IEC 60794-4-20:2018

(Main)Optical fibre cables - Part 4-20: Sectional specification - Aerial optical cables along electrical power lines - Family specification for ADSS (all dielectric self-supported) optical cables

Optical fibre cables - Part 4-20: Sectional specification - Aerial optical cables along electrical power lines - Family specification for ADSS (all dielectric self-supported) optical cables

IEC 60794-4-20:2018 covers optical telecommunication cables, commonly with single-mode fibres used primarily in overhead power lines applications. The cables can also be used in other overhead utility networks, such as for telephony or TV services. Requirements of the sectional specification IEC 60794-4 for aerial optical cables along electrical power lines are applicable to cables covered by this document. This document covers the construction, mechanical, electrical, and optical performance, installation guidelines, acceptance criteria, test requirements, environmental considerations, and accessories compatibility for an all dielectric, self-supporting fibre optic (ADSS) cable. This document provides construction and performance requirements that ensure, within the guidelines of this document, that the required mechanical integrity of the cable components as well as optical fibre mechanical reliability and transmission parameters are maintained. The ADSS cable consists of single mode optical fibres contained in one or more protective dielectric fibre optic units surrounded by or attached to suitable dielectric strength members and sheaths. The cable does not contain metallic components. An ADSS cable is designed to meet the optical and mechanical requirements under different installation, operating and environmental conditions and loadings, as described in Annex B. This document excludes any "lashed" or "wrapped" OPAC cables included in IEC 60794-4. Figure 8 aerial cables are also excluded; they are specified in IEC 60794-3-20. This second edition cancels and replaces the first edition published in 2012 and constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

- this document has been streamlined by cross-referencing IEC 60794-1-1,

- IEC 60794-4 (all parts) and IEC 60794-1-2;

- reference to the MICE table has been deleted;

- the example of test method for particular environment in Annex C has been deleted;

- creep test method has been updated in Annex E.

Keywords: optical telecommunication cables, single-mode fibres used primarily in overhead power lines

Câbles à fibres optiques - Partie 4-20: Spécification intermédiaire - Câbles optiques aériens le long des lignes électriques de puissance - Spécification de famille pour les câbles optiques autoporteurs entièrement diélectriques (ADSS)

.L'IEC 60794-4-20:2018 couvre les câbles optiques de télécommunication généralement équipés de fibres unimodales, utilisés principalement dans des applications le long des lignes aériennes à haute tension. Les câbles peuvent également être utilisés dans d'autres réseaux de services aériens, tels que des services de téléphonie ou de télévision. Les exigences de la spécification intermédiaire IEC 60794-4 pour des câbles optiques aériens le long de lignes électriques de puissance sont applicables aux câbles couverts par le présent document. Le présent document couvre la construction, les performances mécaniques, électriques et optiques, les lignes directrices relatives à l'installation, les critères d'acceptation, les exigences relatives aux essais, les considérations sur l'environnement et la compatibilité des accessoires pour câble fibronique autoporteur entièrement diélectrique (ADSS: all dielectric self-supporting). Le présent document fournit des exigences de performances et de construction qui garantissent, par les lignes directrices du présent document, que sont maintenus l'intégrité mécanique exigée des composants du câble ainsi que les paramètres de transmission et la fiabilité mécanique des fibres optiques. Le câble ADSS est constitué de fibres optiques unimodales contenues dans une ou plusieurs unités fibroniques diélectriques de protection entourées de, ou fixées à des gaines et des éléments de rigidité diélectrique appropriée. Le câble ne contient pas de composants métalliques. Un câble ADSS est conçu pour satisfaire aux exigences mécaniques et optiques dans différentes conditions d’installations, de fonctionnement et d'environnement et pour différentes charges, comme cela est décrit à l'Annexe B.AnchorAnchorAnchorAnchor Le présent document exclut les câbles OPAC "lacés" ou "enroulés" inclus dans l'IEC 60794-4. Les câbles aériens figure-8 sont également exclus; ils sont spécifiés dans l'IEC 60794‑3-20. Cette deuxième édition annule et remplace la première édition parue en 2012 dont elle constitue une révision technique. La présente édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

- le présent document a été simplifié par établissement de correspondances avec les normes IEC 60794-1-1, IEC 60794-4 (toutes les parties) et IEC 60794-1-2;

- la référence au tableau MICE a été supprimée;

- l'exemple de méthode d'essai pour un environnement particulier à l'Annexe C a été supprimé;

- la méthode d'essai de fluage a été mise à jour à l'Annexe E.

Mots-clés: câbles optiques de télécommunication, lignes aériennes à haute tension

General Information

- Status

- Published

- Publication Date

- 27-Aug-2018

- Technical Committee

- SC 86A - Fibres and cables

- Current Stage

- PPUB - Publication issued

- Start Date

- 28-Aug-2018

- Completion Date

- 03-Aug-2018

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60794-4-20:2018 is the IEC sectional specification for ADSS (all dielectric self-supported) optical telecommunication cables intended primarily for installation on overhead power lines. It defines construction and performance requirements for cables containing single-mode fibres without metallic components. The standard covers mechanical, electrical and optical characteristics, installation guidance, acceptance criteria, test methods and environmental considerations to ensure long-term mechanical integrity and optical transmission reliability in overhead utility networks.

Key topics and technical requirements

- Scope and exclusions: Applies to ADSS cables (dielectric strength members and sheaths) used on power lines and other overhead utilities; excludes lashed/wrapped OPAC and Figure‑8 aerial cables (see IEC 60794-3-20).

- Cable construction: Requirements for optical units, dielectric strength members, sheaths and accessory compatibility to maintain fibre mechanical reliability and transmission parameters.

- Optical fibre parameters: Specifications for single-mode fibre attenuation, cut-off wavelength, PMD and other optical characteristics.

- Mechanical and electrical performance: Family and type test categories including tensile performance, sheave tests, repeated bending, impact, crush, torsion and kink resistance.

- Vibration and environmental testing: Aeolian vibration, low-frequency (galloping) tests, temperature cycling, water penetration, UV/weathering, tracking and erosion resistance.

- Creep and long-term behaviour: Updated creep test method (Annex E) to evaluate long-term mechanical performance under sustained loading.

- Testing and acceptance: Type, factory acceptance and routine tests, plus reporting of parameters and installation capability.

- Installation guidance and Annexes: Informative Annex B (installation considerations), Annex A (packaging/marking), Annex D (blank detail specification) and test-related annexes (C and E).

- 2018 revision highlights: Edition 2.0 streamlines cross-references to IEC 60794-1-1, IEC 60794-4 and IEC 60794-1-2, removes the MICE table and an example test in Annex C, and updates the creep test method.

Practical applications and users

Who uses IEC 60794-4-20:2018:

- Cable manufacturers developing ADSS products for power utilities

- Power companies and utility planners specifying fibre on transmission and distribution lines

- Telecom operators and system integrators deploying broadband, telephony or TV over power corridors

- Test laboratories and QC teams performing type and acceptance testing

- Procurement specialists and consultants writing technical specifications and tenders Practical value: ensures ADSS cables meet defined mechanical, optical and environmental benchmarks for safe, durable overhead installations, reducing risk of outages and ensuring regulatory and contractual compliance.

Related standards

- IEC 60794-4 (sectional specifications for aerial optical cables)

- IEC 60794-1-1 and IEC 60794-1-2 (general and testing cross-references)

- IEC 60794-3-20 (Figure‑8 aerial cables)

- Other IEC 60794 series documents governing optical telecommunication cables and test methods

Keywords: optical telecommunication cables, ADSS, all dielectric self-supported, single-mode fibres, overhead power lines, aerial optical cables, IEC 60794-4-20.

REDLINE IEC 60794-4-20:2018 - Optical fibre cables - Part 4-20: Sectional specification - Aerial optical cables along electrical power lines - Family specification for ADSS (all dielectric self-supported) optical cables Released:8/28/2018 Isbn:9782832260098

IEC 60794-4-20:2018 - Optical fibre cables - Part 4-20: Sectional specification - Aerial optical cables along electrical power lines - Family specification for ADSS (all dielectric self-supported) optical cables

Get Certified

Connect with accredited certification bodies for this standard

TL 9000 QuEST Forum

Telecommunications quality management system.

ANCE

Mexican certification and testing association.

Intertek Slovenia

Intertek testing, inspection, and certification services in Slovenia.

Sponsored listings

Frequently Asked Questions

IEC 60794-4-20:2018 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Optical fibre cables - Part 4-20: Sectional specification - Aerial optical cables along electrical power lines - Family specification for ADSS (all dielectric self-supported) optical cables". This standard covers: IEC 60794-4-20:2018 covers optical telecommunication cables, commonly with single-mode fibres used primarily in overhead power lines applications. The cables can also be used in other overhead utility networks, such as for telephony or TV services. Requirements of the sectional specification IEC 60794-4 for aerial optical cables along electrical power lines are applicable to cables covered by this document. This document covers the construction, mechanical, electrical, and optical performance, installation guidelines, acceptance criteria, test requirements, environmental considerations, and accessories compatibility for an all dielectric, self-supporting fibre optic (ADSS) cable. This document provides construction and performance requirements that ensure, within the guidelines of this document, that the required mechanical integrity of the cable components as well as optical fibre mechanical reliability and transmission parameters are maintained. The ADSS cable consists of single mode optical fibres contained in one or more protective dielectric fibre optic units surrounded by or attached to suitable dielectric strength members and sheaths. The cable does not contain metallic components. An ADSS cable is designed to meet the optical and mechanical requirements under different installation, operating and environmental conditions and loadings, as described in Annex B. This document excludes any "lashed" or "wrapped" OPAC cables included in IEC 60794-4. Figure 8 aerial cables are also excluded; they are specified in IEC 60794-3-20. This second edition cancels and replaces the first edition published in 2012 and constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - this document has been streamlined by cross-referencing IEC 60794-1-1, - IEC 60794-4 (all parts) and IEC 60794-1-2; - reference to the MICE table has been deleted; - the example of test method for particular environment in Annex C has been deleted; - creep test method has been updated in Annex E. Keywords: optical telecommunication cables, single-mode fibres used primarily in overhead power lines

IEC 60794-4-20:2018 covers optical telecommunication cables, commonly with single-mode fibres used primarily in overhead power lines applications. The cables can also be used in other overhead utility networks, such as for telephony or TV services. Requirements of the sectional specification IEC 60794-4 for aerial optical cables along electrical power lines are applicable to cables covered by this document. This document covers the construction, mechanical, electrical, and optical performance, installation guidelines, acceptance criteria, test requirements, environmental considerations, and accessories compatibility for an all dielectric, self-supporting fibre optic (ADSS) cable. This document provides construction and performance requirements that ensure, within the guidelines of this document, that the required mechanical integrity of the cable components as well as optical fibre mechanical reliability and transmission parameters are maintained. The ADSS cable consists of single mode optical fibres contained in one or more protective dielectric fibre optic units surrounded by or attached to suitable dielectric strength members and sheaths. The cable does not contain metallic components. An ADSS cable is designed to meet the optical and mechanical requirements under different installation, operating and environmental conditions and loadings, as described in Annex B. This document excludes any "lashed" or "wrapped" OPAC cables included in IEC 60794-4. Figure 8 aerial cables are also excluded; they are specified in IEC 60794-3-20. This second edition cancels and replaces the first edition published in 2012 and constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - this document has been streamlined by cross-referencing IEC 60794-1-1, - IEC 60794-4 (all parts) and IEC 60794-1-2; - reference to the MICE table has been deleted; - the example of test method for particular environment in Annex C has been deleted; - creep test method has been updated in Annex E. Keywords: optical telecommunication cables, single-mode fibres used primarily in overhead power lines

IEC 60794-4-20:2018 is classified under the following ICS (International Classification for Standards) categories: 33.180.10 - Fibres and cables. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60794-4-20:2018 has the following relationships with other standards: It is inter standard links to IEC 60794-4-20:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60794-4-20:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60794-4-20 ®

Edition 2.0 2018-08

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Optical fibre cables –

Part 4-20: Sectional specification – Aerial optical cables along electrical power

lines – Family specification for ADSS (all dielectric self-supported) optical cables

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60794-4-20 ®

Edition 2.0 2018-08

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Optical fibre cables –

Part 4-20: Sectional specification – Aerial optical cables along electrical power

lines – Family specification for ADSS (all dielectric self-supported) optical cables

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 33.180.10 ISBN 978-2-8322-6009-8

– 2 – IEC 60794-4-20:2018 RLV © IEC 2018

CONTENTS

FOREWORD. 5

1 Scope . 7

2 Normative references . 7

3 Terms, definitions and abbreviated terms . 8

4 Optical fibres . 10

General .

Attenuation .

Attenuation coefficient .

Attenuation discontinuities .

Cut-off wavelength of cabled fibre .

Fibre colouring .

Polarisation mode dispersion (PMD) .

5 Cable elements . 11

6 Optical fibre cable constructions . 11

6.1 General . 11

Optical unit .

6.2 Cable protection elements . 11

7 Main requirements for installation and operating conditions . 12

8 Cable design considerations . 12

9 Cable tests . 13

9.1 General . 13

Classification of tests .

Type tests .

Factory acceptance tests .

Routine tests .

9.2 Tensile performance . 14

9.2.1 General . 14

9.2.2 Family requirement . 15

9.2.3 Test conditions . 15

9.3 Sheave test . 15

9.3.1 General . 15

9.3.2 Family requirement . 16

9.3.3 Test conditions . 16

Installation capability .

9.4 Repeated bending . 16

9.4.1 General . 16

9.4.2 Family requirements . 16

9.4.3 Test conditions . 16

9.5 Impact . 17

9.5.1 General . 17

9.5.2 Family requirements . 17

9.5.3 Test conditions . 17

9.6 Crush . 17

9.6.1 General . 17

9.6.2 Test requirements . 17

9.6.3 Test conditions . 17

Kink .

9.7 Torsion . 18

9.7.1 General . 18

9.7.2 Test requirements . 18

Vibration testing .

9.8 Aeolian vibration test . 18

9.8.1 General . 18

9.8.2 Family requirements . 18

9.8.3 Test conditions . 18

9.8.4 Parameters to be reported . 18

9.9 Low frequency vibration test (galloping test) . 19

9.9.1 General . 19

9.9.2 Family requirements . 19

9.9.3 Test conditions . 19

9.10 Temperature cycling . 20

9.10.1 General . 20

9.10.2 Family requirements . 20

9.10.3 Test conditions . 20

9.11 Water penetration . 20

9.12 Weathering resistance Cable UV resistance . 21

9.13 Tracking and erosion resistance test . 21

9.14 Creep behaviour . 21

9.15 Fitting compatibility . 22

Factory acceptance tests .

Routine tests .

10 Quality assurance . 23

Annex A (informative) Packaging and marking . 24

Annex B (informative) Installation considerations for ADSS cables . 25

Annex C (informative) Electrical test (tracking) . 27

C.1 General . 27

C.2 Option C1 C2 – Sheath material qualification . 27

C.2.1 Overview . 27

C.2.2 Test arrangements . 27

C.2.3 Test procedure . 28

C.2.4 Requirements . 28

Option C2 – Example of test for Sahara desert conditions .

C.3 Option C3 – Pollution level and tracking resistance . 31

C.3.1 Overview . 31

C.3.2 Test setup . 31

C.3.3 Test method . 33

C.3.4 Overview of pollution model and electrical test . 34

Annex D (informative) All dielectric self-supported (ADSS) cables to be used in

overhead power lines (blank detail specification) . 36

Bibliography . 38

Figure – Draft of test equipment .

Figure – Test chamber .

– 4 – IEC 60794-4-20:2018 RLV © IEC 2018

Figure B.1 – Example of different span lengths allowed for the same cable, depending

on sag variation . 26

Figure C.1 – Electric scheme for the test . 31

Figure C.2 – Foils of the electrodes . 32

Figure C.3 – Nozzle . 32

Figure C.4 – Details for the spraying . 33

Figure C.5 – Pollution model Distributed element model with dry band arc gap . 34

Figure C.6 – Basic circuit for arcing test Thevenin equivalent circuit . 35

Table 1 – Cable design characteristics . 13

Table 2 – Optional parameters (if required by customer) . 13

Table C.1 – R and C values for different pollution index values . 33

eq eq

Table D.1 – Blank detail specification . 36

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

OPTICAL FIBRE CABLES –

Part 4-20: Sectional specification – Aerial optical cables along

electrical power lines – Family specification for ADSS

(all dielectric self-supported) optical cables

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and

non-governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates

closely with the International Organization for Standardization (ISO) in accordance with conditions determined

by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

– 6 – IEC 60794-4-20:2018 RLV © IEC 2018

International Standard IEC 60794-4-20 has been prepared by subcommittee 86A: Fibres and

cables, of IEC technical committee 86: Fibre optics.

This second edition cancels and replaces the first edition published in 2012 and constitutes a

technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) this document has been streamlined by cross-referencing IEC 60794-1-1,

IEC 60794-4 (all parts) and IEC 60794-1-2;

b) reference to the MICE table has been deleted;

c) the example of test method for particular environment in Annex C has been deleted;

The text of this International Standard is based on the following documents:

FDIS Report on voting

86A/1867/FDIS 86A/1876/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 60794 series, published under the general title Optical fibre

cables, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

OPTICAL FIBRE CABLES –

Part 4-20: Sectional specification – Aerial optical cables along

electrical power lines – Family specification for ADSS

(all dielectric self-supported) optical cables

1 Scope

This part of IEC 60794-4, which is a family specification, covers optical telecommunication

cables, commonly with single-mode fibres to be used primarily in overhead power lines

applications. The cables may can also be used in other overhead utility networks, such as for

telephony or TV services. Requirements of the sectional specification IEC 60794-4 for aerial

optical cables along electrical power lines are applicable to cables covered by this document.

This document covers the construction, mechanical, electrical, and optical performance,

installation guidelines, acceptance criteria, test requirements, environmental considerations,

and accessories compatibility for an all dielectric, self-supporting fibre optic (ADSS) cable.

This document provides construction and performance requirements that ensure, within the

guidelines of this document, that the required mechanical capabilities integrity of the cable

components and maintenance of optical fibre integrity and optical transmissions are proper as

well as optical fibre mechanical reliability and transmission parameters are maintained.

The ADSS cable consists of single mode optical fibres contained in one or more protective

dielectric fibre optic units surrounded by or attached to suitable dielectric strength members

and sheaths. The cable does not contain metallic components. An ADSS cable is designed to

meet the optical and mechanical requirements under different types of installation, operating

and environmental conditions and loadings, as described in Annex B.

This document excludes any "lashed" or "wrapped" OPAC cables included in IEC 60794-4.

Figure 8 aerial cables are also excluded; they are specified in IEC 60794-3-20.

Cables intended for installation in conformity with ISO/IEC 24702 and related standards may

require the specification of additional tests to ensure their suitability in the applicable

environments defined by the mechanical, ingress, climatic and chemical, and electromagnetic

(MICE) classification. These tests are outside of the scope of IEC 60794 cable specifications,

and MICE criteria are not part of the requirements for IEC 60794 specifications. The MICE

tests may be the same as, similar to, or substantially different from, the tests required by

IEC 60794 specifications. Cables manufactured per IEC 60794 specifications may or may not

meet the MICE criteria. For supplemental discussion, see IEC/TR 62362.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60304, Standard colours for insulation for low-frequency cables and wires

IEC 60793-1-40, Optical fibres – Part 1-40: Measurement methods and test procedures –

Attenuation

___________

In some particular situations in the electrical industry, short overhead links can be also designed with

multimode fibres.

– 8 – IEC 60794-4-20:2018 RLV © IEC 2018

IEC 60793-1-44, Optical fibres – Part 1-44: Measurement methods and test procedures – Cut-

off wavelength

IEC 60793-1-48, Optical fibres – Part 1-48: Measurement methods and test procedures –

Polarization mode dispersion

IEC 60793-2, Optical fibres – Part 2: Product specifications – General

IEC 60793-2-50, Optical fibres – Part 2-50: Product specifications – Sectional specification for

class B single-mode fibres

IEC 60794-1-1, Optical fibre cables – Part 1: Generic specification – General

IEC 60794-1-2, Optical fibre cables – Part 1-2: Generic specification – Basic optical cable test

2 3

procedures ,

IEC 60794-1-21:2015, Optical fibre cables – Part 1-21: Generic specification – Basic optical

cable test procedures – Mechanical test methods

IEC 60794-1-22, Optical fibre cables – Part 1-22: Generic specification – Basic optical cable

test procedures – Environmental test methods

IEC 60794-1-23, Optical fibre cables – Part 1-23: Generic specification – Basic optical cable

test procedures – Cable element test methods

IEC 60794-4, Optical fibre cables – Part 4: Sectional Specification – Aerial optical cables

along electrical power lines

IEC 61395, Overhead electrical conductors – Creep test procedures for stranded conductors

ISO 9001, Quality management systems – Requirements

3 Terms, definitions and abbreviated terms

For the purposes of this document, the terms, definitions and abbreviated terms given in

IEC 60794-1-1 and IEC 60794-4, as well as the following, apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

maximum allowable tension

MAT

maximum tensile load that may be applied to the cable without detriment to the performance

requirements (optical performance, fibre durability) due to fibre strain

___________

This document has been withdrawn, but can still be purchased, if necessary. Until IEC 60794-1-21 will be

available, the tests stated in Clause 9 have to be taken from IEC 60794-1-2.

This standard will be replaced by IEC 60794-1-21, Optical fibre cables – Part 1-21: Generic specification –

Basic optical cable test procedures – Mechanical test methods (see also Bibliography), as soon as it will be

available.

Note 1 to entry: Due to installation codes the MAT value is sometimes restricted to be less than 60 % of the

breaking tension of the cable.

3.2

maximum operation tension

MOT

tensile load that can be applied to the cable either permanently or for a long term without

producing any strain to the fibres

Note 1 to entry: This condition should correspond to the tension with no ice and no gale wind at average mean

temperatures throughout the year, assumed to be between 16 ºC and 20 ºC.

3.3

zero strain margin

tensile load that the cable can sustain without strain on fibres due to cable elongation

3.4

breaking tension

tensile load that will produce physical rupture of the cable

Note 1 to entry: There is no optical consideration related to this parameter.

Note 2 to entry: The breaking tension should be calculated. The design model shall be validated; the cables do not

need to be tested.

3.5

maximum installation tension

MIT

maximum load that should be applied during the installation procedure

Note 1 to entry: The maximum installation tension refers mainly to the final adjust of sag (also called sagging

load), and the same tension limit can be used for the deployment of the cable (also called stringing load).

Note 2 to entry: This is a recommended value aimed at avoiding tension values higher than MAT during

operational life due to wind, ice or temperature changes.

3.6

ADSS

all dielectric self supported cable

dielectric cable that is capable of enduring aerial installation and providing long term service,

without any external tensile support

3.7

OPAC

optical attached cable

dielectric, not self-supported, optical attached cable

Note 1 to entry: OPACs can be used with one of the following attachment methods:

• wrapped, known as an all-dielectric (wrap): using special machinery, a lightweight flexible non-metallic cable is

wrapped helically around either the earth wire or the phase conductor;

• lashed: non-metallic cables are installed longitudinally alongside the earth wire, the phase conductor or on a

separate support cable (on a pole route) and are held in position with a binder or adhesive cord;

• spiral attached: similar to the lashed cables except that the method of attachment involves the use of special

preformed spiral attachment clips.

Note 2 to entry: OPAC cable designs are not covered by this specification.

– 10 – IEC 60794-4-20:2018 RLV © IEC 2018

3.8

cable fittings and dampers

3.8.1

suspension cable fitting

device to hold up the cable in intermediate support points along an aerial line, where the

cable is under tension at both sides of the fitting

3.8.2

dead end cable fitting

device designed to terminate an installation run, isolate a splice location or maintenance coil,

provide slack span locations, or provide for extreme angle turns, where the cable is under

tensional load on one side of the fitting and tension free on the other

3.8.2

damper

device attached to a cable in order to suppress or minimize vibrations due to wind

4 Optical fibres

4.1 General

Single mode optical fibres shall be used that meet the requirements of IEC 60793-2-50. In this

clause only the main characteristics are mentioned. Other types of fibre can be agreed upon

between the customer and the supplier; such fibre shall conform to IEC 60793-2. The cabled

fibre shall conform to IEC 60794-4.

Fibres other than those specified above can be used, if mutually agreed between the

customer and supplier. In this case, fibre characteristics and attenuation criteria for

mechanical tests shall be specified in the detail specification.

4.2 Attenuation

4.2.1 Attenuation coefficient

The requirements for the uncabled fibres shall be according to IEC 60793-2-50.

Unless other values are agreed between supplier and customer, the maximum attenuation

coefficient of the cabled fibres shall be 0,35 dB/km when measured at 1 310 nm and/or

0,25 dB/km at 1 550 nm.

Different values from those stated above can be agreed between customer and supplier.

The attenuation coefficient shall be measured in accordance with IEC 60793-1-40.

4.2.2 Attenuation discontinuities

The local attenuation shall not have point discontinuities in excess of 0,10 dB.

The test method used to verify the functional requirements shall be in accordance with

IEC 60793-1-40.

4.3 Cut-off wavelength of cabled fibre

The cabled fibre cut-off wavelength λ shall be lower than the operational wavelength when

CC

measured in accordance with IEC 60793-1-44.

4.4 Fibre colouring

The primary coated fibres shall be coloured for identification. The coloured coating shall be

readily identifiable throughout the lifetime of the cable and shall be at a reasonable match to

the requirements stated on IEC 60304. If required, the colouring shall permit sufficient light to

be transmitted through the primary coating to allow local light injection and detection.

4.5 Polarisation mode dispersion (PMD)

PMD shall meet the values indicated in IEC 60793-2-50. The measurement procedure shall be

in accordance with IEC 60793-1-48.

5 Cable elements

Refer to the relevant parts of the sectional specification IEC 60794-4; the following

requirements apply specifically to ADSS cables.

The material(s) used for a cable element shall be selected to be compatible with the other

elements in contact with it.

Optical elements (cable elements containing optical fibres) and each fibre within a cable

element shall be uniquely identified, for example, by colours, by a positional scheme, by

markings or as agreed between customer and manufacturer.

For loose tube construction, one or more primary coated fibres or optical elements are

packaged, loosely in a tube construction, with a suitable water-blocking system. The plastic

tube may be reinforced with a composite wall.

If required by the customer, the suitability of the tube shall be determined by an evaluation of

its kink resistance in accordance with IEC 60794-1-23, Method G7.

When used, optical fibre ribbons should comply with the requirements stated in IEC 60794-3.

6 Optical fibre cable constructions

6.1 General

The construction and characteristics of cable elements shall conform to IEC 60794-4. The

cable shall not contain any metallic material.

6.2 Optical unit

Optical unit elements as described in Clause 5 may be laid up as follows:

Single optical unit in the cable centre, which may contain one or more optical elements:

a) number of loose tubes using helical or SZ stranding configurations around a central

element of reinforced plastic, epoxy-glass, or other dielectric material. Ribbon elements

may be laid up by stacking two or more elements inside the loose tubes;

b) configuration based on a channelled dielectric rod, containing units such as ribbons or

plastic tubes, which may contain one or more optical elements.

6.2 Cable protection elements

In addition to the optical unit, the cable construction may consist of the following.

a) The outer sheath shall be a weather-resistant type material. In certain conditions, it shall

be necessary to consider the use of a tracking-resistant sheath.

– 12 – IEC 60794-4-20:2018 RLV © IEC 2018

b) An ADSS cable shall contain self-supported systems that are integral to the cable. The

purpose of the support system is to ensure that the cable meets the optical requirements

under specified installation conditions, temperatures, and environmental loading for its

whole operating design life. This standard excludes any “lashed” or “wrapped” OPAC

cables.

c) The basic annular construction may have strength yarns (e.g. aramid yarns) or other

dielectric strands or a channelled dielectric rods as a support structure. In addition, other

cable elements, such as central members, may be load bearing. A single central dielectric

shaft, channelled to accommodate the optical elements, is also accepted.

d) Fibre strain allowance.

ed) The cable shall be designed such that fibre strain does not exceed the limit allowed by the

cable manufacturer under design tension limits of the cable (MAT). Maximum allowable

fibre strain under MAT condition will generally be a function of the proof test level and

strength and fatigue parameters of the optical fibre, 0,33 % is specified for fibre proof

tested to 1 % shall be ≤ 0,2 % for 0,69 GPa proof-tested fibres.

f) A water blocking material shall be used to prevent water penetration to the optical units

and to the cable core. The material shall be easily removed without the use of materials

considered to be hazardous or dangerous. Water swell able blocking materials can also be

used.

When used in the cable construction, the filling compound shall not flow at temperatures

lower than the maximum specified operation temperature of cable.

NOTE In some countries, a special requirement of shotgun resistance can be specified for aerial cables.

ADSS covered by this standard are not designed for this condition.

Cables with reinforced textile protection, could still meet the dielectric condition, but the

increase in diameter and weight would require a significant enhancement of the tensile

performance of the cable.

NOTE In some countries, a special requirement of shotgun resistance can be specified for aerial cables. ADSS

cables covered by this document are not designed for such a condition. Cables with reinforced textile protection

could still meet the dielectric condition, but the increase in diameter and weight would make necessary a significant

enhancement of the tensile performance of the cable.

7 Main requirements for installation and operating conditions

Operating conditions are particularly important for ADSS cables.

Installation and operating conditions shall be agreed between the customer and the supplier.

For the ADSS cable, a detailed study of the field conditions and an important amount a certain

level of technical support by the supplier or third-party expert should precede the agreement.

Annex B provides a general view of such considerations.

The type of fittings and hardware used to attach the ADSS to the structures shall be approved

between the customer and the supplier. Their compatibility has to be checked according to

9.11 and the supplier or the customer fittings' specification shall be verified in accordance

with 9.15 and the fittings product specification.

8 Cable design considerations

Table 1 is a summary of cable characteristics which may be of importance as specifications to

both the customer and the supplier. Table 2 includes optional engineering parameters

relevant for the design and installation of the overhead line with an ADSS cable. Other

characteristics may be mutually agreed upon by both the customer and the supplier. A

complete blank specification is shown in Annex D.

Table 1 – Cable design characteristics

Ref. Characteristics Units

4 Number and type of fibres NA

- Modularity of cable core (fibres per tube) NA

6 Detailed description of cable design construction NA

- Overall cable diameter mm

Cable weight kg/km

9.2 MAT (maximum allowable tension) kN

9-10 Allowable temperature for storage, installation and operation °C

9.3 Minimum bending diameter during installation mm

9.4 Minimum bending radius diameter installed mm

Table 2 – Optional parameters (if required by customer)

Ref. Characteristics Units

9.13 MIT, maximum installation (or sagging) load kN

- Modulus of elasticity MPa

-6

- Coefficient of thermal expansion 10 /°C

9.2 Fibre strain at MAT load %

Annex B Zero strain margin kN

9.9 Creep behaviour mm

Maximum Sag at MOT and MAT m

Environmental loading conditions – Reference to local or regional installation NA

code

Recommended span and sag under MAT limit m/%

C.3 Maximum ADSS cable space potential exposure (generally specified for a low- kV

pollution environment unless specified otherwise by the customer)

9 Cable tests

9.1 General

The parameters specified in this standard may be affected by measurement uncertainty

arising either from measurement errors or calibration errors due to the lack of suitable

standards. Acceptance criteria shall be interpreted with respect to this consideration. For

some of the parameters specified in this standard, the objective is no change in attenuation.

These parameters may be affected by measurement uncertainty arising either from

measurement errors or calibration errors due to a lack of suitable standards. Acceptance

criteria shall be interpreted with respect to this consideration. The total uncertainty of

measurement for this standard shall be ≤0,05 dB for attenuation or 0,05 dB/km for attenuation

coefficient.

Any measured value within this range, either positive or negative, shall be considered as “no

change in attenuation”. By agreement between customer and supplier, minor deviation from

this limit may be accepted at some low frequency, e.g. less than 10 % of the fibres. However,

for mechanical tests no deviation in excess of 0,15 dB shall be accepted.

In mechanical tests, the general optical criteria is no change in attenuation, as described in

IEC 60794-1-1 and IEC 60794-4.

– 14 – IEC 60794-4-20:2018 RLV © IEC 2018

In some environmental and installation tests, some increase is accepted. These are the

sheave test, the aeolian vibration test and the galloping test.

The number of fibres tested shall be representative of the cable design according to fibre

sampling indicated IEC 60794-1-1. Different sampling can be agreed between the customer

and the supplier.

The tests applicable for aerial cables are listed below. The minimum acceptance criteria for

the different designs of cables shall be indicated in the product specification.

The specimens for the tests shall be taken from the supplier in advance to the tests.

9.2 Classification of tests

9.2.1 Type tests

Tests required to be carried out before supplying a cable covered by this standard on a

general commercial basis in order to demonstrate satisfactory performance characteristics to

meet the intended application. These tests shall be carried out on a cable length which meets

the requirements of the relevant routine tests. These tests are of such a nature that, after they

have been made, they need not to be repeated unless significant changes are made in the

cable material, design or type of manufacturing process which might change the performance

characteristics.

A full type verification of a cable design includes all tests and characteristics specified in this

standard. Tests to be repeated shall be agreed between the customer and the supplier.

9.2.2 Factory acceptance tests

Tests made on samples of completed cable, or components taken from a completed cable to

verify that the finished product meets the design specifications. Scope and incidence of

sample tests, if required, shall be agreed between the customer and the supplier.

Failure of a test specimen to comply with any one of the requirements of this standard shall

constitute grounds for rejection of the lot represented by the specimen. If any lot is so

rejected, the supplier shall have the right to test, only once, all individual drums of cables in

the lot and submit those which meet the requirements for acceptance.

9.2.3 Routine tests

Tests made on all production cable lengths to demonstrate their integrity.

Failure of a test specimen to comply with any one of the requirements of this standard shall

constitute grounds for rejection of the lot represented by the specimen. If any lot is so

rejected, the supplier shall have the right to test, only once, all individual drums of cables in

the lot and submit those which meet the requirements for acceptance.

9.2 Tensile performance

9.2.1 General

The tensile performance of the cable is verified with the test methods in 9.2.1 and 9.2.2. The

cable manufacturer shall specify the MOT and the MAT for the ADSS design. Both tests shall

be evaluated on the same cable sample, subjecting in a first step, the sample to the MOT test,

releasing the load to zero tension and then applying the MAT test.

9.3.2 Maximum allowed tension (MAT)

The cable shall be terminated with suitable dead end

...

IEC 60794-4-20 ®

Edition 2.0 2018-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Optical fibre cables –

Part 4-20: Sectional specification – Aerial optical cables along electrical power

lines – Family specification for ADSS (all dielectric self-supported) optical cables

Câbles à fibres optiques –

Partie 4-20: Spécification intermédiaire – Câbles optiques aériens le long des

lignes électriques de puissance – Spécification de famille pour les câbles

optiques autoporteurs entièrement diélectriques (ADSS)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 21 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 16

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC -

Glossaire IEC - std.iec.ch/glossary

webstore.iec.ch/advsearchform

67 000 entrées terminologiques électrotechniques, en anglais

La recherche avancée permet de trouver des publications IEC et en français, extraites des articles Termes et Définitions des

en utilisant différents critères (numéro de référence, texte, publications IEC parues depuis 2002. Plus certaines entrées

comité d’études,…). Elle donne aussi des informations sur les antérieures extraites des publications des CE 37, 77, 86 et

projets et les publications remplacées ou retirées. CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just Si vous désirez nous donner des commentaires sur cette

Published détaille les nouvelles publications parues. publication ou si vous avez des questions contactez-nous:

Disponible en ligne et aussi une fois par mois par email. sales@iec.ch.

IEC 60794-4-20 ®

Edition 2.0 2018-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Optical fibre cables –

Part 4-20: Sectional specification – Aerial optical cables along electrical power

lines – Family specification for ADSS (all dielectric self-supported) optical cables

Câbles à fibres optiques –

Partie 4-20: Spécification intermédiaire – Câbles optiques aériens le long des

lignes électriques de puissance – Spécification de famille pour les câbles

optiques autoporteurs entièrement diélectriques (ADSS)

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 33.180.10 ISBN 978-2-8322-5907-8

– 2 – IEC 60794-4-20:2018 © IEC 2018

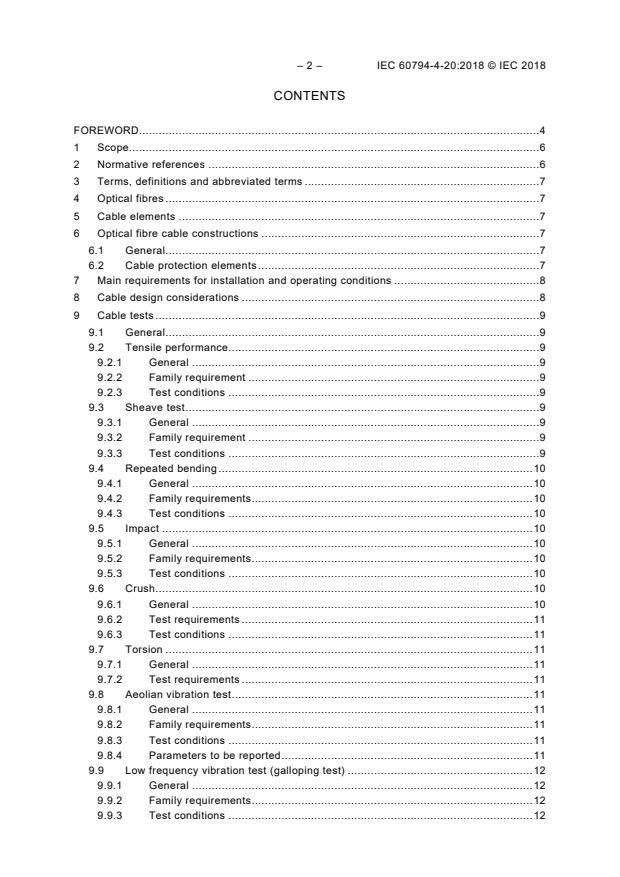

CONTENTS

FOREWORD. 4

1 Scope . 6

2 Normative references . 6

3 Terms, definitions and abbreviated terms . 7

4 Optical fibres . 7

5 Cable elements . 7

6 Optical fibre cable constructions . 7

6.1 General . 7

6.2 Cable protection elements . 7

7 Main requirements for installation and operating conditions . 8

8 Cable design considerations . 8

9 Cable tests . 9

9.1 General . 9

9.2 Tensile performance . 9

9.2.1 General . 9

9.2.2 Family requirement . 9

9.2.3 Test conditions . 9

9.3 Sheave test . 9

9.3.1 General . 9

9.3.2 Family requirement . 9

9.3.3 Test conditions . 9

9.4 Repeated bending . 10

9.4.1 General . 10

9.4.2 Family requirements . 10

9.4.3 Test conditions . 10

9.5 Impact . 10

9.5.1 General . 10

9.5.2 Family requirements . 10

9.5.3 Test conditions . 10

9.6 Crush . 10

9.6.1 General . 10

9.6.2 Test requirements . 11

9.6.3 Test conditions . 11

9.7 Torsion . 11

9.7.1 General . 11

9.7.2 Test requirements . 11

9.8 Aeolian vibration test . 11

9.8.1 General . 11

9.8.2 Family requirements . 11

9.8.3 Test conditions . 11

9.8.4 Parameters to be reported . 11

9.9 Low frequency vibration test (galloping test) . 12

9.9.1 General . 12

9.9.2 Family requirements . 12

9.9.3 Test conditions . 12

9.10 Temperature cycling . 12

9.10.1 General . 12

9.10.2 Family requirements . 12

9.10.3 Test conditions . 12

9.11 Water penetration . 13

9.12 Cable UV resistance . 13

9.13 Tracking and erosion resistance test . 13

9.14 Creep . 13

9.15 Fitting compatibility . 14

10 Quality assurance . 14

Annex A (informative) Packaging and marking . 15

Annex B (informative) Installation considerations for ADSS cables . 16

Annex C (informative) Electrical test (tracking) . 18

C.1 General . 18

C.2 Option C2 – Sheath material qualification . 18

C.2.1 Overview . 18

C.2.2 Test arrangements . 18

C.2.3 Test procedure . 19

C.2.4 Requirements . 19

C.3 Option C3 – Pollution level and tracking resistance . 19

C.3.1 Overview . 19

C.3.2 Test setup . 20

C.3.3 Test method . 22

C.3.4 Overview of pollution model and electrical test . 22

Annex D (informative) All dielectric self-supported (ADSS) cables to be used in

overhead power lines (blank detail specification) . 24

Bibliography . 26

Figure B.1 – Example of different span lengths allowed for the same cable, depending

on sag variation . 17

Figure C.1 – Electric scheme for the test . 20

Figure C.2 – Foils of the electrodes . 20

Figure C.3 – Nozzle . 21

Figure C.4 – Details for the spraying . 21

Figure C.5 – Distributed element model with dry band arc gap . 23

Figure C.6 – Thevenin equivalent circuit . 23

Table 1 – Cable design characteristics . 8

Table 2 – Optional parameters (if required by customer) . 8

Table C.1 – R and C values for different pollution index values . 22

eq eq

Table D.1 – Blank detail specification . 24

– 4 – IEC 60794-4-20:2018 © IEC 2018

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

OPTICAL FIBRE CABLES –

Part 4-20: Sectional specification – Aerial optical cables along

electrical power lines – Family specification for ADSS

(all dielectric self-supported) optical cables

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and

non-governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates

closely with the International Organization for Standardization (ISO) in accordance with conditions determined

by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60794-4-20 has been prepared by subcommittee 86A: Fibres and

cables, of IEC technical committee 86: Fibre optics.

This second edition cancels and replaces the first edition published in 2012 and constitutes a

technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) this document has been streamlined by cross-referencing IEC 60794-1-1,

IEC 60794-4 (all parts) and IEC 60794-1-2;

b) reference to the MICE table has been deleted;

c) the example of test method for particular environment in Annex C has been deleted;

The text of this International Standard is based on the following documents:

FDIS Report on voting

86A/1867/FDIS 86A/1876/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 60794 series, published under the general title Optical fibre

cables, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 60794-4-20:2018 © IEC 2018

OPTICAL FIBRE CABLES –

Part 4-20: Sectional specification – Aerial optical cables along

electrical power lines – Family specification for ADSS

(all dielectric self-supported) optical cables

1 Scope

This part of IEC 60794-4, which is a family specification, covers optical telecommunication

cables, commonly with single-mode fibres used primarily in overhead power lines

applications. The cables can also be used in other overhead utility networks, such as for

telephony or TV services. Requirements of the sectional specification IEC 60794-4 for aerial

optical cables along electrical power lines are applicable to cables covered by this document.

This document covers the construction, mechanical, electrical, and optical performance,

installation guidelines, acceptance criteria, test requirements, environmental considerations,

and accessories compatibility for an all dielectric, self-supporting fibre optic (ADSS) cable.

This document provides construction and performance requirements that ensure, within the

guidelines of this document, that the required mechanical integrity of the cable components as

well as optical fibre mechanical reliability and transmission parameters are maintained.

The ADSS cable consists of single mode optical fibres contained in one or more protective

dielectric fibre optic units surrounded by or attached to suitable dielectric strength members

and sheaths. The cable does not contain metallic components. An ADSS cable is designed to

meet the optical and mechanical requirements under different installation, operating and

environmental conditions and loadings, as described in Annex B.

This document excludes any "lashed" or "wrapped" OPAC cables included in IEC 60794-4.

Figure 8 aerial cables are also excluded; they are specified in IEC 60794-3-20.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60793-2, Optical fibres – Part 2: Product specifications – General

IEC 60793-2-50, Optical fibres – Part 2-50: Product specifications – Sectional specification for

class B single-mode fibres

IEC 60794-1-1, Optical fibre cables – Part 1: Generic specification – General

IEC 60794-1-21:2015, Optical fibre cables – Part 1-21: Generic specification – Basic optical

cable test procedures – Mechanical test methods

IEC 60794-1-22, Optical fibre cables – Part 1-22: Generic specification – Basic optical cable

test procedures – Environmental test methods

___________

In some particular situations in the electrical industry, short overhead links can be also designed with

multimode fibres.

IEC 60794-4, Optical fibre cables – Part 4: Sectional specification – Aerial optical cables

along electrical power lines

ISO 9001, Quality management systems – Requirements

3 Terms, definitions and abbreviated terms

For the purposes of this document, the terms, definitions and abbreviated terms given in

IEC 60794-1-1 and IEC 60794-4 apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

4 Optical fibres

Single-mode optical fibres shall be used that meet the requirements of IEC 60793-2-50. Other

types of fibre can be agreed upon between the customer and the supplier; such fibre shall

conform to IEC 60793-2. The cabled fibre shall conform to IEC 60794-4.

5 Cable elements

Refer to the relevant parts of the sectional specification IEC 60794-4.

6 Optical fibre cable constructions

6.1 General

The construction and characteristics of cable elements shall conform to IEC 60794-4. The

cable shall not contain any metallic material.

6.2 Cable protection elements

In addition to the optical unit, the cable construction may consist of the following.

a) The outer sheath shall be a weather-resistant type material. In certain conditions, it shall

be necessary to consider the use of a tracking-resistant sheath.

b) An ADSS cable shall contain self-supported systems that are integral to the cable. The

purpose of the support system is to ensure that the cable meets the optical requirements

under specified installation conditions, temperatures, and environmental loading for its

whole operating design life.

c) The basic annular construction may have strength yarns (e.g. aramid yarns) or other

dielectric strands or dielectric rods as a support structure. A single central dielectric shaft,

channelled to accommodate the optical elements, is also accepted.

d) The cable shall be designed such that fibre strain does not exceed the limit allowed by the

cable manufacturer under design tension limits of the cable (MAT). Maximum allowable

fibre strain under MAT condition shall be ≤ 0,2 % for 0,69 GPa proof-tested fibres.

NOTE In some countries, a special requirement of shotgun resistance can be specified for aerial cables. ADSS

cables covered by this document are not designed for such a condition. Cables with reinforced textile protection

could still meet the dielectric condition, but the increase in diameter and weight would make necessary a significant

enhancement of the tensile performance of the cable.

– 8 – IEC 60794-4-20:2018 © IEC 2018

7 Main requirements for installation and operating conditions

Operating conditions are particularly important for ADSS cables.

Installation and operating conditions shall be agreed between the customer and the supplier.

For the ADSS cable, a detailed study of the field conditions and a certain level of technical

support by the supplier or third-party expert should precede the agreement. Annex B provides

a general view of such considerations.

The type of fittings and hardware used to attach the ADSS to the structures shall be approved

between the customer and the supplier. Their compatibility shall be verified in accordance

with 9.15 and the fittings product specification.

8 Cable design considerations

Table 1 is a summary of cable characteristics which may be of importance as specifications to

both the customer and the supplier. Table 2 includes optional engineering parameters

relevant for the design and installation of the overhead line with an ADSS cable. Other

characteristics may be mutually agreed upon by both the customer and the supplier. A

complete blank specification is shown in Annex D.

Table 1 – Cable design characteristics

Ref. Characteristics Units

4 Number and type of fibres NA

- Modularity of cable core NA

6 Detailed description of cable construction NA

- Overall cable diameter mm

Cable weight kg/km

9.2 MAT (maximum allowable tension) kN

9-10 Allowable temperature for storage, installation and operation °C

9.3 Minimum bending diameter during installation mm

9.4 Minimum bending diameter installed mm

Table 2 – Optional parameters (if required by customer)

Ref. Characteristics Units

9.13 MIT, maximum installation (or sagging) load kN

- Modulus of elasticity MPa

-6

- Coefficient of thermal expansion 10 /°C

9.2 Fibre strain at MAT load %

Annex B Zero strain margin kN

Environmental loading conditions – Reference to local or regional installation NA

code

Recommended span and sag under MAT limit m/%

C.3 Maximum ADSS cable space potential exposure (generally specified for a low- kV

pollution environment unless specified otherwise by the customer)

9 Cable tests

9.1 General

In mechanical tests, the general optical criteria is no change in attenuation, as described in

IEC 60794-1-1 and IEC 60794-4.

In some environmental and installation tests, some increase is accepted. These are the

sheave test, the aeolian vibration test and the galloping test.

The number of fibres tested shall be representative of the cable design according to fibre

sampling indicated IEC 60794-1-1. Different sampling can be agreed between the customer

and the supplier.

The tests applicable for aerial cables are listed below. The minimum acceptance criteria for

the different designs of cables shall be indicated in the product specification.

9.2 Tensile performance

9.2.1 General

The cable should be tested in accordance with IEC 60794-1-21, method E1. Under this test,

the cables shall meet the specified MAT value.

9.2.2 Family requirement

Loaded with MAT, no change in attenuation at 1 550 nm shall be measured, and the strain in

the fibre shall be ≤ 0.2 % for 0,69 GPa proof-tested fibres. Other values can be agreed

between the customer and the supplier.

NOTE Strain limit values for fibres with different proof test values are under study.

9.2.3 Test conditions

• Test set in a straight path in accordance with Figure 1 of IEC 60794-1-21:2015 (no drums

or pulleys allowed).

• The cable shall be terminated with adequate dead-end fittings.

• Sample length of 25 m minimum.

• MAT is sustained for 1 h.

• The fibres shall be loop-back spliced so that a minimum of 100 m of fibre are under test.

9.3 Sheave test

9.3.1 General

The cable shall be tested in accordance with method E18B of IEC 60794-1-21.

9.3.2 Family requirement

Maximum permanent increase in attenuation: 0,10 dB at 1 550 nm.

No physical damage in cable elements.

9.3.3 Test conditions

• Method E18B of IEC 60794-1-21, procedure 1 or 2.

• Tension level applied during test: maximum stringing load (or MIT).

• Length of the cable: 9 m minimum. Length bent under tension: 2 m.

– 10 – IEC 60794-4-20:2018 © IEC 2018

• The cable should be terminated with the recommended dead-end fittings.

• The fibres shall be loop-back spliced so that a minimum of 100 m of fibre are under test.

• Diameter (D) of roller/cylinders ≥ manufacturer’s minimum bend diameter (approximately

≥ 40 times cable outside diameter is recommended).

• Bending angle: 45° ±15°.

• Moving speed: 1 m/s ≤ speed ≤ 10 m/s.

• Number of complete moving cycles: 20.

9.4 Repeated bending

9.4.1 General

The cable shall be tested in accordance with the method specified in IEC 60794-1-21,

method E6.

9.4.2 Family requirements

Under visual examination without magnification, there shall be no damage to the sheath or