IEC TR 61292-4:2014

(Main)Optical amplifiers - Part 4: Maximum permissible optical power for the damage-free and safe use of optical amplifiers, including Raman amplifiers

Optical amplifiers - Part 4: Maximum permissible optical power for the damage-free and safe use of optical amplifiers, including Raman amplifiers

IEC/TR 61292-4:2014(E) which is a technical report, applies to all commercially available optical amplifiers (OAs), including optical fibre amplifiers (OFAs) using active fibres, as well as Raman amplifiers. Semiconductor optical amplifiers (SOAs) using semiconductor gain media are also included. This technical report provides a simple informative guideline on the threshold of high optical power that causes high-temperature damage of fibre. Also discussed is optical safety for manufacturers and users of optical amplifiers by reiterating substantial parts of existing standards and agreements on eye and skin safety. It is important to point out that the reader should always refer to the latest international standards and agreements because the technologies concerned are rapidly evolving. The present technical report will be frequently reviewed and will be updated by incorporating the results of various studies related to OAs and OA-supported optical systems in a timely manner. This third edition cancels and replaces the second edition, published in 2010, and constitutes a technical revision with updates reflecting new research in the subject area. Keywords: guideline on the threshold of high optical power, maximum permissible optical power, optical amplifiers, Raman amplifiers, semiconductor optical amplifiers (SOAs)

General Information

- Status

- Published

- Publication Date

- 28-Oct-2014

- Technical Committee

- SC 86C - Fibre optic systems, sensing and active devices

- Drafting Committee

- WG 3 - TC 86/SC 86C/WG 3

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 11-Jan-2023

- Completion Date

- 31-Dec-2021

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC TR 61292-4:2014 (Edition 3.0) is a Technical Report from the IEC that gives an informative, practical guideline on the threshold of high optical power and the maximum permissible optical power for the damage‑free and safe use of optical amplifiers. It covers all commercially available optical amplifiers (OAs) - including optical fibre amplifiers (OFAs) using active fibre, Raman amplifiers, and semiconductor optical amplifiers (SOAs). The report focuses on fibre- and system-level hazards from high optical power and reiterates relevant eye and skin safety considerations. This third edition supersedes the 2010 edition and incorporates recent research; users are advised to consult the latest standards and amendments.

Key Topics

- Thresholds for fibre damage: informative guidance on power levels that can cause high‑temperature damage in fibres and components.

- Fibre fuse and propagation: description of fibre fuse initiation and propagation phenomena and their thresholds.

- Loss‑induced heating: risks at connectors and splices where local loss can cause localized heating and damage.

- Connector end‑face damage from contamination: how dust/metal filings and contamination increase damage risk under high power.

- Fibre‑coat burn and tight‑bend heating: effects of tight bending at high power and coating temperature rise.

- Optical safety (eye and skin): maximum transmissible exposure (MPE), maximum permissible optical power in fibres for eye/skin safety, Nominal Ocular Hazard Distance (NOHD), and requirements for Automatic Power Reduction (APR) and power‑reduction timing.

- Measurement conditions and example power limits: practical measurement contexts and example limits for systems with APR.

- Prevention and termination methods: overview (informative annexes) of passive/active mitigation for fibre fuse and related faults.

Applications

This Technical Report is intended for:

- Manufacturers of optical amplifiers and active fibre components - to define safe output limits and safety features (e.g., APR).

- System designers and network architects deploying Raman or high‑power amplification - to set link power budgets and connector/ splice practices.

- Installers and maintenance personnel - to follow practices minimizing connector contamination, manage bend radii, and understand NOHD and PPE needs.

- Safety officers and compliance teams - to align amplifier deployment with eye/skin safety rules and to reference APR and labeling guidance.

Related standards

- IEC 60825‑2 (laser safety / medical aspects)

- ITU‑T G.664 (automatic power reduction recommendations)

- IEC TR 62547, IEC TR 62627‑01 (fibre/cable and interconnecting devices)

- Note: consult current editions and national implementations for compliance.

Keywords: guideline on the threshold of high optical power, maximum permissible optical power, optical amplifiers, Raman amplifiers, semiconductor optical amplifiers (SOAs), optical fibre amplifiers (OFAs).

Buy Documents

IEC TR 61292-4:2014 - Optical amplifiers - Part 4: Maximum permissible optical power for the damage-free and safe use of optical amplifiers, including Raman amplifiers

IEC TR 61292-4:2014 - Optical amplifiers - Part 4: Maximum permissible optical power for the damage-free and safe use of optical amplifiers, including Raman amplifiers Released:10/29/2014

Get Certified

Connect with accredited certification bodies for this standard

TL 9000 QuEST Forum

Telecommunications quality management system.

ANCE

Mexican certification and testing association.

Intertek Slovenia

Intertek testing, inspection, and certification services in Slovenia.

Sponsored listings

Frequently Asked Questions

IEC TR 61292-4:2014 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "Optical amplifiers - Part 4: Maximum permissible optical power for the damage-free and safe use of optical amplifiers, including Raman amplifiers". This standard covers: IEC/TR 61292-4:2014(E) which is a technical report, applies to all commercially available optical amplifiers (OAs), including optical fibre amplifiers (OFAs) using active fibres, as well as Raman amplifiers. Semiconductor optical amplifiers (SOAs) using semiconductor gain media are also included. This technical report provides a simple informative guideline on the threshold of high optical power that causes high-temperature damage of fibre. Also discussed is optical safety for manufacturers and users of optical amplifiers by reiterating substantial parts of existing standards and agreements on eye and skin safety. It is important to point out that the reader should always refer to the latest international standards and agreements because the technologies concerned are rapidly evolving. The present technical report will be frequently reviewed and will be updated by incorporating the results of various studies related to OAs and OA-supported optical systems in a timely manner. This third edition cancels and replaces the second edition, published in 2010, and constitutes a technical revision with updates reflecting new research in the subject area. Keywords: guideline on the threshold of high optical power, maximum permissible optical power, optical amplifiers, Raman amplifiers, semiconductor optical amplifiers (SOAs)

IEC/TR 61292-4:2014(E) which is a technical report, applies to all commercially available optical amplifiers (OAs), including optical fibre amplifiers (OFAs) using active fibres, as well as Raman amplifiers. Semiconductor optical amplifiers (SOAs) using semiconductor gain media are also included. This technical report provides a simple informative guideline on the threshold of high optical power that causes high-temperature damage of fibre. Also discussed is optical safety for manufacturers and users of optical amplifiers by reiterating substantial parts of existing standards and agreements on eye and skin safety. It is important to point out that the reader should always refer to the latest international standards and agreements because the technologies concerned are rapidly evolving. The present technical report will be frequently reviewed and will be updated by incorporating the results of various studies related to OAs and OA-supported optical systems in a timely manner. This third edition cancels and replaces the second edition, published in 2010, and constitutes a technical revision with updates reflecting new research in the subject area. Keywords: guideline on the threshold of high optical power, maximum permissible optical power, optical amplifiers, Raman amplifiers, semiconductor optical amplifiers (SOAs)

IEC TR 61292-4:2014 is classified under the following ICS (International Classification for Standards) categories: 33.160.10 - Amplifiers; 33.180.30 - Optic amplifiers. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 61292-4:2014 has the following relationships with other standards: It is inter standard links to IEC TR 61292-4:2023, IEC TR 61292-4:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC TR 61292-4:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TR 61292-4 ®

Edition 3.0 2014-10

TECHNICAL

REPORT

colour

inside

Optical amplifiers –

Part 4: Maximum permissible optical power for the damage-free and safe use of

optical amplifiers, including Raman amplifiers

61292-4

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC TR 61292-4 ®

Edition 3.0 2014-10

TECHNICAL

REPORT

colour

inside

Optical amplifiers –

Part 4: Maximum permissible optical power for the damage-free and safe use of

optical amplifiers, including Raman amplifiers

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

V

ICS 33.160.10 33.180.30 ISBN 978-2-8322-1907-2

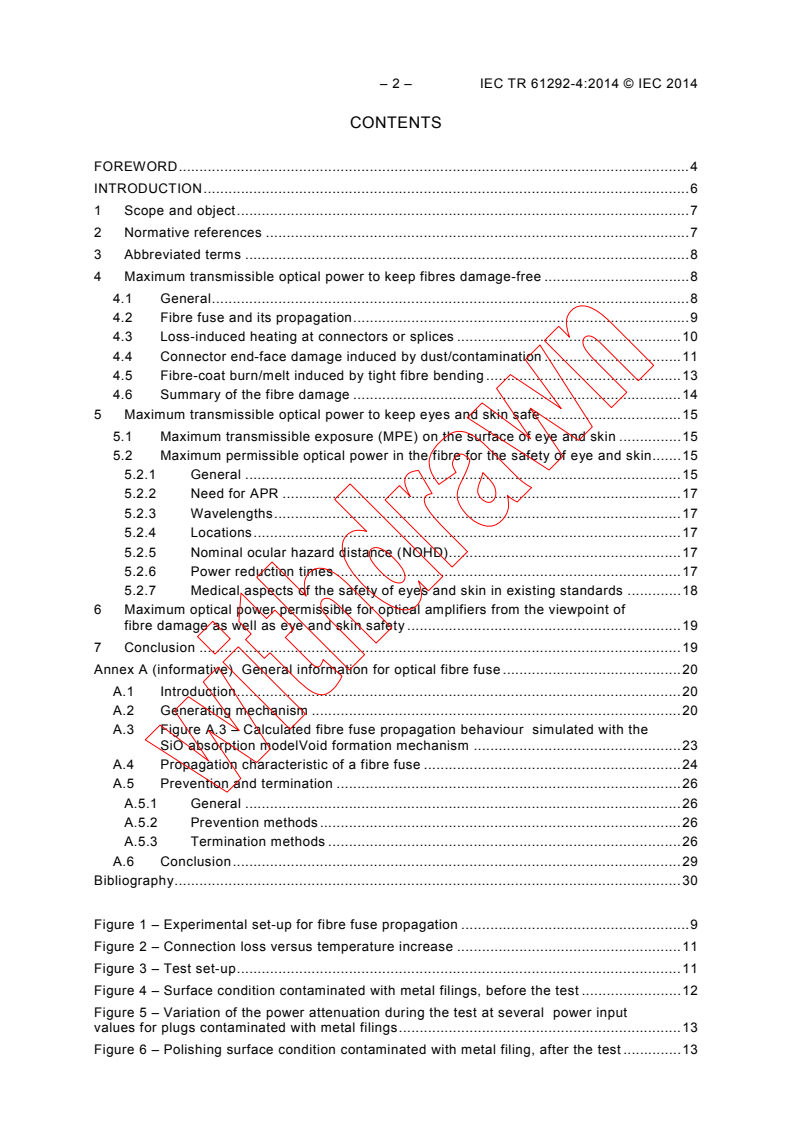

– 2 – IEC TR 61292-4:2014 © IEC 2014

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope and object . 7

2 Normative references . 7

3 Abbreviated terms . 8

4 Maximum transmissible optical power to keep fibres damage-free . 8

4.1 General . 8

4.2 Fibre fuse and its propagation . 9

4.3 Loss-induced heating at connectors or splices . 10

4.4 Connector end-face damage induced by dust/contamination . 11

4.5 Fibre-coat burn/melt induced by tight fibre bending . 13

4.6 Summary of the fibre damage . 14

5 Maximum transmissible optical power to keep eyes and skin safe . 15

5.1 Maximum transmissible exposure (MPE) on the surface of eye and skin . 15

5.2 Maximum permissible optical power in the fibre for the safety of eye and skin. 15

5.2.1 General . 15

5.2.2 Need for APR . 17

5.2.3 Wavelengths . 17

5.2.4 Locations . 17

5.2.5 Nominal ocular hazard distance (NOHD). 17

5.2.6 Power reduction times . 17

5.2.7 Medical aspects of the safety of eyes and skin in existing standards . 18

6 Maximum optical power permissible for optical amplifiers from the viewpoint of

fibre damage as well as eye and skin safety . 19

7 Conclusion . 19

Annex A (informative) General information for optical fibre fuse . 20

A.1 Introduction . 20

A.2 Generating mechanism . 20

A.3 Figure A.3 – Calculated fibre fuse propagation behaviour simulated with the

SiO absorption modelVoid formation mechanism . 23

A.4 Propagation characteristic of a fibre fuse . 24

A.5 Prevention and termination . 26

A.5.1 General . 26

A.5.2 Prevention methods . 26

A.5.3 Termination methods . 26

A.6 Conclusion . 29

Bibliography . 30

Figure 1 – Experimental set-up for fibre fuse propagation . 9

Figure 2 – Connection loss versus temperature increase . 11

Figure 3 – Test set-up . 11

Figure 4 – Surface condition contaminated with metal filings, before the test . 12

Figure 5 – Variation of the power attenuation during the test at several power input

values for plugs contaminated with metal filings . 13

Figure 6 – Polishing surface condition contaminated with metal filing, after the test . 13

Figure 7 – Thermo-viewer image of tightly-bent SMF with optical power of 3 W at

1 480 nm . 14

Figure 8 – Temperature of the coating surface of SMFs against bending with optical

power of 3 W at 1 480 nm . 14

Figure 9 – Maximum permissible power in the fibre against APR power reduction time . 18

Figure A.1 – Front part of the fibre fuse damage generated in the optical fibre . 20

Figure A.2 – SiO absorption model . 22

Figure A.3 – Calculated fibre fuse propagation behaviour simulated with the SiO

absorption modelVoid formation mechanism . 23

Figure A.4 – Series of optical micrographs showing damage generated by 9,0 W

1 480 nm laser light suggesting a mechanism of periodic void formation . 24

Figure A.5 – Images of fibre fuse ignition taken with an ultra-high speed camera and

an optical micrograph of the damaged fibre. 25

Figure A.6 – Power density dependence of the fibre-fuse propagation velocity . 25

Figure A.7 – Optical micrographs showing front part of the fibre fuse damage

generated in SMF-28 fibres with various laser intensities (1 480 nm) . 26

Figure A.8 – Principle of the optical fibre fuse passive termination method and

photograph of the fibre fuse terminator which adopted TEC structure . 27

Figure A.9 – Photograph of hole-assistant fibre and fibre fuse termination using a hole-

assistant fibre . 28

Figure A.10 – Example of fibre fuse active termination scheme . 29

Figure A.11 – Transformation of electric signal by optical fibre fuse . 29

Table 1 – Threshold power of fibre fuse propagation for various fibres . 9

Table 2 – Measurement conditions. 10

Table 3 – Examples of power limits for optical fibre communication systems having

automatic power reduction to reduce emissions to a lower hazard level . 16

Table 4 – Location types within an optical fibre communication system and their

typical installations . 17

– 4 – IEC TR 61292-4:2014 © IEC 2014

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

OPTICAL AMPLIFIERS –

Part 4: Maximum permissible optical power for the damage-free and safe

use of optical amplifiers, including Raman amplifiers

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a technical report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC TR 61292-4, which is a technical report, has been prepared by subcommittee 86C: Fibre

optic systems and active devices, of IEC technical committee 86: Fibre optics.

This third edition cancels and replaces the second edition, published in 2010, and constitutes

a technical revision with updates reflecting new research in the subject area.

The text of this technical report is based on the following documents:

Enquiry draft Report on voting

86C/1158/DTR 86C/1200/RVC

Full information on the voting for the approval of this technical report can be found in the

report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 61292 series, published under the general title, Optical amplifiers,

can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC TR 61292-4:2014 © IEC 2014

INTRODUCTION

This technical report is dedicated to the subject of maximum permissible optical power for

damage-free and safe use of optical amplifiers, including Raman amplifiers. Since the

technology is quite new and still evolving, amendments and new editions to this report can be

expected.

Many new types of optical amplifiers are entering the marketplace and research is also

stimulating many new types of fibre and non-fibre based optical amplifier research. With the

introduction of such technologies as long-haul, over 40 Gb/s, WDM transmission and Raman

amplification, some optical amplifiers may involve optical pump sources with extremely high

optical power – up to, possibly, several watts.

Excessively high optical power may cause physical damage to the fibres/optical

components/equipment as well as present medical danger to the human eye and skin.

The possibility of fibre damage caused by high optical intensity has recently been discussed

at some technical conferences. The use of high intensity optical amplifiers may cause

problems in the fibre such as a fibre fuse, a heating in the splice point (connection point), and

the fibre end-face damage due to dust and the fibre coat burning due to tight fibre bending.

IEC SC 86A (Fibres and cables) has published IEC TR 62547, and SC 86B (Fibre optic

interconnecting devices and passive components) has published IEC TR 62627-01.

IEC TC 31 (Equipment for explosive atmospheres) is also discussing the risk of ignition of

hazardous environments by radiation from optical equipment.

Medical aspects have long been discussed at standards groups. IEC TC 76 (Optical radiation

safety and laser equipment) precisely describes in IEC 60825-2 the concept of hazard level

and labelling and addresses the safety aspects of lasers specifically in relation to tissue

damage.

ITU-T Study Group 15 (Optical and other transport networks) has published Recommendation

G.664, which primarily discusses the automatic laser power reduction functionality for safety.

With the recent growth of interest in fibre Raman amplifiers, however, some difficulties have

been identified among optical amplifier users and manufacturers in fully understanding the

technical details and requirements across all such standards and agreements.

This technical report provides a simple informative guideline on the maximum optical power

permissible for optical amplifiers for optical amplifier users and manufacturers.

OPTICAL AMPLIFIERS

Part 4: Maximum permissible optical power for the damage-free and safe

use of optical amplifiers, including Raman amplifiers

1 Scope and object

This part of IEC 61292, which is a technical report, applies to all commercially available

optical amplifiers (OAs), including optical fibre amplifiers (OFAs) using active fibres, as well

as Raman amplifiers. Semiconductor optical amplifiers (SOAs) using semiconductor gain

media are also included.

This technical report provides a simple informative guideline on the threshold of high optical

power that causes high-temperature damage of fibre. Also discussed is optical safety for

manufacturers and users of optical amplifiers by reiterating substantial parts of existing

standards and agreements on eye and skin safety.

To identify the maximum permissible optical power in the optical amplifier from damage-free

and safety viewpoints, this technical report identifies the following values:

a) the optical power limit that causes thermal damage to the fibre, such as fibre fuse and

fibre-coat burning;

b) the maximum permissible exposure (MPE) to which the eyes/skin can be exposed without

consequential injury;

c) the optical power limit in the fibre that causes MPE on the eyes/skin after free-space

propagation from the fibre;

d) the absolute allowable damage-free and safe level of optical power of the optical amplifier

by comparing (a) and (c).

The objective of this technical report is to minimize potential confusion and misunderstanding

in the industry that might cause unnecessary alarm and hinder the progress and acceptance

of advancing optical amplifier technologies and markets.

It is important to point out that the reader should always refer to the latest international

standards and agreements because the technologies concerned are rapidly evolving.

The present technical report will be frequently reviewed and will be updated by incorporating

the results of various studies related to OAs and OA-supported optical systems in a timely

manner.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60825-1:2007, Safety of laser products – Part 1: Equipment classification and

requirements

– 8 – IEC TR 61292-4:2014 © IEC 2014

IEC 60825-2:2004, Safety of laser products – Part 2: Safety of optical fibre communication

systems (OFCS)

Amendment 1 (2006)

Amendment 2 (2010)

IEC TR 60825-14:2004, Safety of laser products – Part 14: A user’s guide

IEC TR 62547, Guidelines for the measurement of high-power damage sensitivity of single-

mode fibres to bends – Guidance for the interpretation of results

IEC TR 62627-01, Fibre optic interconnecting devices and passive components – Part 01:

Fibre optic connector cleaning methods

ITU-T Recommendation G.664:2012, Optical safety procedures and requirements for optical

transport systems

3 Abbreviated terms

For the purposes of this document, the following abbreviated terms apply.

ALS automatic laser shutdown

APR automatic power reduction

DSF dispersion shifted fibre

LOS loss of signal

MFD mode field diameter

MPE maximum permissible exposure

MPI-R single channel receive main path Interface reference point

MPI-S single channel source main path interface reference point

NOHD nominal ocular hazard distance

NZ-DSF non-zero dispersion shifted single-mode optical fibre

OA optical amplifier

OFA optical fibre amplifier

SMF single mode fibre

SOA semiconductor optical amplifier

4 Maximum transmissible optical power to keep fibres damage-free

4.1 General

The use and reasonably foreseeable misuse of high intensity optical amplifiers may cause

problems in the fibre such as

a) fibre fuse and its propagation,

b) heating in the splice point/connection point,

c) fibre end-face damage due to dust and other contamination,

d) fibre coat burning and ignition of hazardous environments due to tight fibre bending or

breakage.

This clause introduces their results concerning the above issues to give guidelines for the

damage-free use of optical amplifiers. However, it should be noted that the following results

are only valid under the conditions tested and that a higher power might be allowed under

different conditions.

4.2 Fibre fuse and its propagation

The safety of optical amplifiers should be discussed from the viewpoint of laser hazard to the

eyes and skin as well as fibre damage such as fibre-coat burning and fibre fusing. This clause

experimentally analyses the fibre fuse and its propagation caused by high optical power and

discusses the threshold power of fibre fuse propagation [1] . It is defined that the fibre fuse is

the phenomenon in which an intense blue-white flash occurred and ran along the fibre toward

the high power light source while forming periodic and/or non-periodic voids.

Figure 1 shows a typical measurement set-up for the threshold power of fibre fuse

propagation. The fibre fuse is initiated by heating the optical fibre from outside of the fibre by

using an independent heat source, while a high optical power is continuously launched into

the fibre. Once the fibre fuse began propagating, the optical source power is continuously

reduced until the fuse propagation stopped for measuring the threshold power. Table 1 shows

the threshold powers which were measured at various wavelengths of the high-power optical

source for various fibres. Although the threshold power depends on the wavelength of the

high-power optical source, the power for the fuse propagation is less than 1,4 W and 1,2 W

for a standard single mode fibre (SMF) and a dispersion shifted fibre (DSF) respectively,

which are used as the optical fibre for typical optical fibre communication systems.

Sample 10 m - 20 m

SMF SMF

High power

Optical power

optical source

meter

SMF/DSF

Splicing

Heating

(Initiation for fibre fuse)

IEC

Figure 1 – Experimental set-up for fibre fuse propagation

Table 1 – Threshold power of fibre fuse propagation for various fibres

Measurement Threshold power of

Fibre type wavelength fibre fuse propagation

W

µm

Standard single mode fibre 1,064 1 [2]

1,467 1,4 [2]

1,48

∼1,2 [3]

1,55 1,39 [4]

Dispersion shifted fibre 1,064 1,2 [2]

1,467 0,65 [2]

1,55 ~1,1 [5]

Dispersion compensation fibre 1,55 ~0,7 [5]

The difference in the fibre mode-field diameter has been the major reason for the difference in

the threshold powers because the fibre fuse depends on the power density [1].

On the other hand, it is difficult to identify the threshold powers for the fibre fuse self-initiation

(without any external cause) because it varied significantly, although they well exceeded

___________

Figures in square brackets refer to the Bibliography.

– 10 – IEC TR 61292-4:2014 © IEC 2014

1,4 W and 1,2 W for standard single mode fibre (SMF) and dispersion shifted fibre (DSF)

respectively.

Further information such as the generating mechanism, the characteristics of fibre fuse and

the prevention and the termination for the fibre fuse is described in Annex A.

4.3 Loss-induced heating at connectors or splices

In extremely high power optical amplifiers, the loss-induced heating at fibres and connectors

or splices could lead to damage, including fibre-coat burning, fibre fuse, etc. This subclause

provides experimental data and considerations for the information of the thermal effects

induced by connector and splice losses in high-power amplifiers [6].

Figure 2 shows temperature increase versus connection loss, which are measured by the

conditions that shown in Table 2. MU type optical connectors for standard single mode fibre

(SMF) and dispersion shifted fibre (DSF) were used for this measurement. The connector loss

was increased by optical fibre misalignment. The optical source used was a 2-W Raman pump

at 1 480 nm. The connector temperature was measured by a thermocouple placed on the

sleeve. Since the MU ferrule diameter was only 1,25 mm, the sleeve temperature was almost

the same as that of the ferrule; ferrule temperature is the most important factor determining

the long-term reliability of optical connectors [7].

Larger increase in temperature is observed in DSF than in SMF due to higher power density.

The result suggests that the temperature increase could be within 10 °C under practical

conditions of loss and power. A commercial dry-type connector cleaner was used in every test

for cleaning the endface of the connectors.

During repeated connection-disconnection of the connectors, neither damage nor fibre fuse

was observed. The experiments with the use of the cleaner identified no problems in terms of

fibre/connector damage and reliability. Without the cleaner, however, the experiment with the

DSF connector indicated that fibre fuse could occur after repeated connection-disconnection

of more than 200 times.

Such temperature increase, and accordingly the danger of fibre fuse, for non-zero dispersion

shifted single-mode optical fibre (NZ-DSF) connectors will be worse than SMF connectors but

better than DSF connectors; the effective areas are SMF>NZDSF>DSF. Further quantitative

studies are needed. Other types of physical contact (PC) connectors such as SC connectors

will show similar temperature responses because only their ferrule radii differ.

In conclusion, it is shown that the thermal effects induced by connector and splice losses in

high-power amplifiers could be acceptable under any practical conditions foreseeable at this

moment. However, special care should be taken to eliminate dust and contamination from the

connector end faces and splice points that could locally induce high-temperature increases

according to the power density absorbed.

Table 2 – Measurement conditions

Parameter Conditions

Fibre SMF, DSF

Connectors MU type

Ferrule Zirconia

Connector/splice loss Imperfect alignment

Wavelength Raman pump – 1 480 nm

Power 2 W

Temperature measurement Thermocouple on the sleeve

S M F

D S F

0 0,2 0,4 0,6 0,8 1,0 1,2

Connection loss (dB)

IEC

Figure 2 – Connection loss versus temperature increase

4.4 Connector end-face damage induced by dust/contamination

The purpose of this clause is to show the increase in attenuation of the connector under test

when the light power into the fibre is extremely high [8].

Figure 3 shows the scheme of the measurement set-up used in the test. The laser pump of a

Raman amplifier is used with a maximum nominal power of 2 W, at a wavelength of 1 455 nm.

PC for acquisition

and data analysis

Climatic chamber

Branching Branching

device device

Variable power

laser source

Connector

1 1

under test

Power Power

meter 2 meter 1

IEC

Figure 3 – Test set-up

The optical connectors used is SC-PC type with a perfectly clean surface, with skin grease

(from operators), with dust (from the floor of the lab) and with metal filings (from a metallic

sleeve).

a) Test result on clean connectors

Two plugs without defects on the polished fibre surface are used. The laser power is

increased in steps to 1,2 W after a thorough cleaning. The test was conducted at ambient

Temperature increase (degr.)

– 12 – IEC TR 61292-4:2014 © IEC 2014

temperature and in a chamber at 70 °C. During the entire test, the variation of the

attenuation was less than 0,02 dB and the visual examination of the fibre surface at the

microscope did not show any damage.

b) Test result on connectors contaminated with skin grease

A layer of grease was put down on two plugs without any defect, by simply touching the

polishing surface with the hands. When increasing the power from 100 mW to 1 200 mW

at ambient temperature, the attenuation varied within a few hundredths of a dB. The visual

inspection with a microscope after the test showed a cleaning effect, probably due to high

temperature near the fibre. After the surface cleaning, no damage was observed.

c) Test result on connectors contaminated with dust

In this case, dust from the laboratory floor was put on the polishing surface of the plugs.

After the initial increase of the attenuation from zero (= normalized value) to 0,06 dB with

200 mW input power, the attenuation started to decrease with the increase in the power

until –0,15 dB with 1,2 W input power. This effect of improvement in power transmission

could be due to a cleaning action of the high temperature on the finest particles. Also in

this case, after the cleaning at the end of the test, the surfaces did not show any damage.

d) Test result on connectors contaminated with metal dust

In this test, we put down on the plug surfaces metal dust obtained by filing a metallic

sleeve of an adapter. This condition simulates the presence of metallic particles produced

by the friction of the ferule during the insertion into a metallic sleeve.

The first test was performed by heavily contaminating the surfaces, as Figure 4 shows.

This is clear from the initial attenuation value that was 3 dB to 4 dB higher than the ones

for the other conditions.

During the test, already at 200 mW, the attenuation increased by about 0,3 dB. At the

400 mW step, the damage was evident with attenuation increased to 1,1 dB (Figure 5). As

failure occurred, the test was stopped to visually inspect the surfaces.

Obvious signs of burning were observed on the core of both fibres that could not be

eliminated by cleaning the surface. The visual inspection of polished surface through a

microscope (Figure 6) shows fused metal glued on the fibre cores. These clots are not

removable by cleaning the surfaces.

IEC

Figure 4 – Surface condition contaminated with metal filings, before the test

Connection of two plugs contaminated with metal filing

1,6 1,6

1,4 1,4

1,2 1,2

1 1

0,8 0,8

0,6 0,6

0,4 0,4

0,2 0,2

0 0

0 50 100 150 200 250 300

Time (min)

IEC

Figure 5 – Variation of the power attenuation during the test at several

power input values for plugs contaminated with metal filings

Plug 1 Plug 2

IEC

Figure 6 – Polishing surface condition contaminated with metal filing, after the test

In conclusion, it is confirmed that there is no risk of damage on the connectors due to high

optical power under the conditions tested, if the connectors are correctly used and handled. In

particular, it is recommended never to open connectors while high optical power is passing

through them. However, a correct cleaning procedure and visual analysis of the polished

connector surface is fundamental for a good and reliable network, particularly when metallic

sleeves are used.

4.5 Fibre-coat burn/melt induced by tight fibre bending

This subclause provides some examples of the fibre coat burn/melt induced by tight fibre

bending where the fibre coatings used were

a) UV curable resin: white, blue, green and uncoloured, and

b) nylon white [2].

The fibre used was single mode (SMF).

By using a thermo-viewer image of the bent fibre, the highest temperature at the surface of

each fibre coating was measured. Figure 7 shows an image of the tightly bent fibre with an

optical power of 3 W at 1 480 nm. Shown in Figure 8 is the temperature at the coating surface

Variation of attenuation (dB)

Launched power (W)

– 14 – IEC TR 61292-4:2014 © IEC 2014

versus bending diameter for 3 W at 1 480 nm. The temperature of the nylon-coat surface

reached 150 °C or higher; the nylon coating melted or even burned. The nylon coat burned in

the test after the fibre break at the point where the fibre coat melted.

By considering the test results together with the long-term reliability degradation of coated

SMF, it is suggested that the coated fibre bend diameter should be kept at >20 mm and

>30 mm for the optical powers of 1 W and 3 W, respectively, under the conditions tested.

Another test revealed that transparent UV-resin was more durable than coloured UV-resin

against tight bending.

IEC

Figure 7 – Thermo-viewer image of tightly bent SMF with optical power

of 3 W at 1 480 nm

200 °C

150 °C

100 °C

50 °C Nylon (white)

UV (transparent)

0 °C

Ø 20 Ø 15 Ø 10 Ø 5

Diameter of the loop (mm)

IEC

Figure 8 – Temperature of the coating surface of SMFs against bending with optical

power of 3 W at 1 480 nm

4.6 Summary of the fibre damage

In 4.2, it was found that fibre fuse, once it was initiated for any reason, propagated if the input

signal power was higher than 1,4 W and 1,2 W for SMF and DSF, respectively, under the

conditions tested. However, care should be taken not to momentarily push the fibre across a

sharp edge that may induce a tight bend and trigger fibre fuse even at a lower power than the

above.

In 4.3, it was shown that the thermal effects induced by the connector and splice losses in

high-power amplifiers could be acceptable under any practical conditions.

In 4.4, the connectors were tested with the input powers up to 1,2 W. It was found that only

case discovered that the only case that caused permanent damage to the fibre core was when

surfaces were contaminated by metal particles.

In 4.5, fibre coat burning induced by fibre tight bending was addressed. It is suggested that

the bend diameter of coated fibre should be kept over 20 mm and 30 mm for optical powers of

1 W and 3 W, respectively, under the conditions tested.

Based on 4.2 to 4.5, it is concluded that power levels up to at least 1,2 W can be used without

damaging OAs; the actual upper limit of the power is under study by considering, for example,

the types of fibre and cleanliness of the fibre end faces.

In addition, IEC TR 62627-01 has been published in order to prevent damage to the connector

and IEC 62547 in order to measure the damage of fibre tight bending.

5 Maximum transmissible optical power to keep eyes and skin safe

5.1 Maximum transmissible exposure (MPE) on the surface of eye and skin

Definition 3.59 of IEC 60825-1:2014 defines MPE as follows:

" level of laser radiation to which, under normal circumstances, persons may be exposed

without suffering adverse effects"

Here, the MPE values IEC uses have been specified in ANSI-Z136 [10] based on animal

experiments. Clause 4 of IEC TR 60825-14:2004 gives more details of MPE.

Subclause 4.8.2 of IEC 60825-2:2004 includes the following normative text in which it is

requested that optical fibre communication systems be designed not to exceed the maximum

permissible exposure (MPE), including the time period before an automatic power reduction

(APR) system completes its function:

“Where the OFCS uses an automatic power reduction feature to meet the limits of a hazard

level that is lower than that which would have to be assigned if no automatic power reduction

feature would be present, the irradiance or radiation exposure during the maximum time to

reach the lower hazard level shall not exceed the irradiance or radiant exposure limits (MPE).

For controlled locations the measurement distance is 250 mm for this subclause only”.

Here, the hazard levels of the laser products including OAs are determined based on the

classification rule of IEC 60825-1. In the existing standards, automatic laser shutdown (ALS)

could have the same meaning as automatic power reduction (APR).

5.2 Maximum permissible optical power in the fibre for the safety of eye and skin

5.2.1 General

Informative Annex D of IEC 60825-2:2004 and IEC 60825-2:2004/AM2:2010 gives the

following formula that calculates the maximum permissible optical power P in the fibre by

using the maximum permissible exposure (MPE) to the eyes/skin after free-space propagation.

πd MPE 1

P =

4t

πω d

1 − exp − 0,125

(1)

λNOHD

where

P is the total power in fibre, in W;

–2

;

MPE is the maximum permissible exposure, Jm

ω is the mode field diameter (1/e power density), in m;

– 16 – IEC TR 61292-4:2014 © IEC 2014

d is the limiting aperture diameter, in m;

t is the shut down time, in s;

NOHD is the nominal ocular hazard distance, in m;

λ is the wavelength, in m.

Based on Formula (1), Table D.14 of IEC 60825-2:2004 and IEC 60285-2:2004/AMD2:2010

shows examples of power limits for optical fibre communication systems that have the APR to

reduce the power to a lower hazard level. MPEs used in the calculation are shown in Tables 5,

6 and 7 of IEC 60825-14:2004.

Table 3 reiterates Table D.14 of IEC 60825-2:2004 and IEC 60285-2:2004/AMD2:2010. It

shall be noted that the maximum permissible optical power in such OAs can be increased by

reducing the power reduction time of the APR (the shut down time).

Table 3 – Examples of power limits for optical fibre communication systems

having automatic power reduction to reduce emissions to a lower hazard level

Wavelength Fibre mode Maximum Maximum Maximum Shutdown Measurement

field power output power output power output times distance

diameter unrestricted restricted controlled

nm µm mW mW mW s m

980 7 9,4 9,4 – 1 0,1

980 7 N/A 7,2 – 3 0,1

980 7 N/A – 39 3 0,25

1 310 11 78 78 – 1 0,1

1 310 11 N/A 59 – 3 0,1

1 310 11 N/A – 314 3 0,25

1 400 . 1 500 11 1 598 1 598 – 0,3 0,1

1 400 . 1 500 11 650 650 – 1 0,1

1 400 . 1 500 11 N/A 389 – 2 0,1

1 400 . 1 500 11 N/A 288 – 3 0,1

1 400 . 1 500 11 N/A – 2 403 2 0,25

1 400 . 1 500 11 N/A – 1 774 3 0,25

1 550 11 2 539 2 539 – 0,5 0,1

1 550 11 1 273 1 273 – 1 0,1

1 550 11 N/A 639 – 2 0,1

1 550 11 N/A 428 – 3 0,1

1 550 11 N/A – 2 640 3 0,25

NOTE 1 The fibre parameters used are the most conservative case. Listed figures for λ = 1 310 nm . 1 550 nm

are calculated for a fibre of 11 microns mode field diameter (MFD) and those for λ = 980 nm are for 7 microns

MFD.

Many systems operating at 1 550 nm with the use of erbium doped fibre amplifiers (EDFAs) pumped by 1 480 nm

or 980 nm lasers use transmission fibres with smaller MFDs. For example, 1 550 nm dispersion shifted fibre

cables have upper limit values of MFD of 9,1 microns. In this case, the maximum power outputs for unrestricted

and restricted areas at 1 480 nm and 1 550 nm are 1,44 times the values in Table D.14, and those for controlled

areas at 1 480 nm and 1 550 nm are 1,46 times the values in same table.

NOTE 2 Times given in the table are examples; shutdown at any shorter time than the maximum is permissible,

and may permit the use of higher powers (the maximum times are 1 s for unrestricted locations and 3 s for

restricted and controlled locations, respectively).

Here, it is assumed that the user does not employ any optical instrument or viewing optics

within the beam. When optical instruments or viewing optics are not used, devices classified

as 1M are considered safe under the conditions indicated in Clause 8 of IEC 60825-1:2007.

However, they may be hazardous if the user employs optical instruments or viewing optics

within the beam.

5.2.2 Need for APR

Appendix II of ITU-T Recommendation G.664:2012 states the following, suggesting that the

APR is needed not only on the main optical signal sources but also on all pump-lasers

employed:

“In particular Distributed Raman amplification systems will need specific care to ensure

optically safe working conditions, because high pump powers (power levels above + 30 dBm

are not uncommon) may be injected in optical fibre cables.

“Therefore APR procedures are required in order to avoid hazards from laser radiation to

human eye or skin and potential additional hazards such as temperature increase (or even fire)

caused by local increased absorption due to connector pollution/damages or very tight fibre

bends.

“In order to ensure that the power levels emitting from broken or open fibres connections are

at safe levels, it is necessary to reduce the power not only on the main optical signal sources

but also on all pump-las

...

IEC TR 61292-4 ®

Edition 3.0 2014-10

TECHNICAL

REPORT

colour

inside

Optical amplifiers –

Part 4: Maximum permissible optical power for the damage-free and safe use of

optical amplifiers, including Raman amplifiers

61292-4

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC TR 61292-4 ®

Edition 3.0 2014-10

TECHNICAL

REPORT

colour

inside

Optical amplifiers –

Part 4: Maximum permissible optical power for the damage-free and safe use of

optical amplifiers, including Raman amplifiers

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

V

ICS 33.160.10 33.180.30 ISBN 978-2-8322-1907-2

– 2 – IEC TR 61292-4:2014 © IEC 2014

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope and object . 7

2 Normative references . 7

3 Abbreviated terms . 8

4 Maximum transmissible optical power to keep fibres damage-free . 8

4.1 General . 8

4.2 Fibre fuse and its propagation . 9

4.3 Loss-induced heating at connectors or splices . 10

4.4 Connector end-face damage induced by dust/contamination . 11

4.5 Fibre-coat burn/melt induced by tight fibre bending . 13

4.6 Summary of the fibre damage . 14

5 Maximum transmissible optical power to keep eyes and skin safe . 15

5.1 Maximum transmissible exposure (MPE) on the surface of eye and skin . 15

5.2 Maximum permissible optical power in the fibre for the safety of eye and skin. 15

5.2.1 General . 15

5.2.2 Need for APR . 17

5.2.3 Wavelengths . 17

5.2.4 Locations . 17

5.2.5 Nominal ocular hazard distance (NOHD). 17

5.2.6 Power reduction times . 17

5.2.7 Medical aspects of the safety of eyes and skin in existing standards . 18

6 Maximum optical power permissible for optical amplifiers from the viewpoint of

fibre damage as well as eye and skin safety . 19

7 Conclusion . 19

Annex A (informative) General information for optical fibre fuse . 20

A.1 Introduction . 20

A.2 Generating mechanism . 20

A.3 Figure A.3 – Calculated fibre fuse propagation behaviour simulated with the

SiO absorption modelVoid formation mechanism . 23

A.4 Propagation characteristic of a fibre fuse . 24

A.5 Prevention and termination . 26

A.5.1 General . 26

A.5.2 Prevention methods . 26

A.5.3 Termination methods . 26

A.6 Conclusion . 29

Bibliography . 30

Figure 1 – Experimental set-up for fibre fuse propagation . 9

Figure 2 – Connection loss versus temperature increase . 11

Figure 3 – Test set-up . 11

Figure 4 – Surface condition contaminated with metal filings, before the test . 12

Figure 5 – Variation of the power attenuation during the test at several power input

values for plugs contaminated with metal filings . 13

Figure 6 – Polishing surface condition contaminated with metal filing, after the test . 13

Figure 7 – Thermo-viewer image of tightly-bent SMF with optical power of 3 W at

1 480 nm . 14

Figure 8 – Temperature of the coating surface of SMFs against bending with optical

power of 3 W at 1 480 nm . 14

Figure 9 – Maximum permissible power in the fibre against APR power reduction time . 18

Figure A.1 – Front part of the fibre fuse damage generated in the optical fibre . 20

Figure A.2 – SiO absorption model . 22

Figure A.3 – Calculated fibre fuse propagation behaviour simulated with the SiO

absorption modelVoid formation mechanism . 23

Figure A.4 – Series of optical micrographs showing damage generated by 9,0 W

1 480 nm laser light suggesting a mechanism of periodic void formation . 24

Figure A.5 – Images of fibre fuse ignition taken with an ultra-high speed camera and

an optical micrograph of the damaged fibre. 25

Figure A.6 – Power density dependence of the fibre-fuse propagation velocity . 25

Figure A.7 – Optical micrographs showing front part of the fibre fuse damage

generated in SMF-28 fibres with various laser intensities (1 480 nm) . 26

Figure A.8 – Principle of the optical fibre fuse passive termination method and

photograph of the fibre fuse terminator which adopted TEC structure . 27

Figure A.9 – Photograph of hole-assistant fibre and fibre fuse termination using a hole-

assistant fibre . 28

Figure A.10 – Example of fibre fuse active termination scheme . 29

Figure A.11 – Transformation of electric signal by optical fibre fuse . 29

Table 1 – Threshold power of fibre fuse propagation for various fibres . 9

Table 2 – Measurement conditions. 10

Table 3 – Examples of power limits for optical fibre communication systems having

automatic power reduction to reduce emissions to a lower hazard level . 16

Table 4 – Location types within an optical fibre communication system and their

typical installations . 17

– 4 – IEC TR 61292-4:2014 © IEC 2014

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

OPTICAL AMPLIFIERS –

Part 4: Maximum permissible optical power for the damage-free and safe

use of optical amplifiers, including Raman amplifiers

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a technical report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC TR 61292-4, which is a technical report, has been prepared by subcommittee 86C: Fibre

optic systems and active devices, of IEC technical committee 86: Fibre optics.

This third edition cancels and replaces the second edition, published in 2010, and constitutes

a technical revision with updates reflecting new research in the subject area.

The text of this technical report is based on the following documents:

Enquiry draft Report on voting

86C/1158/DTR 86C/1200/RVC

Full information on the voting for the approval of this technical report can be found in the

report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 61292 series, published under the general title, Optical amplifiers,

can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC TR 61292-4:2014 © IEC 2014

INTRODUCTION

This technical report is dedicated to the subject of maximum permissible optical power for

damage-free and safe use of optical amplifiers, including Raman amplifiers. Since the

technology is quite new and still evolving, amendments and new editions to this report can be

expected.

Many new types of optical amplifiers are entering the marketplace and research is also

stimulating many new types of fibre and non-fibre based optical amplifier research. With the

introduction of such technologies as long-haul, over 40 Gb/s, WDM transmission and Raman

amplification, some optical amplifiers may involve optical pump sources with extremely high

optical power – up to, possibly, several watts.

Excessively high optical power may cause physical damage to the fibres/optical

components/equipment as well as present medical danger to the human eye and skin.

The possibility of fibre damage caused by high optical intensity has recently been discussed

at some technical conferences. The use of high intensity optical amplifiers may cause

problems in the fibre such as a fibre fuse, a heating in the splice point (connection point), and

the fibre end-face damage due to dust and the fibre coat burning due to tight fibre bending.

IEC SC 86A (Fibres and cables) has published IEC TR 62547, and SC 86B (Fibre optic

interconnecting devices and passive components) has published IEC TR 62627-01.

IEC TC 31 (Equipment for explosive atmospheres) is also discussing the risk of ignition of

hazardous environments by radiation from optical equipment.

Medical aspects have long been discussed at standards groups. IEC TC 76 (Optical radiation

safety and laser equipment) precisely describes in IEC 60825-2 the concept of hazard level

and labelling and addresses the safety aspects of lasers specifically in relation to tissue

damage.

ITU-T Study Group 15 (Optical and other transport networks) has published Recommendation

G.664, which primarily discusses the automatic laser power reduction functionality for safety.

With the recent growth of interest in fibre Raman amplifiers, however, some difficulties have

been identified among optical amplifier users and manufacturers in fully understanding the

technical details and requirements across all such standards and agreements.

This technical report provides a simple informative guideline on the maximum optical power

permissible for optical amplifiers for optical amplifier users and manufacturers.

OPTICAL AMPLIFIERS

Part 4: Maximum permissible optical power for the damage-free and safe

use of optical amplifiers, including Raman amplifiers

1 Scope and object

This part of IEC 61292, which is a technical report, applies to all commercially available

optical amplifiers (OAs), including optical fibre amplifiers (OFAs) using active fibres, as well

as Raman amplifiers. Semiconductor optical amplifiers (SOAs) using semiconductor gain

media are also included.

This technical report provides a simple informative guideline on the threshold of high optical

power that causes high-temperature damage of fibre. Also discussed is optical safety for

manufacturers and users of optical amplifiers by reiterating substantial parts of existing

standards and agreements on eye and skin safety.

To identify the maximum permissible optical power in the optical amplifier from damage-free

and safety viewpoints, this technical report identifies the following values:

a) the optical power limit that causes thermal damage to the fibre, such as fibre fuse and

fibre-coat burning;

b) the maximum permissible exposure (MPE) to which the eyes/skin can be exposed without

consequential injury;

c) the optical power limit in the fibre that causes MPE on the eyes/skin after free-space

propagation from the fibre;

d) the absolute allowable damage-free and safe level of optical power of the optical amplifier

by comparing (a) and (c).

The objective of this technical report is to minimize potential confusion and misunderstanding

in the industry that might cause unnecessary alarm and hinder the progress and acceptance

of advancing optical amplifier technologies and markets.

It is important to point out that the reader should always refer to the latest international

standards and agreements because the technologies concerned are rapidly evolving.

The present technical report will be frequently reviewed and will be updated by incorporating

the results of various studies related to OAs and OA-supported optical systems in a timely

manner.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60825-1:2007, Safety of laser products – Part 1: Equipment classification and

requirements

– 8 – IEC TR 61292-4:2014 © IEC 2014

IEC 60825-2:2004, Safety of laser products – Part 2: Safety of optical fibre communication

systems (OFCS)

Amendment 1 (2006)

Amendment 2 (2010)

IEC TR 60825-14:2004, Safety of laser products – Part 14: A user’s guide

IEC TR 62547, Guidelines for the measurement of high-power damage sensitivity of single-

mode fibres to bends – Guidance for the interpretation of results

IEC TR 62627-01, Fibre optic interconnecting devices and passive components – Part 01:

Fibre optic connector cleaning methods

ITU-T Recommendation G.664:2012, Optical safety procedures and requirements for optical

transport systems

3 Abbreviated terms

For the purposes of this document, the following abbreviated terms apply.

ALS automatic laser shutdown

APR automatic power reduction

DSF dispersion shifted fibre

LOS loss of signal

MFD mode field diameter

MPE maximum permissible exposure

MPI-R single channel receive main path Interface reference point

MPI-S single channel source main path interface reference point

NOHD nominal ocular hazard distance

NZ-DSF non-zero dispersion shifted single-mode optical fibre

OA optical amplifier

OFA optical fibre amplifier

SMF single mode fibre

SOA semiconductor optical amplifier

4 Maximum transmissible optical power to keep fibres damage-free

4.1 General

The use and reasonably foreseeable misuse of high intensity optical amplifiers may cause

problems in the fibre such as

a) fibre fuse and its propagation,

b) heating in the splice point/connection point,

c) fibre end-face damage due to dust and other contamination,

d) fibre coat burning and ignition of hazardous environments due to tight fibre bending or

breakage.

This clause introduces their results concerning the above issues to give guidelines for the

damage-free use of optical amplifiers. However, it should be noted that the following results

are only valid under the conditions tested and that a higher power might be allowed under

different conditions.

4.2 Fibre fuse and its propagation

The safety of optical amplifiers should be discussed from the viewpoint of laser hazard to the

eyes and skin as well as fibre damage such as fibre-coat burning and fibre fusing. This clause

experimentally analyses the fibre fuse and its propagation caused by high optical power and

discusses the threshold power of fibre fuse propagation [1] . It is defined that the fibre fuse is

the phenomenon in which an intense blue-white flash occurred and ran along the fibre toward

the high power light source while forming periodic and/or non-periodic voids.

Figure 1 shows a typical measurement set-up for the threshold power of fibre fuse

propagation. The fibre fuse is initiated by heating the optical fibre from outside of the fibre by

using an independent heat source, while a high optical power is continuously launched into

the fibre. Once the fibre fuse began propagating, the optical source power is continuously

reduced until the fuse propagation stopped for measuring the threshold power. Table 1 shows

the threshold powers which were measured at various wavelengths of the high-power optical

source for various fibres. Although the threshold power depends on the wavelength of the

high-power optical source, the power for the fuse propagation is less than 1,4 W and 1,2 W

for a standard single mode fibre (SMF) and a dispersion shifted fibre (DSF) respectively,

which are used as the optical fibre for typical optical fibre communication systems.

Sample 10 m - 20 m

SMF SMF

High power

Optical power

optical source

meter

SMF/DSF

Splicing

Heating

(Initiation for fibre fuse)

IEC

Figure 1 – Experimental set-up for fibre fuse propagation

Table 1 – Threshold power of fibre fuse propagation for various fibres

Measurement Threshold power of

Fibre type wavelength fibre fuse propagation

W

µm

Standard single mode fibre 1,064 1 [2]

1,467 1,4 [2]

1,48

∼1,2 [3]

1,55 1,39 [4]

Dispersion shifted fibre 1,064 1,2 [2]

1,467 0,65 [2]

1,55 ~1,1 [5]

Dispersion compensation fibre 1,55 ~0,7 [5]

The difference in the fibre mode-field diameter has been the major reason for the difference in

the threshold powers because the fibre fuse depends on the power density [1].

On the other hand, it is difficult to identify the threshold powers for the fibre fuse self-initiation

(without any external cause) because it varied significantly, although they well exceeded

___________

Figures in square brackets refer to the Bibliography.

– 10 – IEC TR 61292-4:2014 © IEC 2014

1,4 W and 1,2 W for standard single mode fibre (SMF) and dispersion shifted fibre (DSF)

respectively.

Further information such as the generating mechanism, the characteristics of fibre fuse and

the prevention and the termination for the fibre fuse is described in Annex A.

4.3 Loss-induced heating at connectors or splices

In extremely high power optical amplifiers, the loss-induced heating at fibres and connectors

or splices could lead to damage, including fibre-coat burning, fibre fuse, etc. This subclause

provides experimental data and considerations for the information of the thermal effects

induced by connector and splice losses in high-power amplifiers [6].

Figure 2 shows temperature increase versus connection loss, which are measured by the

conditions that shown in Table 2. MU type optical connectors for standard single mode fibre

(SMF) and dispersion shifted fibre (DSF) were used for this measurement. The connector loss

was increased by optical fibre misalignment. The optical source used was a 2-W Raman pump

at 1 480 nm. The connector temperature was measured by a thermocouple placed on the

sleeve. Since the MU ferrule diameter was only 1,25 mm, the sleeve temperature was almost

the same as that of the ferrule; ferrule temperature is the most important factor determining

the long-term reliability of optical connectors [7].

Larger increase in temperature is observed in DSF than in SMF due to higher power density.

The result suggests that the temperature increase could be within 10 °C under practical

conditions of loss and power. A commercial dry-type connector cleaner was used in every test

for cleaning the endface of the connectors.

During repeated connection-disconnection of the connectors, neither damage nor fibre fuse

was observed. The experiments with the use of the cleaner identified no problems in terms of

fibre/connector damage and reliability. Without the cleaner, however, the experiment with the

DSF connector indicated that fibre fuse could occur after repeated connection-disconnection

of more than 200 times.

Such temperature increase, and accordingly the danger of fibre fuse, for non-zero dispersion

shifted single-mode optical fibre (NZ-DSF) connectors will be worse than SMF connectors but

better than DSF connectors; the effective areas are SMF>NZDSF>DSF. Further quantitative

studies are needed. Other types of physical contact (PC) connectors such as SC connectors

will show similar temperature responses because only their ferrule radii differ.

In conclusion, it is shown that the thermal effects induced by connector and splice losses in

high-power amplifiers could be acceptable under any practical conditions foreseeable at this

moment. However, special care should be taken to eliminate dust and contamination from the

connector end faces and splice points that could locally induce high-temperature increases

according to the power density absorbed.

Table 2 – Measurement conditions

Parameter Conditions

Fibre SMF, DSF

Connectors MU type

Ferrule Zirconia

Connector/splice loss Imperfect alignment

Wavelength Raman pump – 1 480 nm

Power 2 W

Temperature measurement Thermocouple on the sleeve

S M F

D S F

0 0,2 0,4 0,6 0,8 1,0 1,2

Connection loss (dB)

IEC

Figure 2 – Connection loss versus temperature increase

4.4 Connector end-face damage induced by dust/contamination

The purpose of this clause is to show the increase in attenuation of the connector under test

when the light power into the fibre is extremely high [8].

Figure 3 shows the scheme of the measurement set-up used in the test. The laser pump of a

Raman amplifier is used with a maximum nominal power of 2 W, at a wavelength of 1 455 nm.

PC for acquisition

and data analysis

Climatic chamber

Branching Branching

device device

Variable power