IEC 61757-2-1:2021

(Main)Fibre optic sensors - Part 2-1: Temperature measurement - Temperature sensors based on fibre Bragg gratings

Fibre optic sensors - Part 2-1: Temperature measurement - Temperature sensors based on fibre Bragg gratings

IEC 61757-2-1:2021 specifies the terminology, characteristic performance parameters and related test methods of optical temperature sensors based on fibre Bragg gratings (FBG) that carry out temperature measurements in the temperature range between ‑260 °C and 600 °C. Generic specifications for fibre optic sensors are defined in IEC 61757.

Capteurs fibroniques - Partie 2-1: Mesure de la température - Capteurs de température basés sur des réseaux de Bragg à fibres

IEC 61757-2-1:2021 spécifie la terminologie, les paramètres de performance caractéristiques et les méthodes d’essai associées des capteurs de température optiques basés sur des réseaux de Bragg à fibres (FBG) qui réalisent des mesures de température dans la plage de températures comprise entre –260 °C et 600 °C. Les spécifications génériques applicables aux capteurs fibroniques sont définies dans l’IEC 61757.

General Information

- Status

- Published

- Publication Date

- 27-Jul-2021

- Technical Committee

- SC 86C - Fibre optic systems, sensing and active devices

- Drafting Committee

- WG 2 - TC 86/SC 86C/WG 2

- Current Stage

- PPUB - Publication issued

- Start Date

- 28-Jul-2021

- Completion Date

- 03-Sep-2021

Overview

IEC 61757-2-1:2021 is an international standard published by the International Electrotechnical Commission (IEC) that specifies terminology, characteristic performance parameters, and test methods for fibre optic temperature sensors based on fibre Bragg gratings (FBG). These sensors are designed for precise temperature measurements within a wide range, from -260 °C up to 600 °C. This standard is part of the broader IEC 61757 series, which defines generic specifications for fibre optic sensors.

By establishing a common framework for FBG temperature sensors, IEC 61757-2-1:2021 enables consistent testing, calibration, and evaluation, facilitating global adoption and ensuring sensor reliability and performance in diverse industries.

Key Topics

Fibre Bragg Gratings (FBG): Understanding the physical principle behind FBG sensors, where the Bragg wavelength shifts predictably with temperature changes, allowing accurate temperature measurement.

Performance Parameters: Definition and measurement of key characteristics such as:

- Bragg wavelength precision

- Peak spectral width

- Reflectivity and side-lobe suppression ratio

- Signal-to-noise ratio

- Thermal time constant (response time)

- Sensor stability over time

Test Methods and Calibration: Detailed procedures for setting up test equipment including temperature calibration baths and optical spectrum analyzers. The standard covers measurement protocols, evaluation methods, and reporting formats to ensure traceability and accuracy.

Terminology and Symbols: Standardized terms, abbreviations, and symbols are provided to ensure clear communication and documentation within the industry.

Measurement Uncertainty: Guidelines on contributions to uncertainty and methods to minimize errors in temperature determination.

Applications

IEC 61757-2-1:2021 applies to industries and applications where precise, reliable temperature measurement is crucial, including:

Industrial Process Control: Monitoring temperatures in harsh environments where electrical sensors cannot operate safely, such as in chemical plants or furnaces.

Aerospace and Automotive: Temperature sensing in engines and critical components where compact, lightweight, and immunity to electromagnetic interference (EMI) is required.

Energy Sector: Use in power generation, including nuclear facilities, where high temperature ranges and sensor stability over long periods are vital.

Medical and Environmental Monitoring: Temperature measurement in medical devices and remote or harsh environmental conditions.

Research and Development: Providing a basis for designing, calibrating, and evaluating custom FBG temperature sensors in laboratories.

Related Standards

IEC 61757: The parent series that outlines generic requirements and general specifications for fibre optic sensors, providing foundational principles for IEC 61757-2-1.

ISO/IEC Standards: Other related international standards for test methods and calibration in temperature sensing and fibre optic technologies, complementing IEC 61757-2-1 for integrated sensor systems.

Industry-Specific Standards: Depending on application domain, IEC 61757-2-1 may be used alongside standards for process control, aerospace safety, and medical device regulations.

IEC 61757-2-1:2021 is a critical resource for engineers, manufacturers, and quality assurance professionals committed to deploying fibre Bragg grating based temperature sensors with international conformity, ensuring precision, reliability, and interoperability across diverse applications and industries.

Get Certified

Connect with accredited certification bodies for this standard

TL 9000 QuEST Forum

Telecommunications quality management system.

ANCE

Mexican certification and testing association.

Intertek Slovenia

Intertek testing, inspection, and certification services in Slovenia.

Sponsored listings

Frequently Asked Questions

IEC 61757-2-1:2021 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Fibre optic sensors - Part 2-1: Temperature measurement - Temperature sensors based on fibre Bragg gratings". This standard covers: IEC 61757-2-1:2021 specifies the terminology, characteristic performance parameters and related test methods of optical temperature sensors based on fibre Bragg gratings (FBG) that carry out temperature measurements in the temperature range between ‑260 °C and 600 °C. Generic specifications for fibre optic sensors are defined in IEC 61757.

IEC 61757-2-1:2021 specifies the terminology, characteristic performance parameters and related test methods of optical temperature sensors based on fibre Bragg gratings (FBG) that carry out temperature measurements in the temperature range between ‑260 °C and 600 °C. Generic specifications for fibre optic sensors are defined in IEC 61757.

IEC 61757-2-1:2021 is classified under the following ICS (International Classification for Standards) categories: 33.180.99 - Other fibre optic equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61757-2-1:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61757-2-1 ®

Edition 1.0 2021-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Fibre optic sensors –

Part 2-1: Temperature measurement – Temperature sensors based on fibre

Bragg gratings

Capteurs fibroniques –

Partie 2-1: Mesure de la température – Capteurs de température basés

sur des réseaux de Bragg à fibres

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 18 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC online collection - oc.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications. Avec un

en utilisant différents critères (numéro de référence, texte, abonnement, vous aurez toujours accès à un contenu à jour

comité d’études, …). Elle donne aussi des informations sur adapté à vos besoins.

les projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au

Restez informé sur les nouvelles publications IEC. Just

monde, avec plus de 22 000 articles terminologiques en

Published détaille les nouvelles publications parues.

anglais et en français, ainsi que les termes équivalents dans

Disponible en ligne et une fois par mois par email.

16 langues additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 61757-2-1 ®

Edition 1.0 2021-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Fibre optic sensors –

Part 2-1: Temperature measurement – Temperature sensors based on fibre

Bragg gratings

Capteurs fibroniques –

Partie 2-1: Mesure de la température – Capteurs de température basés

sur des réseaux de Bragg à fibres

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 33.180.99 ISBN 978-2-8322-1009-5

– 2 – IEC 61757-2-1:2021 © IEC 2021

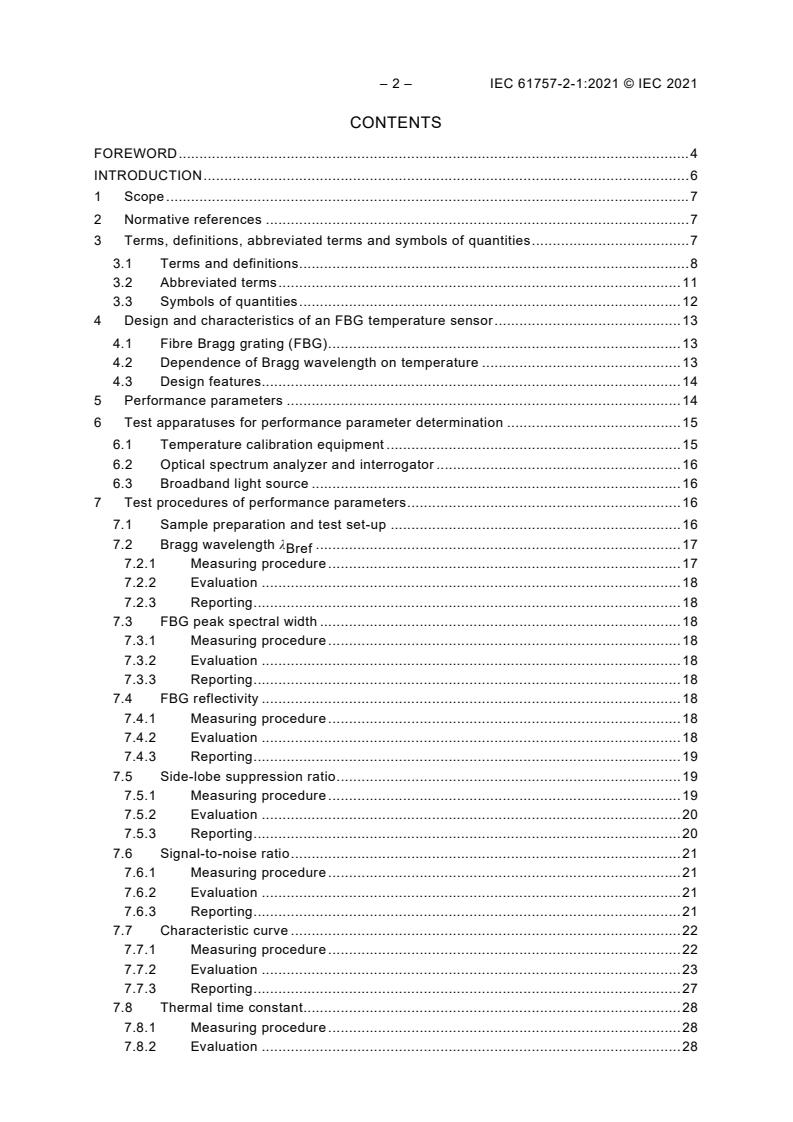

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms, definitions, abbreviated terms and symbols of quantities . 7

3.1 Terms and definitions . 8

3.2 Abbreviated terms . 11

3.3 Symbols of quantities . 12

4 Design and characteristics of an FBG temperature sensor . 13

4.1 Fibre Bragg grating (FBG) . 13

4.2 Dependence of Bragg wavelength on temperature . 13

4.3 Design features. 14

5 Performance parameters . 14

6 Test apparatuses for performance parameter determination . 15

6.1 Temperature calibration equipment . 15

6.2 Optical spectrum analyzer and interrogator . 16

6.3 Broadband light source . 16

7 Test procedures of performance parameters . 16

7.1 Sample preparation and test set-up . 16

7.2 Bragg wavelength λ . 17

Bref

7.2.1 Measuring procedure . 17

7.2.2 Evaluation . 18

7.2.3 Reporting . 18

7.3 FBG peak spectral width . 18

7.3.1 Measuring procedure . 18

7.3.2 Evaluation . 18

7.3.3 Reporting . 18

7.4 FBG reflectivity . 18

7.4.1 Measuring procedure . 18

7.4.2 Evaluation . 18

7.4.3 Reporting . 19

7.5 Side-lobe suppression ratio . 19

7.5.1 Measuring procedure . 19

7.5.2 Evaluation . 20

7.5.3 Reporting . 20

7.6 Signal-to-noise ratio . 21

7.6.1 Measuring procedure . 21

7.6.2 Evaluation . 21

7.6.3 Reporting . 21

7.7 Characteristic curve . 22

7.7.1 Measuring procedure . 22

7.7.2 Evaluation . 23

7.7.3 Reporting . 27

7.8 Thermal time constant. 28

7.8.1 Measuring procedure . 28

7.8.2 Evaluation . 28

7.8.3 Reporting . 28

7.9 Sensor stability . 29

7.9.1 Measuring procedure . 29

7.9.2 Evaluation . 29

7.9.3 Reporting . 29

Annex A (informative) Blank detail specification . 30

A.1 General . 30

A.2 Mechanical and optical set-up . 30

A.3 Operational characteristics . 30

A.4 Limiting parameters . 31

A.5 Further information given upon request . 31

Annex B (informative) Examples of specific temperature calibration equipment . 32

B.1 Simple liquid bath . 32

B.2 Liquid tube-thermostat . 33

B.3 Solid-state calibration equipment . 34

Annex C (informative) Contributions to measurement uncertainty . 37

Bibliography . 38

Figure 1 – Principal test set-up for FBG . 17

Figure 2 – Determination of the FBG reflectivity from the reflection spectrum (left) and

transmission spectrum (right) . 19

Figure 3 – Side-lobes in the case of a single FBG temperature sensor . 20

Figure 4 – Signal-to-noise ratio determination . 21

Figure 5 – Example of a polynomial fit of calibration points λ (T ) . 24

B,i N,i

Figure 6 – Example of a third-order polynomial fit . 25

Figure 7 – Example of a fourth-order polynomial fit . 26

Figure 8 – Example of a polynomial fit of the sensitivity . 27

Figure 9 – Typical response time curve . 28

Figure B.1 – Schematic representation of a simple liquid bath [3] . 32

Figure B.2 – Schematic representation of liquid calibration device for connection to

laboratory liquid thermostats [4] . 33

Figure B.3 – Schematic representation of a long-tube fluid calibration device [3] . 34

Figure B.4 – Schematic representation of a solid-state calibration device for higher

temperatures [4] . 35

Figure B.5 – Schematic representation of a dry-block calibrator for calibrating an FBG

temperature sensor at higher temperatures . 36

Table 1 – Calibration bath fluids. 15

– 4 – IEC 61757-2-1:2021 © IEC 2021

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FIBRE OPTIC SENSORS –

Part 2-1: Temperature measurement –

Temperature sensors based on fibre Bragg gratings

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 61757-2-1 has been prepared by subcommittee 86C: Fibre optic systems and active

devices, of IEC technical committee 86: Fibre optics. It is an International Standard.

The text of this International Standard is based on the following documents:

FDIS Report on voting

86C/1725/FDIS 86C/1737/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement,

available at www.iec.ch/members_experts/refdocs. The main document types developed by

IEC are described in greater detail at www.iec.ch/standardsdev/publications.

A list of all parts in the IEC 61757 series, published under the general title Fibre optic

sensors, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 61757-2-1:2021 © IEC 2021

INTRODUCTION

This document is based on the guideline VDI/VDE 2660 Blatt 2:2020-04, Technical

temperature measurement – Optical temperature sensor based on fibre Bragg gratings –

Recommendation on temperature measurement and statement of measurement uncertainty

[1] . It was prepared in cooperation with VDI/VDE-GMA Technical Committee 2.17 "Fibre optic

measurement techniques".

The IEC 61757 series is published with the following logic: the sub-parts are numbered as

IEC 61757-M-T, where M denotes the measure and T, the technology.

___________

Numbers in square brackets refer to the Bibliography.

FIBRE OPTIC SENSORS –

Part 2-1: Temperature measurement –

Temperature sensors based on fibre Bragg gratings

1 Scope

This part of IEC 61757 specifies the terminology, characteristic performance parameters and

related test methods of optical temperature sensors based on fibre Bragg gratings (FBG) that

carry out temperature measurements in the temperature range between –260 °C and 600 °C.

Generic specifications for fibre optic sensors are defined in IEC 61757.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60050 (all parts), International Electrotechnical Vocabulary (IEV) (available at

www.electropedia.org)

IEC 61757, Fibre optic sensors – Generic specification

IEC 61757-1-1:2020, Fibre optic sensors – Part 1-1: Strain measurement – Strain sensors

based on fibre Bragg gratings

ISO/IEC GUIDE 98-3, Uncertainty of measurement – Part 3: Guide to the expression of

uncertainty in measurement (GUM:1995)

3 Terms, definitions, abbreviated terms and symbols of quantities

For the purposes of this document, terms and definitions given in IEC 60050 (all parts),

IEC 61757, IEC 61757-1-1, and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

– 8 – IEC 61757-2-1:2021 © IEC 2021

3.1 Terms and definitions

3.1.1

Bragg wavelength under reference conditions

λ

Bref

wavelength of maximal reflectance or minimal transmittance of a mechanically stress-free

fibre Bragg grating at reference or standard temperature conditions, without the effect of a

temperature change

Note 1 to entry: The term Bragg wavelength λ specified in the data sheet of the manufacturer of a fibre Bragg

B

grating normally describes the Bragg wavelength without further details on reference or standard temperature

conditions.

[SOURCE: IEC 61757-1-1:2020, 3.3, modified – transformed to temperature sensing.]

3.1.2

birefringence

optical property of the directional dependence of the index of refraction of an optically

anisotropic material having orientation-dependent refractive indices that lead to different

propagation velocities of light in different propagation and polarization directions

Note 1 to entry: In fibre optic sensors terminology, the term "birefringence" is mainly applied when optical

waveguides with birefringence properties, such as PANDA or bow-tie fibres, are used. Birefringence in fibre Bragg

gratings becomes important only when polarized light is used for the measurement. Because of the properties of

fibre Bragg gratings, this can lead to an additional systematic increase in the measurement uncertainty.

[SOURCE: IEC 61757-1-1:2020,3.22, modified – clarified and Note modified.]

3.1.3

drift

shift of the characteristic curve (or, rarely, change of the characteristic curve parameters)

under the same measuring and operating conditions or reference conditions due to material

ageing or/and mechanical and/or thermal continuous or alternating stress

3.1.4

dynamic measurement deviation

ΔT(t)

time-dependent thermal measurement deviation resulting from time-varying differences

between the sensor temperature T (t) and the temperature of the medium T (t) with

S M

ΔTt T t− T t

() () ()

SM (1)

3.1.5

FBG peak

reflection peak or transmission minimum in the Bragg grating reflectance or transmittance

spectrum

Note 1 to entry: Maximum peak value is typically at the Bragg wavelength λ .

B

3.1.6

FBG peak spectral width

full width at half maximum (FWHM) of the FBG peak

Note 1 to entry: Full width at half maximum of the FBG peak is the wavelength range of the spectrum for which

the amplitude is greater than 50 % (3 dB).

[SOURCE: IEC 61757-1-1:2020, 3.7, modified – transformed for temperature sensor.]

=

3.1.7

FBG period

Λ

distance between the periodically changing refractive index zones (grating planes) in an

optical waveguide having an effective refractive index n

eff

Note 1 to entry: The FBG period defines the Bragg wavelength λ through the formula

B

k⋅λ

B

Λ=

for k = positive integer

(2)

2 n

eff

[SOURCE: IEC 61757-1-1:2020, 3.18, modified – definition extended.]

3.1.8

FBG temperature sensor

fibre optic sensor that uses a fibre Bragg grating as a sensitive element for temperature

measurements

Note 1 to entry: FBG temperature sensors can be used in a series configuration with multiple gratings allowing to

perform distributed measurements.

3.1.9

FBG temperature sensing system

measurement set-up consisting of one or more serial arranged FBG temperature sensors

connected to an interrogation unit consisting of a light source, detector module, processor,

data archive, and user interface

Note 1 to entry: An FBG temperature sensing system normally works as follows: After light from the light source is

sent into the fibre and partially reflected or transmitted by the FBG temperature sensor, it is guided to the detector

module of the interrogator, which determines the FBG peak wavelength. From a shift of the FBG peak wavelength

caused by temperature change, the temperature change can be quantitatively determined in the measuring units.

3.1.10

maximum operating temperature

highest value of temperature at which the FBG temperature sensor meets the specified

performance

3.1.11

minimum operating temperature

lowest value of temperature at which the FBG temperature sensor meets the specified

performance

3.1.12

minimum bending radius

minimum radius at which an FBG temperature sensor is bent without change of the specified

performance parameters

Note 1 to entry: This value can differ from the minimum bending radius given for transport and storage.

[SOURCE: IEC 61757-1-1:2020, 3.16, modified – transformed for temperature sensor.]

3.1.13

parasitic strain effect

non-thermally induced deformation of the fibre Bragg grating during temperature

measurement resulting in a change in the wavelength response of the FBG

Note 1 to entry: A non-rateable deformation of the FBG during temperature measurement occurs as an apparent

temperature change in the response signal and shall therefore be excluded or be assessable.

– 10 – IEC 61757-2-1:2021 © IEC 2021

3.1.14

reference wavelength

λ

ref

wavelength response of a fibre Bragg grating to which a specific temperature T value is

ref

referred

Note 1 to entry: Depending on the evaluation method, the interrogator devices of the sensor often emit different

wavelengths to determine the filter function of the Bragg grating. The reference wavelength is not necessarily equal

to the Bragg wavelength λ . However, because of the small difference between the reference wavelength and

B

Bragg wavelength, both wavelengths can be used in Formulae (6) to (8) and in Formulae (16) to (20) without

relevant errors occurring.

[SOURCE: IEC 61757-1-1:2020, 3.4, modified – transformed to temperature sensing]

3.1.15

reference wavelength at reference temperature

λ

Tref

not

Bragg wavelength of the fibre Bragg grating for a specified reference temperature T

ref

equal to 0 °C

3.1.16

reference wavelength at 0 °C

λ

Tref,0

Bragg wavelength of the fibre Bragg grating at reference temperature T = 0 °C

3.1.17

response time

t

R

time after which the difference between the sensor temperature T (t) and the temperature of

S

the medium T is smaller than a meaningful defined fraction δ of the initial temperature

M

difference T (0) – T , as described by Formula (3)

S M

Tt−= T δT 0−T

( ) ( )

sR M S M (3)

3.1.18

sensitive area

length of the fibre Bragg grating that is sensitive to the

temperature to be measured and thereby changes the wavelength response of the fibre Bragg

grating

3.1.19

side-lobe suppression ratio

R

SLS

ratio of the intensity of the FBG peak to the nearest largest side-lobe

Note 1 to entry: It is expressed in dB.

3.1.20

sensor stability

ability of the FBG temperature sensor to keep its performance characteristics under specified

limits within a specified time interval, all other conditions being the same

3.1.21

static thermal measurement deviation

ΔT

th

time-invariant temperature difference in the steady state between the sensor temperature

T (t) and the temperature of the medium T

S M

ΔT Tt− T for t→∞

()

th S M (4)

3.1.22

temperature sensitivity

S(T)

ratio of the wavelength change Δλ of an FBG temperature sensor caused by a temperature

T

change ΔT in steady state, which is the temperature-dependent slope of the characteristic

curve λ (T) expressed in nm/K

T

∆λ

T

S T = (5)

( )

∆T

Note 1 to entry: The unit can also be pm/K.

3.1.23

operating temperature range

interval for which the FBG temperature sensor under specified conditions is able to perform

temperature measurements in accordance with the specified performance

3.1.24

thermal time constant

τ

t

time it takes an FBG temperature sensor to reach 63,2 % of the total difference between the

initial and the final medium or body temperature when subjected to a step-like change in

temperature under defined conditions

Note 1 to entry: In many industrial applications, the thermal time constant is also provided for 50 % of the total

temperature difference and for 90 % of the total temperature difference, so as to characterize the dynamic

behaviour of the temperature sensor. The dynamic response of some surface temperature sensors, such as

jacketed thermocouples with a measuring point at the temperature sensor bottom and similar approaches, does not

follow an exponential function but is rather characterized by an initial rapid rise in temperature and a subsequent

slow creep to the final value. For these temperature sensors, the thermal time constant is also specified for 95 %

and 99 % of the total temperature difference.

3.1.25

thermal measurement deviation

(t) and the temperature of

time-dependent difference between the sensor temperature T

S

origin to be measured, of the measuring medium or body T (t)

M

Note 1 to entry: For t → ∞, the thermal measurement deviation is equal to static thermal measurement deviation.

3.2 Abbreviated terms

ASE amplified spontaneous emission

FBG fibre Bragg grating

ITS-90 international temperature scale of 1990

OSA optical spectrum analyzer

=

– 12 – IEC 61757-2-1:2021 © IEC 2021

3.3 Symbols of quantities

k number of order (mathematical description)

ΔL length change of the Bragg grating due to external load in the fibre direction

n index of refraction

n effective index of refraction (of the Bragg grating)

eff

P incident optical power

P optical power of the nearest side-lobe

SL

P optical power of the FBG at λ

λB B

R FBG reflectivity

FBG

R side-lobe suppression ratio expressed in dB

SLS

SNR FBG signal-to-noise ratio

FBG

S(T) temperature sensitivity in nm/K

T temperature in °C

T reference temperature for T = 0 °C, at which the FBG has the reference

wavelength λ in °C

T reference temperature (freely selectable) in °C

B

T actual temperature of the medium/measuring object to be measured in °C

M

T actual temperature provided by the standard thermometer

N

T defined reference temperature at which the FBG has the reference

ref

wavelength λ in °C

ref

T output signal of the temperature sensor (measured temperature) in °C

S

T (0) output signal of the temperature sensor at an abrupt change of the

S

temperature of the measuring body or medium in °C

ΔT static thermal measurement deviation in K

th

x i-th measured value

i

α coefficient of thermal expansion in 1/K

δ part of the initial temperature difference, which has appropriately to be

determined according to the uncertainty of measurement in K

σ mechanical stress

ε strain applied to the temperature sensor (always considered in the direction

of the fibre axis)

p effective photo-elastic (stress-optical) constant

ε

λ reference wavelength for T = 0 °C in m

λ Bragg wavelength in m

B

λ reference wavelength of the FBG of a temperature sensor at T = 0 °C in m

FBG0

λ Bragg wavelength under reference conditions, mechanically stress-free

Bref

operated at a specified reference temperature in m

λ reference wavelength in m

ref

λ Bragg wavelength of the FBG at reference temperature T = 0 °C

Tref,0 0

λ

Bragg wavelength of the FBG at reference specified temperature T ≠ 0 °C

Tref

ref

Λ FBG period

τ, t thermal time constant

ξ thermo-optic coefficient

4 Design and characteristics of an FBG temperature sensor

4.1 Fibre Bragg grating (FBG)

A detailed description of the structure, function, principle characteristics and manufacturing

process of an FBG is provided in IEC 61757-1-1.

4.2 Dependence of Bragg wavelength on temperature

As explained in IEC 61757-1-1, the change of the Bragg wavelength caused by a change in

the grating temperature can be described by Formula (6).

∂∂nn∂∂ΛΛ

eff eff

Δλ =22⋅+ΛΔnL⋅ +⋅+ΛΔnT⋅

B eff eff (6)

∂∂LL ∂∂TT

where

Δλ is the Bragg wavelength shift;

B

T is the temperature;

ΔT is the temperature difference;

n is the effective index of refraction (of the Bragg grating);

eff

ΔL is the change of length of the Bragg grating due to external load in fibre direction;

Λ is the FBG period.

The first two terms on the right side of Formula (6) describe the effects resulting from the

mechanical deformation (∂Λ/∂L) and the elasto-optical response (∂n /∂L) of the optical fibre;

eff

these effects are to be considered parasitic in temperature measurements. The last two terms

in Formula (6) describe the effects of temperature on the quantities n and Λ.

eff

The term (∂Λ/∂T) describes the effect of the thermal expansion of the Bragg grating with

regard to the grating period Λ. The thermal effect on the refractive index of the optical fibre,

on the other hand, is expressed by the term (∂n /∂T).

eff

In practice, the effects of strain and temperature are approximately described by the linear

relationship displayed in Formula (7).

Δλ εT,

( )

B

= 1− p ⋅+εα+ξ⋅ΔT

( )

( )

ε (7)

λ

B

where

ε is the strain of the fibre in axial direction;

is the effective photo-elastic (stress-optical) constant;

p

ε

α is the coefficient of thermal expansion;

ξ is the thermo-optic coefficient.

When a temperature change is applied to a mechanically unstressed FBG, a corresponding

shift of the Bragg wavelength is observed in the optical spectrum. In practice, the effect of a

temperature change ΔT on the Bragg wavelength can approximately be described by the

linear relationship in Formula (8)

– 14 – IEC 61757-2-1:2021 © IEC 2021

Δλ (T)

B

αT+ξ⋅∆

( )

(8)

λ

B

where

λ , Δλ are the Bragg wavelength and wavelength shift;

B

T, ΔT are the temperature and temperature difference;

α is the coefficient of thermal expansion;

ξ is the thermo-optic coefficient.

4.3 Design features

Fibre Bragg gratings are usually supplied with a so-called primary coating, which protects the

sensor against damage or fibre breakage. If the fibre Bragg grating is applied without

mechanical stress to the measurement object, the fibre sensor usually includes this primary

coating. Since the thickness of the coating is in the range of several tens of micrometres, the

heat transfer from the object of measurement to the sensor is not impeded significantly.

However, the impact of thermally induced deformations of the temperature sensor caused by

the object of measurement shall be considered. The coating can also remain on the sensor

fibre in other installations of the FBG sensor. In certain cases, the coating can be removed

during the manufacturing process of encapsulated temperature sensors, in order to achieve

mechanical decoupling. In these cases, precautions should be taken not to expose the fibre to

corrosion, the so-called stress corrosion.

Depending on the measurement application, an FBG is pre-assembled in steel tubes, ceramic

tubes or other housings to form the complete FBG temperature sensor. The pre-assembly

usually includes gluing, screwing or fastening of the components. It is essential to achieve

optimal heat transfer (heat transition, heat conduction) to the temperature-sensing element,

which depends on both the mechanical and the thermal coupling.

Depending on the measurement task, the temperature sensor may contain a single FBG or a

chain of concatenated FBGs (sensor array). A single sensor arrangement allows local

(pointwise) measurement of temperature, whereas a chain of concatenated fibre Bragg

gratings (so-called quasi-distributed temperature sensors) allows measurement of

temperature profiles or temperatures at different locations on the object of measurement with

a single optical fibre sensor.

When several FBG sensors are concatenated with relatively long connecting fibre cables, the

transmission losses of the entire FBG temperature sensor shall be considered. When

specifying the transmission loss in the FBG temperature sensor, all loss contributions should

be determined, including attenuation in the optical fibre and in the FBG outside the FBG

spectrum as well as losses in connectors and splices. The signal amplitudes in the FBG

transmission spectrum can be reduced by application-specific effects impacting the sensor

quality. For example, transmission losses of serially operated wavelength-multiplexed FBG

temperature sensors should be considered separately.

5 Performance parameters

A single FBG temperature sensor shall be characterized by the following technical

performance parameters. Clause 7 describes the related test procedures to determine the

parameters:

– Bragg wavelength λ (7.2)

Bref

– FBG peak spectral width (7.3)

– FBG reflectivity (7.4)

=

– side-lobe suppression ratio (7.5)

– signal-to-noise ratio (7.6)

– characteristic curve (7.7)

– sensitivity (7.7.2)

– hysteresis (7.7.2)

– thermal time constant (7.8)

– response times (on request only) (7.8.2)

– sensor stability (7.9)

These performance parameters and additional technical information are needed for practical

applications and shall be provided by the manufacturer when referring to this document. A

blank detailed specification template is provided in Annex A.

6 Test apparatuses for performance parameter determination

6.1 Temperature calibration equipment

Suitable temperature calibration equipment shall be used for determining the performance

parameters and for calibrating an FBG temperature sensor. The principal options are

commercially available stirred liquid baths (up to approximately 550 °C) as well as block

calibrators or the specific temperature calibration equipment shown in Annex B. For higher

temperatures, tube furnaces are usually employed, whose limited thermal properties can be

appreciably improved through the use of so-called compensation bodies (metal inserts) or

heat pipes.

A temperature calibration bath is a uniform enclosure with a stirred fluid that can be adjusted

to various temperature test points. By using a stirred fluid (e.g. water, silicone oil, methanol,

ethanol), baths provide excellent thermal contact, uniformity, and stability for temperature

sensor calibration. They offer a large working volume and flexibility for calibrating temperature

sensors of different shapes and sizes. Typically, temperature calibration baths are equipped

with a reference thermometer for calibration traceability. Depending on the temperature

range, the fluids listed in Table 1 should be used for testing and calibration of FBG

temperature sensors.

Block calibrators use pre-drilled metal inserts for inserting the temperature sensor to be

calibrated. These block calibrators have a removable metal insert with pre-drilled holes where

sensors are inserted for measurement. The insert provides a stable temperature source,

which can be adjusted to different test points. In order to provide sufficiently good thermal

contact between the metal insert and the temperature sensor, inserts with different hole sizes

are available. Typically, block calibrators are equipped with a reference thermometer for

calibration traceability.

Table 1 – Calibration bath fluids

Temperature range Medium

−180 °C to −90 °C Refrigerant R13

−140 °C to 5 °C Pentane

−110 °C to 5 °C Alcohol

−90 °C to 10 °C Methanol

−40 °C to 60 °C Water/glycol mixture

+5 °C to 95 °C Water

−30 °C to 300 °C Silicon or mineral oil

– 16 – IEC 61757-2-1:2021 © IEC 2021

6.2 Optical spectrum analyzer and interrogator

A commercial high resolution optical spectrum analyzer or an optical spectrum analyzer

system specifically designed for FBG spectral analysis shall be used to perform

comprehensive spectral analysis. The minimum requirements for such a device are:

– spectral resolution ≤ 2 pm for a single FBG under test (≤ 1 pm for a chain of concatenated

FBGs under test)

– wavelength deviation ≤ ±5 pm

– dynamic range ≥ 40 dB

If the entire fibre optic temperature measurement system (FBG temperature sensor and

interrogator) is to be characterised, the tests should be carried out as far as possible with the

interrogator provided.

6.3 Broadband light source

A commercial off-the-shelf high quality amplified spontaneous emission (ASE) light source

designed for FBG spectrum analysis shall be used to perform comprehensive spectrum

analysis. The minimum requirements for such a device are:

– total output power: > +3 dBm (> 2 mW) at 840 nm to 853 nm and

> +10 dBm (> 10 mW) at 975 nm to 1 050 nm

– spectral power density: > -20 dBm/nm at 840 nm to 853 nm and

> -30 dBm/nm at 975 nm to 1 050 nm

– output power stability: < ±0,01 dB

7 Test procedures of performance parameters

7.1 Sample preparation and test set-up

The FBG temperature sensor to be tested shall be stored for at least a pre-determined

duration in a standard atmospheric environment of (23 ± 5) °C and (50 ± 10) % RH before the

test is started. The pre-determined duration should be decided according to the thermal

capacity of the optical fibre sensors to be tested. The sensor shall be installed in the

temperature calibration device according to the manufacturer’s instruc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...