climatic categories are:

65 / 125 / 56

40 / 100 / 56

40 / 100 / 21

40 / 85 / 56

40 / 70 / 21

25 / 70 / 21

25 / 55 / 04

10 / 40 / 04

10 / 55 / 04

1.4.8 Preferred environmental severities

a) Vibration (IEC 60068-2-6, Test Fc)

Frequency Vibration amplitude or acceleration No. of sweep cycles

10-500 Hz 0,35 mm or 49 m/s² (5 g) 10

10-500 Hz 0,75 mm or 98 m/s² (10 g) 10

10-2000 Hz 0,75 mm or 98 m/s² (10 g) 8

10-2000 Hz 1,5 mm or 196 m/s² (20 g) 8

Duration of the sweep endurance in each of the three axes is given by a specified number of

sweep cycles. Sweep rate: 1 octave per minute ± 10 %.

Cross-over frequency between 57 Hz and 62 Hz.

b) Bump (IEC 60068-2-29, Test Eb): 1 000 + 10 bumps at 390 m/s , duration 6 ms.

c) Shock (IEC 60068-2-27, Test Ea)

11 ms, 490 m/s , 50 g

11 ms, 294 m/s , 30 g

d) Acceleration (IEC 60068-2-7, Test Ga)

m/s g

98 10

196 20

490 50

19 600 2 000

49 000 5 000

98 000 10 000

196 000 20 000

294 000 30 000

Duration of 1 min in each direction prescribed in the specification.

e) Low air pressure (IEC 60068-2-13, Test M): 80 mbar

– 16 – 62246-1 IEC:2002(E)

1.5 Marking

The sectional or detail specifications shall indicate the identification criteria and other

information to be shown on the unit and/or package. The letter or colour code shall be

described in full or reference made to the appropriate specifications. The order of priority for

marking small units shall be specified.

The marking shall, as a minimum, consist of:

– the trade mark or the manufacturer's name;

– the unit type and variants' code;

– the coded date of manufacture, quantified by months or less.

Each package of reed contact unit shall be marked with the following information:

– date code;

– number of the detail specification;

– manufacturer's factory identification code;

– additional marking as required by the detail specification.

1.6 Order of precedence

Where any discrepancies occur for any reasons, documents shall rank in the following order

of authority:

a) the detail specification,

b) the sectional specification,

c) the generic specification,

d) any other international documents (for example, of the IEC) to which reference is made.

The same order of precedence shall apply to equivalent national documents.

1.7 Precautions regarding mercury (for mercury wetted contact units)

1.7.1 General

As mercury is a toxicologically and environmentally hazardous substance, all applicable

international and local laws and regulations have to be complied with.

1.7.2 Information sheet

A sheet containing relevant general information about mercury on

a) physical properties,

b) important characteristics,

c) hazards/symptoms,

d) preventive measures,

e) fire extinguishing/first aid,

f) spillage,

g) storage,

h) labelling,

should be given to the user.

62246-1 IEC:2002(E) – 17 –

1.7.3 Recommendations for control and disposal

a) Control of mercury wetted contact units:

– the contact units shall be stored in the manufacturer's packaging until required for

assembly;

– sufficient number of contact units should be released from stock to cover the

immediate assembly programme; unused contact units should be returned to stock;

– contact units rejected either due to damage or failure should be stored in a suitable

container until disposal;

– contact units should be regularly monitored to ensure that no units are lost or mislaid.

b) Disposal of mercury wetted contact units:

– it is illegal to put mercury wetted reed contact units in any quantity in domestic or

industrial general waste, unless local laws allow exceptions for the maximum amount

of mercury used per total weight of disposal (percentage or ppm). Local laws and

regulations have to be followed;

– contact units in any condition (intact or damaged) which are ready for disposal should

be stored separately in an impervious container until there is sufficient quantity to be

taken or sent to a licensed disposal or recycling site;

– the licensed site may be for instance an incinerator, an adequate land-fill or a metal-

recovery dealer; licensing is the prerogative of the local authorities.

2 Quality assessment procedures

2.1 General

The basic concept of the IECQ system for quality assessment is to provide assurance to the

purchaser that the components which are released conform to the requirements in the

relevant specifications.

Before a manufacturer is permitted to produce, test and deliver components under the IECQ

quality assessment system, it is necessary that his production organization, facilities, storage

and delivery systems organization, facilities for inspection and tests of components, and

arrangements for calibration meet the requirements of the IECQ system. In particular, it shall

be demonstrated that all appropriate parts of the organization and its facilities are under the

direct control or surveillance of the person appointed as chief inspector. This approval of

manufacturers is granted in accordance with IEC QC 001002.

The procedures for the qualification approval of electronic components as stipulated in IEC

QC 001002 comprise the following consecutive basic steps:

a) qualification approval;

b) quality conformance inspection.

2.1.1 Primary stage of manufacture

The primary stage of manufacture is defined as the plating and related processing of the

contact blades.

2.1.2 Structurally similar components

The blank detail specification(s) shall define those reed contact units within its scope which

may be considered as structurally similar.

– 18 – 62246-1 IEC:2002(E)

2.1.3 Subcontracting

Subcontracting is permitted for any stages preceding the primary stage of manufacture

(see 2.1.1). Subcontracting shall be in accordance with requirements of annex B to clause 2

of QC 001002-3. Subcontracting the primary stage of manufacture and/or subsequent stages

to an unapproved manufacturer is forbidden.

2.2 Qualification approval procedures

These procedures shall be in accordance with the requirements of QC 001002-3.

The manufacturer shall comply with the requirements for the primary stage of manufacture

(see 2.1.1) as well as with the requirements given in the sectional and detail specifications.

In addition, the manufacturer shall produce test evidence of conformance to the specification

requirements either on three consecutive lots for lot-by-lot inspection and on one lot for

periodic inspection, or on a fixed sample subjected to the prescribed sequences of tests.

Samples shall be taken from the lots in accordance with IEC 60410. Normal inspection shall

be used, but where the sample size is less than that which would give acceptance on zero

defectives, additional specimens shall be taken to meet the sample size required to give

acceptance on one defective.

2.3 Quality conformance inspection requirements

The quality conformance inspection shall be in accordance with the requirements of QC

001002-3.

The blank detail specification shall prescribe the minimum test schedule which shall be

included in each detail specification for those reed contact units covered by the scope of the

specification.

This test schedule shall also specify the division into groups and subgroups (see 3.2.3 of

IEC QC 001002-3) for the purpose of lot-by-lot and periodic inspection.

The blank detail specification shall show the order in which the tests or conditions in the sub-

group shall be carried out where this order may affect the test results. The blank detail

specification shall also indicate wherever any particular order of testing in any subgroup is to

be observed.

Where a subgroup contains a destructive test, this shall either be stated in full or the symbol

"D" shall be placed alongside of the title of the subgroup in the schedule of inspection

requirements in the blank detail specification.

2.3.1 Delivery of units subjected to destructive tests or non-destructive tests

Units subjected to destructive tests shall not be included in the lot for delivery. Units

subjected to non-destructive tests may be delivered provided they are re-tested to Group A

(see 3.2.3 of IEC QC 001002-3) requirements and satisfy them.

2.3.2 Delayed delivery

Units which have been held by the manufacturer for a period exceeding 12 months following

acceptance inspection, shall be re-inspected as prescribed in the detail specification, unless

another period is specified therein.

If this has been done for the complete lot, no further retesting before delivery is needed for

another period of one year or as otherwise specified in the detail specification.

62246-1 IEC:2002(E) – 19 –

2.3.3 Supplementary procedure for deliveries

When this has been nationally recognized, manufacturers may, at their discretion, supply

units that have met a higher assessment level against orders for a lower assessment level.

2.3.4 Unchecked parameters

When, in detail specifications, supplementary information is given, this shall not be the

subject of inspection.

2.3.5 Release for delivery before the completion of Group B tests

When the conditions of IEC 60410 for reduced inspection have been satisfied for all Group B

(see 3.2.3 of IEC QC 001002-3) tests, the manufacturer is permitted to release the units

before the completion of such tests.

2.3.6 Screening procedures

When screening is specified in the detail specification or the purchase order, it is to be

applied to all devices in the production lot prior to the formation of samples for quality

conformance testing (lot-by-lot and periodic).

The test shall be performed in the given order; when, however, part of screening sequence is

already performed during production and in the same sequence, it need not be repeated.

Any device found defective during any of the tests shall be removed and not considered as

part of the production lot for subsequent sampling purposes.

3 Test and measurement procedures

3.1 General

The blank detail specifications shall contain tables showing the tests to be made, which

measurements are to be made before and after each test or subgroup of tests, and the

sequence in which they shall be carried out.

3.2 Alternative procedures

The test and measurement methods given in the relevant specification are not necessarily the

only methods which can be used. However, the manufacturer shall satisfy the National

Supervising Inspectorate that any alternative methods which he may use will give results

equivalent to those obtained by the methods specified.

Alternative methods shall not be used where methods are specifically designated as referee

or reference methods.

3.3 Standard conditions for testing

Unless otherwise prescribed, all tests shall be carried out under standard atmospheric

conditions for testing, as specified in IEC 60068-1. The stages of each test shall be carried

out in the order written.

For those measurements that require the reed contact unit to be energized, the reed contact

unit shall be positioned in its test coil, as prescribed in the detail specification.

Test coils and test systems shall, wherever possible, be selected from the list of standard test

coils in annex A and from the test systems in annex B.

– 20 – 62246-1 IEC:2002(E)

The test shall be carried out in an environment in such a way that no external field or body

shall influence the test results by an amount equivalent to 0,5 A × turns or 2 %, whichever is

the greater.

The voltage of the test supply as measured at the test specimen shall remain within 0,5 % of

the nominal value at all test conditions other than the voltage test, unless otherwise

prescribed.

In case of mercury wetted contact units the tests shall be made with the unit in the preferred

position, unless otherwise prescribed in the detail specification. The preferred position shall

be described in the detail specification.

3.4 Visual inspection and check of dimensions

3.4.1 Visual inspection

Unless otherwise prescribed in the detail specification, inspection shall be performed under

normal visual conditions. The workmanship, seals, finish, mercury wetting and marking shall

be as prescribed in the detail specification.

If prescribed in the detail specification, more detailed visual inspection under specified

magnification shall be made for failures such as:

– glass defects: cracks, bubbles, crystallisation, devitrification chips, cold-seals, short-seals,

unwetted parts, etc.

– geometrical defects: contact alignment, overlapping failures, burrs, parallelism, etc.

– mechanical defects: blistering, unplated areas, staining, rusting, magnetic and unmagnetic

dirt, whisker growth, etc.

– mercury defects: insufficient wetting, unwanted wetting, mercury level, mercury outside

envelope, mercury surface condition, etc.

3.4.2 Outline dimensions

The outline dimensions shall be checked and shall comply with those prescribed in the detail

specification.

3.4.3 Mass

The nominal mass shall be prescribed in the detail specification.

3.4.4 Information to be stated in the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...