IEC 60793-1-20:2014

(Main)Optical fibres - Part 1-20: Measurement methods and test procedures - Fibre geometry

Optical fibres - Part 1-20: Measurement methods and test procedures - Fibre geometry

IEC 60793-1-20:2014 establishes uniform requirements for measuring the geometrical characteristics of uncoated optical fibres. The geometry of uncoated optical fibres directly affect splicing, connectorization and cabling and so are fundamental parameters requiring careful specification, quality control, and thus measurement. This second edition cancels and replaces the first edition, published in 2001, and constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

- the reference test method for all fibre types is changed to the video grey scale transmitted near field method from the refracted near field method;

- the test lengths for all fibre types are now to be specified in the fibre's detail specification;

- the core illumination wavelength for all multimode fibre types may now to be specified in the fibre's detail specification although defaults are given;

- the core k-factor (decision level) is now to be specified in the detail specification for all multimode fibre types;

- this edition is substantially more specific in describing the measurement;

- data reduction and transformation is fully described;

- the data reduction methodology for both refracted near-field and transmitted near-field methods are now unified and consistent. Keywords: measuring the geometrical characteristics of uncoated optical fibres The contents of the corrigendum of March 2016 have been included in this copy.

Fibres optiques - Partie 1-20: Méthodes de mesure et procédures d'essai - Géométrie de la fibre

L'IEC 60793-1-20:2014 établit des exigences uniformes pour mesurer les caractéristiques géométriques des fibres optiques nues. La géométrie des fibres optiques nues affecte directement l'épissurage, le montage des connecteurs (connectorisation) et le câblage et est donc un paramètre fondamental nécessitant une spécification minutieuse, un contrôle qualité et par la même, des mesures. Cette deuxième édition annule et remplace la première édition, publiée en 2001, dont elle constitue une révision technique. Cette édition contient les modifications techniques principales suivantes par rapport à l'édition précédente:

- la méthode d'essai de référence pour tous les types de fibres est modifiée de la méthode du champ proche réfracté à la méthode du champ proche transmis sur vidéo en niveaux de gris;

- les longueurs d'essai de tous les types de fibres doivent désormais être spécifiées dans la spécification particulière de la fibre;

- bien que des valeurs par défaut soient données, la longueur d'onde d'illumination du coeur pour tous les types de fibres multimodales peut désormais être spécifiée dans la spécification particulière de la fibre;

- le facteur k appliqué sur le coeur (niveau de décision) doit maintenant être spécifié dans la spécification particulière pour tous les types de fibres multimodales;

- la présente édition décrit le mesurage de manière bien plus spécifique;

- la réduction et la transformation des données sont décrites de manière exhaustive;

- la méthodologie de réduction des données pour la méthode du champ proche réfracté et pour la méthode du champ proche transmis est maintenant unifiée et cohérente. Mots clés: mesurer les caractéristiques géométriques des fibres optiques nues Le contenu du corrigendum de mars 2016 a été pris en considération dans cet exemplaire.

General Information

- Status

- Published

- Publication Date

- 09-Oct-2014

- Technical Committee

- SC 86A - Fibres and cables

- Drafting Committee

- WG 1 - TC 86/SC 86A/WG 1

- Current Stage

- PPUB - Publication issued

- Start Date

- 10-Oct-2014

- Completion Date

- 31-Dec-2014

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60793-1-20:2014 is an international standard developed by the International Electrotechnical Commission (IEC) focused on the measurement methods and test procedures for fibre geometry of optical fibres. This standard establishes uniform requirements for measuring the geometrical characteristics of uncoated optical fibres, which are critical to ensuring quality and performance.

The geometry of an uncoated optical fibre-such as core diameter, cladding diameter, and concentricity-directly impacts key processes like splicing, connectorization, and cabling. Accurate measurement of these geometrical parameters ensures reliability and compatibility in fibre optic communications infrastructure.

This second edition supersedes the 2001 version with updated methodologies and specifications, providing enhanced measurement accuracy and clarity for manufacturers and quality control professionals.

Key Topics

- Reference Test Methods: The standard updates the reference test method from the refracted near-field scanning to the more precise video grey scale transmitted near-field method for all fibre types.

- Measurement Techniques: Detailed procedures for one-dimensional and multidimensional scanning offer comprehensive approaches to capturing fibre geometry.

- Data Reduction and Processing: IEC 60793-1-20:2014 introduces a unified methodology for data reduction, ensuring consistency between refracted near-field and transmitted near-field methods.

- Specification Parameters: The fibre’s detail specification now includes test lengths, core illumination wavelength for multimode fibres, and the core k-factor decision level, enhancing measurement transparency.

- Apparatus and Calibration: Requirements for instrumentation, including light sources and detection systems, are clearly defined to maintain measurement accuracy.

- Edge Detection and Ellipse Fitting: The standard covers advanced computational techniques for edge detection and ellipse fitting from raw data to determine precise fibre geometry metrics.

Applications

IEC 60793-1-20:2014 is essential for:

- Quality Control in Optical Fibre Manufacturing: Helps manufacturers consistently verify whether fibres conform to design specifications for geometry, reducing defects during production.

- Telecommunications Infrastructure: Optical fibre geometrical precision affects splicing quality and connector performance, directly impacting network reliability and data transmission integrity.

- Research & Development: Provides standardized test procedures aiding R&D engineers in fibre design and optimization.

- Cabling and Installation: Enables installers and system designers to ensure compatibility between fibre components, reducing signal loss at joins and connections.

- Certification and Compliance: Facilitates internationally accepted benchmarks for fibre geometry, supporting global trade and regulatory adherence.

Related Standards

- IEC 60793-1 Series: Other parts covering optical fibre characteristics such as tensile strength and attenuation.

- IEC 60794: Standard for optical fibre cables that require compatible fibre geometrical specifications.

- IEC 61300: Test procedures for fibre optic interconnecting devices and passive components.

- ITU-T G.652: Defines single-mode optical fibre characteristics, closely related to geometrical standards like IEC 60793-1-20.

Keywords

- Optical fibre geometry measurement

- Uncoated optical fibre testing

- Fibre splicing and connectorization standards

- Optical fibre quality control

- IEC optical fibre standards

- Video grey scale transmitted near-field method

- Fibre core and cladding diameter measurement

- Optical fibre specification compliance

Adhering to IEC 60793-1-20:2014 guarantees that optical fibre geometrical measurements meet rigorous and consistent international requirements, supporting the advancement and reliability of modern optical communication systems worldwide.

Get Certified

Connect with accredited certification bodies for this standard

TL 9000 QuEST Forum

Telecommunications quality management system.

ANCE

Mexican certification and testing association.

Intertek Slovenia

Intertek testing, inspection, and certification services in Slovenia.

Sponsored listings

Frequently Asked Questions

IEC 60793-1-20:2014 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Optical fibres - Part 1-20: Measurement methods and test procedures - Fibre geometry". This standard covers: IEC 60793-1-20:2014 establishes uniform requirements for measuring the geometrical characteristics of uncoated optical fibres. The geometry of uncoated optical fibres directly affect splicing, connectorization and cabling and so are fundamental parameters requiring careful specification, quality control, and thus measurement. This second edition cancels and replaces the first edition, published in 2001, and constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - the reference test method for all fibre types is changed to the video grey scale transmitted near field method from the refracted near field method; - the test lengths for all fibre types are now to be specified in the fibre's detail specification; - the core illumination wavelength for all multimode fibre types may now to be specified in the fibre's detail specification although defaults are given; - the core k-factor (decision level) is now to be specified in the detail specification for all multimode fibre types; - this edition is substantially more specific in describing the measurement; - data reduction and transformation is fully described; - the data reduction methodology for both refracted near-field and transmitted near-field methods are now unified and consistent. Keywords: measuring the geometrical characteristics of uncoated optical fibres The contents of the corrigendum of March 2016 have been included in this copy.

IEC 60793-1-20:2014 establishes uniform requirements for measuring the geometrical characteristics of uncoated optical fibres. The geometry of uncoated optical fibres directly affect splicing, connectorization and cabling and so are fundamental parameters requiring careful specification, quality control, and thus measurement. This second edition cancels and replaces the first edition, published in 2001, and constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - the reference test method for all fibre types is changed to the video grey scale transmitted near field method from the refracted near field method; - the test lengths for all fibre types are now to be specified in the fibre's detail specification; - the core illumination wavelength for all multimode fibre types may now to be specified in the fibre's detail specification although defaults are given; - the core k-factor (decision level) is now to be specified in the detail specification for all multimode fibre types; - this edition is substantially more specific in describing the measurement; - data reduction and transformation is fully described; - the data reduction methodology for both refracted near-field and transmitted near-field methods are now unified and consistent. Keywords: measuring the geometrical characteristics of uncoated optical fibres The contents of the corrigendum of March 2016 have been included in this copy.

IEC 60793-1-20:2014 is classified under the following ICS (International Classification for Standards) categories: 33.180.10 - Fibres and cables. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60793-1-20:2014 has the following relationships with other standards: It is inter standard links to IEC 60793-1-20:2014/COR1:2016, IEC 60793-1-20:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60793-1-20:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60793-1-20 ®

Edition 2.0 2014-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Optical fibres –

Part 1-20: Measurement methods and test procedures – Fibre geometry

Fibres optiques –

Partie 1-20: Méthodes de mesure et procédures d'essai – Géométrie de la fibre

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

14 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

Plus de 55 000 entrées terminologiques électrotechniques, en

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 60793-1-20 ®

Edition 2.0 2014-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Optical fibres –

Part 1-20: Measurement methods and test procedures – Fibre geometry

Fibres optiques –

Partie 1-20: Méthodes de mesure et procédures d'essai – Géométrie de la fibre

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX X

ICS 33.180.10 ISBN 978-2-8322-1884-6

– 2 – IEC 60793-1-20:2014 © IEC 2014

CONTENTS

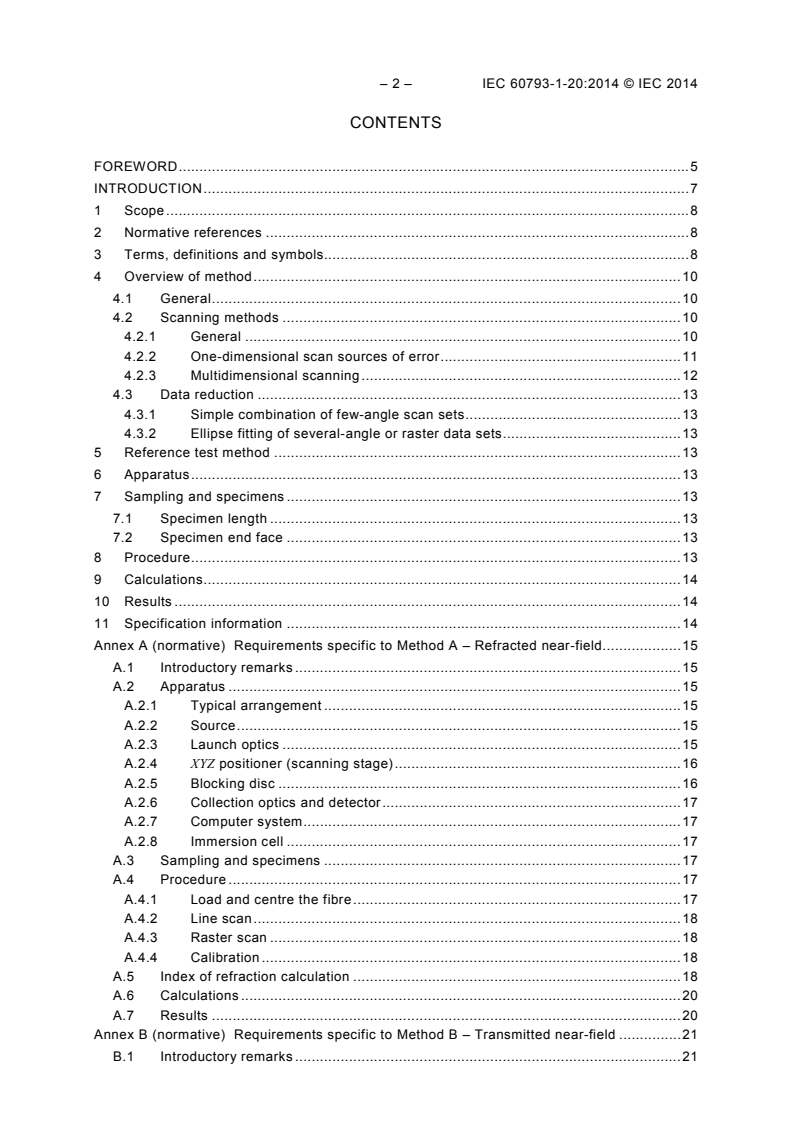

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 8

3 Terms, definitions and symbols. 8

4 Overview of method . 10

4.1 General . 10

4.2 Scanning methods . 10

4.2.1 General . 10

4.2.2 One-dimensional scan sources of error . 11

4.2.3 Multidimensional scanning . 12

4.3 Data reduction . 13

4.3.1 Simple combination of few-angle scan sets . 13

4.3.2 Ellipse fitting of several-angle or raster data sets . 13

5 Reference test method . 13

6 Apparatus . 13

7 Sampling and specimens . 13

7.1 Specimen length . 13

7.2 Specimen end face . 13

8 Procedure . 13

9 Calculations . 14

10 Results . 14

11 Specification information . 14

Annex A (normative) Requirements specific to Method A – Refracted near-field. 15

A.1 Introductory remarks . 15

A.2 Apparatus . 15

A.2.1 Typical arrangement . 15

A.2.2 Source . 15

A.2.3 Launch optics . 15

A.2.4 XYZ positioner (scanning stage) . 16

A.2.5 Blocking disc . 16

A.2.6 Collection optics and detector . 17

A.2.7 Computer system . 17

A.2.8 Immersion cell . 17

A.3 Sampling and specimens . 17

A.4 Procedure . 17

A.4.1 Load and centre the fibre . 17

A.4.2 Line scan . 18

A.4.3 Raster scan . 18

A.4.4 Calibration . 18

A.5 Index of refraction calculation . 18

A.6 Calculations . 20

A.7 Results . 20

Annex B (normative) Requirements specific to Method B – Transmitted near-field . 21

B.1 Introductory remarks . 21

B.2 Apparatus . 21

B.2.1 Typical arrangement . 21

B.2.2 Light sources . 22

B.2.3 Fibre support and positioning apparatus . 23

B.2.4 Cladding mode stripper . 23

B.2.5 Detection . 23

B.2.6 Magnifying optics . 24

B.2.7 Video image monitor (video grey-scale technique) . 25

B.2.8 Computer. 25

B.3 Sampling and specimens . 25

B.4 Procedure . 25

B.4.1 Equipment calibration . 25

B.4.2 Measurement . 25

B.5 Calculations . 27

B.6 Results . 27

Annex C (normative) Edge detection and edge table construction . 28

C.1 Introductory remarks . 28

C.2 Boundary detection by decision level . 28

C.2.1 General approach . 28

C.2.2 Class A multimode fibre core reference level and k factor . 29

C.2.3 Class B and C single-mode fibres . 30

C.2.4 Direct geometry computation of one-dimensional data . 30

C.3 Assembling edge tables from raw data . 31

C.3.1 General . 31

C.3.2 Edge tables from raster data . 31

C.3.3 Edge tables from multi-angular one-dimensional scans . 32

Annex D (normative) Edge table ellipse fitting and filtering. 33

D.1 Introductory remarks . 33

D.2 General mathematical expressions for ellipse fitting . 33

D.3 Edge table filtering . 34

D.4 Geometric parameter extraction . 35

Annex E (informative) Fitting category A1 core near-field data to a power law model . 36

E.1 Introductory remarks . 36

E.2 Preconditioning data for fitting . 36

E.2.1 Motivation . 36

E.2.2 Transformation of a two-dimensional image to one-dimensional radial

near-field . 36

E.2.3 Pre-processing of one-dimensional near-field data . 39

E.2.4 Baseline subtraction . 41

E.3 Fitting a power-law function to an category A1 fibre near-field profile . 41

Annex F (informative) Mapping class A core diameter measurements . 43

F.1 Introductory remarks . 43

F.2 Mapping function . 43

Bibliography . 44

Figure 1 – Sampling on a chord . 11

Figure 2 – Scan of a non-circular body . 12

Figure A.1 – Refracted near-field method – Cell . 16

– 4 – IEC 60793-1-20:2014 © IEC 2014

Figure A.2 – Typical instrument arrangement . 16

Figure A.3– Typical index profile line scan of a category A1 fibre . 19

Figure A.4 – Typical raster index profile on a category A1 fibre . 19

Figure B.1 – Typical arrangement, grey scale technique . 21

Figure B.2 – Typical arrangement, mechanical scanning technique . 22

Figure B.3 – Typical 1-D near-field scan, category A1 core . 26

Figure B.4 − Typical raster near-field data, category A1 fibre . 27

Figure C.1 – Typical one-dimensional data set, cladding only . 29

Figure C.2 – Typical graded index core profile . 30

Figure C.3 – Raster data, cladding only . 31

Figure E.1 – Filtering concept . 38

Figure E.2 – Illustration of 1-D near-field preconditioning, typical video line . 40

INTERNATIONAL ELECTROTECHNICAL COMMISSION

______________

OPTICAL FIBRES –

Part 1-20: Measurement methods and test procedures –

Fibre geometry

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60793-1-20 has been prepared by subcommittee SC86A: Fibre

and cables, of IEC technical committee TC86: Fibre optics.

This second edition cancels and replaces the first edition, published in 2001, and constitutes

a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

• the reference test method for all fibre types is changed to the video grey scale transmitted

near field method from the refracted near field method;

• the test lengths for all fibre types are now to be specified in the fibre’s detail specification;

• the core illumination wavelength for all multimode fibre types may now to be specified in

the fibre’s detail specification although defaults are given;

– 6 – IEC 60793-1-20:2014 © IEC 2014

• the core k-factor (decision level) is now to be specified in the detail specification for all

multimode fibre types;

• this edition is substantially more specific in describing the measurement; data reduction

and transformation is fully described;

• the data reduction methodology for both refracted near-field and transmitted near-field

methods are now unified and consistent.

The text of this standard is based on the following documents:

CDV Report on voting

86A/1562/CDV 86A/1623/RVC

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60793 series, published under the general title Optical fibres, can

be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

The contents of the corrigendum of March 2016 have been included in this copy.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

INTRODUCTION

This standard gives two methods for measuring fibre geometry characteristics:

– Method A: Refracted near-field, described in Annex A;

– Method B: Transmitted near-field, described in Annex B.

Methods A and B apply to the geometry measurement of all class A multimode fibres, class B

single-mode fibres and class C single-mode interconnection fibres. The fibre’s applicable

product specifications, IEC 60793-2-10, IEC 60793-2-20, IEC 60793-2-30, IEC 60793-2-40,

IEC 60793-2-50 and IEC 60793-2-60, provide relevant measurement details, including sample

lengths and k factors.

The geometric parameters measurable by the methods described in this standard are as

follows:

– cladding diameter;

– cladding non-circularity;

– core diameter (class A fibre only);

– core non-circularity (class A fibre only);

– core-cladding concentricity error.

NOTE 1 The core diameter of class B and class C fibres is not specified. The equivalent parameter is mode field

diameter, determined by IEC 60793-1-45.

NOTE 2 These methods specify both one-dimensional (1-D) and two-dimensional (2-D) data collection

techniques and data analyses. The 1-D methods by themselves cannot detemine non-circularity nor concentricity

error. When non-circular bodies are measured with 1-D methods, body diameters suffer additional uncertainties.

These limitations may be overcome by scanning and analysing multiple 1-D data sets. Clause 5 provides further

information.

Information common to both methods appears in Clauses 2 through 10, and information

pertaining to each individual method appears in Annexes A and B, respectively. Annex C

describes normative methods used to find the optical boundaries of the core and the cladding,

Annex D describes normative procedures to fit ellipses to sets of detected boundaries. Annex

E provides an informative fitting procedure of power-law models to graded-index core profiles.

Annex F describes an informative methodology relating to the transformation of core diameter

measurements determined with methods other than the reference method to approximate

reference method values.

– 8 – IEC 60793-1-20:2014 © IEC 2014

OPTICAL FIBRES –

Part 1–20: Measurement methods and test procedures –

Fibre geometry

1 Scope

This part of IEC 60793 establishes uniform requirements for measuring the geometrical

characteristics of uncoated optical fibres.

The geometry of uncoated optical fibres directly affect splicing, connectorization and cabling

and so are fundamental parameters requiring careful specification, quality control, and thus

measurement.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60793-2-10, Optical fibres – Part 2-10: Product specifications – Sectional specification for

category A1 multimode fibres

IEC 60793-2-20, Optical fibres – Part 2-20: Product specifications – Sectional specification for

category A2 multimode fibres

IEC 60793-2-30, Optical fibres – Part 2-30: Product specifications – Sectional specification for

category A3 multimode fibres

IEC 60793-2-40, Optical fibres – Part 2-40: Product specifications – Specification for category

A4 multimode fibres

IEC 60793-2-50, Optical fibres – Part 2-50: Product specifications – Sectional specification for

class B single-mode fibres

IEC 60793-2-60, Optical fibres – Part 2-60: Product specifications – Sectional specification for

category C single-mode intraconnection fibres

IEC 61745, End-face image analysis procedure for the calibration of optical fibre geometry

test sets

3 Terms, definitions and symbols

3.1 Terms and definitions

For the purposes of this document, the following terms, definitions and symbols apply:

3.1.1

body

general term describing an entity whose geometry is measured (i.e. cladding or core)

3.1.2

reference point

fixed coordinate in the scan’s plane

Note 1 to entry: This point is arbitrary (say the lower left corner of a video image, or the rough centre of the fibre

after the fibre is located in a scanning apparatus).

3.1.3

centre

centre of a body in the measurement plane with respect to the reference point, expressed in

micrometres

3.1.4

diameter

average diameter, in micrometres, of a nearly circular body

3.1.5

non-circularity

difference between the maximum and minimum radial deviation from the body’s centre,

normalized to the body’s diameter, expressed as a per cent

3.1.6

concentricity error

scalar distance, in micrometres between two body centres

3.1.7

scan

term used to define the collection of data along one axis of the Cartesian coordinate plane, at

a fixed angular orientation and a fixed offset from the reference point

3.1.8

scan set or set

one or more scans used together to determine the fibre’s geometry

Note 1 to entry: The set can be one scan (see limitations below), a set of scans at different angular orientations

with respect to the fibre, or a raster scan (like a video image).

3.1.9

edge table

set of number pairs representing a set of points in the scanning plane which define a closed

curve line of delineation between the cladding and the surrounding media (the cladding edge

table) or the core and the cladding (the core edge table)

3.1.10

elliptical model

ellipse fit

best fit ellipse to an edge table

3.2 Symbols

The symbols defined below are used to indicate various aspects of a scanned data set. Scans

can be one-dimensional, or two-dimensional raster scans (where the scan axes are

orthogonal on a Cartesian plane), or a set of one-dimensional scans at a set of angles.

i The index used for the scanning axis or the ‘fast’ axis in the case of a raster scan.

j The index used for the ‘slow’ axis in a raster scan.

k The index used for the angle in a multi-angular scan set.

I The set of data from one-dimensional or two-dimensional scanning. The data can be

near-field intensity data (from Method B) or index of refraction (Method A); in this

– 10 – IEC 60793-1-20:2014 © IEC 2014

standard, no delineation is made as either type of data is intermediate and is further

analysed to extract the fibre’s geometry. A single datum from a set is indicated by

subscript in a manner consistent with the nature of the data set: I for the ith point of

i

the scan in a single scan set; I for a raster data point at the jth location on the slow

j,i

th th

axis and the ith position on the fast axis; I for the i point at the k angle.

k,I

x The positional data, in micrometres, of the set. For a single scan set, the meaning of x

is clear. For a raster scan set or a multi-angle set, x refers to the positional data of the

‘fast’ axis (raster) or scan positions (for each angle). (Raster sets whose individual

lines have different fast-axis positions or multi-angle sets where each angle uses a

different set of positions are allowed by this standard, but this complication is ignored

in the forthcoming analytical development).

y The positional data, in micrometres, of the raster lines (the slow-axis locations) in a

raster scan set.

th

φ The angles in a multi-angle set. The k angle in the set is indicated by subscript: φ .

k

nS The number of points in a single scan. In the case of raster scan sets n is the number

S

of points of the fast axis. In multi-angular scan sets, nS is the number of points in any

scan. (This standard’s nomenclature ignores cases where the number of points varies

between raster lines or angles, although such data sets are allowed.)

nR The number of raster rows (slow axis scans) in a raster set.

nφ The number of angles in a multi-angle set.

NOTE The following symbols are used to describe an edge table.

X,Y A set of locations in the X-Y scan plane of the fibre which delineate a body from its

surroundings.

n The number of edge points in an edge table.

e

4 Overview of method

4.1 General

In essence, each method (A or B) defined herein describes a way of producing an image of

the fibre in a plane normal to its axis of propagation. This resultant image is then further

analysed (as described in Annexes C, D and E) to reduce the image to an expression of the

fibre’s geometry. Methods A and B can produce images which are one-dimensional (i.e. along

only one axis in the plane of the image), or two-dimensional. It is obvious that a two-

dimensional image is more information rich, and thus these images produce more complete

geometric information; the non-circularity of a body cannot be determined from a one-

dimensional scan, nor can concentricity errors be determined with any certainty.

The analysis of the image consists of two steps. The first step is to quantify where in the

image the body of interest is delineated (see Annex C). The second step reduces the

ensemble of these points of delineation to one or more geometric parameters: diameter, non-

circularity and centre (if both, the cladding and core are measured and their centres

determined then concentricity error may also be determined). Annex D describes methods

which can be used on both the cladding and core of all fibre types and Annex E describes a

method that may be used for the core body of class A fibres.

This standard addresses a range of needs, and as such, allows for a range of for data

collection and reduction. The specific limitations and uses of these approaches are discussed

below.

4.2 Scanning methods

4.2.1 General

As noted above, sampling a two-dimensional body in only one-dimension has limitations. Ideal

fibres are perfectly circular and the core and cladding are concentric; real fibres are

noncircular and have concentricity errors. Non-circularity and concentricity cannot be

measured by a one-dimensional scan and one-dimensional scanning may under- or over-

estimate the average diameter of a noncircular body. One-dimensional scanning may be

useful for fibres whose non-circularity and concentricity errors are known to be small and one-

dimensional scans are commonly used to determine the core diameter of class A fibres.

4.2.2 One-dimensional scan sources of error

4.2.2.1 Scanning a chord

Actual diameter

Measured diameter

IEC

Figure 1 – Sampling on a chord

Figure 1 illustrates the error that occurs when the sampling axis is not co-linear with the

centre of the body. When the sampling axis misses the body’s centre, the body’s diameter is

underestimated. This is a second order error.

4.2.2.2 Scanning non-circular bodies

If a body is non-circular, a one-dimensional scan will not fully describe the body’s shape.

Sampling a body in one dimension will generally under-estimate or over-estimate the average

diameter of the body. It may be assumed that this problem can be rectified by sampling the

body in two orthogonal axes (i.e. X and Y), but in general, this is not sufficient. Consider

Figure 2:

– 12 – IEC 60793-1-20:2014 © IEC 2014

IEC

IEC

Figre 2a – Major diameter Figure 2b – Average diameter

Figure 2 – Scan of a non-circular body

Figure 2 illustrates errors that occur when an elliptical body is sampled on one or two axes. In

the major diameter example (Figure 2a), the ellipse’s major diameter is aligned with the X

axis. In this case, sampling only in X will over-estimate the body’s average diameter; the fact

that the body is non-circular will be missed (likewise, sampling the body only in Y will

underestimate the body’s diameter). In this orientation, if the body is sampled on both axes

the body will be completely characterized: both its average diameter and non-circularity are

discovered. However, in the ‘average diameter’ case, sampling on either axes gives the same,

approximately correct diameter for both axes; if both axes are sampled it would appear that

the body is perfectly circular. Analysing ±45 ° scans will give the correct non-circularity and

diameter, but there is no way to know the proper angular scan angles beforehand. At

orientations other than –45 ° and +45 °, the body’s average diameter will be measured

correctly, but the body’s circularity will be underestimated.

4.2.2.3 Concentricity indeterminacy

If a single axis is scanned, the core’s centre relative to the cladding centre cannot be known.

Scanning two orthogonal axes can provide a reasonable estimate of the core’s centre. This

estimate will degrade if the core is scanned on a chord far from the core’s centre. If the core

is substantially smaller than the cladding and is significantly non-concentric, then one or more

scans may miss the core entirely.

4.2.3 Multidimensional scanning

4.2.3.1 Multi-angle scanning

As suggested in 5.2.2.2 and 5.2.2.3, the estimation of the geometry of the fibre can be

improved by scanning on two orthogonal axes. Combining scans over more than two angles

(for example at 0 °, 45 °, 90 ° and 135 °) will improve these estimates further. Acquiring data

at multiple angles can be accomplished by rotating the fibre in its holding chuck, or, if the

scanner is so designed, by the mechanics of the scanner itself. Note that all angular scans

shall share a single frame of reference (a common origin) or errors will be introduced.

4.2.3.2 Raster scanning

If the scanner is capable of motion on two orthogonal axes, then it is possible that a two-

dimensional image of the fibre may be constructed by performing a raster scan.

Measurement of the transmitted near-field using grey-scale video is inherently a raster scan.

4.3 Data reduction

4.3.1 Simple combination of few-angle scan sets

When reducing data sets where only a few angular orientations are measured, it is generally

sufficient to employ simple data reduction. For each body, the diameter can be determined by

averaging the diameters of each angular scan; the non-circularity by using the maximum and

minimum diameters from the set of angles. When both cladding and core are measured, the

concentricity error can be determined simply from the angle showing the worst-case

centration error. See Annex D for more information.

4.3.2 Ellipse fitting of several-angle or raster data sets

When many data points may be extracted from the scan set, as is the case when many angles

are scanned or when raster scanning is employed, the edge tables may be fit to elliptical

models. Annex E describes the methodology to fit a body’s edge table (determined as

described in Annex D).

For both the cladding and the core for all fibre categories, ellipse fitting is the reference

method.

5 Reference test method

The reference test method (RTM) is the video grey-scale transmitted near-field method

described in Annex B for all fibre categories. Data analysis shall employ boundary detection

as described in Annex C, and ellipse fitting to reduce the edge tables to geometry, as

described in Annex D. See Annexes A and B for a discussion of reference sample lengths for

all fibre classes, and refer to Annex C for a discussion of the decision threshold factor k for

class A fibres.

6 Apparatus

Annexes A and B include layout drawings and other equipment requirements for each of the

Methods A and B, respectively.

7 Sampling and specimens

7.1 Specimen length

Annexes A and B specify the required sample lengths for their respective methods.

7.2 Specimen end face

Prepare a clean, flat end face, perpendicular to the fibre axis, at the input and output ends of

each specimen. The accuracy of measurements is affected by a non-perpendicular end face.

End angles less than 1 ° are recommended.

See Clause B.2 for the tighter requirements on end faces when using Method B.

8 Procedure

Use the procedures given in IEC 61745 for calibration. Annexes A and B document the

procedures for Methods A and B, respectively.

– 14 – IEC 60793-1-20:2014 © IEC 2014

9 Calculations

Refer to Annexes C, D and E for details regarding the calculations.

10 Results

The following information shall be provided with each measurement:

– date and title of measurement;

– identification and description of specimen;

– measurement results for each parameter specified (see the applicable annex).

The following information shall be available upon request:

– measurement method used: Method A or B;

– specimen length;

– arrangement of measurement set-up;

– details of measurement apparatus (see applicable annex);

– relative humidity and ambient temperature at the time of the measurement;

– most recent calibration information.

11 Specification information

The detail specification shall specify the following information:

– type of fibre to be measured;

– failure or acceptance criteria;

– information to be reported;

– any deviations to the procedure that apply.

Annex A

(normative)

Requirements specific to Method A – Refracted near-field

A.1 Introductory remarks

The refracted near-field measurement directly measures the refractive index variation across

the fibre (core and cladding). The method can be calibrated to give absolute values of

refractive indices. It can be used to obtain profiles of both single-mode and multimode fibres.

A refracted near-field measurement determines the radial dependence of relative index

variations of a fibre by scanning a spot of light across its end-face. If a theoretical ray of light

could be generated, then changes in index could be detected by injecting the ray into the fibre

at an angle greater than the maximum numerical aperture of the fibre and measuring its exit

angle. Since an ideal ray cannot be generated and since the fibre’s physical dimensions are

of the order of 100 optical wavelengths, an integral approach using an angular bundle of rays

is taken. A small spot of light with a numerical aperture greater than the fibre’s is scanned

across the end-face of a fibre at a normal angle of incidence. The light cone which exits the

fibre is then sampled at a small range of high angles (i.e. greater than the numerical

aperture). The total power in this sampled region is then determined as a function of the radial

location of the launch spot. As the light traverses the local index differences in the fibre, it

refracts, changing its exit angle. Light that passes through the core and then the cladding will

exit the fibre at shallower angles than light that passes solely through the cladding. Since only

high angle light is sampled, the core region’s total detected power will be lower than the

cladding. The relative power at a given scan position is thus directly proportional to the fibre’s

index at that position.

A.2 Apparatus

A.2.1 Typical arrangement

See Figures A.1 and A.2 for schematic diagrams of the test apparatus.

A.2.2 Source

Provide a stable laser giving a few milliwatts of power in the TEM mode.

A HeNe laser, which has a wav

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...