IEC 62945:2018

(Main)Radiation protection instrumentation - Measuring the imaging performance of X-ray computed tomography (CT) security-screening systems

Radiation protection instrumentation - Measuring the imaging performance of X-ray computed tomography (CT) security-screening systems

IEC 62945:2018 provides test methods for the evaluation of image quality of computed tomography (CT) security-screening systems. The quality of data for automated analysis is the primary concern. Security screening systems are generally used to scan parcels, including luggage, for the presence of illicit items such as explosives, drugs, or other contraband. Many of the screening systems currently used, particularly in transportation security applications, are based on CT imaging technology.

Instrumentation pour la radioprotection - Mesure des performances d'imagerie des systèmes de contrôle de sécurité utilisant la tomographie par ordinateur (CT) à rayons X

L'IEC 62945:2018 fournit des méthodes d'essai pour l'évaluation de la qualité d'image des systèmes de contrôle de sécurité utilisant la tomographie par ordinateur (CT). La qualité des données aux fins des analyses automatisées constitue un enjeu majeur. Les systèmes de contrôle de sécurité sont généralement utilisés pour analyser des colis, notamment des bagages, en vue de détecter la présence d'articles illicites, tels que des explosifs, des drogues ou d'autres produits de contrebande. Un grand nombre des systèmes de contrôle actuellement utilisés, en particulier dans les applications de sécurité dans le domaine du transport, reposent sur la technologie d'imagerie CT.

General Information

- Status

- Published

- Publication Date

- 11-Sep-2018

- Technical Committee

- SC 45B - Radiation protection instrumentation

- Drafting Committee

- WG 17 - TC 45/SC 45B/WG 17

- Current Stage

- PPUB - Publication issued

- Start Date

- 12-Sep-2018

- Completion Date

- 31-Aug-2018

Overview

IEC 62945:2018 is an international standard published by the International Electrotechnical Commission (IEC) that focuses on radiation protection instrumentation specifically for evaluating the imaging performance of X-ray computed tomography (CT) security-screening systems. These systems are widely employed in security contexts to scan parcels, luggage, and other items to detect illicit materials such as explosives, drugs, and contraband. The standard defines comprehensive test methods aimed at assessing the quality of CT imaging data, emphasizing data suitability for automated analysis.

This standard addresses the need for uniform evaluation procedures to ensure reliable and consistent image quality in CT-based security screening, supporting efforts to enhance safety and effectiveness in transportation security and other applications.

Key Topics

Imaging Performance Evaluation

IEC 62945:2018 details rigorous test methods for evaluating multiple aspects of CT imaging quality including:

- Object length accuracy: Ensures accurate measurement of imaged object's dimensions.

- Path-length CT value and effective atomic number (Z_eff): Assesses the system's ability to distinguish materials based on X-ray attenuation.

- Noise Equivalent Quanta (NEQ): Measures imaging noise characteristics affecting image clarity.

- CT value consistency and uniformity: Evaluates stability and uniform distribution of CT values across images.

- X-ray energy spectrum consistency: Confirms the stability of the energy spectrum affecting material discrimination.

- Artifact assessment: Identifies and quantifies streak artifacts impacting image interpretability.

- Slice Sensitivity Profile (SSP): Measures the system’s spatial resolution in the slice direction.

- Image registration: Assesses accuracy in spatial alignment of scanned images.

Test Articles and Procedures

The standard prescribes detailed test articles with explicit design and construction criteria, including phantoms and specially designed objects to simulate real scanning conditions. It includes guidance on:

- Test article assembly and component specifications.

- Manual data recording formats and environmental measurement requirements.

- Presentation guidelines and statistical data analysis for reporting results.

Environmental and Operational Conditions

To maintain reliability and reproducibility, the standard defines environmental conditions and system configurations for testing, ensuring results are consistent across varied setups and evaluators.

Applications

IEC 62945:2018 is crucial for:

- Manufacturers of CT security-screening systems who require a benchmark to validate and improve imaging performance during development and quality control.

- Security agencies deploying CT scanners at airports, border crossings, courthouses, or other sensitive locations where non-invasive, high-performance screening is necessary.

- Regulatory bodies tasked with certification and compliance audits of screening technologies.

- Research and development teams focusing on enhancing automated threat detection through improved image quality metrics.

By implementing the test methods detailed in this standard, stakeholders can ensure that CT security-screening systems provide accurate, reliable, and reproducible imagery that supports effective threat detection and radiation safety.

Related Standards

IEC 62945:2018 complements other international standards related to radiation safety and imaging system performance, including:

- IEC 60601 series – Requirements for electrical medical equipment safety, applicable to X-ray devices.

- IEC 61223 – Evaluation and routine testing in medical imaging, which includes aspects relevant to CT image quality.

- ISO/IEC 27037 – For management and acquisition of digital evidence, potentially intersecting with digital security screening.

- Additional IEC standards on radiation protection instrumentation and general CT imaging system performance.

Adherence to IEC 62945:2018 helps harmonize global practices in CT security-screening system testing, embedding radiation protection principles and advanced imaging performance metrics into the security technology lifecycle.

Keywords: IEC 62945, X-ray computed tomography, CT security-screening, imaging performance evaluation, radiation protection instrumentation, CT image quality test methods, security screening systems, noise equivalent quanta, artifact assessment, slice sensitivity profile, image registration, automated threat detection.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

IEC 62945:2018 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Radiation protection instrumentation - Measuring the imaging performance of X-ray computed tomography (CT) security-screening systems". This standard covers: IEC 62945:2018 provides test methods for the evaluation of image quality of computed tomography (CT) security-screening systems. The quality of data for automated analysis is the primary concern. Security screening systems are generally used to scan parcels, including luggage, for the presence of illicit items such as explosives, drugs, or other contraband. Many of the screening systems currently used, particularly in transportation security applications, are based on CT imaging technology.

IEC 62945:2018 provides test methods for the evaluation of image quality of computed tomography (CT) security-screening systems. The quality of data for automated analysis is the primary concern. Security screening systems are generally used to scan parcels, including luggage, for the presence of illicit items such as explosives, drugs, or other contraband. Many of the screening systems currently used, particularly in transportation security applications, are based on CT imaging technology.

IEC 62945:2018 is classified under the following ICS (International Classification for Standards) categories: 13.280 - Radiation protection. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62945:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62945 ®

Edition 1.0 2018-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Radiation protection instrumentation – Measuring the imaging performance of

X-ray computed tomography (CT) security-screening systems

Instrumentation pour la radioprotection – Mesure des performances d'imagerie

des systèmes de contrôle de sécurité utilisant la tomographie par ordinateur

(CT) à rayons X

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 21 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 16

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC -

Glossaire IEC - std.iec.ch/glossary

webstore.iec.ch/advsearchform

67 000 entrées terminologiques électrotechniques, en anglais

La recherche avancée permet de trouver des publications IEC et en français, extraites des articles Termes et Définitions des

en utilisant différents critères (numéro de référence, texte, publications IEC parues depuis 2002. Plus certaines entrées

comité d’études,…). Elle donne aussi des informations sur les antérieures extraites des publications des CE 37, 77, 86 et

projets et les publications remplacées ou retirées. CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just Si vous désirez nous donner des commentaires sur cette

Published détaille les nouvelles publications parues. publication ou si vous avez des questions contactez-nous:

Disponible en ligne et aussi une fois par mois par email. sales@iec.ch.

IEC 62945 ®

Edition 1.0 2018-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Radiation protection instrumentation – Measuring the imaging performance of

X-ray computed tomography (CT) security-screening systems

Instrumentation pour la radioprotection – Mesure des performances d'imagerie

des systèmes de contrôle de sécurité utilisant la tomographie par ordinateur

(CT) à rayons X

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 13.280 ISBN 978-2-8322-6025-8

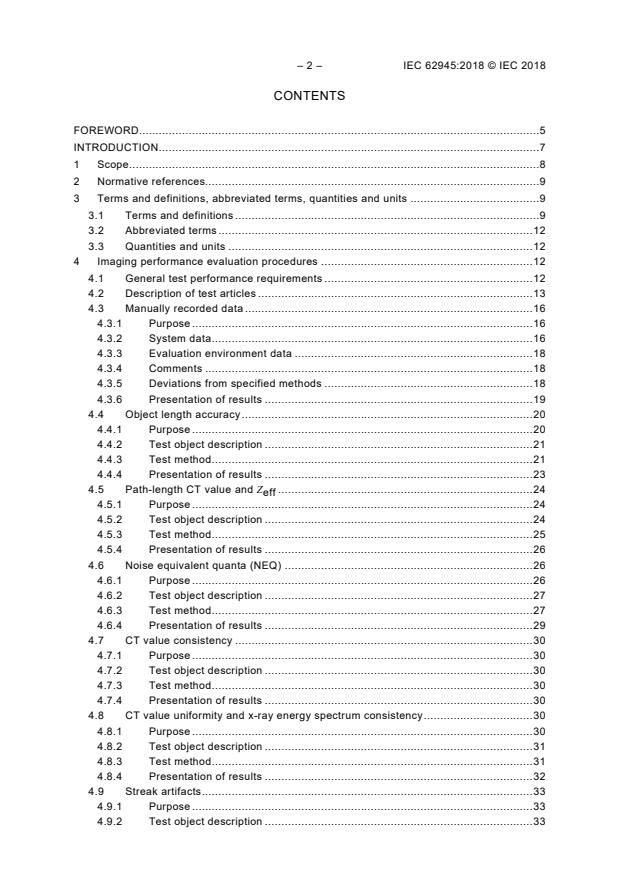

– 2 – IEC 62945:2018 © IEC 2018

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references. 9

3 Terms and definitions, abbreviated terms, quantities and units . 9

3.1 Terms and definitions . 9

3.2 Abbreviated terms . 12

3.3 Quantities and units . 12

4 Imaging performance evaluation procedures . 12

4.1 General test performance requirements . 12

4.2 Description of test articles . 13

4.3 Manually recorded data . 16

4.3.1 Purpose . 16

4.3.2 System data . 16

4.3.3 Evaluation environment data . 18

4.3.4 Comments . 18

4.3.5 Deviations from specified methods . 18

4.3.6 Presentation of results . 19

4.4 Object length accuracy . 20

4.4.1 Purpose . 20

4.4.2 Test object description . 21

4.4.3 Test method . 21

4.4.4 Presentation of results . 23

4.5 Path-length CT value and Z . 24

eff

4.5.1 Purpose . 24

4.5.2 Test object description . 24

4.5.3 Test method . 25

4.5.4 Presentation of results . 26

4.6 Noise equivalent quanta (NEQ) . 26

4.6.1 Purpose . 26

4.6.2 Test object description . 27

4.6.3 Test method . 27

4.6.4 Presentation of results . 29

4.7 CT value consistency . 30

4.7.1 Purpose . 30

4.7.2 Test object description . 30

4.7.3 Test method . 30

4.7.4 Presentation of results . 30

4.8 CT value uniformity and x-ray energy spectrum consistency . 30

4.8.1 Purpose . 30

4.8.2 Test object description . 31

4.8.3 Test method . 31

4.8.4 Presentation of results . 32

4.9 Streak artifacts . 33

4.9.1 Purpose . 33

4.9.2 Test object description . 33

4.9.3 Test method . 33

4.9.4 Presentation of results . 34

4.10 Slice sensitivity profile (SSP) . 35

4.10.1 Purpose . 35

4.10.2 Test object description . 35

4.10.3 Test method . 35

4.10.4 Presentation of results . 36

4.11 Image registration . 36

4.11.1 Purpose . 36

4.11.2 Test object description . 36

4.11.3 Test method . 37

4.11.4 Presentation of results . 40

5 Environmental requirements. 40

Annex A (normative) Detailed test article specifications and drawings . 41

A.1 General . 41

A.2 Commercial parts . 41

A.3 Outer enclosure . 41

A.4 Detailed drawings of custom components . 42

Annex B (informative) Example of reporting format . 66

B.1 General . 66

B.2 Example report . 66

Annex C (informative) Statistical guidance on multiple scans, summary statistics, and

comparison of results . 70

C.1 General . 70

C.2 Scenario A: Comparing a single CT system between its baseline and

candidate (revised) configuration . 70

C.3 Scenario B: Comparing a single (candidate) system against an existing

historical population of systems . 71

Bibliography . 72

Figure 1 – Reference axes for testing procedures . 13

Figure 2 – Test article A . 14

Figure 3 – Test article B . 15

Figure 4 – Format example for manually recorded data . 20

Figure 5 – Object length test object . 21

Figure 6 – Output from object length procedure when test article is submitted within

angular tolerance . 24

Figure 7 – Output from object length procedure when test article rotation is outside of

angular tolerance . 24

Figure 8 – Path-length test object . 25

Figure 9 – Example plot of path-length test results . 26

Figure 10 – NEQ test object . 27

Figure 11 – Z uniformity test object and streak artifact test object . 31

Figure 12 – Pins in test object axial slice (large circle), midpoints between neighboring

pin pairs (small circles), traced line, and rectangular ROI. 33

Figure 13 – Slanted edge test object used to measure z resolution . 35

Figure 14 – Registration test object (not to scale) . 37

– 4 – IEC 62945:2018 © IEC 2018

Figure 15 – CT image of registration test object, slice plane 1 . 38

Figure 16 – Horizontal line profile through CT slice of the registration test object . 38

Figure 17 – Projection image of the registration test object and vertical profile through

image . 39

Figure A.1 – Assembly of Case A test article . 43

Figure A.2 – Assembly of Case B test article . 44

Figure A.3 – Test component sub-assembly of Case A test article (drawing 1 of 2) . 45

Figure A.4 – Test component sub-assembly, Case A test article (drawing 2 of 2) . 46

Figure A.5 – Test component sub-assembly, Case B test article (drawing 1 of 2) . 47

Figure A.6 – Test component sub-assembly, Case B test article (drawing 2 of 2) . 48

Figure A.7 – Sub-components for Case A cylinder test object . 49

Figure A.8 – Ring sub-components for Case A cylinder test object . 50

Figure A.9 – Pin sub-components for Case A cylinder test object (streak artifacts) . 51

Figure A.10 – Al sub-component for image registration test object, Case A . 52

Figure A.11 – POM sub-components for image registration test object, Case A . 53

Figure A.12 – Cylinder test object (NEQ and CT value consistency), Case B . 54

Figure A.13 – Object length test object, Cases A and B . 55

Figure A.14 – Path length test object, Case A . 56

Figure A.15 – SSP test object, Case B . 57

Figure A.16 – Partition panel for component support, Cases A and B (drawing 1 of 4) . 58

Figure A.17 – Partition panel for component support, Case A (drawing 2 of 4) . 59

Figure A.18 – Partition panel for component support, Case B (drawing 3 of 4) . 60

Figure A.19 – Partition panel for component support, Case B (drawing 4 of 4) . 61

Figure A.20 – Component support rods, Cases A and B . 62

Figure A.21 – Assembly washers, Cases A and B . 63

Figure A.22 – Sub-assembly for Case A cylinder test object . 64

Figure A.23 – Sub-assembly for Case A image registration test object . 65

Table 1 – List of test methods and indicators measured . 16

Table 2 – NEQ procedure results . 29

Table 3 – CT value uniformity results . 32

Table 4 – Streak artifact procedure results . 34

Table 5 – SSP procedure results . 36

Table A.1 – Commercial foils required for fabrication of CT value uniformity and x-ray

energy spectrum consistency test object (4.8) . 41

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

RADIATION PROTECTION INSTRUMENTATION –

MEASURING THE IMAGING PERFORMANCE OF X-RAY

COMPUTED TOMOGRAPHY (CT) SECURITY-SCREENING SYSTEMS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62945 has been prepared by subcommittee 45B: Radiation

protection instrumentation, of IEC technical committee 45: Nuclear instrumentation.

The text of this International Standard is based on the following documents:

FDIS Report on voting

45B/908/FDIS 45B/910/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 6 – IEC 62945:2018 © IEC 2018

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

INTRODUCTION

This document establishes standard test methods and test objects for measuring the imaging

performance of x-ray computed tomography (CT) security-screening systems. The quality of

data for automated analysis is the primary concern. This document does not address the

system’s ability to use its image data to automatically detect explosives or other threat

materials, which is typically verified by an appropriate regulatory body.

Three annexes are included. Annex A (normative) provides mechanical drawings of the

imaging test objects that compose the test article. A sample test report form is given in Annex

B (informative). Annex C (informative) offers statistical guidance on multiple scans, summary

statistics, and comparison of results. Finally, a bibliography is given (informative).

– 8 – IEC 62945:2018 © IEC 2018

RADIATION PROTECTION INSTRUMENTATION –

MEASURING THE IMAGING PERFORMANCE OF X-RAY

COMPUTED TOMOGRAPHY (CT) SECURITY-SCREENING SYSTEMS

1 Scope

This document provides test methods for the evaluation of image quality of computed

tomography (CT) security-screening systems. The quality of data for automated analysis is

the primary concern. This document does not address the system’s ability to use this image

data to automatically detect explosives or other threat materials, nor is it intended for vendor-

to-vendor comparisons of threat-detection performance.

Security screening systems are generally used to scan parcels, including luggage, for the

presence of illicit items such as explosives, drugs, or other contraband. Many of the screening

systems currently used, particularly in transportation security applications, are based on CT

imaging technology. Generally, as the parcel is transported through the system, the system

collects a CT image of the parcel. These data are then subjected to automated analysis to

determine whether a threat may be present or the parcel is considered clear. If the automated

analysis determines a threat may be present, the image is often presented to a system

operator who can override the automated decision, clearing the parcel, or referring it for

further processing such as opening it and manually searching for threats.

Historically, government regulators have established evaluation procedures to determine

whether a system’s automated detection performance is adequate for use in applications

within their borders. Typically, a vendor submits a copy of their product, including their

software to the regulator’s facility. The regulator runs a wide variety of parcels with threats

inside through the system as well as parcels without threats that represent the typical stream

of commerce. Detection and false alarm rates are determined and compared against

performance criteria. If the criteria are met, the system is approved for use. This testing

ensures that the system is capable of meeting the required criteria, but how does one ensure

that all copies of the system meet the criteria? Normal manufacturing variability, quality

control issues, or aging of the equipment may degrade performance versus what was

observed on the article tested by the regulator. Replicating the original test on each machine

in question is impractical. Transporting the regulator’s threat set to a factory site or to

locations where the machines are in use presents significant security and in some cases

safety concerns. This document seeks to address this issue by specifying a suite of test

methods that can be carried out on site without need for hazardous materials.

The performance testing carried out by the regulators essentially evaluates the combination of

the system’s ability to produce an image of the parcel along with its automatic analysis of that

image data to reach a decision of threat or clear. The second part of this sequence, the

analysis, is implemented through software. Regulators generally require that this software be

designed so as to not evolve through use. The software used at all locations in the field must

perform the same as the software did at the time of evaluation by the regulator. Configuration

management of such software is a well-known and straightforward art. Therefore, the real

opportunity for performance variation comes from the imaging system that provides the data

to the analysis software. If one can quantitatively validate that the quality of the image

produced by the system in question is statistically equivalent to the image produced by the

article evaluated by the regulator, one can be highly confident that the performance of the

system in question is the same as what was approved by the regulator.

Purchasers of CT systems for security screening applications are generally not CT experts.

Inconsistencies in methods for measuring seemingly standard image quality values (resolution,

signal-to-noise, etc.) can confuse the potential user of such CT systems. Other standards

exist for testing aspects of CT image quality, particularly in the medical field. This document

specifies a set of methods to apply in assessing CT image quality geared towards security

screening. An application of this document would be in the factory acceptance testing of

equipment. The document could be used to indicate whether the unit offered for sale

produces the equivalent image quality as the unit that was tested by the cognizant regulatory

agency. Since various image quality metrics can be traded off against one another and

achieve similar levels of threat detection, it is generally not valid, in contrast to medical CT, to

make model-to-model or manufacturer-to-manufacturer comparisons of individual test results

for CT systems used for security-screening.

This document does not address image quality presented to the operator. The image quality

provided to the operator is not necessarily at the same level as that used by the automated

analysis. The data may be degraded before presenting to the operator to decrease resources

required for rendering the image on the screen. Conversely, the data used in the automated

analysis may be intentionally degraded to control the computational loading of the analysis

computer. The user of this document may want to separately assess the quality of the images

presented to the system’s operator. A wide range of methods is available for this purpose

including the use of visual line pair gauges and ASTM F792 [1].

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60050-395:2014, International Electrotechnical Vocabulary – Part 395: Nuclear

instrumentation: Physical phenomena, basic concepts, instruments, systems, equipment and

detectors

IEC 60050-881, International Electrotechnical Vocabulary. Radiology and radiological physics

ASTM E1695, Standard Test Method for Measurement of Computed Tomography (CT) System

Performance

ASTM publications are available from the ASTM International, 100 Barr Harbor Drive, West Conshohocken, PA

19428-2959, USA (http://www.astm.org/).

ASTM D6100, Standard Specification for Extruded, Compression Molded and Injection Molded

Polyoxymethylene Shapes (POM)

SAE AMS 4027: Aluminum Alloy, Sheet and Plate, 1.0Mg – 0.60Si – 0.28Cu – 0.20Cr (6061; -

T6 Sheet, -T651 Plate), Solution and Precipitation Heat Treated

SAE AMS 4117: Aluminum Alloy, Rolled or Cold Finished Bars, Rods, and Wire and Flash

Welded Rings, 1.0Mg – 0.60Si – 0.28Cu – 0.20Cr, (6061; -T6, -T651), Solution and

Precipitation Heat Treated

3 Terms and definitions, abbreviated terms, quantities and units

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply. The general

terminology concerning x-ray systems and radiological physics is given in IEC 60050-395 and

IEC 60050-881.

___________

Numbers in square brackets refer to the Bibliography.

– 10 – IEC 62945:2018 © IEC 2018

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1.1

computed tomography

CT

process of rendering a three-dimensional image of a volume based on x-ray projection data

3.1.2

CT value

value reported by CT systems on a per voxel basis that is a function of the material’s density

and atomic number

3.1.3

coronal image

two-dimensional image produced by summing a three-dimensional volume image along the y-

axis

Note 1 to entry: Axes defined in Figure 1.

3.1.4

effective atomic number

Z

eff

material property that represents the atomic number of a theoretical element that, if the

material were replaced by the element, would produce the same x-ray attenuation

characteristics

Note 1 to entry: Z measurements can be scanner-dependent and should not be considered absolute values.

eff

3.1.5

mean

for n quantities, x , x , … x , the quotient of the sum of the quantities by n:

1 2 n

𝑛𝑛

𝑥𝑥̅= � 𝑥𝑥

𝑖𝑖

𝑛𝑛

𝑖𝑖=1

3.1.6

modulation transfer function

MTF

frequency-dependent measure of an imaging system’s resolution or ability to reproduce object

contrast. In one dimension it is computed from the system's response to an edge of high

contrast using ASTM E1695

3.1.7

multi-energy

x-ray imaging system that collects image data at more than one x-ray energy spectrum

Note 1 to entry: This can be accomplished, for example, by varying the x-ray tube voltage, using an energy

discriminating detector, or using multiple sets of detectors with differing energy response.

3.1.8

noise equivalent quanta

NEQ

spatial-frequency-dependent measure of noise, interpreted as the number of quanta (radiation

exposure) that an ideal detector would have needed to yield the same signal-to-noise ratio as

an actual imaging system. It is computed from measurements of average CT value in an

imaged object, the system’s modulation transfer function and noise power spectrum

3.1.9

noise power spectrum

NPS

spatial-frequency-dependent variance of an imaging system’s noise, computed using the

Fourier transform of uniform noise-limited images

3.1.10

projection image

x-ray image created by detecting the x-ray intensity transmitted through the subject, resulting

in an image in which all the subject’s components appear to be projected onto a single image

plane

3.1.11

registration

spatial relationship between the coordinate systems of multiple imaging subsystems. It

determines the ability to accurately correlate observations from one image to the others

3.1.12

slice

cross-sectional image of the inspected object

Note 1 to entry: The normal of the plane of the image is in the direction of the conveyer belt motion (z axis).

3.1.13

slice sensitivity profile

SSP

frequency-dependent measure of CT image resolution along the direction of the conveyer belt

motion (z axis)

3.1.14

standard deviation

sample standard deviation, σ , of n quantities, x , x , … x given by:

n 1 2 n

𝑛𝑛 2

𝜎𝜎 = � ∑ (𝑥𝑥 −𝑥𝑥̅) where 𝑥𝑥̅ is given by 3.1.5

𝑛𝑛 𝑖𝑖

𝑖𝑖=1

𝑛𝑛−1

3.1.15

standard mode of operation

mode of operation normally recommended by the manufacturer for inspection of parcels

Note 1 to entry: Some systems have special modes for collecting extra data for training. This would not be

considered a standard mode of operation.

3.1.16

test article

item, to be imaged by the system, containing multiple test objects in a specific geometric

layout

Note 1 to entry: As used in this document, test article refers to the specific items defined in 4.2.

– 12 – IEC 62945:2018 © IEC 2018

3.1.17

test object

individual object having specific properties (size, shape, materials, etc.) that when imaged by

the system allows a certain image quality evaluation to be carried out

3.1.18

voxel

volume element representing a rectangular prism-shaped region in space within a volumetric

image

3.2 Abbreviated terms

CT computed tomography

MTF modulation transfer function

NEQ noise equivalent quanta

NPS noise power spectrum

POM polyoxymethylene

NOTE POM is the acetal copolymer (CH O) of which the test objects of this document are fabricated.

2 n

ROI region of interest (in an image)

SNR signal-to-noise ratio

SSP slice sensitivity profile

3.3 Quantities and units

In this document, the units are the multiples and sub-multiples of units of the International

System of Units (SI) [2]. The definitions of radiation quantities are given in

IEC 60050-395:2014.

The following units may also be used:

–19

• for energy: electron-volt (symbol: eV), 1 eV = 1,602 x 10 J;

• for time: years (symbol: y), days (symbol: d), hours (symbol: h), minutes (symbol: min):

• for temperature: degrees Celsius (symbol: ºC), 0 ºC = 273,15 K.

Multiples and submultiples of SI units are used, when practicable, according to the SI system.

4 Imaging performance evaluation procedures

4.1 General test performance requirements

System components and adjustments should be as for the standard commercial product in

normal security screening operation mode; any deviations shall be noted by the evaluators in

the manually recorded data. If the system is approved to operate under more than one

configuration, the user may want to request the test be carried out at all appropriate settings.

Evaluation is to be based on images or other data normally used in standard mode of

operation. The exposure time and level shall be chosen as that used when the CT system is

operated for the intended use in the security screening application. A calibration of the CT

system shall be carried out prior to any testing. Any recalibration of the CT system shall be

allowed according to the standard operation of the system. In order to ensure that the system

is using a configuration approved by the appropriate regulatory agency, the user may wish to

request that the vendor provide the specific settings used during the evaluation such as: tube

voltage(s), amperage, voxel size, belt speed, etc. Changes in CT image reconstruction

software should be followed by gathering a new baseline measurement set. Alternatively, new

baseline results may be recomputed offline if the data are available.

The test articles (see 4.2) shall be presented to the system in a controlled position and

orientation. The main axis of each test article should be parallel to the conveyor belt motion

direction and the front of the article shall enter the system first (front designated via labeling).

The test method described in 6.3 determines the angle of rotation and side to side offset of

the test articles relative to the centerline of the system conveyor. Results for rotations more

than 2 degrees off parallel from conveyor centerline shall be rejected. This document requires

that the test articles be measured at the center of the belt, directly on the belt, within ± 2 cm

of the conveyor centerline. If the user decides to also run the test articles off centerline, the

parallel requirement shall still be met, and the data shall be segregated and treated

separately.

For reference, Figure 1 shows the coordinate system that shall be used for all procedure

descriptions. The z axis is aligned along the direction of the conveyor motion. The y axis is in

the vertical direction and the x axis is across the belt. The positive/negative direction of the

axis system is immaterial as used in this document.

Not all the methods stated are applicable to all CT systems. Each method shall identify

whether it is applicable to all CT types or only a subset.

Each of the test methods specified in this document can include required procedures and

examples of optional techniques for achieving the required results. This is necessary because

of the range of implementations used in security CT equipment. Each test method identifies

where latitude for deviation from the analysis techniques exists. Any deviation from provided

example techniques shall be documented including rationale for deviating from the suggested

standard method of analysis. Such documentation shall be provided to the end user of the

image quality evaluation.

Y

X

Z

IEC

Figure 1 – Reference axes for testing procedures

4.2 Description of test articles

Execution of this document requires two test articles. They are designated “test article A” and

“test article B,” and are represented in Figure 2 and Figure 3. The articles consist of several

test objects supported in a machined frame within a commercial or custom-built carrying case.

– 14 – IEC 62945:2018 © IEC 2018

The placement of the test objects has been selected to minimize artifacts from one test object

interfering with the image of another test object.

When fabricating test articles for use in this document, the test objects and the supporting

structural frame shall be built in accordance with the detailed drawing package included in

Annex B. The outer case should be selected for durability. It shall be large enough to contain

the specified support structure. If commercial encasements are used, they may need to be

modified to remove any metal structures (hinges, handles, fasteners, etc.) from the sides, top

and bottom. Removing structures on the front and back surfaces (facing the z direction) is

optional. If a commercial case is used, it shall be modified to remove any significant plastic

structure along the sides, top, and bottom that might interfere with the imaging of the test

object. Comparison of testing results, across time for example,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...