IEC TS 60034-34:2020

(Main)Rotating electrical machines - Part 34: AC adjustable speed rolling mill motors

Rotating electrical machines - Part 34: AC adjustable speed rolling mill motors

IEC TS 60034-34:2020 is applicable to AC adjustable speed rolling mill motors and identifies specific requirements for AC adjustable speed rolling mill motors, where those performance characteristics are different from those for conventional AC motors.

Various types of overload capacity conditions and overloads are defined. The possible effect on motor insulation life due to operating the motor beyond its design capability is discussed.

Requirements for confirmation of motor under specified variable speed operational conditions are introduced.

General Information

- Status

- Published

- Publication Date

- 18-Nov-2020

- Technical Committee

- TC 2 - Rotating machinery

- Drafting Committee

- MT 15 - TC 2/MT 15

- Current Stage

- PPUB - Publication issued

- Start Date

- 19-Nov-2020

- Completion Date

- 11-Dec-2020

Overview

IEC TS 60034-34:2020 is a Technical Specification from the IEC that defines specific requirements for AC adjustable speed rolling mill motors where their performance differs from conventional AC motors. It covers motor design, thermal behaviour, overload capacity, testing and verification under the variable-speed, high-duty conditions typical in rolling-mill applications. The document helps manufacturers, OEMs, mill operators and test engineers ensure motors meet performance, reliability and safety expectations for rolling mills.

Key topics and requirements

- Scope and terminology: Definitions tailored for adjustable-speed control, rolling operation patterns and monitoring/protection sequences.

- Terminal voltage and speed characteristics: Guidance on motor terminal voltage behaviour (induction and synchronous) across speed ranges.

- Duty type & temperature class: Selection of duty (e.g., continuous or intermittent), winding temperature rise (Class B/F) and evaluation of winding temperature deviation within one rolling cycle.

- Overload capacity: Definitions of various overload types (continuous and short-time) and limits; Annex A specifies short-time overload capability patterns.

- Thermal life / insulation evaluation: Methods to estimate reduced insulation life when motors are operated beyond design limits (simplified and precise approaches in Annexes C and D).

- Mechanical requirements: Shaft/transmission strength, torsional vibration considerations, thrust and radial loads, overspeed and mounting code guidance.

- Withstand voltage: Requirements and tests for ground insulation, turn-to-turn insulation and rotor/damper bars under converter-fed conditions.

- Factory and site tests: Required factory tests and recommended site trials, including vector-control verification, acceleration/deceleration, no-load characteristics and bearing temperature rise tests.

- Grounding and bearing protection: Protective earthing (PE), functional earthing (FE) and measures against bearing currents.

- Control system guidance: Informative annexes provide typical control system configurations for induction and synchronous motors and explain significance of acceleration/deceleration tests.

- Documentation: Rating plate requirements and test records.

Practical applications and users

This TS is intended for:

- Motor manufacturers designing AC adjustable speed rolling mill motors for hot/cold, continuous or reversing rolling mills.

- OEMs and system integrators who specify motor-drive systems (inverters, vector control, synchronous systems).

- Plant operators, maintenance and commissioning teams performing factory acceptance tests (FAT) and site trial operations.

- Design engineers assessing overload scenarios, insulation life, bearing protection and mechanical loads for rolling mill drives.

Practical benefits include improved motor selection for heavy-duty rolling patterns, clearer factory/site test protocols, and guidance to reduce unexpected insulation degradation and mechanical failures.

Related standards

- IEC 60034 series (rotating electrical machines) - provides general requirements for motors; IEC TS 60034-34:2020 supplements these for rolling-mill specific, adjustable-speed applications.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC TS 60034-34:2020 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Rotating electrical machines - Part 34: AC adjustable speed rolling mill motors". This standard covers: IEC TS 60034-34:2020 is applicable to AC adjustable speed rolling mill motors and identifies specific requirements for AC adjustable speed rolling mill motors, where those performance characteristics are different from those for conventional AC motors. Various types of overload capacity conditions and overloads are defined. The possible effect on motor insulation life due to operating the motor beyond its design capability is discussed. Requirements for confirmation of motor under specified variable speed operational conditions are introduced.

IEC TS 60034-34:2020 is applicable to AC adjustable speed rolling mill motors and identifies specific requirements for AC adjustable speed rolling mill motors, where those performance characteristics are different from those for conventional AC motors. Various types of overload capacity conditions and overloads are defined. The possible effect on motor insulation life due to operating the motor beyond its design capability is discussed. Requirements for confirmation of motor under specified variable speed operational conditions are introduced.

IEC TS 60034-34:2020 is classified under the following ICS (International Classification for Standards) categories: 29.160.01 - Rotating machinery in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 60034-34:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TS 60034-34 ®

Edition 1.0 2020-11

TECHNICAL

SPECIFICATION

colour

inside

Rotating electrical machines –

Part 34: AC adjustable speed rolling mill motors

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC TS 60034-34 ®

Edition 1.0 2020-11

TECHNICAL

SPECIFICATION

colour

inside

Rotating electrical machines –

Part 34: AC adjustable speed rolling mill motors

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.160.01 ISBN 978-2-8322-9046-0

– 2 – IEC TS 60034-34:2020 © IEC 2020

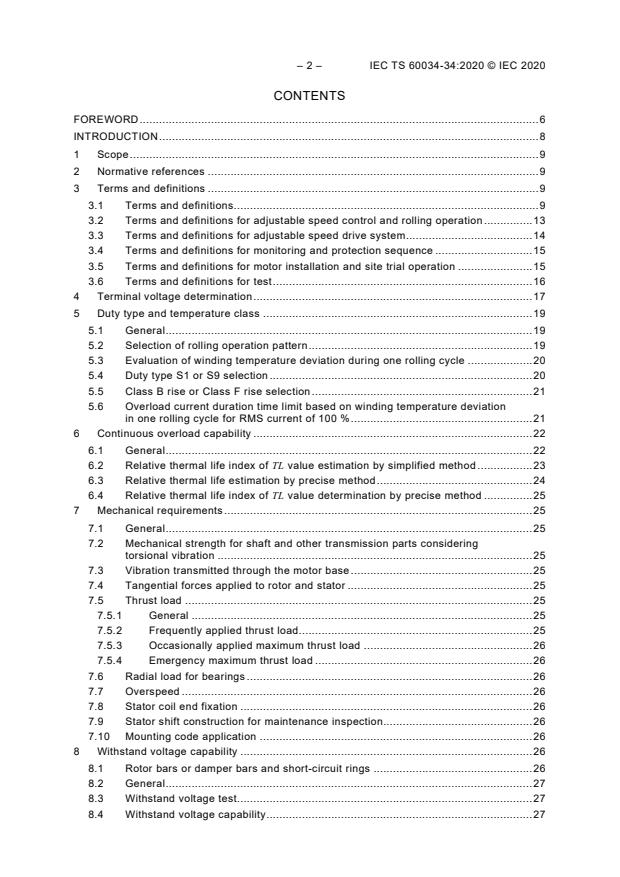

CONTENTS

FOREWORD . 6

INTRODUCTION . 8

1 Scope . 9

2 Normative references . 9

3 Terms and definitions . 9

3.1 Terms and definitions . 9

3.2 Terms and definitions for adjustable speed control and rolling operation . 13

3.3 Terms and definitions for adjustable speed drive system . 14

3.4 Terms and definitions for monitoring and protection sequence . 15

3.5 Terms and definitions for motor installation and site trial operation . 15

3.6 Terms and definitions for test . 16

4 Terminal voltage determination . 17

5 Duty type and temperature class . 19

5.1 General . 19

5.2 Selection of rolling operation pattern . 19

5.3 Evaluation of winding temperature deviation during one rolling cycle . 20

5.4 Duty type S1 or S9 selection . 20

5.5 Class B rise or Class F rise selection . 21

5.6 Overload current duration time limit based on winding temperature deviation

in one rolling cycle for RMS current of 100 % . 21

6 Continuous overload capability . 22

6.1 General . 22

6.2 Relative thermal life index of TL value estimation by simplified method . 23

6.3 Relative thermal life estimation by precise method . 24

6.4 Relative thermal life index of TL value determination by precise method . 25

7 Mechanical requirements . 25

7.1 General . 25

7.2 Mechanical strength for shaft and other transmission parts considering

torsional vibration . 25

7.3 Vibration transmitted through the motor base . 25

7.4 Tangential forces applied to rotor and stator . 25

7.5 Thrust load . 25

7.5.1 General . 25

7.5.2 Frequently applied thrust load . 25

7.5.3 Occasionally applied maximum thrust load . 26

7.5.4 Emergency maximum thrust load . 26

7.6 Radial load for bearings . 26

7.7 Overspeed . 26

7.8 Stator coil end fixation . 26

7.9 Stator shift construction for maintenance inspection. 26

7.10 Mounting code application . 26

8 Withstand voltage capability . 26

8.1 Rotor bars or damper bars and short-circuit rings . 26

8.2 General . 27

8.3 Withstand voltage test . 27

8.4 Withstand voltage capability . 27

8.4.1 General . 27

8.4.2 Ground insulation . 27

8.4.3 Turn-to-turn insulation . 29

9 Factory tests and recommended site operation tests . 29

9.1 General . 29

9.1.1 General scope for the tests . 29

9.1.2 Requirements of the site operation test where vector control is applied . 29

9.2 Factory test . 30

9.3 Preparation before trial operation at site . 30

9.3.1 General . 30

9.3.2 Calibration of feedback signals for the converter . 31

9.3.3 Insulation resistance tests for motor . 31

9.3.4 Insulation resistance tests for bearings . 31

9.3.5 Performance test for bearing lubrication oil supply unit . 31

9.3.6 Confirmation of lubrication oil surface level for bearings . 31

9.3.7 Performance test for cooling systems . 31

9.3.8 Confirmation of alarm issue levels for motor protection . 31

9.3.9 Synchronous motor pole position confirmation test . 32

9.4 Site uncoupled trial operation . 32

9.4.1 General . 32

9.4.2 Rotational speed build-up test . 32

9.4.3 Bearing temperature rise test . 32

9.5 Site no-load characteristic test . 32

9.5.1 Induction motor no-load characteristics test . 32

9.5.2 Synchronous motor no-load characteristics test . 33

9.5.3 No-load characteristics test record. 33

9.6 Site acceleration and deceleration test . 33

10 Grounding . 34

10.1 General . 34

10.2 Protection against bearing currents . 34

10.3 Protective earthing (PE) . 34

10.4 Functional earthing (FE) . 34

11 Rating plate . 35

Annex A (normative) Short-time overload capability . 36

A.1 General . 36

A.2 Frequently applied Art-1 short-time overload capability specification . 36

A.3 Frequently applied Art-2 short-time overload capability specification . 39

Annex B (normative) Rolling operation pattern designation . 42

B.1 General . 42

B.2 Rolling operation pattern for hot reversing rolling . 42

B.3 Rolling operation pattern for hot continuous rolling of sheet strip . 43

B.4 Rolling operation pattern for continuous caster directly connected hot

continuous rolling mills . 44

B.5 Rolling operation pattern for hot continuous rolling for wire and rod mills . 45

B.6 Rolling operation pattern for cold reversing rolling mills . 46

B.7 Rolling operation pattern for cold continuous rolling . 47

B.8 Operation pattern for coilers and reels . 48

Annex C (informative) Determination of winding temperature deviation in one rolling

cycle . 50

– 4 – IEC TS 60034-34:2020 © IEC 2020

C.1 General . 50

C.2 Simplified method for estimation of the winding temperature deviation

between maximum and mean values in one rolling cycle . 50

C.3 Precise method for estimation of the winding temperature deviation between

maximum and mean in one rolling cycle . 52

Annex D (informative) Evaluation of reduced insulation life . 57

Annex E (informative) Control system configuration for the assumed adjustable speed

rolling mill induction motors . 59

E.1 Induction motor model and controller configuration . 59

E.2 Significance of acceleration and deceleration tests . 62

Annex F (informative) Control system configuration for the assumed adjustable speed

rolling mill synchronous motors . 63

F.1 Control device configuration and synchronous machine model . 63

F.2 Significance of acceleration and deceleration tests . 66

F.3 Magnetic pole position confirmation test . 67

Annex G (informative) Mounting code application for the rolling mill motor special

cases . 68

G.1 General . 68

G.2 IM code application for the twin-drive rolling mill configuration . 68

G.2.1 General . 68

G.2.2 IM code application for common base configuration . 68

G.3 IM code application for sub-base insertion under the motor base for lifting-up

motor shaft centre . 69

G.4 Coupling supply for cylindrical shaft extension . 70

Bibliography . 71

Figure 1 – Example of induction motor terminal voltage versus speed . 18

Figure 2 – Example of synchronous motor terminal voltage versus speed . 18

Figure 3 – Selection of motor temperature rise based on the temperature deviation in

one rolling cycle and shock load conditions . 21

Figure 4 – Example of overload current duration time limit based on winding

temperature deviation between maximum and mean, in one rolling cycle RMS current

of 100 % . 22

Figure 5 – Example of discrete constant loads with 115 % continuous overload . 24

Figure 6 – 2-level inverter configuration, waveform and switching surge voltage . 28

Figure 7 – 3-level inverter configuration, waveform and switching surge voltage . 28

Figure 8 – Example of protective earthing and functional earthing. 35

Figure A.1 – Art-1 short-time overload capability of Type-A motors . 37

Figure A.2 – Art-1 short-time overload capability of Type-B motors . 38

Figure A.3 – Art-2 short-time overload capability of Type-A motors . 40

Figure A.4 – Art-2 short-time overload capability of Type-B motors . 41

Figure B.1 – Typical rolling operation pattern for hot reversing rolling . 43

Figure B.2 – Typical rolling operation for hot continuous rolling of sheet strip . 44

Figure B.3 – Typical rolling operation pattern for continuous caster connected hot

continuous rolling for sheet strip . 45

Figure B.4 – Typical rolling operation pattern for hot continuous rolling for wire and

rod mills . 46

Figure B.5 – Typical rolling operation pattern for cold reversing rolling mills . 47

Figure B.6 – Typical rolling operation pattern for cold continuous rolling . 48

Figure B.7 – Typical rolling operation pattern for coilers and reels . 49

Figure C.1 – Winding temperature rise as a step response for the first order delay

system with the winding thermal equivalent time constant of T . 50

Figure C.2 – Numerical calculation result for the condition in Table C.1 . 52

Figure C.3 – Equivalent rectangular current waveform introduction . 52

Figure C.4 – Torque, speed, and current deviation in one rolling cycle for hot strip mill

finishing motor . 54

Figure C.5 – An example of winding temperature deviation estimation in one rolling

cycle by the precise method . 55

Figure D.1 – Example of stator coil insulation surface crack caused by repetitive

mechanical stress . 58

Figure E.1 – Example configuration of induction motor (IM) control system . 60

Figure F.1 – Principle of armature reaction compensation . 64

Figure F.2 – Example configuration of synchronous motor (SM) control system . 65

Figure F.3 – Armature current and field current waveform example for the adjustable

speed rolling mill synchronous motor for reversing rotational direction mill . 66

Figure G.1 – IM code application for bottom forward twin drive configuration with

common motor bases . 69

Figure G.2 – IM code application for sub-base insertion under the motor base for

increasing motor shaft centre . 70

Table 1 – Thermal life shortening due to the super-temperature in one rolling cycle . 20

Table A.1 – Art-1 short-time overload capability of Type-A motors . 38

Table A.2 – Art-1 short-time overload capability of Type-B motors . 39

Table A.3 – Art-2 short-time overload capability of Type-A motors . 40

Table A.4 – Art-2 short-time overload capability of Type-B motors . 41

Table C.1 – Calculation example for repetitive 225 % overload current with RMS = 1,0 . 51

Table C.2 – An example of winding temperature deviation estimation in one rolling

cycle by the precise method . 56

– 6 – IEC TS 60034-34:2020 © IEC 2020

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ROTATING ELECTRICAL MACHINES –

Part 34: AC adjustable speed rolling mill motors

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. In exceptional

circumstances, a technical committee may propose the publication of a Technical Specification

when

• the required support cannot be obtained for the publication of an International Standard,

despite repeated efforts, or

• the subject is still under technical development or where, for any other reason, there is the

future but no immediate possibility of an agreement on an International Standard.

Technical Specifications are subject to review within three years of publication to decide

whether they can be transformed into International Standards.

IEC TS 60034-34, which is a Technical Specification, has been prepared by IEC technical

committee 2: Rotating machinery.

The text of this Technical Specification is based on the following documents:

Draft TS Report on voting

2/1995/DTS 2/2017/RVDTS

Full information on the voting for the approval of this Technical Specification can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60034 series, published under the general title Rotating electrical

machines, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

– 8 – IEC TS 60034-34:2020 © IEC 2020

INTRODUCTION

Rolling mill DC motors have 100 years of successful history. These metal rolling mill motors

have been manufactured based on specific U.S.A. National Electric Manufacturers Association

(NEMA) standards.

However, the control technology development, owing to progress in semiconductor device

technology and micro-processor application technology, has made it practical to use AC

adjustable speed rolling mill motors, both induction and synchronous motor types.

On the other hand, structures and characteristics of AC motors are far different from those for

DC motors. Therefore, for application of AC adjustable speed rolling mill motors the purchaser

and equipment supplier need a common understanding. This document incorporates various

technical aspects of experience with DC mill motors and AC motor application experiences.

It introduces the field weakening control concept and overload operation as applied to AC

adjustable speed rolling mill motors, and uses this information to specify factory test voltages

to be used.

Various types of overload capacity conditions and overloads are defined. The possible effect

on motor insulation life due to operating the motor beyond its design capability is discussed.

Requirements for confirmation of motor under specified variable speed operational conditions

are introduced.

Rolling loads are defined for several application conditions. These supplement the duty

classifications in IEC 60034-1 with specific cases.

ROTATING ELECTRICAL MACHINES –

Part 34: AC adjustable speed rolling mill motors

1 Scope

This part of IEC 60034 is applicable to AC adjustable speed rolling mill motors and identifies

specific requirements for AC adjustable speed rolling mill motors, where those performance

characteristics are different from those for conventional AC motors.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60034-1:2017, Rotating electrical machines – Part 1: Rating and performance

IEC 60034-2 (all parts), Rotating electrical machines

IEC 60034-7:1992, Rotating electrical machines – Part 7: Classification of types of

constructions and mounting arrangements (IM Code)

IEC 60034-7:1992/AMD1:2000

IEC 60417, Graphical symbols for use on equipment – 12-month subscription to regularly

updated online database comprising all graphical symbols published in IEC 60417

IEC 61800-4:2002, Adjustable speed electrical power drive systems – Part 4: General

requirements – Rating specifications for a.c. power drive systems above 1 000 V a.c. and not

exceeding 35 kV

3 Terms and definitions

For purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1 Terms and definitions

3.1.1

AC adjustable speed rolling mill motor

motor which is applied to metal rolling mill applications

Note 1 to entry: AC motors for rolling mills have the following specific features:

a) high short time overload capability;

b) strong mechanical construction to withstand shock load torque and vibration.

– 10 – IEC TS 60034-34:2020 © IEC 2020

3.1.2

acceleration and deceleration torque

motor output torque available to accelerate or decelerate the driven load to a different speed

3.1.3

base frequency

frequency at rated output of the AC adjustable speed motor

Note 1 to entry: The motor base frequency is the transition point from the constant torque region to the reduced

torque region when field weakening control is used.

Note 2 to entry: Base frequency is measured in hertz (Hz).

3.1.4

base speed

specified motor rotational speed at which the motor is capable of continuously delivering rated

torque and rated output

Note 1 to entry: Base speed is the transition point between constant torque and field weakening operation.

[SOURCE: IEC 61800-4:2002, 3.4.4, modified – introduction of rated output condition.]

3.1.5

continuous overload capability

capability for long time overload operation where thermal equilibrium is reached

3.1.6

coupled

condition where the motor is attached to the driven equipment by means of a mechanical device

or coupling

3.1.7

cut-off output

mechanical protection level based on motor output which, when exceeded, results in an

immediate trip of the motor

3.1.8

cut-off torque

mechanical protection level based on motor torque which, when exceeded, results in an

immediate trip of the motor

3.1.9

endshield bearing type motor

motor which has bearings mounted to the motor frame

3.1.10

field weakening range

speed range from base to top where motor flux is reduced from the value for rated torque

Note 1 to entry: IEC 61800-4:2002, 3.4.5 uses a similar term: "field weakening operation".

3.1.11

frequently applied overload output

output greater than rated which is frequently applied as part of normal rolling operation

3.1.12

frequently applied overload torque

torque greater than rated which is frequently applied as part of normal rolling operation

Note 1 to entry: This is a limit torque for normal rolling process which may be frequently applied provided the RMS

value for load current does not exceed 1,0 p.u.

3.1.13

impact speed drop

phenomenon where rolling speed drops transiently due to a sudden load change due to material

impact on the mechanical equipment (see Figure 1)

10 %

ΔV

d

T

d

ΔVT×

dd

𝜔𝜔 = (%s)

impact_drop

Where

𝜔𝜔 is the impact speed drop;

impact_drop

ΔV is the maximum speed drop (%);

d

T is the period of speed drop (s).

d

3.1.14

journal

part of the shaft where the load surface is in contact with the bearing sleeve

[SOURCE: IEC 60050-411:1996, 411-43-06, modified – relation with bearing sleeve is added.]

3.1.15

maximum safe operating speed

maximum motor rotational speed which does not lead to mechanical deformation nor

deterioration in continuous operation

Note 1 to entry: The definition of maximum safe operating speed is modified from that in IEC TS 60034-25:2014,

18.6

3.1.16

overspeed

motor rotational speed which exceeds motor maximum safe speed

[SOURCE: IEC 60034-1:2017, 9.7, modified: changed to noun phrase and meaning of the speed

is added.]

3.1.17

pedestal bearing type motor

motor which has separate bearing pedestal stands

3.1.18

radial load for bearing

mechanical load applied to the bearings in a radial direction

3.1.19

rated current

motor current when delivering rated output power

– 12 – IEC TS 60034-34:2020 © IEC 2020

3.1.20

rated frequency

specified frequency corresponding to rated output of the motor

Note 1 to entry: Rated frequency is expressed in hertz (Hz).

3.1.21

rated output

output in mechanical power which is available at the shaft

Note 1 to entry: Rated output is expressed in watts (W) or kilowatts (kW).

Note 2 to entry: It is the practice in some countries for the mechanical power available at the shafts of motors to be

expressed in horsepower (1 h.p. is equivalent to 745,7 W; 1 ch (cheval or metric horsepower) is equivalent to 736 W).

[SOURCE: IEC 60034-1:2017, 3.3, modified – “mechanical” and “available at the shaft”, have

been added.]

3.1.22

rated power factor

motor power factor when delivering rated output

rated speed

specified rotational speed of the motor used to define the rated output power

Note 1 to entry: The definition of rated speed in 3.49 of IEC 61800-2:2015 does not consider rated output power in

the field weakening range. The definition in IEC 61800-2 corresponds to term 3.1.4 of this document.

3.1.23

rated torque

motor torque at rated output and rated rotational speed

[SOURCE: IEC 60050-411:1996, 411-48-05, modified – definition simplified, considering the

definition of 3.1.21: “rated output”.]

3.1.24

rating

set of rated values and operating conditions

[SOURCE: IEC 60034-1:2017, 3.2]

3.1.25

reversing operation

operation where normal motor rotation and opposite to normal motor rotation are repeated

alternatively during load cycle

3.1.26

rolling torque

load torque

motor output torque for metal rolling or other connected load requirements

3.1.27

shock load

mechanical impact load applied from an external source

3.1.28

short time overload capability

capability for short time overload operation where thermal equilibrium is not reached

3.1.29

sleeve bearing

bearing where the load surface supporting the journal is cylindrical

[SOURCE: IEC 60050-411:1996, 411-42-07, modified – structure and shape are described.]

3.1.30

stall operation

operation generating torque while the motor is not rotating

Note 1 to entry: Special care should be taken to avoid overheating the converter power semiconductor devices and

slip rings of a synchronous motor.

3.1.31

terminal voltage

line-to-line voltage at the motor terminals

3.1.32

thrust load

mechanical load applied to the bearings in an axial direction

3.1.33

top frequency

maximum design operational frequency of the AC adjustable speed rolling mill motor

Note 1 to entry: Top frequency is expressed in hertz (Hz).

3.1.34

top speed

specified highest motor rotational speed at which continuously rated output is available

3.1.35

torsional vibration

vibration caused by transient torque in the multi-mass spring system consisting of the motor,

shafts, couplings, gears and driven equipment

3.2 Terms and definitions for adjustable speed control and rolling operation

3.2.1

automatic field weakening control

method which controls flux current inversely with speed to maintain the induction voltage

constant from motor base speed to top speed

3.2.2

complete drive module

CDM

drive module consisting of, but not limited to, the basic drive module, which includes the electric

power converter and related control, and extensions such as protection devices, transformers

and auxiliaries, but excluding the motor and sensors which are mechanically coupled to the

motor shaft

Note 1 to entry: Basic drive module (BDM) is defined in 3.4 for and Figure 2 of IEC 61800-2:2015.

[SOURCE: IEC 61800-2:2015, 3.8, modified – “the electric power converter and related control”

is added]

3.2.3

current control

control of motor current

– 14 – IEC TS 60034-34:2020 © IEC 2020

3.2.4

flux component current

component of current which is in quadrature with the motor’s inductive voltage

3.2.5

overload current

motor current that exceeds motor design value

3.2.6

speed control

control of motor rotation speed

[SOURCE: IEC 61800-4:2002, Annex B]

3.2.7

torque control

control of motor torque

3.2.8

torque current

component of current which is the same phase as the motor’s inductive voltage and produces

motor torque

3.2.9

unity power factor control

method which controls converter input power factor to 1,0

3.2.10

vector control

method which independently controls motor flux and torque producing currents

3.3 Terms and definitions for adjustable speed drive system

3.3.1

AC power drive system

power drive system for adjustable speed AC motor, which is defined in IEC 61800-2 for

equipment below 1 000 V (low voltage) and IEC 61800-4 for equipment above 1 000 V (high

voltage)

Note 1 to entry: PDS can include all equipment and control including the transformer, converter, motor and auxiliary

systems.

[SOURCE: IEC 61800-2:2015, Clause 1, IEC 61800-4:2002, Clause 1.]

3.3.2

converter

unit which changes the form of main electrical power to the form supplied to the motor(s) by

changing one or more of the voltage, current, and/or frequency

Note 1 to entry: The converter comprises electronic commutating devices and their associated commutation circuits.

It is controlled by transistors or thyristors or any other power switching semiconductor devices.

Note 2 to entry: The converter can be line-commutated or self-commutated and can consist, for example, of one or

more rectifiers.

[SOURCE: IEC 61800-2:2015, 3.9, modified – Reference to Figure 1 has been deleted.]

3.3.3

functional earthing

FE

grounding of electrical power system and equipment not for personal safety

Note 1 to entry: The definition of functional earthing is modified from that in IEC 60050-195:1998, 195-1-13.

3.3.4

harmonics

multiples of converter input power frequency included in converter output voltage and current

3.3.5

protective earthing

PE

grounding of electrical power system and equipment for personal safety

Note 1 to entry: The definition of protective earthing is modified from that in IEC 60050-195:1998, 195-1-11.

3.3.6

pulse width modulation control

PWM control

converter control method creating constant voltage pulse trains of various widths simulating

variable frequency AC voltages

[SOURCE: IEC 60050-551:1998, 551-16-30, modified – definition is limited to the case

simulating sinusoidal waveform.]

3.3.7

rated inverter voltage

output fundamental wave RMS voltage which defines inverter rated capacity

3.4 Terms and definitions for monitoring and protection sequence

3.4.1

overcurrent protection

protection against motor current exceeding design limits

3.4.2

overspeed protection

protection against motor speed exceeding design limits

3.4.3

overvoltage protection

protection against motor voltage exceeding design limits

3.5 Terms and definitions for motor installation and site trial operation

3.5.1

base

common supporting structure for all motor components

Note 1 to entry: Motor components include the stator and bearings.

3.5.2

shaft centring

installation adjustment to fit the motor shaft to the motor rotation shaft centre

3.5.3

sole plate

steel plate for the purpose of ensuring a level motor installation

– 16 – IEC TS 60034-34:2020 © IEC 2020

3.5.4

trial operation

initial motor no-load operation uncoupled and coupled to the driven equipment

3.6 Terms and definitions for test

3.6.1

factory test

test conducted at the manufacturer’s location

3.6.2

full load

load which causes a machine to operate at its rating, and which may be called “rated load”

[SOURCE: IEC 60034-1:2017, 3.6]

3.6.3

insulation resistance test

measurement to judge motor insulation condition using an insulation resistance tester

Note 1 to entry: An insulation resistance tester is usually used for measurement of insulation resistance. It is

necessary to select applying voltage which is suitable for rated voltage and condition of the machine. 250 V or 500 V

for low voltage circuit and 1 000V for high voltage circuit are used for the insulation resistance test.

[SOURCE: IEC 60034-27-4:2018, IEV 411-53-48]

3.6.4

no-load

state of a machine rotating with zero output power (but under otherwise normal operating

conditions)

[SOURCE: IEC 60034-1:2017, 3.5]

3.6.5

no-load saturation curve

performance curves of field current versus induced voltage when the synchronous motor

operates as a generator at rated speed with the armature winding open-circuited

3.6.6

no-load test

test to determine machine characteristics under no load conditions

[SOURCE: IEC 60050-411:1996, 411-53-57, modified: simplified by referring to no load

conditions and purpose of the test is added.]

3.6.7

site operation test

test conducted at the purchaser’s location

3.6.8

thermal equivalent time constant

time constant, replacing several individual time constants, which determine

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...