IEC 60794-2-50:2008

(Main)Optical fibre cables - Part 2-50: Indoor cables - Family specification for simplex and duplex cables for use in terminated cable assemblies

Optical fibre cables - Part 2-50: Indoor cables - Family specification for simplex and duplex cables for use in terminated cable assemblies

IEC 60794-2-50:2008 provides requirements for simplex and duplex optical fibre cables for use in terminated cable assemblies or for termination with optical fibre passive components. This standard cancels and replaces IEC/PAS 60794-2-50 published in 2004. This standard is to be used in conjunction with IEC 60794-1-1, IEC 60794-1-2 and IEC 60794-2.

Câbles à fibres optiques - Partie 2-50: Câbles intérieurs - Spécification de famille pour les câbles simplex et duplex utilisés dans les ensembles de câbles équipés

La CEI 60794-2-50:2008 donne les exigences pour les câbles simplex et duplex à fibres optiques utilisés dans des ensembles de câbles équipés ou en vue de la finition par des composants passifs à fibres optiques. La présente norme annule et remplace la CEI/PAS 60794-2-50 parue en 2004. La présente norme doit être lue conjointement avec la CEI 60794-1-1, la CEI 60794-1-2 et la CEI 60794-2.

General Information

- Status

- Published

- Publication Date

- 28-Apr-2008

- Technical Committee

- SC 86A - Fibres and cables

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 10-Jan-2020

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60794-2-50:2008 - "Optical fibre cables - Part 2-50: Indoor cables - Family specification for simplex and duplex cables for use in terminated cable assemblies" - specifies requirements for simplex and duplex indoor optical fibre cables intended for terminated cable assemblies (for example patchcords, work‑area cords and equipment cords) or for termination with passive optical components. This 2008 edition cancels IEC/PAS 60794-2-50 (2004) and is intended to be used together with IEC 60794-1-1, IEC 60794-1-2 and IEC 60794-2.

Key topics and technical requirements

- Scope & purpose: Family specification for cables used in terminated assemblies; does not specify the finished terminated assembly itself.

- Design life & safety: Cables shall be designed for an expected operating lifetime of 15 years; materials must not present health hazards in intended use.

- Fiber types: Accepts multimode and single‑mode fibres complying with IEC 60793 sectional product specifications (A1 and B classes).

- Construction rules: Requirements for optical fibres, primary coating, buffers, tubes, strength/anti‑buckling members, sheaths and sheath marking. Buffers must be removable in one operation over 15 mm; buffered fibre diameters nominal 0.3–1.3 mm (tolerance ±0.05 mm).

- No splices in delivery: There shall be no fibre splice in a delivery length and each fibre must be identifiable throughout the cable.

- Test suite: Mechanical and environmental test methods include tensile, crush, impact, repeated bending, bend, torsion, low‑temperature bend, kink, sheath pull‑off, buffered fibre movement under compression, temperature cycling, sheath shrinkage, transmission requirements and fire performance. Several normative annexes (e.g., Methods E21, E22, F11, F12) give detailed test procedures.

Applications and users

This standard is directly applicable to:

- Cable manufacturers designing and producing simplex/duplex indoor cables for terminated assemblies (patchcords, work‑area cords, equipment cords)

- Test laboratories performing acceptance and type testing for indoor optical fibre cables

- Procurement/specification authors and systems integrators who require compliant cable products for enterprise, data center and telecom indoor installations

- Component manufacturers (connectors, assemblies) ensuring compatibility with cable family specifications

Practical benefits: ensures interoperability, predictable mechanical and optical performance, safety and lifecycle expectations for indoor terminated cable assemblies.

Related standards

- IEC 60794-1-1 (generic specification - general)

- IEC 60794-1-2 (basic optical cable test procedures)

- IEC 60794-2 (indoor cables - sectional specification)

- IEC 60793-2-10 / IEC 60793-2-50 (fibre product specifications)

- IEC 60068 series (environmental testing)

- ISO/IEC 11801 (generic cabling for customer premises)

Keywords: IEC 60794-2-50:2008, optical fibre cables, indoor cables, simplex duplex, terminated cable assemblies, patchcords, buffer dimensions, sheath pull-off, temperature cycling, cable testing.

Buy Documents

IEC 60794-2-50:2008 - Optical fibre cables - Part 2-50: Indoor cables - Family specification for simplex and duplex cables for use in terminated cable assemblies Released:4/29/2008

IEC 60794-2-50:2008 - Optical fibre cables - Part 2-50: Indoor cables - Family specification for simplex and duplex cables for use in terminated cable assemblies Released:4/29/2008

Get Certified

Connect with accredited certification bodies for this standard

TL 9000 QuEST Forum

Telecommunications quality management system.

ANCE

Mexican certification and testing association.

Intertek Slovenia

Intertek testing, inspection, and certification services in Slovenia.

Sponsored listings

Frequently Asked Questions

IEC 60794-2-50:2008 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Optical fibre cables - Part 2-50: Indoor cables - Family specification for simplex and duplex cables for use in terminated cable assemblies". This standard covers: IEC 60794-2-50:2008 provides requirements for simplex and duplex optical fibre cables for use in terminated cable assemblies or for termination with optical fibre passive components. This standard cancels and replaces IEC/PAS 60794-2-50 published in 2004. This standard is to be used in conjunction with IEC 60794-1-1, IEC 60794-1-2 and IEC 60794-2.

IEC 60794-2-50:2008 provides requirements for simplex and duplex optical fibre cables for use in terminated cable assemblies or for termination with optical fibre passive components. This standard cancels and replaces IEC/PAS 60794-2-50 published in 2004. This standard is to be used in conjunction with IEC 60794-1-1, IEC 60794-1-2 and IEC 60794-2.

IEC 60794-2-50:2008 is classified under the following ICS (International Classification for Standards) categories: 33.180.10 - Fibres and cables. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60794-2-50:2008 has the following relationships with other standards: It is inter standard links to IEC PAS 60794-2-50:2004, IEC 60794-2-50:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60794-2-50:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60794-2-50

Edition 1.0 2008-04

INTERNATIONAL

STANDARD

Optical fibre cables –

Part 2-50: Indoor cables – Family specification for simplex and duplex cables

for use in terminated cable assemblies

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60794-2-50

Edition 1.0 2008-04

INTERNATIONAL

STANDARD

Optical fibre cables –

Part 2-50: Indoor cables – Family specification for simplex and duplex cables

for use in terminated cable assemblies

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

V

ICS 33.180-10 ISBN 2-8318-9738-6

– 2 – 60794-2-50 © IEC:2008(E)

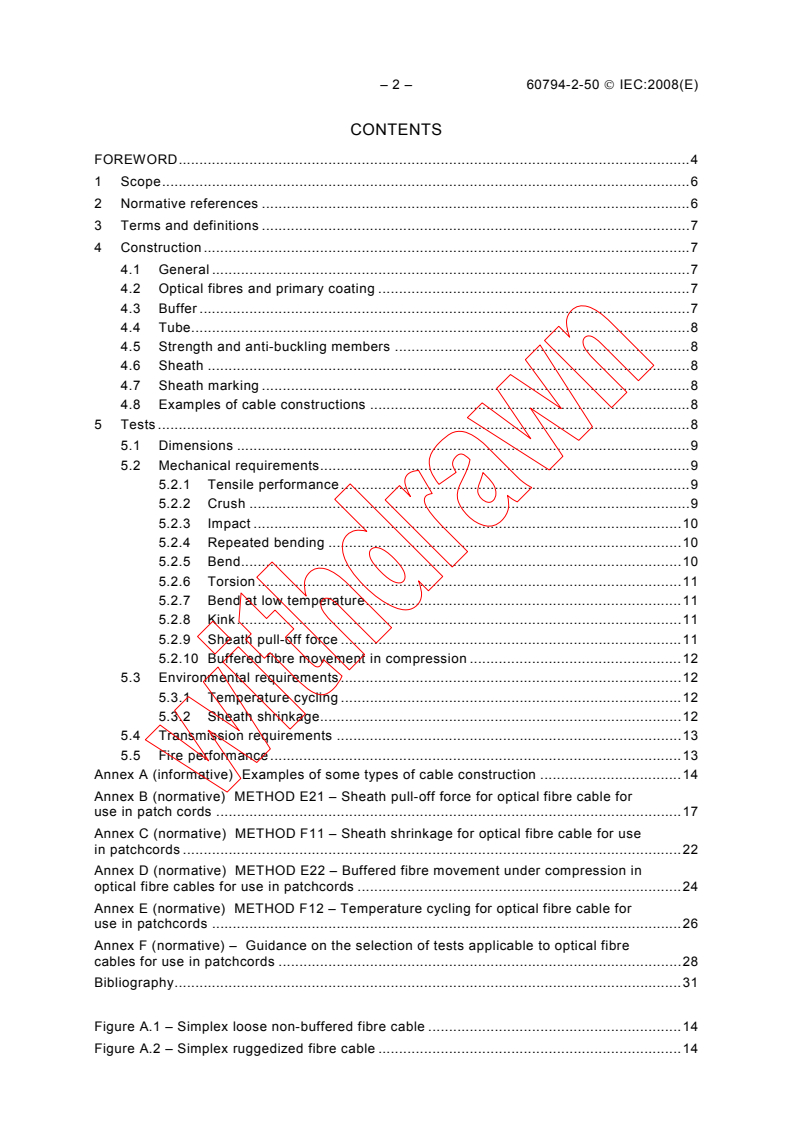

CONTENTS

FOREWORD.4

1 Scope.6

2 Normative references .6

3 Terms and definitions .7

4 Construction .7

4.1 General .7

4.2 Optical fibres and primary coating .7

4.3 Buffer .7

4.4 Tube.8

4.5 Strength and anti-buckling members .8

4.6 Sheath .8

4.7 Sheath marking .8

4.8 Examples of cable constructions .8

5 Tests .8

5.1 Dimensions .9

5.2 Mechanical requirements.9

5.2.1 Tensile performance.9

5.2.2 Crush .9

5.2.3 Impact .10

5.2.4 Repeated bending .10

5.2.5 Bend.10

5.2.6 Torsion .11

5.2.7 Bend at low temperature.11

5.2.8 Kink.11

5.2.9 Sheath pull-off force .11

5.2.10 Buffered fibre movement in compression .12

5.3 Environmental requirements .12

5.3.1 Temperature cycling .12

5.3.2 Sheath shrinkage.12

5.4 Transmission requirements .13

5.5 Fire performance.13

Annex A (informative) Examples of some types of cable construction .14

Annex B (normative) METHOD E21 – Sheath pull-off force for optical fibre cable for

use in patch cords .17

Annex C (normative) METHOD F11 – Sheath shrinkage for optical fibre cable for use

in patchcords .22

Annex D (normative) METHOD E22 – Buffered fibre movement under compression in

optical fibre cables for use in patchcords .24

Annex E (normative) METHOD F12 – Temperature cycling for optical fibre cable for

use in patchcords .26

Annex F (normative) – Guidance on the selection of tests applicable to optical fibre

cables for use in patchcords .28

Bibliography.31

Figure A.1 – Simplex loose non-buffered fibre cable .

Figure A.2 – Simplex ruggedized fibre cable .14

60794-2-50 © IEC:2008(E) – 3 –

Figure A.3 – Duplex loose non-buffered fibre cable.14

Figure A.4 – Duplex ruggedized fibre cable.15

Figure A.5 – Duplex ruggedized fibre zip cord.15

Figure A.6 – Duplex ruggedized flat cable.15

Figure A.7 – Duplex ruggedized round cable.16

Figure B.1 – Schematic of test arrangement .19

Figure B.2 – Example of pulling jig.20

Figure B.3 – Cable sample preparation .21

Figure D.1 – Test set up for fibre movement under compression.25

Table 1 – Dimensions of buffered fibres.8

Table 2 – Temperature cycling severities .12

Table F.1 – Cable test method summary.28

Table F.2 – Cable testing agreement .30

– 4 – 60794-2-50 © IEC:2008(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

OPTICAL FIBRE CABLES –

Part 2-50: Indoor cables –

Family specification for simplex and duplex cables

for use in terminated cable assemblies

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60794-2-50 has been prepared by subcommittee 86A: Fibres and

cables, of IEC technical committee 86: Fibre optics.

This standard cancels and replaces IEC/PAS 60794-2-50 published in 2004. This first edition

constitutes a technical revision.

This standard is to be used in conjunction with IEC 60794-1-1, IEC 60794-1-2 and

IEC 60794-2.

60794-2-50 © IEC:2008(E) – 5 –

The text of this standard is based on the following documents:

FDIS Report on voting

86A/1204/FDIS 86A/1223/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of IEC 60794 series, under the general title Optical fibre cables, can be

found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication will be issued at a later date.

– 6 – 60794-2-50 © IEC:2008(E)

OPTICAL FIBRE CABLES –

Part 2-50: Indoor cables –

Family specification for simplex and duplex cables

for use in terminated cable assemblies

1 Scope

This part of IEC 60794 is a family specification that covers requirements for simplex and

duplex optical fibre cables for use in terminated cable assemblies or for termination with

optical fibre passive components.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

They complete the normative references already listed in the generic specification

(IEC 60794-1-1and IEC 60794-1-2) or in the sectional specification (IEC 60794-2 series).

IEC 60068-2-14, Environmental testing – Part 2: Tests. Test N: Change of temperature

IEC 60189-1, Low-frequency cables and wires with PVC insulation and PVC sheath – Part 1:

General test and measuring methods

IEC 60793-1-1, Optical fibres – Part 1-1: Measurement methods and test procedures –

General and guidance

IEC 60793-1-20, Optical fibres – Part 1-20: Measurement methods and test procedures –

Fibre geometry

IEC 60793-1-21, Optical fibres – Part 1-21: Measurement methods and test procedures –

Coating geometry

IEC 60793-1-40, Optical fibres – Part 1-40: Measurement methods and test procedures –

Attenuation

IEC 60793-1-46, Optical fibres – Part 1-46: Measurement methods and test procedures –

Monitoring of changes in optical transmittance

IEC 60793-2-10, Optical fibres – Part 2-10: Product specifications – Sectional specification for

category A1 multimode fibres

IEC 60793-2-50, Optical fibres – Part 2-50: Product specifications – Sectional specification for

class B single-mode fibres

IEC 60794-1-1, Optical fibre cables – Part 1-1: Generic specification – General

IEC 60794-1-2, Optical fibre cables – Part 1-2: Generic specification – Basic optical cable test

procedures

60794-2-50 © IEC:2008(E) – 7 –

IEC 60794-2, Optical fibre cables – Part 2: Indoor cables – Sectional specification

IEC 60811-1-3, Common test methods for insulating and sheathing materials of electric and

optical cables – Part 1-3: General application – Methods for determining the density – Water

absorption tests – Shrinkage test

IEC 60811-1-4, Common test methods for insulating and sheathing materials of electric

cables – Part 1: Methods for general application – Section Four: Tests at low temperature

ISO/IEC 11801, Information technology – Generic cabling for customer premises

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

terminated cable assembly

short length of cable provisioned with a connector at both ends

NOTE Examples from ISO/IEC 11801 are:

Patchcords are used to establish connections on a patch panel. Typical length of the patchcord 1m to 10 m.

Work area cords are used to connect outlet to the terminal equipment. Typical length of the work area cords

according to this specification is between 1m and 35 m.

Equipment cords should fulfill the requirements of patchcords or work area cords depending on their application.

4 Construction

4.1 General

In addition to the constructional requirements in IEC 60794-2, the following considerations

apply to simplex and duplex indoor cables for use in terminated cable assemblies.

It is not the intention of this standard to specify the finished terminated cable assembly

complete with terminations.

The cable shall be designed and manufactured for an expected operating lifetime of 15 years.

The materials in the cable shall not present a health hazard within its intended use.

There shall be no fibre splice in a delivery length. It shall be possible to identify each

individual fibre throughout the length of the cable.

4.2 Optical fibres and primary coating

Multimode or single-mode optical fibres meeting the requirements of IEC 60793-2-10, type

A1a and A1b, and IEC 60793-2-50, type B, shall be used.

4.3 Buffer

If a tight or semi-tight (loosely applied) buffer is required, it shall consist of one or more layers

of inert material. Semi-tight tubes may be filled. Unless otherwise specified, the buffer shall

be removable in one operation over a length of 15 mm.

Buffer dimensions are shown in Table 1.

– 8 – 60794-2-50 © IEC:2008(E)

Table 1 – Dimensions of buffered fibres

Nominal diameter (mm) 0,3 – 1,3

Tolerances (mm) ± 0,05

4.4 Tube

One or two primary coated or buffered fibres are packaged (loosely or not) in a tube

construction which may be filled. The tube may be reinforced with a composite wall.

If required the suitability of the tube shall be determined by an evaluation of its kink

resistance in accordance with IEC 60794-1-2, Method G7.

4.5 Strength and anti-buckling members

The cable shall be designed with sufficient strength members to meet the requirements of this

standard.

The strength and/or anti-buckling member may be either metallic or non-metallic and may be

located in the cable core and/or under the sheath and/or in the sheath.

4.6 Sheath

The cable shall have a uniform overall protective sheath. The cable diameter shall be

specified in the relevant detail specification (or product specification). Sheath removal is an

important feature of these cables. This is tested by the method E21 described in Annex B of

this standard.

4.7 Sheath marking

If required, the cable shall be marked as agreed between the customer and supplier. The

marking shall be resistant to abrasion.

4.8 Examples of cable constructions

Examples of some main types of cable construction are shown in Figures A.1 to A.7.

Other configurations are not excluded if they meet the mechanical, environmental,

transmission and termination requirements given in this standard.

5 Tests

Compliance with the specification requirements shall be verified by carrying out tests selected

from the following subclauses. It is not intended that all tests be carried out in all cases, and

Annex F provides guidance on the selection of tests. The tests to be applied and the

frequency of testing shall be agreed between the customer and supplier.

Some of the following tests can be performed on a short sample length of cable which is still

an integral part of a longer length, thus making it possible to detect permanent changes in

attenuation.

60794-2-50 © IEC:2008(E) – 9 –

Single-mode cables shall be measured at 1 550 nm and 1 625 nm and multimode cables

shall be measured at 1 300 nm unless otherwise agreed. Measurements shall be carried out

according to IEC 60793-1-40.

If loops are used within a test to fix the ends of a cable, the diameter shall not be so small as

to cause excessive mode filtering in multimode fibre.

Unless otherwise specified, all tests shall be carried out at ambient temperature, as described

in IEC 60793-1-1, Clause 5.

5.1 Dimensions

The fibre dimensions and tolerances shall be checked in accordance with test method of

IEC 60793-1-20 or IEC 60793-1-21. The diameter of the buffer and of the cable, as well as the

thickness of the sheath, shall be measured in accordance with the methods of

IEC 60189-1.

5.2 Mechanical requirements

5.2.1 Tensile performance

Method: IEC 60794-1-2-E1A.

Diameter of chuck drums and transfer devices: not less than the minimum dynamic bending

diameter specified for the cable, at least 250 mm diameter.

Rate of transfer device: either 100 mm/min or 100 N/min.

Load: 100 N applied for 5 min for simplex cables, 200 N for 5 min for duplex cables.

Length of sample: sufficient to achieve the desired accuracy of measurement of attenuation

change and shall be agreed between the customer and the supplier.

Requirements: the maximum increase in attenuation during the test shall be specified in the

product specification, there shall be no change in attenuation after the test, and there shall be

no damage to the cable elements.

5.2.2 Crush

Method: IEC 60794-1-2-E3.

Force: 500 N.

Duration: 1 min.

Length between test locations: 500 mm.

Requirements: the maximum increase in attenuation during the test shall be specified in the

product specification, there shall be no change in attenuation after the test, and there shall be

no damage to the cable elements.

NOTE For cables having a non-circular cross section, the force should be applied in the direction of the minor

axis (perpendicular to the major axis).

___________

OM3 multimode cables should be tested at 850 nm and may be tested at 1300 in addition, all other

multimode cables should be tested at 1300 nm.

– 10 – 60794-2-50 © IEC:2008(E)

5.2.3 Impact

Method: IEC 60794-1-2-E4.

Radius of striking surface: 12,5 mm.

Impact energy: 1,0 J.

Number of impacts: at least 3, each separated at least 500 mm.

Requirements: the maximum increase in attenuation after the test shall be specified in the

product specification and there shall be no fibre breakage or damage to the cable elements.

Any imprint of the striking surface on the cable sheath is not considered as a mechanical

damage.

NOTE For cables having a non-circular cross section, the force should be applied in the direction of the minor

axis (perpendicular to the major axis).

5.2.4 Repeated bending

Method: IEC 60794-1-2-E6.

Bending radius: 30 mm for simplex, 20 times cable diameter for duplex (for non-circular

cables, the cable diameter is the minor dimension).

Number of cycles: 200.

Mass of weights: sufficient to contour the apparatus e.g. 1 kg to 2 kg.

Requirements: the maximum increase in attenuation during the test shall be specified in the

product specification, there shall be no change in attenuation after the test, and there shall be

no damage to the cable elements.

NOTE For cables having a non-circular cross section, the bend requirements are determined using the minor axis

as the cable diameter with bending in the direction of the preferential bend.

5.2.5 Bend

Method: IEC 60794-1-2-E11A.

Mandrel diameter: 60 mm.

Number of turns per helix: 6.

Number of cycles: 3.

Length of sample: sufficient to carry out the test.

Prior to bending: at both ends of the sample all the cable components shall be fixed together,

e.g. by loops or glue.

Requirements: the maximum increase in attenuation during the test shall be specified in the

product specification, there shall be no change in attenuation after the test, and there shall be

no damage to the cable elements.

NOTE For cables having a non-circular cross section, the bend requirements are determined using the minor axis

as the cable diameter with bending in the direction of the preferential bend.

60794-2-50 © IEC:2008(E) – 11 –

5.2.6 Torsion

Method: IEC 60794-1-2-E7.

Number of cycles: 10.

Distance between fixed and rotating clamps: 250 mm.

Tension load: according to Table 1 of IEC 60794-1-2-E7.

Length of sample: sufficient to carry out the test.

Requirements: the maximum increase in attenuation during the test shall be specified in the

product specification, there shall be no change in attenuation after the test, and there shall be

no damage to the cable elements.

5.2.7 Bend at low temperature

Method: IEC 60794-1-2-E11A (see IEC 60811-1-4, Clause 8)

Bendin

...

IEC 60794-2-50

Edition 1.0 2008-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Optical fibre cables –

Part 2-50: Indoor cables – Family specification for simplex and duplex cables for

use in terminated cable assemblies

Câbles à fibres optiques –

Partie 2-50: Câbles intérieurs – Spécification de famille pour les câbles simplex

et duplex utilisés dans les ensembles de câbles équipés

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60794-2-50

Edition 1.0 2008-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Optical fibre cables –

Part 2-50: Indoor cables – Family specification for simplex and duplex cables for

use in terminated cable assemblies

Câbles à fibres optiques –

Partie 2-50: Câbles intérieurs – Spécification de famille pour les câbles simplex

et duplex utilisés dans les ensembles de câbles équipés

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

V

CODE PRIX

ICS 33.180.10 ISBN 2-8318-9902-8

– 2 – 60794-2-50 © IEC:2008

CONTENTS

FOREWORD.4

1 Scope.6

2 Normative references .6

3 Terms and definitions .7

4 Construction .7

4.1 General .7

4.2 Optical fibres and primary coating .7

4.3 Buffer .7

4.4 Tube.8

4.5 Strength and anti-buckling members .8

4.6 Sheath .8

4.7 Sheath marking .8

4.8 Examples of cable constructions .8

5 Tests .8

5.1 Dimensions .9

5.2 Mechanical requirements.9

5.2.1 Tensile performance.9

5.2.2 Crush .9

5.2.3 Impact .10

5.2.4 Repeated bending .10

5.2.5 Bend.10

5.2.6 Torsion .11

5.2.7 Bend at low temperature.11

5.2.8 Kink.11

5.2.9 Sheath pull-off force .11

5.2.10 Buffered fibre movement in compression .12

5.3 Environmental requirements .12

5.3.1 Temperature cycling .12

5.3.2 Sheath shrinkage.13

5.4 Transmission requirements .13

5.5 Fire performance.13

Annex A (informative) Examples of some types of cable construction .14

Annex B (normative) METHOD E21 – Sheath pull-off force for optical fibre cable for

use in patch cords .17

Annex C (normative) METHOD F11 – Sheath shrinkage for optical fibre cable for use

in patchcords .22

Annex D (normative) METHOD E22 – Buffered fibre movement under compression in

optical fibre cables for use in patchcords .24

Annex E (normative) METHOD F12 – Temperature cycling for optical fibre cable for

use in patchcords .26

Annex F (normative) Guidance on the selection of tests applicable to optical fibre

cables for use in patchcords .28

Bibliography.

Figure A.1 – Simplex loose non-buffered fibre cable .14

60794-2-50 © IEC:2008 – 3 –

Figure A.2 – Simplex ruggedized fibre cable .14

Figure A.3 – Duplex loose non-buffered fibre cable.14

Figure A.4 – Duplex ruggedized fibre cable.15

Figure A.5 – Duplex ruggedized fibre zip cord.15

Figure A.6 – Duplex ruggedized flat cable.15

Figure A.7 – Duplex ruggedized round cable.16

Figure B.1 – Schematic of test arrangement .19

Figure B.2 – Example of pulling jig.20

Figure B.3 – Cable sample preparation .21

Figure D.1 – Test set up for fibre movement under compression.25

Table 1 – Dimensions of buffered fibres.8

Table 2 – Temperature cycling severities .12

Table F.1 – Cable test method summary.28

Table F.2 – Cable testing agreement .30

– 4 – 60794-2-50 © IEC:2008

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

OPTICAL FIBRE CABLES –

Part 2-50: Indoor cables –

Family specification for simplex and duplex cables

for use in terminated cable assemblies

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60794-2-50 has been prepared by subcommittee 86A: Fibres and

cables, of IEC technical committee 86: Fibre optics.

This standard cancels and replaces IEC/PAS 60794-2-50 published in 2004. This first edition

constitutes a technical revision.

This standard is to be used in conjunction with IEC 60794-1-1, IEC 60794-1-2 and

IEC 60794-2.

This bilingual version, published in 2008-07, corresponds to the English version.

60794-2-50 © IEC:2008 – 5 –

The text of this standard is based on the following documents:

FDIS Report on voting

86A/1204/FDIS 86A/1223/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

The French version of this standard has not been voted upon.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of IEC 60794 series, under the general title Optical fibre cables, can be

found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 60794-2-50 © IEC:2008

OPTICAL FIBRE CABLES –

Part 2-50: Indoor cables –

Family specification for simplex and duplex cables

for use in terminated cable assemblies

1 Scope

This part of IEC 60794 is a family specification that covers requirements for simplex and

duplex optical fibre cables for use in terminated cable assemblies or for termination with

optical fibre passive components.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

They complete the normative references already listed in the generic specification

(IEC 60794-1-1 and IEC 60794-1-2) or in the sectional specification (IEC 60794-2 series).

IEC 60068-2-14, Environmental testing – Part 2: Tests. Test N: Change of temperature

IEC 60189-1, Low-frequency cables and wires with PVC insulation and PVC sheath – Part 1:

General test and measuring methods

IEC 60793-1-1:2008, Optical fibres – Part 1-1: Measurement methods and test procedures –

General and guidance

IEC 60793-1-20, Optical fibres – Part 1-20: Measurement methods and test procedures –

Fibre geometry

IEC 60793-1-21, Optical fibres – Part 1-21: Measurement methods and test procedures –

Coating geometry

IEC 60793-1-40, Optical fibres – Part 1-40: Measurement methods and test procedures –

Attenuation

IEC 60793-1-46, Optical fibres – Part 1-46: Measurement methods and test procedures –

Monitoring of changes in optical transmittance

IEC 60793-2-10, Optical fibres – Part 2-10: Product specifications – Sectional specification for

category A1 multimode fibres

IEC 60793-2-50, Optical fibres – Part 2-50: Product specifications – Sectional specification for

class B single-mode fibres

IEC 60794-1-1, Optical fibre cables – Part 1-1: Generic specification – General

IEC 60794-1-2:2003, Optical fibre cables – Part 1-2: Generic specification – Basic optical

cable test procedures

60794-2-50 © IEC:2008 – 7 –

IEC 60794-2, Optical fibre cables – Part 2: Indoor cables – Sectional specification

IEC 60811-1-3, Common test methods for insulating and sheathing materials of electric and

optical cables – Part 1-3: General application – Methods for determining the density – Water

absorption tests – Shrinkage test

IEC 60811-1-4:1985, Common test methods for insulating and sheathing materials of electric

cables – Part 1: Methods for general application – Section Four: Tests at low temperature

Amendment 1 (1993)

Amendment 2 (2001)

ISO/IEC 11801, Information technology – Generic cabling for customer premises

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

terminated cable assembly

short length of cable provisioned with a connector at both ends

NOTE Examples from ISO/IEC 11801 are:

Patchcords are used to establish connections on a patch panel. Typical length of the patchcord 1 m to 10 m.

Work area cords are used to connect outlet to the terminal equipment. Typical length of the work area cords

according to this specification is between 1 m and 35 m.

Equipment cords should fulfill the requirements of patchcords or work area cords depending on their application.

4 Construction

4.1 General

In addition to the constructional requirements in IEC 60794-2, the following considerations

apply to simplex and duplex indoor cables for use in terminated cable assemblies.

It is not the intention of this standard to specify the finished terminated cable assembly

complete with terminations.

The cable shall be designed and manufactured for an expected operating lifetime of 15 years.

The materials in the cable shall not present a health hazard within its intended use.

There shall be no fibre splice in a delivery length. It shall be possible to identify each

individual fibre throughout the length of the cable.

4.2 Optical fibres and primary coating

Multimode or single-mode optical fibres meeting the requirements of IEC 60793-2-10, type

A1a and A1b, and IEC 60793-2-50, type B, shall be used.

4.3 Buffer

If a tight or semi-tight (loosely applied) buffer is required, it shall consist of one or more layers

of inert material. Semi-tight tubes may be filled. Unless otherwise specified, the buffer shall

be removable in one operation over a length of 15 mm.

Buffer dimensions are shown in Table 1.

– 8 – 60794-2-50 © IEC:2008

Table 1 – Dimensions of buffered fibres

Nominal diameter (mm) 0,3 – 1,3

Tolerances (mm) ± 0,05

4.4 Tube

One or two primary coated or buffered fibres are packaged (loosely or not) in a tube

construction which may be filled. The tube may be reinforced with a composite wall.

If required the suitability of the tube shall be determined by an evaluation of its kink

resistance in accordance with IEC 60794-1-2, Method G7.

4.5 Strength and anti-buckling members

The cable shall be designed with sufficient strength members to meet the requirements of this

standard.

The strength and/or anti-buckling member may be either metallic or non-metallic and may be

located in the cable core and/or under the sheath and/or in the sheath.

4.6 Sheath

The cable shall have a uniform overall protective sheath. The cable diameter shall be

specified in the relevant detail specification (or product specification). Sheath removal is an

important feature of these cables. This is tested by the method E21 described in Annex B of

this standard.

4.7 Sheath marking

If required, the cable shall be marked as agreed between the customer and supplier. The

marking shall be resistant to abrasion.

4.8 Examples of cable constructions

Examples of some main types of cable construction are shown in Figures A.1 to A.7.

Other configurations are not excluded if they meet the mechanical, environmental,

transmission and termination requirements given in this standard.

5 Tests

Compliance with the specification requirements shall be verified by carrying out tests selected

from the following subclauses. It is not intended that all tests be carried out in all cases, and

Annex F provides guidance on the selection of tests. The tests to be applied and the

frequency of testing shall be agreed between the customer and supplier.

Some of the following tests can be performed on a short sample length of cable which is still

an integral part of a longer length, thus making it possible to detect permanent changes in

attenuation.

60794-2-50 © IEC:2008 – 9 –

)

Single-mode cables shall be measured at 1 550 nm and 1 625 nm and multimode cables

shall be measured at 1 300 nm unless otherwise agreed. Measurements shall be carried out

according to IEC 60793-1-40.

If loops are used within a test to fix the ends of a cable, the diameter shall not be so small as

to cause excessive mode filtering in multimode fibre.

Unless otherwise specified, all tests shall be carried out at ambient temperature, as described

in IEC 60793-1-1, Clause 5.

5.1 Dimensions

The fibre dimensions and tolerances shall be checked in accordance with test method of

IEC 60793-1-20 or IEC 60793-1-21. The diameter of the buffer and of the cable, as well as the

thickness of the sheath, shall be measured in accordance with the methods of

IEC 60189-1.

5.2 Mechanical requirements

5.2.1 Tensile performance

Method: IEC 60794-1-2-E1A.

Diameter of chuck drums and transfer devices: not less than the minimum dynamic bending

diameter specified for the cable, at least 250 mm diameter.

Rate of transfer device: either 100 mm/min or 100 N/min.

Load: 100 N applied for 5 min for simplex cables, 200 N for 5 min for duplex cables.

Length of sample: sufficient to achieve the desired accuracy of measurement of attenuation

change and shall be agreed between the customer and the supplier.

Requirements: the maximum increase in attenuation during the test shall be specified in the

product specification, there shall be no change in attenuation after the test, and there shall be

no damage to the cable elements.

5.2.2 Crush

Method: IEC 60794-1-2-E3.

Force: 500 N.

Duration: 1 min.

Length between test locations: 500 mm.

Requirements: the maximum increase in attenuation during the test shall be specified in the

product specification, there shall be no change in attenuation after the test, and there shall be

no damage to the cable elements.

NOTE For cables having a non-circular cross section, the force should be applied in the direction of the minor

axis (perpendicular to the major axis).

___________

)

OM3 multimode cables should be tested at 850 nm and may be tested at 1 300 in addition, all other

multimode cables should be tested at 1 300 nm.

– 10 – 60794-2-50 © IEC:2008

5.2.3 Impact

Method: IEC 60794-1-2-E4.

Radius of striking surface: 12,5 mm.

Impact energy: 1,0 J.

Number of impacts: at least 3, each separated at least 500 mm.

Requirements: the maximum increase in attenuation after the test shall be specified in the

product specification and there shall be no fibre breakage or damage to the cable elements.

Any imprint of the striking surface on the cable sheath is not considered as a mechanical

damage.

NOTE For cables having a non-circular cross section, the force should be applied in the direction of the minor

axis (perpendicular to the major axis).

5.2.4 Repeated bending

Method: IEC 60794-1-2-E6.

Bending radius: 30 mm for simplex, 20 times cable diameter for duplex (for non-circular

cables, the cable diameter is the minor dimension).

Number of cycles: 200.

Mass of weights: sufficient to contour the apparatus e.g. 1 kg to 2 kg.

Requirements: the maximum increase in attenuation during the test shall be specified in the

product specification, there shall be no change in attenuation after the test, and there shall be

no damage to the cable elements.

NOTE For cables having a non-circular cross section, the bend requirements are determined using the minor axis

as the cable diameter with bending in the direction of the preferential bend.

5.2.5 Bend

Method: IEC 60794-1-2-E11A.

Mandrel diameter: 60 mm.

Number of turns per helix: 6.

Number of cycles: 3.

Length of sample: sufficient to carry out the test.

Prior to bending: at both ends of the sample all the cable components shall be fixed together,

e.g. by loops or glue.

Requirements: the maximum increase in attenuation during the test shall be specified in the

product specification, there shall be no change in attenuation after the test, and there shall be

no damage to the cable elements.

NOTE For cables having a non-circular cross section, the bend requirements are determined using the minor axis

as the cable diameter with bending in the direction of the preferential bend.

60794-2-50 © IEC:2008 – 11 –

5.2.6 Torsion

Method: IEC 60794-1-2-E7.

Number of cycles: 10.

Distance between fixed and rotating clamps: 250 mm.

Tension load: according to Table 1 of IEC 60794-1-2-E7.

Length of sample: sufficient to carry out the test.

Requirements: the maximum increase in attenuation during the test shall be specified in the

product specification, there shall be no change in attenuation after the test, and there shall be

no damage to the cable elements.

5.2.7 Bend at low temperature

Method: IEC 60794-1-2-E11A (see IEC 60811-1-4, Clause 8)

Bending radius: 10 times cable diameter (for non-circular cables, the cable diameter is the

minor dimension) but not less than 30 mm.

Number of cycles: 2.

Test temperature: 0 °C, –10 °C or –15 °C depending on application and customer

requirements.

Number of turns per helix: according to Clause 8 of IEC 60811-1-4.

Requirements: in addition to the requirement of Clause 8 of IEC 60811-1-4, no fibre shall

break during the test and there shall be no damage to the cable elements.

5.2.8 Kink

Method: IEC 60794-1-2-E10.

Minimum loop, horizontal inner dimension: (for non-circular cables, the cable diameter is the

minor dimension), see Figure E.10.

– For cables outer diameter ≤ 3,0 mm, to be 10 mm.

– For cables outer diameter > 3,0 mm, to be 5 × the cable diameter.

NOTE This is not an operational parameter; this is to address short-term installation/handling performance.

Requirement: no kink shall occur.

5.2.9 Sheath pull-off force

Method: see Annex B.

Rate of separation: ≤ 200 mm/min.

Strip length: 50 mm.

Requirement: the force to strip the sheath shall not be greater than 15 N.

– 12 – 60794-2-50 © IEC:2008

5.2.10 Buffered fibre movement in compression

Method: See Annex D.

Compression distance: 1 mm.

Number of movements: 5.

Requirement: the maximum increase in attenuation during the test shall be specified in the

product specification and the reaction force shall be less than 1 N at 0,4 mm.

5.3 Environmental requirements

5.3.1 Temperature cycling

Method: See Annex E.

Severity taken from Table 2 below.

Period: t sufficient that the cable has reached, and stabilised to, the specified temperature.

Number of cycles: 4.

Length of sample: 10 m.

Requirements: maximum increase in attenuation shall be as shown in Table 2 below.

Measurement uncertainty:

– 0,05 dB for cables with single-mode fibres;

– 0,10 dB for cables with multimode fibres.

Table 2 – Temperature cycling severities

Low High Maximum increase in Maximum increase in Maximum increase in

temperature temperature attenuation at attenuation at attenuation at

T T 1 300 nm 1 550 nm 1 625 nm

A B

dB dB dB

°C °C

a) 0 +50 0,1 0,1 0,2

b) –5 +50 0,1 0,2 0,3

c) –20 +60 0,3 0,5 1,0

d) –45 +60 0,3 0,5 1,0

e) –25 +70 0,3 0,5 1,0

f) –40 +85 0,3 0,5 1,0

NOTE Condition a), b), c), d) e) or f) should be selected depending on application and user requirements, for

example condition c) is appropriate for applications to ISO/IEC 11801. The low temperature requirement for the

completed patchcord assembly is –10 °C.

60794-2-50 © IEC:2008 – 13 –

5.3.2 Sheath shrinkage

Method: see Annex C.

Exposure temperature: 70 °C.

Exposure duration: 24 hours per cycle.

Number of cycles: 4.

Requirement: the average of the sheath shrinkage values shall not exceed 20 mm.

5.4 Transmission requirements

The transmission requirements shall be verified in accordance with IEC 60794-1-2 and shall

be agreed between customer and supplier. Maximum cable attenuation shall comply with

IEC 60794-1-1.

5.5 Fire performance

IEC/TR 62222 provides guidance and recommendations for the requirements and test

methods for the fire performance of communication cables when installed in buildings. The

recommendations relate to typical applications and installation practices, and an assessment

of the fire hazards presented. Account is also taken of applicable legislation and regulation.

IEC/TR 62222 references several IEC fire performance test methods and also other test

methods that may be required by local or National legislation and regulation. The tests to be

applied, and the requirements, shall be agreed between the customer and supplier taking into

account the fire hazard presented by the end use application of the terminated cable

assembly in which the cable is intended to be used.

– 14 – 60794-2-50 © IEC:2008

Annex A

(informative)

Examples of some types of cable construction

NOTE The main dimensions should be agreed between the customer and the supplier.

Sheath

Strength member embedded

in the sheath

Primary-coated optical fibre

IEC 445/08

Figure A.1 – Simplex loose non-buffered fibre cable

Sheath

Strength member

Buffer

Primary coating

Fibre

IEC 446/08

Figure A.2 – Simplex ruggedized fibre cable

Sheath

Strength member embedded

in the sheath

Primary-coated optical fibre

IEC 447/08

Figure A.3 – Duplex loose non-buffered fibre cable

60794-2-50 © IEC:2008 – 15 –

Sheath

Strength member

Buffer

Primary coating

Fibre

IEC 448/08

Figure A.4 – Duplex ruggedized fibre cable

Sheath

Strength member

Buffer

Primary coating

Fibre

IEC 449/08

Figure A.5 – Duplex ruggedized fibre zip cord

Strength member

Optional strength member

Primary coated

optical fibre

Buffer

Sheath

Common sheath

IEC 450/08

Figure A.6 – Duplex ruggedized flat cable

– 16 – 60794-2-50 © IEC:2008

Primary coated

optical fibre

Buffer

Strength member

Sheath

Common sheath

Filler (optional)

IEC 451/08

Figure A.7 – Duplex ruggedized round cable

60794-2-50 © IEC:2008 – 17 –

Annex B

(normative)

METHOD E21 –

Sheath pull-off force for optical fibre cable for use in patch cords

B.1 Object

The purpose of this test is to measure the force required to remove a length of sheath from an

optical fibre cable intended for use in patchcords.

B.2 General

This test method is designed to measure the force required to remove the cable sheath. It can

be applied to round simplex and round duplex optical fibre cables for use in patchcords, or

round single fibre elements or sub-elements of larger cables.

B.3 Sample

A length of cable long enough to be retained in the tensile rig shall be cut and removed from

the supply reel. The sample is prepared as shown in Figure B.3, using the following method.

At one end of the sample, mark the cable at distances 50 mm and 53 mm from the end. A

circumferential cut is then made at the two marked points where the section of sheath is to be

removed. A longitudinal cut is then made between the two circumferential cuts. Remove the

sheathing between the two cuts. During sample preparation, if any damage is imparted to the

cable core, that sample shall be discarded.

B.4 Apparatus

A schematic of the test arrangement is shown in Figure B.1.

B.4.1 Tensile test rig

A controllable tensile facility shall be used with the ability to pull over a specified distance at a

controlled speed.

B.4.2 Recording equipment

A set of measurement equipment shall be used, linked to the tensile test rig that can record

the forces required to remove the sheath from the cable core. Measurements shall be

recorded in newtons.

B.4.3 Stripping tools

Tools capable of removing at least a 3 mm length of outer sheath at a distance 50 mm from

the end of the cable, leaving the cable core undamaged, may be used.

B.4.4 Pulling jig

A pulling jig as shown in Figure B.2 shall be designed to fit into the gap formed in the sample

sheath by removing the 3 mm section, allowing the 50 mm strip length of sheath to be pulled

longitudinally from the prepared end of the cable.

– 18 – 60794-2-50 © IEC:2008

B.4.5 Cable anchor

A method shall be provided to secure the anchor end of the cable while the pull is carried out.

B.5 Procedure

The prepared end of the cable is inserted into the pulling jig (see Figure B.1) mounted on the

test rig. The opposite end of the sample is then mounted in the cable anchor at zero load. A

controlled pull is then carried out at the specified speed. Readings are taken to record the

peak values of each test pull.

B.6 Requirements

The force required to remove the sheath from the cable core shall comply with the values

given in the detail specification.

B.7 Details to be specified

The detail specification shall include:

a) rate of separation (speed of pull);

b) strip length (length of sheath removed);

c) force to strip the length of sheath.

60794-2-50 © IEC:2008 – 19 –

Direction of pull

Anchor end of cable

IEC 577/08

Figure B.1 – Schematic of test arrangement

– 20 – 60794-2-50 © IEC:2008

Dimensions in millimetres

20 20

2,5 ∅5

Dimensions and design of the securing

end of this tool can be modified to

suit the type of pulling rig used

IEC 578/08

Figure B.2 – Example of pulling jig

1,4 slot

∅6

∅13

∅16

60794-2-50 © IEC:2008 – 21 –

50 mm

Strip length

3 mm gap

This length to suit

retaining set up

IEC 579/08

Figure B.3 – Cable sample preparation

– 22 – 60794-2-50 © IEC:2008

Annex C

(normative)

METHOD F11 –

Sheath shrinkage for optical fibre cable for use in patchcords

C.1 Object

The purpose of this test is to measure the shrinkage behaviour of the sheath due to ageing of

simplex and duplex optical fibre cables intended for use in patchcords.

C.2 General

This test method is based on IEC 60811-1-3 with modifications related to the sampling and

measuring method.

C.3 Apparatus

A container (with typical dimensions 0,5 m × 0,5 m) into which the test sample is placed. The

base of the container shall be covered with talc or paper to minimise frictional forces on the

test sample and to permit free movement of the sheath.

A temperature chamber able to accommodate the test sample container, and maintain the

specified temperature within ± 3 ºC as described in IEC 60068-2-14, Method Nb.

A length measuring device with a minimum resolution of 0,5 mm.

C.4 Conditioning

The cable on the supply reel shall be conditioned for 24 h at a room temperature of 23 ± 5 °C

before cutting the test samples.

C.5 Sampling

A 2 m length of cable shall be removed from the supply reel and disposed, before cutting the

test sample lengths. Five test samples each with a length of 1 050 mm ± 5 mm shall be cut

from the cable.

C.6 Procedure

Two marks separated by a distance of 1 000 mm ± 0,5 mm shall be applied to each test

sample. The marks shall be located at approximately 25 mm from each end of the test

sample.

The distance (L ) between the sheath marks on each test sample shall be measured and

recorded. The test samples shall be coiled with a radius of not less than 150 mm and in such

a manner as to permit free movement of the sheath. A test sample coil is then placed

approximately horizontally in the container.

The temperature chamber shall be heated up to the specified temperature.

The container with horizontally positioned samples is then placed in the temperature chamber.

60794-2-50 © IEC:2008 – 23 –

After the specified heating time, the container with samples shall be removed from the

chamber and allowed to cool to room temperature.

Four such cycles shall be carried out.

After four cycles, the distance (L ) between the sheath marks on each test sample shall be

measured and recorded.

The sheath shrinkage of each test sample is calculated as:

ΔL = (L – L ) mm

x 1 2

where

L is the initial distance measured between the sheath marks;

L is the distance measured between the sheath marks after four cycles.

C.7 Requirements

The average sheath shrinkage of the five samples shall not exceed the value given in the

relevant specification.

C.8 Details to be specified

The detail specification shall include:

a) details of temperature chamber and exposure high temperature;

b) duration of exposure to high temperature;

c) number of samples;

d) method of sheath marking and length measurement;

e) sample configuration and fixing in the container;

f) number of cycles;

g) average sheath shrinkage.

– 24 – 60794-2-50 © IEC:2008

Annex D

(normative)

METHOD E22 –

Buffered fibre movement under compression in optical fibre

cables for use in patchcords

D.1 Object

The purpose of this test is to examine the attenuation behaviour (change in attenuation) and

the reaction force when a buffered fibre in a cable intended for use in patchcords moves

under axial compression only.

D.2 Apparatus

A device to fix one cable end without compression and a chuck to fix the buffered fibre

protruding from this cable end. The chuck shall be movable towards the cable end for an

adjustable distance (see Figure D.1). The fixed distance between the chuck and the cable end

shall be 7 mm.

Load cell for monitoring the force on the chuck with a maximum error of ± 3 %.

Attenuation monitoring equipment as described in IEC 60793-1-46.

D.3 Sampling

A 5 m long cable sample shall be taken from a finished cable length.

At both ends of the sample, 2 m of the cable sheath and other cable elements are removed,

leaving a central 1,0 m length of cable sheath on the sample.

D.4 Procedure

One end of the 1,0 m length of sheathed cable sample including the strength member is fixed

at one side in the cable fixing device (1 in Figure D.1) and the exposed buffered fibre is fixed

in the fibre chuck (2 in Figure D.1).

At the other end of the 1,0 m sample the fibre and the sheath are glued together by e.g. epoxy

to prevent any movement of the fibre within the cable sample.

The unsheathed fibres are connected to the attenuation monitoring equipment (see

Figure D.1).

The chuck is moved towards the fixed cable end for the required compression distance given

in the relevant detail specification.

During the movement, any attenuation change and the reaction force are monitored.

The test shall be carried out at ambient temperature.

60794-2-50 © IEC:2008 – 25 –

D.5 Requirement

Attenuation change and the reaction force at 0,4 mm displacement shall not exceed the

values given in the relevant specification.

D.6 Details to be specified

The detail specification shall include:

a) compression distance;

b) method of monitoring attenuation change;

c) number of movements;

d) reaction force;

e) change in attenuation.

1 000 mm

7 mm

Epoxy Cable

1 2

Buffered fibre

Buffered fibre

002 dB

Attenuation

monitoring

IEC 580/08

Key

1 Cable fixing

2 Fibre chuck and load cell

Compression movement

Figure D.1 – Test set up for fibre movement under compression

– 26 – 60794-2-50 © IEC:2008

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...