IEC TR 62246-3:2018

(Main)Reed switches - Part 3: Reliability data for reed switch-devices in typical safety applications

Reed switches - Part 3: Reliability data for reed switch-devices in typical safety applications

IEC TR 62246-3:2018(E) provides basic technical background and experience about reliability data for reed switch-devices applied to machinery systems as well as E/E/PE safety-related control systems during the life cycle phases in general and industrial safety applications.

The document selects typical safety applications from group safety standards, and includes national safety standards and regulations accordingly. This document shows major reliability aspects for a proper design according to the standards, but it does not cover all details of an individual design. The responsibility for the verification of system design remains with the system integrator/manufacturer.

General Information

- Status

- Withdrawn

- Publication Date

- 20-Jun-2018

- Withdrawal Date

- 31-Oct-2023

- Technical Committee

- TC 94 - Electrical relays

- Drafting Committee

- WG 6 - TC 94/WG 6

- Current Stage

- WPUB - Publication withdrawn

- Start Date

- 01-Nov-2023

- Completion Date

- 01-Nov-2023

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC TR 62246-3:2018 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "Reed switches - Part 3: Reliability data for reed switch-devices in typical safety applications". This standard covers: IEC TR 62246-3:2018(E) provides basic technical background and experience about reliability data for reed switch-devices applied to machinery systems as well as E/E/PE safety-related control systems during the life cycle phases in general and industrial safety applications. The document selects typical safety applications from group safety standards, and includes national safety standards and regulations accordingly. This document shows major reliability aspects for a proper design according to the standards, but it does not cover all details of an individual design. The responsibility for the verification of system design remains with the system integrator/manufacturer.

IEC TR 62246-3:2018(E) provides basic technical background and experience about reliability data for reed switch-devices applied to machinery systems as well as E/E/PE safety-related control systems during the life cycle phases in general and industrial safety applications. The document selects typical safety applications from group safety standards, and includes national safety standards and regulations accordingly. This document shows major reliability aspects for a proper design according to the standards, but it does not cover all details of an individual design. The responsibility for the verification of system design remains with the system integrator/manufacturer.

IEC TR 62246-3:2018 is classified under the following ICS (International Classification for Standards) categories: 29.120.70 - Relays. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 62246-3:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TR 62246-3 ®

Edition 1.0 2018-06

TECHNICAL

REPORT

colour

inside

Reed switches –

Part 3: Reliability data for reed switch-devices in typical safety applications

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC TR 62246-3 ®

Edition 1.0 2018-06

TECHNICAL

REPORT

colour

inside

Reed switches –

Part 3: Reliability data for reed switch-devices in typical safety applications

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.120.70 ISBN 978-2-8322-5811-8

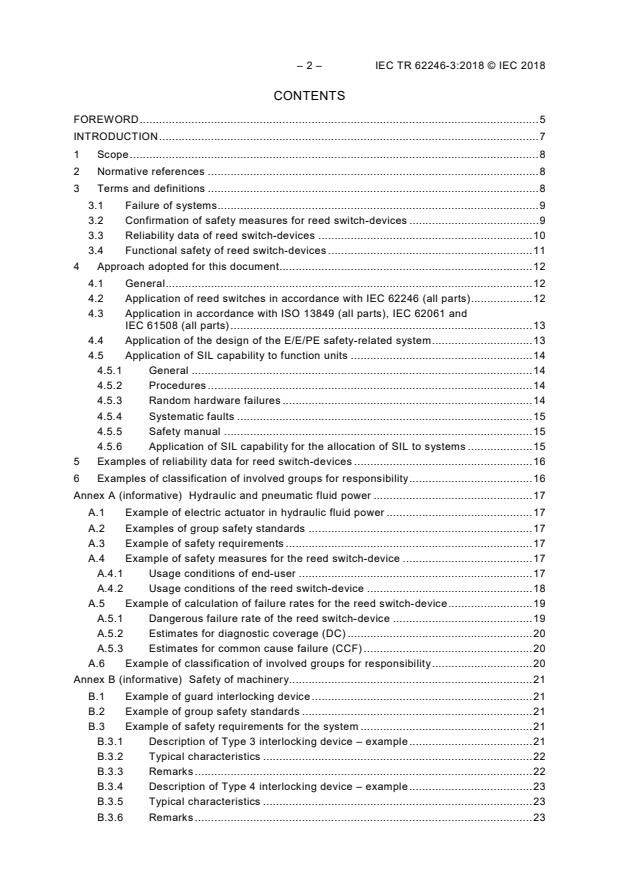

– 2 – IEC TR 62246-3:2018 © IEC 2018

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 8

3.1 Failure of systems . 9

3.2 Confirmation of safety measures for reed switch-devices . 9

3.3 Reliability data of reed switch-devices . 10

3.4 Functional safety of reed switch-devices . 11

4 Approach adopted for this document. 12

4.1 General . 12

4.2 Application of reed switches in accordance with IEC 62246 (all parts) . 12

4.3 Application in accordance with ISO 13849 (all parts), IEC 62061 and

IEC 61508 (all parts) . 13

4.4 Application of the design of the E/E/PE safety-related system . 13

4.5 Application of SIL capability to function units . 14

4.5.1 General . 14

4.5.2 Procedures . 14

4.5.3 Random hardware failures . 14

4.5.4 Systematic faults . 15

4.5.5 Safety manual . 15

4.5.6 Application of SIL capability for the allocation of SIL to systems . 15

5 Examples of reliability data for reed switch-devices . 16

6 Examples of classification of involved groups for responsibility . 16

Annex A (informative) Hydraulic and pneumatic fluid power . 17

A.1 Example of electric actuator in hydraulic fluid power . 17

A.2 Examples of group safety standards . 17

A.3 Example of safety requirements . 17

A.4 Example of safety measures for the reed switch-device . 17

A.4.1 Usage conditions of end-user . 17

A.4.2 Usage conditions of the reed switch-device . 18

A.5 Example of calculation of failure rates for the reed switch-device . 19

A.5.1 Dangerous failure rate of the reed switch-device . 19

A.5.2 Estimates for diagnostic coverage (DC) . 20

A.5.3 Estimates for common cause failure (CCF) . 20

A.6 Example of classification of involved groups for responsibility . 20

Annex B (informative) Safety of machinery. 21

B.1 Example of guard interlocking device . 21

B.2 Example of group safety standards . 21

B.3 Example of safety requirements for the system . 21

B.3.1 Description of Type 3 interlocking device – example . 21

B.3.2 Typical characteristics . 22

B.3.3 Remarks . 22

B.3.4 Description of Type 4 interlocking device – example . 23

B.3.5 Typical characteristics . 23

B.3.6 Remarks . 23

B.4 Example of safety measures for the reed switch-device . 23

B.4.1 Usage conditions of end-user . 23

B.4.2 Usage conditions of the reed switch-device . 24

B.5 Example of calculation of failure rates for the reed switch-device . 24

B.5.1 General . 24

B.5.2 Dangerous failure rate of reed switch-device . 24

B.5.3 Estimation for diagnostic coverage (DC) . 24

B.5.4 Estimates for common cause failure (CCF) . 24

B.6 Example of classification of involved groups for responsibility . 25

Annex C (informative) Automatic electrical controls for household and similar use . 26

C.1 Example of automatic electrical burner control system . 26

C.2 Examples of group safety standards . 26

C.3 Example of safety requirements for the system . 26

C.4 Example of safety measures for the reed switch-device . 27

C.4.1 Usage conditions of end-user . 27

C.4.2 Usage conditions of reed switch-device . 28

C.5 Example of calculation of failure rates for the reed switch-device . 28

C.5.1 Dangerous failure rate of reed switch-device . 28

C.5.2 Estimates for diagnostic coverage (DC) . 29

C.5.3 Estimates for common cause failure (CCF) . 29

C.5.4 Accident damage reduction . 29

C.6 Example of classification of involved groups for responsibility . 29

Annex D (informative) Household and similar electric appliances . 31

D.1 Example of automatic electric washing machine . 31

D.2 Examples of group safety standards . 31

D.3 Example of safety requirements for the system . 31

D.4 Example of safety measures for the reed switch-device . 31

D.4.1 Usage conditions of end-user . 31

D.4.2 Usage conditions of reed switch-device . 32

D.5 Example of calculation of failure rates for the reed switch-device . 33

D.5.1 Dangerous failure rate of reed switch-device . 33

D.5.2 Estimates for diagnostic coverage (DC) . 33

D.5.3 Estimation for common cause failure (CCF) . 33

D.6 Example of classification of involved groups for responsibility . 33

Annex E (informative) Electric power systems . 35

E.1 Example of measuring and protection relay system . 35

E.2 Industrial standards . 35

E.3 Safety requirements for the system – example . 35

E.4 Safety measures for the reed switch device – example . 35

E.4.1 Usage conditions of end-user . 35

E.4.2 Usage conditions of the reed switch-device . 36

E.5 Example of the calculation of failure rates for the reed switch-device . 37

E.6 Example of classification of involved groups for responsibility . 37

Annex F (informative) Railway application . 39

F.1 Example of automatic train control (ATC) system . 39

F.2 Examples of group safety standards . 39

F.3 Example of safety requirements for the system . 39

F.4 Example of safety measures for the reed switch-device . 39

– 4 – IEC TR 62246-3:2018 © IEC 2018

F.4.1 Usage conditions of end-user . 39

F.4.2 Usage conditions of the reed switch-device . 40

F.5 Example of calculation of failure rates for the reed switch-device . 41

F.6 Example of classification of involved groups for responsibility . 42

Bibliography . 43

Figure A.1 – Architecture of an electric actuator in hydraulic fluid power . 18

Figure A.2 – Control circuit of reed switches of magnetic proximity switches . 19

Figure A.3 – B value estimated by Weibull analysis . 19

Figure B.1 – Electric interlocking device with a proximity switch actuated by a magnet

actuator . 22

Figure B.2 – Electric interlocking device with two proximity switches . 22

Figure B.3 – Typical architecture of guard interlocking device . 23

Figure C.1 – Architecture of a microcomputer type gas meter . 27

Figure C.2 – Control circuit of a reed switch in flow sensor . 28

Figure C.3 – Accident occurrences and casualties by year (Japan) . 29

Figure D.1 – Architecture of an automatic electric washing machine . 32

Figure D.2 – Control circuit of a magnetic proximity switch. 33

Figure E.1 – Architecture of a measuring and protection relay system . 36

Figure E.2 – Control circuit of a reed switch in a measuring and protection relay . 37

Figure F.1 – Architecture of the automatic train control (ATC) system . 40

Figure F.2 – Control circuit of reed switches in the ATC system . 41

Table 1 – Diagnostic coverage (DC) . 10

Table 2 – Maximum allowable safety integrity level for a safety function carried out by

a type A safety-related element or subsystem . 13

Table 3 – Performance level . 13

Table 4 – Architectural constraints on subsystems: maximum SIL that can be claimed

for a safety-related control function (SRCF) using this subsystem . 14

Table A.1 – Possible sharing of responsibility on an electric actuator . 20

Table B.1 – Possible sharing of responsibility on a guard interlocking device . 25

Table C.1 – Detection methods and action in the event of emergency . 26

Table C.2 – Possible sharing of responsibility on microcomputer type gas meter . 30

Table D.1 – Possible sharing of responsibility on an automatic electric washing

machine . 34

Table E.1 – Failure rates of reed relays in a measuring and protection relay system . 37

Table E.2 – Possible sharing of responsibility on a measuring and protection relay

system . 38

Table F.1 – Field failure rates of reed relays in the ATC system . 41

Table F.2 – Possible sharing of responsibility on reed relays in the ATC system . 42

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

REED SWITCHES –

Part 3: Reliability data for reed switch-devices

in typical safety applications

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a technical report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC TR 62246-3, which is a Technical Report, has been prepared by IEC technical committee

94: All-or-nothing electrical relays.

The text of this Technical Report is based on the following documents:

Draft TR Report on voting

94/425/DTR 94/429/RVDTR

Full information on the voting for the approval of this Technical Report can be found in the

report on voting indicated in the above table.

– 6 – IEC TR 62246-3:2018 © IEC 2018

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62246 series, published under the general title Reed switches, can

be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

INTRODUCTION

This Technical Report:

– provides reliability data for reed switch-devices applied to machinery systems and also

E/E/PE systems;

– selects typical safety applications for reed switch-devices according to the requirements

from typical group safety standards;

– selects references, terms and definitions for machinery systems, E/E/PE systems and reed

switch-devices, lifecycle activities, safety integrity and performance level, failures and

safety measures for the reed switch-devices from typical group safety standards;

– addresses a way to share the responsibility on the components in the life cycle phases;

– addresses the application of IEC 62246 (all parts);

– considers the relation between safety requirements for the system from industrial

standards and basic safety measures for the reed switch-devices of a single E/E/PE

safety-related system and for two E/E/PE safety-related systems operating in:

• a low demand mode of operation,

• a high demand or continuous mode of operation.

– considers usage conditions at the end-user side:

• environmental conditions for reed switches’ use;

• proof test period;

• preventive maintenance.

– considers usage conditions at the E/E/PE system manufacturer side:

• switching load;

• failure mode;

• diagnostic coverage for reed switch-devices.

– considers usage conditions at the component manufacturer side:

– considers how to evaluate the risk of the reed switch-devices fault occurrence based on

the requirements from ISO 13849 (all parts), IEC 62061 and IEC 61508 (all parts):

– addresses a way to calculate reliability data of the reed switch-devices based on the

requirements from ISO 13849 (all parts), IEC 62061 and IEC 61508 (all parts)

– analyses dangerous failure rates, B values of the reed switch-devices according to the

10D

switching loads;

– calculates dangerous failure rates of the reed switch-devices based on usage rate per

year;

– considers long-term field demonstration tests and operating experiences of the systems.

– 8 – IEC TR 62246-3:2018 © IEC 2018

REED SWITCHES –

Part 3: Reliability data for reed switch-devices

in typical safety applications

1 Scope

This part of IEC 62246, which is a Technical Report, provides basic technical background and

experience about reliability data for reed switch-devices applied to machinery systems as well

as E/E/PE safety-related control systems during the life cycle phases in general and industrial

safety applications.

The document selects typical safety applications from group safety standards, and includes

national safety standards and regulations accordingly. This document shows major reliability

aspects for a proper design according to the standards, but it does not cover all details of an

individual design. The responsibility for the verification of system design remains with the

system integrator/manufacturer.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 61508 (all parts), Functional safety of electrical/electronic/programmable electronic

safety-related systems

IEC 62061:2005, Safety of machinery – Functional safety of safety-related electrical,

electronic and programmable electronic control systems

IEC 62061:2005/AMD1:2012

IEC 62061:2005/AMD2:2015

IEC 62246-1-1:2018, Reed switches – Part 1-1: Generic specification – Blank detail

specification

ISO 13849 (all parts), Safety of machinery – Safety-related parts of control systems

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 13849 (all parts),

IEC 62061, IEC 61508 (all parts), and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1 Failure of systems

3.1.1

average probability of failure on demand

PFD

avg

mean unavailability (see IEC 60050-191) of an E/E/PE safety-related system to perform the

specific safety function when a demand occurs from the EUC or EUC control system

Note 1 to entry: The mean unavailability over a given time interval [t1, t2] is generally noted by U (t1, t2).

Note 2 to entry: Two kind of failures contribute to PFD and PFD : the dangerous undetected failures that have

avg

occurred since the last proof test and genuine on demand failures caused by the demands (proof tests and safety

demands) themselves. The first one is time dependent and characterized by their dangerous failure rate λ (t)

DU

whilst the second one is dependent only on the number of demands and is characterized by a probability of failure

per demand (denoted by γ).

Note 3 to entry: As genuine on-demand failures cannot be detected by tests, it is necessary to identify them and

take them into consideration when calculating the target failure measures.

[SOURCE: IEC 61508-4:2010, 3.6.18]

3.1.2

probability of dangerous failure per hour

PFH

average probability of dangerous failure per hour in a safety-related control system or

subsystem

[SOURCE: IEC 61508-4:2010, 3.6.19, modified – Replacement of "of an E/E/PE safety

related system to perform the specified safety function over a given period of time" by " per

hour in a safety-related control system or subsystem" and deletion of the notes to entry.]

3.2 Confirmation of safety measures for reed switch-devices

3.2.1

proof test period

periodic test performed to detect failures in a reed switch-device so that, if necessary, the

reed switch-device can be restored to an “as new” condition or as close as practical to this

condition

Note 1 to entry: The effectiveness of the proof test will be dependent upon how close to the “as new” condition

the system is restored. For the proof test to be fully effective, it will be necessary to detect 100 % of all dangerous

failures. Although in practice 100 % is not easily achieved for other than low-complexity E/E/PE safety-related

systems, this is the target. As a minimum, all the safety functions which are executed are checked according to the

E/E/PE safety requirements specification. If separate channels are used, these tests are done for each channel

separately.

Note 2 to entry: The proof test is not always usable. For example, for reed relays in E/E/PE systems, functional

operating characteristics are confirmed according to the periodic proof tests by end-users.

[SOURCE: IEC 61508-4:2010, 3.8.5, modified – The term "proof test" has been replaced by

"proof test period" and the entire definition and notes to entry have been redrafted.]

3.2.2

diagnostic coverage

DC

fraction of dangerous failures detected by automatic on-line diagnostic tests

Note 1 to entry: The fraction of dangerous failures is computed by using the dangerous failure rate associated

with the detected dangerous failures divided by the total rate of dangerous failures

Note 2 to entry: The value of DC is given in four levels (see Table 1).

– 10 – IEC TR 62246-3:2018 © IEC 2018

Table 1 – Diagnostic coverage (DC)

DC

Denotation Range

None DC < 60 %

Low 60 % ≤ DC < 90 %

Medium 90 % ≤ DC < 99 %

High 99 % ≤ DC

NOTE The choice of the DC ranges is based on the key values 60 %, 90 % and 99 % also established in other

standards (e.g. IEC 61508 (all parts)) dealing with diagnostic coverage of tests. Investigations show that (1 –

DC) rather than DC itself is a characteristics measure for the effectiveness of the test. (1 – DC) for the key

values 60 %, 90 % and 99 % forms a kind of logarithmic scale fitting to the logarithmic PL-scale. A DC-value

less than 60 % has only slight effect on the reliability of the tested system and is therefore called “none”. A

DC-value greater than 99 % for complex systems is very hard to achieve. To be practicable, the number of

ranges was restricted to four. The indicated borders of this table are assumed within an accuracy of 5 %.

[SOURCE: ISO13849-1:2015, 4.5.3]

3.2.3

proven in use

demonstration, based on an analysis of operational experience for a specific configuration of

an element, that the likelihood of dangerous systematic faults is low enough so that every

safety function that uses the element achieves its required safety integrity level

Note 1 to entry: Field experience is one of the techniques and measures to avoid faults during E/E/PE system

integration and E/E/PE system safety validation. Field experience is referred to as “effectiveness low” in case of a)

and “effectiveness high” in case of b) respectively:

a) With no serious failure in terms of experience for at least one year, over at least ten pieces of equipment

with an operating time of 10 000 h, and different fields of use, 95 % of statistical correctness, and safety;

b) Detailed documentation of all changes (including minor changes) under experience for at least two years,

over at least ten pieces of equipment with an operating time of 10 million hours, and different fields of use,

99,9 % of statistical correctness, and past operation.

Note 2 to entry: "proven in use" is not always usable. For example, applications referred to in IEC 61508 (all

parts) are confirmed based on field feedback data.

[SOURCE: IEC 61508-4:2010, 3.8.18, modified – Addition of the notes to entry.]

3.2.4

common cause failure

CCF

failures of different items, resulting from a single event, where these failures are not

consequences of each other

Note 1 to entry: Common cause failures should not be confused with common mode failures (see

ISO 12100-1:2003, 3.34).

3.3 Reliability data of reed switch-devices

3.3.1

dangerous failure

failure of element and/or subsystem and/or system that plays a part in implementing the

safety function that:

a) prevents a safety function from operating when required (demand mode) or causes a

safety function to fail (continuous mode); or

b) decreases the probability that the safety function operates correctly when required

Note 1 to entry: For reed switch-devices, it means OFF failure (failure to open) in high demand mode of operation

or continuous mode of operation and ON failure (failure to close) in low demand mode of operation.

Note 2 to entry: For reed switch-devices, it means that the OFF-failure (failure to open) in the high demand or

continuous mode of operation and the ON-failure (failure to close) in the low demand mode of operation can be a

dangerous failure for the achievement of an invariable safe-state, and both of the OFF- and ON-failures can be a

dangerous failure for the achievement of an intrinsically variable safe-state.

Note 3 to entry: Invariable safe-state is the state of the overall system in which the safety control-system

concerned can be in one of the activated or inert state to achieve the safe state of the overall system, and the

intrinsically variable safe-state is the state of the overall system in which the safety control-system has to change

its own state from the activated to the inert or from the inert to the activated or both to achieve the safe state of the

overall system.

Note 4 to entry: Activated state is in the lower degree of disorder (i.e., the higher degree of order) and the inert

state is in the higher degree of disorder. The measure of disorder of a system is entropy that is also a measure of

the ”multiplicity” associated with the system state.

[SOURCE: IEC 61508-4:2010, 3.6.7, modified – Addition of the notes to entry.]

3.3.2

B value

10D

number of cycles until 10 % of the components have a dangerous failure

Note 1 to entry: The B value will be specified by the manufacturer of safety devices.

10D

[SOURCE: ISO 13849-1:2015, Table 1]

3.4 Functional safety of reed switch-devices

3.4.1

element safety function of reed switch-device

function to open and/or close as the input and output devices within the stated safety

accuracy in accordance with the following a) to c) applications:

a) the reed switch-device operating its element safety function to materialize an invariable

safe state;

b) the reed switch-device operating its element safety function to materialize an intrinsically

variable safe state;

c) the reed switch-device operating element safety functions to materialize reciprocally

variable safe states

Note 1 to entry: An OFF failure (failure to open) of the form A contact can be a safe failure, an ON failure (failure

to close) of the form A contact can be a dangerous failure, an OFF failure (failure to open) of the form B contact

can be a dangerous failure, and ON failure (failure to close) of the form B contact can be a safe failure regardless

of modes of operation.

Note 2 to entry: For example, a stationary machine is often a safe state for a machinery production system.

Note 3 to entry: All the failure modes of the form A and B contacts can be dangerous failure modes regardless of

modes of operation because the reed switch-device has to repeat to contact and open appropriately according to

circumstances.

Note 4 to entry: An automated steering gear for automobiles controls variable safe courses in accordance with

circumstances, i.e., a variable safe state to prevent collisions.

Note 5 to entry: Any failure mode of the form A and B contacts can be dangerous to one of the safe states but

safe to another safe state regardless of modes of operation because the safe states are mutually reciprocal, i.e., a

safe open state of contact that can be a dangerous state for another contact and a dangerous closed state of

contact that can be a safe state for another contact.

Note 6 to entry: For example, an explosion of air bags for automobiles is a safe situation when an auto crashes

but an unexpected explosion is a dangerous situation when the auto is running normally.

– 12 – IEC TR 62246-3:2018 © IEC 2018

3.4.2

SIL capability of function unit(s)

characteristic of a function unit(s) to which the capability of SIL 1, 2, 3 or 4 is allocated

Note 1 to entry: The allocation is done respectively under specified conditions and circumstances in accordance

with IEC 61508-2 and IEC 61508-3.

[SOURCE EC 60079-29-3:2014, 3.15, modified – Addition of “of function unit(s)” in the term.]

4 Approach adopted for this document

4.1 General

The approach adopted is to raise the following necessities.

In fields such as process industries, machine manufacturing industries, transportation,

general household electrical appliances applying reed switch-devices, there is a growing

demand for functional safety assessment (FSA).

Reed switch manufacturers should do some assessment of their final assembly (reed

switch-devices) and provide important reliability data relating to their reed switch-devices to

other product manufacturers, system integrators or users.

This document describes the process which should be applied in accordance with the

structure of the applications described in this document.

4.2 Application of reed switches in accordance with IEC 62246 (all parts)

When applying reed switches into the following specific products as switching elements, the

contact ratings are intended to be used in conjunction with IEC 62246-1-1:2018 unless

otherwise specified in the detail specifications:

a) reed relays:

electromechanical control circuit devices, consisting of reed switches and coil fitting into a

housing which could be plastic or metal (see IEC 61810-1:2015 and IEC 61811-1:2015);

b) reed switches for electromechanical control circuit devices, consisting of reed switches

and magnet actuator fitting into a housing which could be plastic or metal (see

IEC 60947-5-1:2016);

c) magnetic proximity switches:

electromechanical control circuit devices without external power supply, consisting of reed

switches and magnet actuator, either separated or in the same housing which could be

plastic or metal; they can detect the presence of magnetic objects without contact (see

IEC 60947-5-2:2007);

d) magnetic safety switches:

guard interlocking devices that are designed to protect both people and machines,

consisting of reed switches, overcurrent protection, non-coded or coded magnet actuator

in a separate housing which could be plastic or metal (see IEC 60947-5-3:2013 and

ISO 14119:2013);

e) reed sensors:

electromechanical control circuit devices built using reed switches with additional

functionalities such as the ability to withstand higher shock, easier mounting, additional

intelligent circuitry, etc. (see IEC 60947-5-9:2006).

EXAMPLE 1 Shock reed sensor: a ring magnet is mounted on a very precise tension spring and this assembly is

slid over a reed switch. Depending on the impact to trigger the reed switch, different tension springs are used.

EXAMPLE 2 Thermal reed sensor: a reed switch is enclosed in special ferrite compound which loses its magnetic

permeability at its Curie temperature, and is sandwiched between two permanent magnets.

EXAMPLE 3 Pressure reed sensor: a magnet actuator in mounted on a very precise tension spring and this

assembly is a distance away from a reed switch. Pressure drops cause the spring with attached magnet actuator to

move towards the reed switch, causing the contacts to close.

4.3 Application in accordance with ISO 13849 (all parts), IEC 62061 and IEC 61508 (all

parts)

Reed switch-device manufacturers should provide reliability data such as λ values when

D1

they are applied into machinery systems based on the requirements from ISO 13849-1 and

IEC 62061.

When applied into E/E/PE systems, where no application sector standard exists, they should

provide reliability data such as field failure rates: λ , λ and SFF based on the requirements

s D2

from IEC 61508 (all parts).

4.4 Application of the design of the E/E/PE safety-related system

The design of the E/E/PE safety-related system (including the overall hardware and software

architecture, sensors, programmable electronics, ASICs, embedded software, application

software, data, etc.), shall meet all of the following requirements (see Table 2, Table 3 and

Table 4).

For hardware safety integrity, these include:

– the architecture constraints on hardware safety integrity, and

– the requirements for quantifying the effect of random failures.

Table 2 – Maximum allowable safety integrity level for a safety function

carried out by a type A safety-related element or subsystem

Safety failure fraction of an element Hardware fault tolerance

0 1 2

< 60 % SIL 1 SIL 2 SIL 3

60 % to < 90 % SIL 2 SIL 3 SIL 4

90 % to < 99 % SIL 3 SIL 4 SIL 4

≥ 99 % SIL 3 SIL 4 SIL 4

NOTE 1 Refer to IEC 62061 which gives SIL3 max. and PL e and category 4, however when using IEC 61508

(all parts), it is possible to achieve SIL 4 only.

NOTE 2 This table is based on IEC 61508-2:2010, Table 2.

Table 3 – Performance level

PL Average probability of dangerous failure per hour [PFH ]

D

-5 -4

a ≥ 10 to < 10

-6 -5

b ≥ 3 × 10 to < 10

-6 -6

c ≥ 10 to < 3 × 10

-7 -6

d ≥ 10 to < 10

-8 -7

e ≥ 10 to < 10

NOTE This table is based on ISO 13849-1:2015, Table 3.

– 14 – IEC TR 62246-3:2018 © IEC 2018

Table 4 – Architectural constraints on subsystems: maximum SIL that can be claimed

for a safety-related control function (SRCF) using this subsystem

Hardware fault tolerance (see Note 1)

Safe failure fraction

0 1 2

< 60 % Not allowed (for SIL 1 SIL 2

exception see Note 3)

60 % to < 90 % SIL 1 SIL 2 SIL 3

90 % to < 99 % SIL 2 SIL 3 SIL 3 (see Note 2)

≥ 99 % SIL 3 SIL 3 (see Note 2) SIL 3 (see Note 2)

NOTE 1 A hardware fault tolerance of N means that N+1 faults could cause a loss of the safety-related control

function.

NOTE 2 A SIL 4 claim limit is not considered in this document. For SIL 4 see IEC 61508-1.

NOTE 3 See IEC 62061:2005 and IEC 62061:2005/AMD2:2015, 6.7.6.4 or for subsystems where fault

exclusions have been applied to faults that could lead to a dangerous failure, see IEC 62061:2005,

IEC 62061:2005/AMD1:2012 and IEC 62061:2005/AMD2:2015, 6.7.7.

NOTE 4 This table is based on IEC 62061:2005, Table 5.

4.5 Application of SIL capability to function units

4.5.1 General

The procedures to allocate SIL capability to function units of reed switch-devices are intended

to be specified based on the agreement between system and reed switch-devices

manufacturers for the realization of an E/E/PE safety-related system.

4.5.2 Procedures

The allocation of SIL capability to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...