IEC PAS 62246-2-1:2008

(Main)Reed contact units - Part 2-1: Heavy-duty reed switches - Quality assessment specification

Reed contact units - Part 2-1: Heavy-duty reed switches - Quality assessment specification

IEC/PAS 62246-2-1:2008(E) defines requirements and tests for heavy-duty reed switches intended to be incorporated into devices that can be used in various industrial applications. Is to be used in conjunction with IEC 62246-2 and selects from IEC 62246-2 and from other sources the appropriate test procedures to be used in detail specifications derived from this PAS.

General Information

- Status

- Replaced

- Publication Date

- 08-Apr-2008

- Technical Committee

- TC 94 - Electrical relays

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 24-May-2013

- Completion Date

- 13-Feb-2026

Relations

- Replaced By

IEC 62246-1-1:2013 - Reed switches - Part 1-1: Generic specification - Quality assessment - Effective Date

- 05-Sep-2023

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC PAS 62246-2-1:2008 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Reed contact units - Part 2-1: Heavy-duty reed switches - Quality assessment specification". This standard covers: IEC/PAS 62246-2-1:2008(E) defines requirements and tests for heavy-duty reed switches intended to be incorporated into devices that can be used in various industrial applications. Is to be used in conjunction with IEC 62246-2 and selects from IEC 62246-2 and from other sources the appropriate test procedures to be used in detail specifications derived from this PAS.

IEC/PAS 62246-2-1:2008(E) defines requirements and tests for heavy-duty reed switches intended to be incorporated into devices that can be used in various industrial applications. Is to be used in conjunction with IEC 62246-2 and selects from IEC 62246-2 and from other sources the appropriate test procedures to be used in detail specifications derived from this PAS.

IEC PAS 62246-2-1:2008 is classified under the following ICS (International Classification for Standards) categories: 29.120.70 - Relays. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC PAS 62246-2-1:2008 has the following relationships with other standards: It is inter standard links to IEC 62246-1-1:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC PAS 62246-2-1:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC/PAS 62246-2-1

Edition 1.0 2008-04

PUBLICLY AVAILABLE

SPECIFICATION

PRE-STANDARD

Reed contact units –

Part 2-1: Heavy-duty reed switches – Quality assessment specification

IEC/PAS 62246-2-1:2008(E)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC/PAS 62246-2-1

Edition 1.0 2008-04

PUBLICLY AVAILABLE

SPECIFICATION

PRE-STANDARD

Reed contact units –

Part 2-1: Heavy-duty reed switches – Quality assessment specification

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

W

ICS 29.120.70 ISBN 2-8318-9669-X

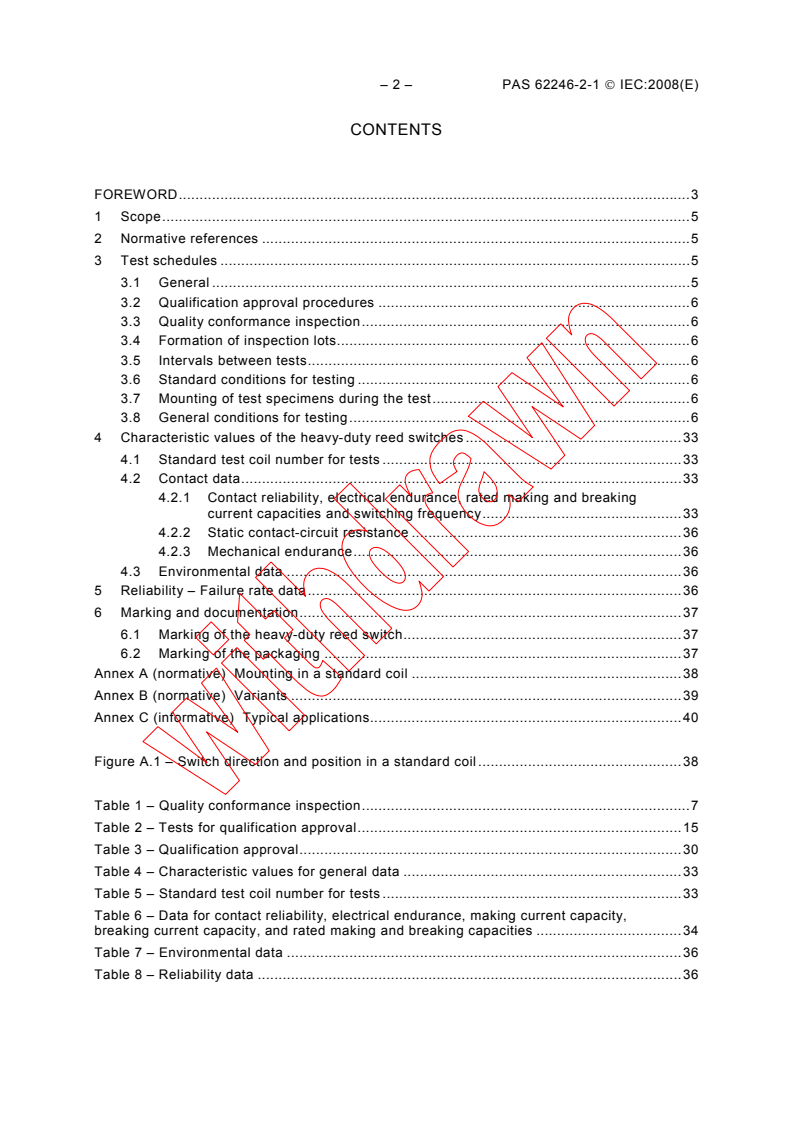

– 2 – PAS 62246-2-1 © IEC:2008(E)

CONTENTS

FOREWORD.3

1 Scope.5

2 Normative references .5

3 Test schedules .5

3.1 General .5

3.2 Qualification approval procedures .6

3.3 Quality conformance inspection.6

3.4 Formation of inspection lots.6

3.5 Intervals between tests.6

3.6 Standard conditions for testing .6

3.7 Mounting of test specimens during the test.6

3.8 General conditions for testing.6

4 Characteristic values of the heavy-duty reed switches .33

4.1 Standard test coil number for tests .33

4.2 Contact data.33

4.2.1 Contact reliability, electrical endurance, rated making and breaking

current capacities and switching frequency.33

4.2.2 Static contact-circuit resistance .36

4.2.3 Mechanical endurance.36

4.3 Environmental data .36

5 Reliability – Failure rate data.36

6 Marking and documentation.37

6.1 Marking of the heavy-duty reed switch.37

6.2 Marking of the packaging .37

Annex A (normative) Mounting in a standard coil .38

Annex B (normative) Variants .39

Annex C (informative) Typical applications.40

Figure A.1 – Switch direction and position in a standard coil.38

Table 1 – Quality conformance inspection.7

Table 2 – Tests for qualification approval.15

Table 3 – Qualification approval.30

Table 4 – Characteristic values for general data .33

Table 5 – Standard test coil number for tests .33

Table 6 – Data for contact reliability, electrical endurance, making current capacity,

breaking current capacity, and rated making and breaking capacities .34

Table 7 – Environmental data .36

Table 8 – Reliability data .36

PAS 62246-2-1 © IEC:2008(E) – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

REED CONTACT UNITS –

Part 2-1: Heavy-duty reed switches –

Quality assessment specification

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

A PAS is a technical specification not fulfilling the requirements for a standard, but made

available to the public.

IEC/PAS 62246-2-1 has been processed by IEC Technical Committee 94: All-or-nothing

electrical relays.

The text of this PAS is based on the This PAS was approved for

following document: publication by the P-members of the

committee concerned as indicated in

the following document

Draft PAS Report on voting

94/264/NP 94/271/RVN

Following the publication of this PAS, which is a pre-standard publication, the technical

committee or subcommittee concerned will transform it into an International Standard. It is

intended to incorporate its contents into the next edition of IEC 62246-2 during the upcoming

maintenance cycle for that standard.

– 4 – PAS 62246-2-1 © IEC:2008(E)

This PAS shall remain valid for an initial maximum period of 3 years starting from the

publication date. The validity may be extended for a single 3-year period, following which it

shall be revised to become another type of normative document, or shall be withdrawn.

PAS 62246-2-1 © IEC:2008(E) – 5 –

REED CONTACT UNITS –

Part 2-1: Heavy-duty reed switches –

Quality assessment specification

1 Scope

This PAS defines requirements and tests for heavy-duty reed switches intended to be

incorporated into devices that can be used in various industrial applications.

This PAS is to be used in conjunction with IEC 62246-2.

This PAS selects from IEC 62246-2 and from other sources the appropriate test procedures to

be used in detail specifications derived from this PAS.

Two different product variants (variant A and variant B) are specified depending on

characteristic values and tests (see Annex B).

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60068-2-11 (1981): Environmental testing – Part 2: Tests. Test Ka: Salt mist

IEC 60068-2-14 (1984): Environmental testing – Part 2: Tests. Test N: Change of temperature

IEC 60068-2-20 (1979): Environmental testing. Part 2: Tests. Test T: Soldering

Amendment 2 (1987)

IEC 60068-2-21 (2006): Environmental testing – Part 2-21: Tests – Test U: Robustness of

terminations and integral mounting devices

IEC 60068-2-29 (1987): Environmental testing. Part 2: Tests. Test Eb and guidance: Bump

IEC 60068-2-78 (2001): Environmental testing – Part 2-78: Tests – Test Cab: Damp heat,

steady state

IEC 60127-2 (2003): Miniature fuses – Part 2: Cartridge fuse-links

IEC 61373 (1999): Railway applications – Rolling stock equipment – Shock and vibration tests

IEC 62246-1 (2002): Reed contact units – Part 1: Generic specification

IEC 62246-2 (2007): Reed contact units – Part 2: Heavy-duty reed switches

3 Test schedules

3.1 General

Test procedures are referenced in the corresponding subclauses of IEC 62246-2.

– 6 – PAS 62246-2-1 © IEC:2008(E)

3.2 Qualification approval procedures

Qualification approval procedures are indicated in Table 2 and Table 3:

– sampling and test schedule are specified in Table 2 and Table 3;

– the tests specified and their order is mandatory;

– tests stated in Table 2 are mandatory for the variants except when otherwise specified;

– tests stated in Table 3 are mandatory only for the variants indicated.

3.3 Quality conformance inspection

Quality conformance inspection contains the tests stated in Table 1:

– Group A: routine tests;

– Groups A and B: lot-by-lot tests;

– Group C: periodic tests.

Unless otherwise stated in this PAS, all tests of Table 1 are mandatory.

Where a subgroup contains cumulative tests, the order of the tests is mandatory. Specimens

that have been subjected to tests denoted as destructive (D) shall not be released for delivery.

Specimens that have been subjected to tests denoted as non-destructive (ND) are permitted

to be released for delivery.

3.4 Formation of inspection lots

The basis for determination of sample size for the quality conformance inspection is the

heavy-duty reed switch quantity produced during one month.

3.5 Intervals between tests

The following are the intervals necessary between tests:

– Subgroup A0: at shipment;

– Subgroups A4 and B1: at least once a month;

– Subgroup C1: at least once a year;

– Subgroup C4: at least once every two years.

3.6 Standard conditions for testing

If not otherwise stated, all tests shall be performed under standard conditions for testing

according to 3.3 of IEC 62246-1.

3.7 Mounting of test specimens during the test

The following requirement shall apply for shock and vibration tests:

The heavy-duty reed switch shall be mounted by its normal mounting method to the test

fixture, where inherent resonances have been minimized so as not to invalidate the test.

3.8 General conditions for testing

Unless otherwise stated, the test coil number and when applicable its polarity specified in

Table 5 shall be used for all tests. Unless otherwise stated in this PAS, the polarity shall be

as specified by the manufacturer.

PAS 62246-2-1 © IEC:2008(E) – 7 –

Table 1 – Quality conformance inspection

Group A

Subgroup A0

For all tests in this subgroup: 100 % test.

Test Test conditions according to Performance

Test

No. IEC 62246-2 requirements

A0 – 1

Visual inspection and Subclause 3.4 According to Table 4

check of dimensions

(ND) Marking as specified in 6.1

A0 – 2 Functional tests (ND) Subclause 3.5, Procedure 1

Application points and standard test coil number: According to Table 5

Must-operate value: According to Table 4

Saturate value: 150 % of must-operate

Must-release value:

Contact failure-to-make and failure-to-break by

monitoring a current, typically 10 mA at 24 V d.c.

A0 – 3 Contact-circuit Subclause 3.7 Initial value according to Table 4

resistance (ND)

Application points: terminals of closed

contacts

Standard test coil number: According to Table 5

Test coil voltage: 150 % of must-operate

Test voltage max.: 6 V d.c.

Test current max.: 1 A

A0 – 4 Dielectric test (ND) Subclause 3.8

Application points and test voltage: According to Table 4

Duration of test: 1 min Maximum leakage current:

0,5 mA

A shorter test with a higher voltage may be stated in

the detail specification

A0 – 5 Operate, release, Subclause 3.10

transfer or bridging

and bounce times (ND) Application points and standard test coil number: According to Table 5

Test coil voltage: 150 % of must-operate

1) operate time According to Table 4

2) release time

3) operate bounce time

Contact failure-to-make and failure-to-break by

monitoring a current, typically 10 mA at 24 V d.c.

A0 – 6 Sealing (ND) Subclause 3.22

Application points and standard test coil number: According to Table 5

Arc time during test: According to Table 7

Test coil voltage: 150 % of must-operate

Test voltage: 100 V – 110 V d.c.

Test current: 0,5 A – 0,55 A

Total number of operations required: 3

– 8 – PAS 62246-2-1 © IEC:2008(E)

Table 1 – Quality conformance inspection (continued)

Subgroup A4 (period: inspection lot refers to the production volume in one month)

Test Test conditions according to Performance

Test IL AQL

No. IEC 62246-2 requirements

1 Visual inspection and Subclause 3.4 According to Table 4

check of dimensions

Marking as specified in 6.1

(ND)

2 Functional tests (ND) Subclause 3.5, Procedure 1

Application points and standard test coil According to Table 5

number:

Must-operate value: According to Table 4

Saturate value: 150 % of must-operate

Must-release value:

Contact failure-to-make and failure-to-

break by monitoring a current, typically

10 mA at 24 V d.c.

Contact-circuit Subclause 3.7 Initial value according to Table 4

resistance (ND)

Application points: terminals of

closed contacts

Standard test coil number: According to Table 5

Test coil voltage: 150 % of must-operate

Test voltage max.: 6 V d.c.

Test current max.: 1 A

4 Dielectric test (ND) Subclause 3.8 S4 1,0

Application points and test voltage: According to Table 4

Duration of test: 1 min Maximum leakage current:

0,5 mA

A shorter test with a higher voltage may be

stated in the detail specification

5 Operate, release, Subclause 3.10

transfer or bridging

and bounce times (ND) Application points and standard test coil According to Table 5

number:

Test coil voltage: 150 % of must-operate

1) operate time: According to Table 4

2) release time:

3) operate bounce time:

Contact failure-to-make and failure-to-

break by monitoring a current, typically

10 mA at 24 V d.c.

6 Sealing (ND) Subclause 3.22

Application points and standard test coil According to Table 5

number:

Arc time during test: According to Table 7

Test coil voltage: 150 % of must-operate

Test voltage: 100 V – 110 V d.c.

Test current: 0,5 A – 0,55 A

Total number of operations required: 3

PAS 62246-2-1 © IEC:2008(E) – 9 –

Table 1 – Quality conformance inspection (continued)

Subgroup B1 (period: inspection lot refers to the production volume of one month)

Test Test conditions according to Performance

Test IL AQL

No. IEC 62246-2 requirements

7 Contact reliability test Subclause 3.32 S3 2,5

(D)

Test switch type and standard test coil According to Table 5

number:

Test coil voltage: 150 % of must-operate

Coil suppression: N/A

Duty cycle: 50 %

Switching load conditions: According to Table 6

Monitoring conditions: According to Table 6

At each cycle during the test

Final measurements:

Test 3 – contact-circuit resistance According to Table 4

Test 2 – functional tests According to Table 4

– 10 – PAS 62246-2-1 © IEC:2008(E)

Table 1 – Quality conformance inspection (continued)

Subgroup C1 (period: one year)

Test

Test Test conditions according to Sample Acceptable Performance

No. IEC 62246-2 size number of requirements

failures

8 Robustness of Subclause 3.12 (in accordance with 6 0 According to Table 4

terminals (D) IEC 60068-2-21) No breaking or loosening of

terminals

Procedure: test Ua1 – tensile

Final measurements:

Test 1 – visual inspection No cracks or other

deterioration

Test 2 – functional tests According to Table 4

Test 6 – sealing According to Table 7

9 Soldering (D) Subclause 3.13 (in accordance with 5 0 The dipped surface shall be

IEC 60068-2-20, test Ta, method 1) 95 % covered with new

solder coating, the

remaining 5 % may contain

only small pinholes

Temperature: (235 ± 5) °C

Duration: (2 ± 0,5) s

Application point: 5 mm from the glass-

to-metal seals

Subclause 3.13 (in accordance with

IEC 60068-2-20, test Ta, method 2)

Temperature: (350 ± 5) °C

Duration: (3 ± 0,5) s

Application point: 5 mm from the glass-

to-metal seals

Final measurements:

No cracks or other

Test 1 – visual test

deterioration

According to Table 4

Test 2 – functional tests

According to Table 7

Test 6 – sealing

PAS 62246-2-1 © IEC:2008(E) – 11 –

Table 1 – Quality conformance inspection (continued)

Subgroup C1 (period: one year)

Acceptable

Test Test conditions according to Sample Performance

Test number of

No. IEC 62246-2 size requirements

failures

10 Rapid change of Subclause 3.16 (in accordance with 6 0

temperature (D) IEC 60068-2-14)

Low temperature: – 50 °C

High temperature: 100 °C

Exposure time: 20 min

Transition time: 1 min

Number of cycles: 10

Final measurements:

Test 4 – dielectric test According to Table 4

Test 2 – functional tests According to Table 4

Test 3 – contact-circuit resistance According to Table 4

Test 1 – visual inspection No cracks or other

deterioration

Test 6 – sealing test According to Table 7

11 Vibration (D) Subclause 3.19 6 0 No opening of closed

Functional contact circuit with

Test switch type and standard test coil energization condition or

number: according to Table 5 closing of opened contact

Test coil voltage: 150 % of must-operate circuit shall exceed 10 µs

Axis of mounting: The movable contact shall

be located in the transverse

direction

Vibration conditions:

Application: three directions

According to Table 7

Number of sweeps per direction: 3

Sweep rate: 1 octave/min ± 10 %

Total duration: approx. 3×10 min

Test contact voltage and current:

24 V d.c. max., 10 mA max.

Final measurements:

Test 1 – visual inspection

No cracks or other

deterioration

Test 2 – functional tests

According to Table 4

Test 6 – sealing

According to Table 7

– 12 – PAS 62246-2-1 © IEC:2008(E)

Table 1 – Quality conformance inspection (continued)

Subgroup C1 (period: one year)

Acceptable

Test Test conditions according to Sample Performance

Test number of

No. IEC 62246-2 size requirements

failures

12 Electrical Subclause 3.23 6 0

endurance (D)

Test switch type and standard test coil According to Table 5

number:

Test coil voltage: 150 % of must-operate

Coil suppression: N/A

Duty cycle: 50 %

Switching load conditions: According to Table 6

Monitoring conditions: According to Table 6

At each cycle during the

test

Final measurements:

Test 3 – contact-circuit resistance According to Table 4

If applicable:

Test 2 – functional tests According to Table 4

Test 4 – dielectric test According to Table 4

PAS 62246-2-1 © IEC:2008(E) – 13 –

Table 1 – Quality conformance inspection (continued)

Subgroup C4 (period: at least once every two years)

Acceptable

Test Test conditions according to Sample Performance

Test number of

No. IEC 62246-2 size requirements

failures

13 Shock (D) Subclause 3.20 6 0 No opening of closed

Functional contact circuit with

Test switch type and standard test coil energization condition, or

number: According to Table 5 closing of opened contact

Test coil voltage: 150 % of must-operate circuit shall exceed 10 µs

Axis of mounting: The movable contact shall

be located in the transverse

Shock conditions: direction

Application: three directions

Number of shocks: 18 (three positive and According to Table 7

three negative in each of the three

orthogonal planes)

Duration: 30 ms

Test contact voltage and current:

24 V d.c. max., 10 mA max.

Final measurements:

Test 1 – visual inspection No cracks or other

deterioration

Test 2 – functional tests According to Table 4

Test 6 – sealing According to Table 7

14 Mechanical Subclause 3.24 20 1

endurance (D) There shall be no broken

Test switch type and standard test coil parts

number:

Test coil voltage: 150 % of must-operate

According to Table 5

Coil suppression: N/A

Duty cycle: 50 %

Number of cycles per second: 50 to 60

Periodic measurements:

6 6 6 6

1×10 ; 3×10 ; 5×10 ; 7×10 ;

7 7 7 7 8

1×10 ; 3×10 ; 5×10 ; 7×10 ;and 10

±20 % change of must-

Limits for failure to make:

operate value

50 % change of must-

Limits for failure to break:

release value

According to Table 4

Test 3 – contact-circuit resistance

According to Table 4

Test 2 – functional tests

– 14 – PAS 62246-2-1 © IEC:2008(E)

Table 1 – Quality conformance inspection (continued)

Subgroup C4 (period: at least once every two years)

Acceptable

Test Test conditions according to Sample Performance

Test number of

No. IEC 62246-2 size requirements

failures

15 Making current Subclause 3.34 6 0

capacity (D)

Test switch type and standard test coil According to Table 5

number:

Test coil voltage: 150 % of must-operate

Coil suppression: N/A

Making load conditions: According to Table 6

Monitoring conditions: At each cycle during the

test

monitoring times: t = 400 ms, τ = 50 ms

1 1

According to Table 4

Test 3 – contact-circuit resistance

If applicable:

According to Table 4

Test 2 – functional tests

According to Table 4

Test 4 – dielectric test

16 Breaking current Subclause 3.35 6 0

capacity (D)

Test switch type and standard test coil According to Table 5

number:

Test coil voltage: 150 % of must-operate

Coil suppression: N/A

Breaking load conditions: According to Table 6

Monitoring conditions: At each cycle during the

test

monitoring times: t = 100 ms, τ = 50 ms

2 2

According to Table 4

Test 3 – contact-circuit resistance

If applicable:

According to Table 4

Test 2 – functional tests

According to Table 4

Test 4 – dielectric test

17 Rated impulse Subclause 3.29 3 0

voltage (D)

Test voltage: 3 000 V d.c. According to Table 6

Test voltage wave form: 1,2 / 50 µs

Variant B only

Number of pulses: 6 pulses (three

positive and three negative)

Final measurements:

No cracks or other

Test 1 – visual test

deterioration

Test 2 – functional tests According to Table 4

Test 4 – dielectric test According to Table 4

PAS 62246-2-1 © IEC:2008(E) – 15 –

Table 2 – Tests for qualification approval

Acceptable

Test Test conditions according to Sample Performance

Test number of

No. IEC 62246-2 size requirements

failures

1 Visual inspection Subclause 3.4 According to Table 4

and check of

dimensions (ND) Marking as specified in 6.1

2 Functional tests Subclause 3.5, Procedure 1

(ND)

Application points and standard test coil According to Table 5

number:

Must-operate value: According to Table 4

Saturate value: 150 % of must-operate

Must-release value:

Contact failure-to-make and failure-to-

break by monitoring a current, typically

10 mA at 24 V d.c.

3 Contact circuit Subclause 3.7 Initial value according to

resistance (ND) Table 4

Application points: terminals of

closed contacts

Standard test coil number: According to Table 5

Test coil voltage: 150 % of must-operate

Test voltage max.: 6 V d.c.

Test current max.: 1 A

Dielectric test Subclause 3.8

(ND)

Application points and test voltage: According to Table 4

Duration of test: 1 min Maximum leakage current:

0,5 mA

170 0

A shorter test with a higher voltage may

be stated in the detail specification

Operate, release, Subclause 3.10

transfer or

bridging, and Application points and standard test coil According to Table 5

bounce times number:

(ND)

Test coil voltage: 150 % of must-operate

1) operate time: According to Table 4

2) release time:

3) operate bounce time:

Contact failure-to-make and failure-to-

break by monitoring a current, typically

10 mA at 24 V d.c.

6 Sealing (ND) Subclause 3.22

Application points and standard test coil According to Table 5

number:

Arc time during test According to Table 7

Test coil voltage: 150 % of must-operate

Test voltage: 100 V – 110 V d.c.

Test current: 0,5 A – 0,55 A

Total number of operations required: 3

– 16 – PAS 62246-2-1 © IEC:2008(E)

Table 2 – Tests for qualification approval (continued)

Acceptable

Test Test conditions according to Sample Performance

Test number of

No. IEC 62246-2 size requirements

failures

7 Remanence test Subclause 3.6 6 0

(ND)

Application points and standard test coil According to Table 5

number:

Saturate value: 150 % of must-operate Remanence value:

Just-operate value 1 Maximum 10 %

Saturate value (reverse polarity): 150 %

of must-operate

Just-operate value 2

8 Insulation test Subclause 3.9 6 0

(ND)

Application points and test voltage: According to Table 4

9 Contact sticking Subclause 3.11, Procedure 1 6 0

(ND) Application points and standard test coil According to Table 5

Thermal sticking number:

Upper category temperature: 150 °C

Saturate value: 150 % of must-operate

Test period: minimum 24 h

Maximum permitted value: Permitted value: max.10 %

Magnetostrictive Subclause 3.11.2

According to Table 5

sticking Application points and standard test coil

number:

Pulsing rate: 10 cycles per second

Limits for the peak-to-peak value of the Zero failure-to-break

pulse: 200 % and 100 % of must-operate

Number of test cycles: 5

Minimum contact circuit resistance According to Table 4

defining failure-to-break:

10 Robustness of Subclause 3.12 (in accordance with 6 0 According to Table 4

terminals (D) IEC 60068-2-21) No breaking or loosening of

terminals

Procedure: test Ua1 – tensile

Final measurements:

Test 1 – visual inspection No cracks or other

deterioration

Test 2 – functional tests According to Table 4

Test 6 – sealing According to Table 7

PAS 62246-2-1 © IEC:2008(E) – 17 –

Table 2 – Tests for qualification approval (continued)

Acceptable

Test Test conditions according to Sample Performance

Test number of

No. IEC 62246-2 size requirements

failures

6 0

11 Soldering (D) Subclause 3.13 (in accordance with When inspected with a

IEC 60068-2-20, test Ta, method 1) magnifying lens the dipped

surface shall be 95 %

covered with new solder

coating, the remaining 5 %

Temperature: (235 ± 5) °C

may contain only small

Duration: (2 ± 0,5) s

pinholes

Application point: 5 mm from the

glass-to-metal seals

Subclause 3.13 (in accordance with

IEC 60068-2-20), test Ta, method 2)

Temperature: (350 ± 5) °C

Duration: (3 ± 0,5) s

Application point: 5 mm

from the glass-to-metal seals

Final measurements:

No cracks or other

Test 1 – visual test

deterioration

According to Table 4

Test 2 – functional tests

According to Table 7

Test 6 – sealing

12 Climatic Subclause 3.14 6 0

sequence (D)

Dry heat, 3.14.1 of IEC 62246-1

Application points and standard test coil According to Table 5

number:

Temperature: 200 °C

Duration: 16 h

Recovery: 4 h

During the last 2 h of dry heat exposure: Value according to Table 4

monitoring of contact-circuit resistance

Number of cycles per second: 2

Duty factor: 1:1

Test contact voltage: max. 6 V d.c. or a.c.

Test contact current: max. 1 A

Before the end of dry heat exposure:

Test 2 – functional tests According to Table 4

Damp heat cyclic, 3.14.1, one cycle

Temperature 55 °C

Recovery: 4 h

Cold, 3.14.1

Temperature: – 50 °C

Duration: 2 h

Before the end of cold exposure:

Test 2 – functional tests

According to Table 4

Damp heat cyclic, 3.14.1, one cycle

Temperature: 55 °C

Recovery: 4 h

– 18 – PAS 62246-2-1 © IEC:2008(E)

Table 2 – Tests for qualification approval (continued)

Acceptable

Test Test conditions according to Sample Performance

Test number of

No. IEC 62246-2 size requirements

failures

12 Final measurements:

Climatic

sequence

(continued) Test 4 – dielectric test According to Table 4

Test 2 – functional tests According to Table 4

Test 3 – contact-circuit resistance According to Table 4

Test 1 – visual inspection No cracks or other

deterioration

Test 6 – sealing test According to Table 7

13 6 0

Damp heat, Subclause 3.15 (in accordance with

steady state IEC 60068-2-78)

(D)

Temperature: 200 °C

Conditioning time: 10 days

Final measurements:

Test 4 – dielectric test According to Table 4

Test 2 – functional tests According to Table 4

Test 3 – contact-circuit resistance According to Table 4

Test 1 – visual inspection No cracks or other

deterioration

Test 6 – sealing test According to Table 7

Test 11 – solderability

14 Rapid change Subclause 3.16 (in accordance with 6 0

of IEC 60068-2-14)

temperature

(D) Low temperature: – 50 °C

High temperature: 100 °C

Exposure time: 20 min

Transition time: 1 min

Number of cycles: 10

Final measurements:

Test 4 – dielectric test According to Table 4

Test 2 – functional tests According to Table 4

Test 3 – contact-circuit resistance According to Table 4

Test 1 – visual inspection No cracks or other

deterioration

Test 6 – sealing test According to Table 7

PAS 62246-2-1 © IEC:2008(E) – 19 –

Table 2 – Tests for qualification approval (continued)

Acceptable

Test Test conditions according to Sample Performance

Test number of

no. IEC 62246-2 size requirements

failures

6 0

15 Salt mist (D) Subclause 3.17 (in accordance with

IEC 60068-2-11)

Concentration: 5 ± 1 % by weight

PH value: 6,5 to 7,2

Temperature: 35 °C

Durations: 168 h

Final measurements:

Test 4 – dielectric test According to Table 4

Test 2 – functional tests According to Table 4

Test 3 – contact-circuit resistance According to Table 4

Test 1 – visual inspection No breaking or loosening of

terminals

Test 6 – sealing test According to Table 7

16 Bump (D) Subclause 3.18 (in accordance with 6 0 No opening of closed contact

IEC 60068-2-29, test Eb) circuit with energization

condition or closing of opened

contact circuit shall exceed

Standard test coil according to Table 5 10 µs

Test coil voltage: 150 % of must-operate

Peak acceleration: 150 m/s

Duration: 6 ms

Number of bumps: 100 + 5

Final measurements:

Test 2 – functional tests According to Table 4

Test 1 – visual inspection No breaking or loosening of

terminals

Test 6 – sealing test According to Table 7

– 20 – PAS 62246-2-1 © IEC:2008(E)

Table 2 – Tests for qualification approval (continued)

Acceptable

Test Test conditions according to Sample Performance

Test number of

No. IEC 62246-2 size requirements

failures

6 0

17 Vibration (D) Subclause 3.19 No opening of closed contact

Functional circuit with energization

Test switch type and standard test coil condition or closing of opened

number: according to Table 5 contact circuit shall exceed

Test coil voltage: 150 % of must-operate 10 µs

Axis of mounting: The movable contact shall be

located in the transverse

direction

Vibration conditions:

Application: three directions

According to Table 7

Number of sweeps per direction: 3

Sweep rate: 1 octave/min ± 10 %

Total duration: approx. 3×10 min

Test contact voltage and current:

24 V d.c. max., 10 mA max.

Final measurements:

Test 1 – visual inspection

No cracks or other

deterioration

Test 2 – functional tests

According to Table 4

Test 6 – sealing

According to Table 7

Clause 9 of IEC 61373 applies 6 0

Vibration (D)

Survival

Test switch type and standard test coil

The movable contact shall be

number: according to Table 5

located in the transverse

Test coil voltage: 150 % of must-operate

direction

Axis of mounting:

Vibration conditions:

Application: three directions

Frequency: 5 Hz to 150 Hz

Number of sweeps per direction: 3

Sweep rate: 1 octave/min ± 10 %

Test duration: min. 5 h each

Peak to peak values:

Vertical direction: 7,90 m/s

Transverse direction: 3,5 m/s

Longitudinal direction: 5,50 m/s

Test contact voltage and current:

24 V d.c. max., 10 mA max.

Final measurements:

Test 1 – visual inspection

No cracks or other

deterioration

Test 2 – functional tests

According to Table 4

Test 6 – sealing

According to Table 7

PAS 62246-2-1 © IEC:2008(E) – 21 –

Table 2 – Tests for qualification approval (continued)

Acceptable

Test Test conditions according to Sample Performance

Test number of

No. IEC 62246-2 size requirements

failures

6 0

18 Shock (D) Subclause 3.20 No opening of closed contact

Functional circuit with energization

Test switch type and standard test coil condition, or closing of opened

number: According to Table 5 contact circuit shall exceed

Test coil voltage: 150 % of must-operate 10 µs

Axis of mounting: The movable contact shall be

located in the transverse

Shock conditions: direction

Application: three directions

Number of shocks: 18 (three positive and According to Table 7

three negative in each of the three

orthogonal planes)

Duration: 30 ms

Test contact voltage and current:

24 V d.c. max., 10 mA max.

Final measurements:

Test 1 – visual inspection No cracks or other

deterioration

Test 2 – functional tests According to Table 4

According to Table 7

Test 6 – sealing

6 0

Shock (D) Subclause 3.20 No cracks or other

Survival deterioration

Test switch type and standard test coil

number: according to Table 5

Test coil voltage: 150 % of must-operate

Axis of mounting: The movable contact shall be

located in the transverse

direction

Shock conditions:

According to Table 7

Application: three directions

Number of shocks: 18 (three positive and

three negative in each of the three

orthogonal planes)

Duration: 30 ms

Final measurements:

Test 1 – visual inspection According to Table 4

According to Table 4

Test 2 – functional tests

Test 6 – sealing According to Table 7

– 22 – PAS 62246-2-1 © IEC:2008(E)

Table 2 – Tests for qualification approval (continued)

Acceptable

Test Test conditions according to Sample Performance

Test number of

No. IEC 62246-2 size requirements

failures

6 0

19 Electrical Subclause 3.23

endurance (D)

Test switch type and standard test coil According to Table 5

number:

Test coil voltage: 150 % of must-operate

Coil suppression: N/A

Duty cycle: 50 %

Switching load conditions: According to Table 6

Monitoring conditions: According to Table 6

At each cycle during the test

Final measurements:

Test 3 – contact-circuit resistance According to Table 4

If applicable:

Test 2 – functional tests According to Table 4

Test 4 – dielectric test According to Table 4

20 Mechanical Subclause 3.24 20 1

endurance (D) There shall be no broken parts

Test switch type and standard test coil

number:

According to Table 5

Test coil voltage: 150 % of must-operate

Coil suppression: N/A

Duty cycle: 50 %

Number of cycles per second: 50 to 60

Periodic measurements:

6 6 6 6

1×10 ; 3×10 ; 5×10 ; 7×10 ;

7 7 7 7 8

1×10 ; 3×10 ; 5×10 ; 7×10 ;and 10

±20 % change of must-operate

Limits for failure to make:

value

50 % change of must-release

Limits for failure to break:

value

According to Table 4

Test 3 – contact-circuit resistance

According to Table 4

Test 2 – functional tests

PAS 62246-2-1 © IEC:2008(E) – 23 –

Table 2 – Tests for qualification approval (continued)

Acceptable

Test Test conditions according to Sample Performance

Test number of

No. IEC 62246-2 size requirements

failures

21 Maximum Subclause 3.25, Procedure 1 6 0

cycling

frequency Test switch type and standard test coil According to Table 5

number:

Test coil voltage: 150 % of must-operate

Maximum bounce time: 3 ms

Coil suppression: N/A According to Table 4

Duty cycle: 50 %

Maximum cycling frequency per second: 60

22 Rated Subclause 3.31 3 0

conditional

short-circuit Test switch type and standard test coil According to Table 5

current (D) number:

Test coil voltage: 150 % of must-operate

Not required Coil suppression: N/A

for Variant B

Type of SCPD: quick acting fuse type

FH in accordance with IEC 60127-2,

standard sheet 1. According to Table 7

Ratings of SCPD: 5 A 250 V

Test voltage: 264 V a.c. or 115 V d.c.

r.m.s. test current: 20 A a.c. and d.c.

Minimum time interval between tests: 3 min

Number of tests: 3

Final measurements:

Test 1 – visual test No cracks or other

deterioration

Test 2 – functional tests According to Table 4

Test 4 – dielectric test According to Table 4

23 Contact Subclause 3.32 20 0

reliability test

(D) Test switch type and standard test coil According to Table 5

number:

Test coil voltage: 150 % of must-operate

Coil suppression: N/A

Duty cycle: 50 %

Switching load conditions: According to Table 6

Monitoring conditions: According to Table 6

At each operating cycle

Final measurements:

Test 3 – contact-circuit resistance According to Table 4

Test 2 – functional tests According to Table 4

– 24 – PAS 62246-2-1 © IEC:2008(E)

Table 2 – Tests for qualification approval (continued)

Acceptable

Test Test conditions according to Sample Performance

Test number of

No. IEC 62246-2 size requirements

defectives

3 0

24 Temperature Subclause 3.33

rise (ND)

Test switch type and standard test coil According to Table 5

number:

Test coil voltage: 150 % of must-operate

Coil suppression: N/A

Testing current: According to Table 4

Measurement positions: terminals

Measurement duration: 1,5 h

Final measurements:

Test 1 – visual test No damage or other

deterioration

Test 3 – contact-circuit resistance According to Table 4

Test 2 – functional test According to Table 4

25 6 0

Making Subclause 3.34

current

capacity (D) Test switch type and standard test coil According to Table 5

number:

Test coil voltage: 150 % of must-operate

Coil suppression: N/A

Making load conditions: According t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...