IEC 61784-3-8:2010

(Main)Industrial communication networks - Profiles - Part 3-8: Functional safety fieldbuses - Additional specifications for CPF 8

Industrial communication networks - Profiles - Part 3-8: Functional safety fieldbuses - Additional specifications for CPF 8

IEC 61784-3-8:2010(E) specifies a safety communication layer (services and protocol) based on CPF 8 of IEC 61784-1 and IEC 61158 Type 18. It identifies the principles for functional safety communications defined in IEC 61784-3 that are relevant for this safety communication layer.

General Information

- Status

- Published

- Publication Date

- 28-Jun-2010

- Technical Committee

- SC 65C - Industrial networks

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 28-Jul-2016

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61784-3-8:2010 defines a functional safety communication layer for industrial fieldbuses based on CPF 8 of IEC 61784-1 and IEC 61158 Type 18. The standard specifies services, protocol elements and management rules for transmitting safety-related data across CPF 8 networks (notably CC-Link Safety™). It identifies the functional-safety principles from IEC 61784-3 that are applicable to this safety communication layer and provides normative requirements and informative assessment guidance.

Key topics and technical requirements

- Safety communication layer (SCL) - structure and relationship with other layers (FAL, DLL, PhL) for CPF 8 networks.

- Safety services and interfaces - definitions for SASEs/SARs (safety application service elements / safety application relationships) including device manager, connection manager and cyclic transmission classes.

- Safety PDU format - abstract and transfer syntax for safety Protocol Data Units, ensuring consistent encoding and integrity handling.

- Safety measures - mandatory mechanisms such as sequence numbering, time expectations, connection authentication, feedback messages and alternative data integrity assurance systems.

- State model and timers - state descriptions (Idle, Running, Fail-safe, forced termination) and monitor timer operation for master/slave/data monitoring.

- Management procedures - connection establishment/confirmation, safety slave verification and safety parameter transmission.

- System requirements - installation guidance, indicators/switches, maintenance and calculation of safety function response time and residual error rate.

- Assessment guidance and annexes - informative material (e.g., hash function calculation) to support conformity assessment and implementation.

Practical applications

IEC 61784-3-8 is intended for manufacturers, integrators and system architects implementing or certifying CPF 8 safety fieldbus solutions in industrial environments where functional safety is critical. Typical uses include:

- Implementing CC-Link Safety™ nodes and gateways with defined safety services and PDUs.

- Designing safety controllers, I/O modules and safety monitoring equipment to conform with CPF 8 communication requirements.

- Performing safety assessments, verification and maintenance planning based on the standard’s system requirement and residual error rate guidance.

Who uses this standard

- Industrial automation vendors building CPF 8 / CC‑Link Safety™ devices

- Control system integrators and machine builders

- Functional safety engineers responsible for SIL-level communications

- Certification and testing laboratories assessing CPF 8 implementations

Related standards

- IEC 61784-1 (Profiles - CPF definitions)

- IEC 61784-3 (Functional safety fieldbus principles)

- IEC 61158 Type 18 (Fieldbus data link and physical layer specifications used by CPF 8)

Keywords: IEC 61784-3-8, CPF 8, functional safety fieldbus, safety communication layer, CC-Link Safety, IEC 61158, safety PDU, residual error rate.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

Sponsored listings

Frequently Asked Questions

IEC 61784-3-8:2010 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Industrial communication networks - Profiles - Part 3-8: Functional safety fieldbuses - Additional specifications for CPF 8". This standard covers: IEC 61784-3-8:2010(E) specifies a safety communication layer (services and protocol) based on CPF 8 of IEC 61784-1 and IEC 61158 Type 18. It identifies the principles for functional safety communications defined in IEC 61784-3 that are relevant for this safety communication layer.

IEC 61784-3-8:2010(E) specifies a safety communication layer (services and protocol) based on CPF 8 of IEC 61784-1 and IEC 61158 Type 18. It identifies the principles for functional safety communications defined in IEC 61784-3 that are relevant for this safety communication layer.

IEC 61784-3-8:2010 is classified under the following ICS (International Classification for Standards) categories: 25.040.40 - Industrial process measurement and control; 35.100.05 - Multilayer applications. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61784-3-8:2010 has the following relationships with other standards: It is inter standard links to IEC 61784-3-8:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61784-3-8:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61784-3-8 ®

Edition 1.0 2010-06

INTERNATIONAL

STANDARD

colour

inside

Industrial communication networks – Profiles –

Part 3-8: Functional safety fieldbuses – Additional specifications for CPF 8

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 61784-3-8 ®

Edition 1.0 2010-06

INTERNATIONAL

STANDARD

colour

inside

Industrial communication networks – Profiles –

Part 3-8: Functional safety fieldbuses – Additional specifications for CPF 8

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

X

ICS 25.040.40; 35.100.05 ISBN 978-2-88910-980-7

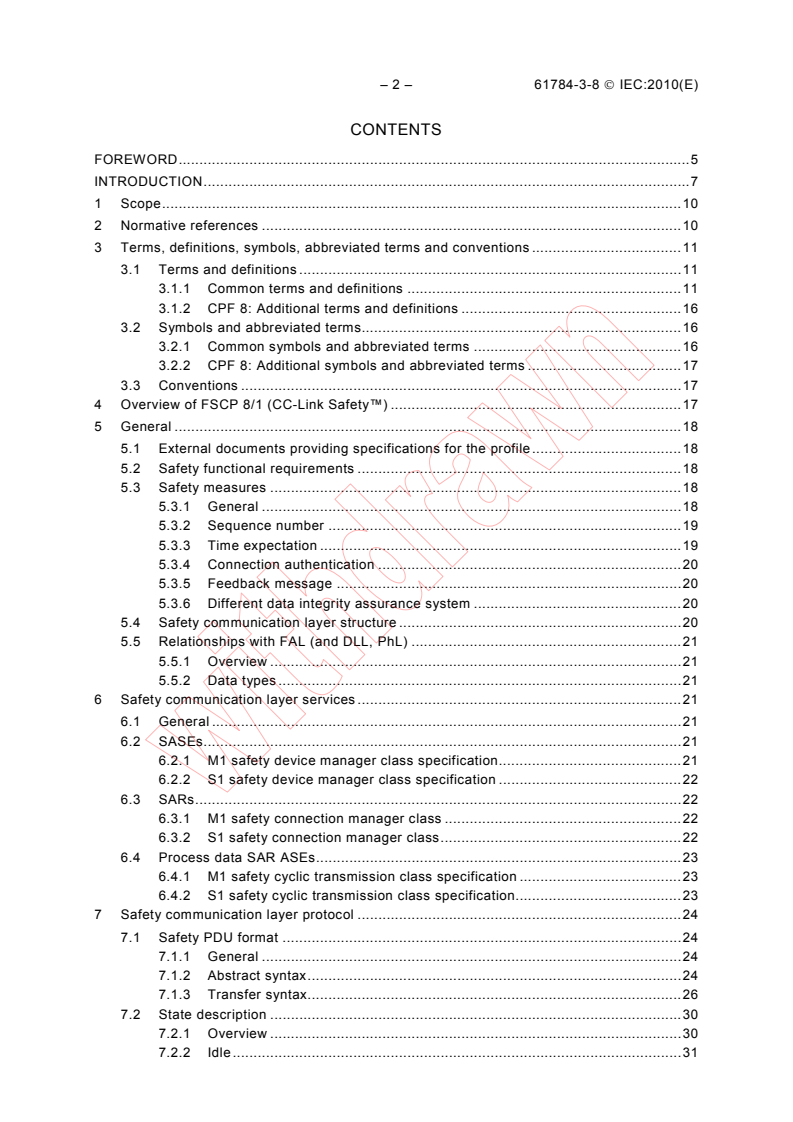

– 2 – 61784-3-8 © IEC:2010(E)

CONTENTS

FOREWORD.5

INTRODUCTION.7

1 Scope.10

2 Normative references .10

3 Terms, definitions, symbols, abbreviated terms and conventions .11

3.1 Terms and definitions .11

3.1.1 Common terms and definitions .11

3.1.2 CPF 8: Additional terms and definitions .16

3.2 Symbols and abbreviated terms.16

3.2.1 Common symbols and abbreviated terms .16

3.2.2 CPF 8: Additional symbols and abbreviated terms .17

3.3 Conventions .17

4 Overview of FSCP 8/1 (CC-Link Safety™) .17

5 General .18

5.1 External documents providing specifications for the profile.18

5.2 Safety functional requirements .18

5.3 Safety measures .18

5.3.1 General .18

5.3.2 Sequence number .19

5.3.3 Time expectation .19

5.3.4 Connection authentication .20

5.3.5 Feedback message .20

5.3.6 Different data integrity assurance system .20

5.4 Safety communication layer structure .20

5.5 Relationships with FAL (and DLL, PhL) .21

5.5.1 Overview .21

5.5.2 Data types .21

6 Safety communication layer services .21

6.1 General .21

6.2 SASEs.21

6.2.1 M1 safety device manager class specification.21

6.2.2 S1 safety device manager class specification .22

6.3 SARs.22

6.3.1 M1 safety connection manager class .22

6.3.2 S1 safety connection manager class.22

6.4 Process data SAR ASEs.23

6.4.1 M1 safety cyclic transmission class specification .23

6.4.2 S1 safety cyclic transmission class specification.23

7 Safety communication layer protocol .24

7.1 Safety PDU format .24

7.1.1 General .24

7.1.2 Abstract syntax.24

7.1.3 Transfer syntax.26

7.2 State description .30

7.2.1 Overview .30

7.2.2 Idle.31

61784-3-8 © IEC:2010(E) – 3 –

7.2.3 FAL running.31

7.2.4 SCL running .32

7.2.5 Fail safe .32

7.2.6 Safety data transmission and processing.32

7.2.7 Forced termination .34

8 Safety communication layer management.34

8.1 General .34

8.2 Connection establishment and confirmation processing.35

8.3 Safety slave verification .35

8.3.1 General .35

8.3.2 Safety slave information verification process .35

8.3.3 Safety slave parameter transmission .35

9 System requirements.36

9.1 Indicators and switches .36

9.1.1 Switches.36

9.1.2 Indicators .36

9.2 Installation guidelines.37

9.3 Safety function response time .37

9.3.1 General .37

9.3.2 Time calculation .37

9.4 Duration of demands .39

9.5 Constraints for calculation of system characteristics.39

9.5.1 System characteristics.39

9.5.2 Residual error rate (Λ) .39

9.6 Maintenance.40

9.7 Safety manual .40

10 Assessment.41

Annex A (informative) Additional information for functional safety communication

profiles of CPF 8.42

A.1 Hash function calculation.42

A.2 … .42

Annex B (informative) Information for assessment of the functional safety

communication profiles of CPF 8 .43

Bibliography.44

Table 1 – Selection of the various measures for possible errors.19

Table 2 – M1 safety device manager attribute format .24

Table 3 – S1 safety device manager attribute format .24

Table 4 – M1 safety connection manager attribute format .24

Table 5 – S1 safety connection manager attribute format.25

Table 6 – M1 safety cyclic transmission attribute format .25

Table 7 – S1 safety cyclic transmission attribute format .26

Table 8 – M1 safety device manager attribute encoding.26

Table 9 – S1 safety device manager attribute encoding .27

Table 10 – M1 safety connection manager attribute encoding .27

Table 11 – S1 safety connection manager attribute encoding.27

– 4 – 61784-3-8 © IEC:2010(E)

Table 12 – M1 safety cyclic transmission attribute encoding .28

Table 13 – S1 safety cyclic transmission attribute encoding.29

Table 14 – Safety master monitor timer operation .33

Table 15 – Safety slave monitor timer operation .33

Table 16 – Safety data monitor timer operation.33

Table 17 – Details of connection establishment and confirmation processing.35

Table 18 – Details of slave information verification processing.35

Table 19 – Details of safety slave parameter transmission processing .36

Table 20 – Monitor LEDs .36

Table 21 – Safety function response time calculation.38

Table 22 – Safety function response time definition of terms.38

Table 23 – Number of occupied slots and safety data .39

Table 24 – Residual error rate Λ (occupied slots = 1).40

Table 25 – Residual error rate Λ (occupied slots = 2).40

Figure 1 – Relationships of IEC 61784-3 with other standards (machinery) .7

Figure 2 – Relationships of IEC 61784-3 with other standards (process).8

Figure 3 – Relationship between SCL and the other layers of IEC 61158 Type 18.21

Figure 4 – State diagram .31

61784-3-8 © IEC:2010(E) – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

INDUSTRIAL COMMUNICATION NETWORKS –

PROFILES –

Part 3-8: Functional safety fieldbuses –

Additional specifications for CPF 8

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

International Standard IEC 61784-3-8 has been prepared by subcommittee 65C: Industrial

networks, of IEC technical committee 65: Industrial process measurement, control and

automation.

The text of this standard is based on the following documents:

FDIS Report on voting

65C/591A/FDIS 65C/603/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 6 – 61784-3-8 © IEC:2010(E)

A list of all parts of the IEC 61784-3 series, published under the general title Industrial

communication networks – Profiles – Functional safety fieldbuses, can be found on the IEC

website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

61784-3-8 © IEC:2010(E) – 7 –

INTRODUCTION

The IEC 61158 fieldbus standard together with its companion standards IEC 61784-1 and

IEC 61784-2 defines a set of communication protocols that enable distributed control of

automation applications. Fieldbus technology is now considered well accepted and well

proven. Thus many fieldbus enhancements are emerging, addressing not yet standardized

areas such as real time, safety-related and security-related applications.

This standard explains the relevant principles for functional safety communications with

reference to IEC 61508 series and specifies several safety communication layers (profiles and

corresponding protocols) based on the communication profiles and protocol layers of

IEC 61784-1, IEC 61784-2 and the IEC 61158 series. It does not cover electrical safety and

intrinsic safety aspects.

Figure 1 shows the relationships between this standard and relevant safety and fieldbus

standards in a machinery environment.

Product standards

ISO 12100-1 and ISO 14121

ISO 12100-1 and ISO 14121

IEC 61496 IEC 61800-5-2 ISO 10218-1 Safety of machinery – Principles for

IEC 61496 IEC 61131-6 IEC 61800-5-2 ISO 10218-1 Safety of machinery – Principles for

IEC 61131-6

design and risk assessment

Safety f. e.g. Safety for PLC Safety functions Safety requirements

Safety f. e.g. Safety functions Safety requirements design and risk assessment

Safety for PLC

(under consideration)

light curtains for drives for robots

light curtains (under consideration) for drives for robots

Design of safety-related electrical, electronic and program-

IEC 61784-4 IEC 62443

IEC 61784-4 IEC 62443

mable electronic control systems (SRECS) for machinery

Security Security

Security Security

(profile-specific) (common part)

(profile-specific) (common part)

SIL based PL based

IEC 61784-5 IEC 61918

IEC 61784-5 IEC 61918

Installation guide Installation guide

Design objective

Installation guide Installation guide

(profile-specific) (common part)

(profile-specific) (common part)

Applicable standards

ISO 13849-1, -2

ISO 13849-1, -2

IEC 60204-1

IEC 60204-1

Safety-related parts

Safety-related parts

Safety of electrical

Safety of electrical

IEC 61000-1-2

IEC 61000-1-2 of machinery

of machinery

equipment

equipment

Methodology EMC & FS

Methodology EMC & FS (SRPCS)

(SRPCS)

IEC 61784-3 IEC 61326-3-1

IEC 61784-3 IEC 61326-3-1 Non-electrical

Non-electrical

Test EMC & FS

Functional safety

Functional safety Test EMC & FS

communication

communication Electrical

Electrical

US: NFPA 79

profiles US: NFPA 79

profiles

(2006)

(2006)

IEC 62061

IEC 62061

Functional safety

Functional safety

IEC 61158 series /

IEC 61158 series /

for machinery

for machinery

IEC 61784-1, -2 IEC 61508 series

(SRECS)

IEC 61784-1, -2 IEC 61508 series

(SRECS)

Functional safety (FS)

Fieldbus for use in (including EMC for

Functional safety (FS)

Fieldbus for use in (including EMC for

(basic standard)

industrial environment)

industrial control systems (basic standard)

industrial environment)

industrial control systems

Key

(yellow) safety-related standards

(blue) fieldbus-related standards

(dashed yellow) this standard

NOTE Subclauses 6.7.6.4 (high complexity) and 6.7.8.1.6 (low complexity) of IEC 62061 specify the relationship

between PL (Category) and SIL.

Figure 1 – Relationships of IEC 61784-3 with other standards (machinery)

– 8 – 61784-3-8 © IEC:2010(E)

Figure 2 shows the relationships between this standard and relevant safety and fieldbus

standards in a process environment.

Product standards

IEC 61496 IEC 61800-5-2 ISO 10218-1

IEC 61131-6

IEC 61496 IEC 61131-6 IEC 61800-5-2 ISO 10218-1

Safety f. e.g. Safety functions Safety requirements

Safety for PLC

Safety f. e.g. Safety for PLC Safety functions Safety requirements

light curtains (under consideration) for drives for robots

(under consideration)

light curtains for drives for robots

IEC 61784-4 IEC 62443

IEC 61784-4 IEC 62443

Security Security

Security Security

(profile-specific) (common part)

(profile-specific) (common part)

See safety standards for machinery

(Figure 1)

IEC 61784-5 IEC 61918

IEC 61784-5 IEC 61918

Installation guide Installation guide

Installation guide Installation guide

(profile-specific) (common part)

(profile-specific) (common part)

Valid also in process industries,

whenever applicable

a)

a)

IEC 61326-3-2

IEC 61326-3-2

EMC and

EMC and

functional safety

functional safety

IEC 61784-3

IEC 61784-3

Functional safety

Functional safety

communication

communication

profiles

profiles

US:

US:

ISA-84.00.01

ISA-84.00.01

b)

b)

(3 parts = modified

IEC 61511 series

IEC 61511 series (3 parts = modified

IEC 61511)

Functional safety –

IEC 61158 series / Functional safety – IEC 61511)

IEC 61158 series /

Safety instrumented

Safety instrumented

IEC 61784-1, -2 IEC 61508 series

IEC 61784-1, -2 IEC 61508 series

systems for the

systems for the

Fieldbus for use in Functional safety (FS)

Functional safety (FS)

Fieldbus for use in DE: VDI 2180

process industry sector DE: VDI 2180

process industry sector

(basic standard)

(basic standard)

industrial control systems Part 1-4

industrial control systems

Part 1-4

Key

(yellow) safety-related standards

(blue) fieldbus-related standards

(dashed yellow) this standard

a

For specified electromagnetic environments; otherwise IEC 61326-3-1.

b

EN ratified.

Figure 2 – Relationships of IEC 61784-3 with other standards (process)

Safety communication layers which are implemented as parts of safety-related systems

according to IEC 61508 series provide the necessary confidence in the transportation of

messages (information) between two or more participants on a fieldbus in a safety-related

system, or sufficient confidence of safe behaviour in the event of fieldbus errors or failures.

Safety communication layers specified in this standard do this in such a way that a fieldbus

can be used for applications requiring functional safety up to the Safety Integrity Level (SIL)

specified by its corresponding functional safety communication profile.

The resulting SIL claim of a system depends on the implementation of the selected functional

safety communication profile within this system – implementation of a functional safety

communication profile in a standard device is not sufficient to qualify it as a safety device.

61784-3-8 © IEC:2010(E) – 9 –

This standard describes:

⎯ basic principles for implementing the requirements of IEC 61508 series for safety-

related data communications, including possible transmission faults, remedial

measures and considerations affecting data integrity;

⎯ individual description of functional safety profiles for several communication profile

families in IEC 61784-1 and IEC 61784-2;

⎯ safety layer extensions to the communication service and protocols sections of the

IEC 61158 series.

– 10 – 61784-3-8 © IEC:2010(E)

INDUSTRIAL COMMUNICATION NETWORKS –

PROFILES –

Part 3-8: Functional safety fieldbuses –

Additional specifications for CPF 8

1 Scope

This part of the IEC 61784-3 series specifies a safety communication layer (services and

protocol) based on CPF 8 of IEC 61784-1 and IEC 61158 Type 18. It identifies the principles

for functional safety communications defined in IEC 61784-3 that are relevant for this safety

communication layer.

NOTE 1 It does not cover electrical safety and intrinsic safety aspects. Electrical safety relates to hazards such

as electrical shock. Intrinsic safety relates to hazards associated with potentially explosive atmospheres.

This part defines mechanisms for the transmission of safety-relevant messages among

participants within a distributed network using fieldbus technology in accordance with the

requirements of IEC 61508 series for functional safety. These mechanisms may be used in

various industrial applications such as process control, manufacturing automation and

machinery.

This part provides guidelines for both developers and assessors of compliant devices and

systems.

NOTE 2 The resulting SIL claim of a system depends on the implementation of the selected functional safety

communication profile within this system – implementation of a functional safety communication profile according to

this part in a standard device is not sufficient to qualify it as a safety device.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60204-1, Safety of machinery – Electrical equipment of machines – Part 1: General

requirements

IEC 61131-2, Programmable controllers – Part 2: Equipment requirements and tests

IEC 61158 (all parts), Industrial communication networks – Fieldbus specifications

IEC 61158-2, Industrial communication networks – Fieldbus specifications – Part 2: Physical

layer specification and service definition

IEC 61158-3-18, Industrial communication networks – Fieldbus specifications – Part 3-18:

Data-link layer service definition – Type 18 elements

IEC 61158-4-18, Industrial communication networks – Fieldbus specifications – Part 4-18:

Data-link layer protocol specification – Type 18 elements

—————————

In the following pages of this standard, “this part” will be used for “this part of the IEC 61784-3 series”.

In the following pages of this standard, “IEC 61508” will be used for “IEC 61508 series”.

61784-3-8 © IEC:2010(E) – 11 –

IEC 61158-5-18, Industrial communication networks – Fieldbus specifications – Part 5-18:

Application layer service definition – Type 18 elements

IEC 61158-6-18, Industrial communication networks – Fieldbus specifications – Part 6-18:

Application layer protocol specification – Type 18 elements

IEC 61326-3-1, Electrical equipment for measurement, control and laboratory use – EMC

requirements – Part 3-1: Immunity requirements for safety-related systems and for equipment

intended to perform safety related functions (functional safety) – General industrial

applications

IEC 61326-3-2, Electrical equipment for measurement, control and laboratory use – EMC

requirements – Part 3-2: Immunity requirements for safety-related systems and for equipment

intended to perform safety related functions (functional safety) – Industrial applications with

specified electromagnetic environment

IEC 61508 (all parts), Functional safety of electrical/electronic/programmable electronic

safety-related systems

IEC 61511 (all parts), Functional safety – Safety instrumented systems for the process

industry sector

IEC 61784-1, Industrial communication networks – Profiles – Part 1: Fieldbus profiles

IEC 61784-3: 2010 Industrial communication networks – Profiles – Part 3: Functional safety

fieldbuses – General rules and profile definitions

IEC 62061, Safety of machinery – Functional safety of safety-related electrical, electronic and

programmable electronic control systems

3 Terms, definitions, symbols, abbreviated terms and conventions

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1.1 Common terms and definitions

3.1.1.1

availability

probability for an automated system that for a given period of time there are no unsatisfactory

system conditions such as loss of production

3.1.1.2

black channel

communication channel without available evidence of design or validation according to

IEC 61508

3.1.1.3

communication channel

logical connection between two end-points within a communication system

—————————

In preparation.

– 12 – 61784-3-8 © IEC:2010(E)

3.1.1.4

communication system

arrangement of hardware, software and propagation media to allow the transfer of messages

(ISO/IEC 7498 application layer) from one application to another

3.1.1.5

connection

logical binding between two application objects within the same or different devices

3.1.1.6

Cyclic Redundancy Check (CRC)

redundant data derived from, and stored or transmitted together with, a block of data

in order to detect data corruption

procedure used to calculate the redundant data

NOTE 1 Terms “CRC code” and "CRC signature", and labels such as CRC1, CRC2, may also be used in this

standard to refer to the redundant data.

NOTE 2 See also [32], [33] .

3.1.1.7

error

discrepancy between a computed, observed or measured value or condition and the true,

specified or theoretically correct value or condition

[IEC 61508-4:2010 ], [IEC 61158]

NOTE 1 Errors may be due to design mistakes within hardware/software and/or corrupted information due to

electromagnetic interference and/or other effects.

NOTE 2 Errors do not necessarily result in a failure or a fault.

3.1.1.8

failure

termination of the ability of a functional unit to perform a required function or operation of a

functional unit in any way other than as required

NOTE 1 The definition in IEC 61508-4 is the same, with additional notes.

[IEC 61508-4:2010, modified], [ISO/IEC 2382-14.01.11, modified]

NOTE 2 Failure may be due to an error (for example, problem with hardware/software design or message

disruption).

3.1.1.9

fault

abnormal condition that may cause a reduction in, or loss of, the capability of a functional unit

to perform a required function

NOTE IEV 191-05-01 defines “fault” as a state characterized by the inability to perform a required function,

excluding the inability during preventive maintenance or other planned actions, or due to lack of external resources.

[IEC 61508-4:2010, modified], [ISO/IEC 2382-14.01.10, modified]

3.1.1.10

fieldbus

communication system based on serial data transfer and used in industrial automation or

process control applications

—————————

Figures in square brackets refer to the bibliography.

To be published.

61784-3-8 © IEC:2010(E) – 13 –

3.1.1.11

frame

denigrated synonym for DLPDU

3.1.1.12

hash function

(mathematical) function that maps values from a (possibly very) large set of values into a

(usually) smaller range of values

NOTE 1 Hash functions can be used to detect data corruption.

NOTE 2 Common hash functions include parity, checksum or CRC.

[IEC/TR 62210, modified]

3.1.1.13

hazard

state or set of conditions of a system that, together with other related conditions will inevitably

lead to harm to persons, property or environment

3.1.1.14

master

active communication entity able to initiate and schedule communication activities by other

stations which may be masters or slaves

3.1.1.15

message

ordered series of octets intended to convey information

[ISO/IEC 2382-16.02.01, modified]

3.1.1.16

performance level (PL)

discrete level used to specify the ability of safety-related parts of control systems to perform a

safety function under foreseeable conditions

[ISO 13849-1]

3.1.1.17

protective extra-low-voltage (PELV)

electrical circuit in which the voltage cannot exceed a.c. 30 V r.m.s., 42,4 V peak or d.c. 60 V

in normal and single-fault condition, except earth faults in other circuits

NOTE A PELV circuit is similar to an SELV circuit that is connected to protective earth.

[IEC 61131-2]

3.1.1.18

redundancy

existence of means, in addition to the means which would be sufficient for a functional unit to

perform a required function or for data to represent information

NOTE The definition in IEC 61508-4 is the same, with additional example and notes.

[IEC 61508-4:2010, modified], [ISO/IEC 2382-14.01.12, modified]

3.1.1.19

reliability

probability that an automated system can perform a required function under given conditions

for a given time interval (t1,t2)

NOTE 1 It is generally assumed that the automated system is in a state to perform this required function at the

beginning of the time interval.

– 14 – 61784-3-8 © IEC:2010(E)

NOTE 2 The term "reliability" is also used to denote the reliability performance quantified by this probability.

NOTE 3 Within the MTBF or MTTF period of time, the probability that an automated system will perform a

required function under given conditions is decreasing.

NOTE 4 Reliability differs from availability.

[IEC 62059-11, modified]

3.1.1.20

risk

combination of the probability of occurrence of harm and the severity of that harm

NOTE For more discussion on this concept see Annex A of IEC 61508-5:2010 .

[IEC 61508-4:2010], [ISO/IEC Guide 51:1999, definition 3.2]

3.1.1.21

safety communication layer (SCL)

communication layer that includes all the necessary measures to ensure safe transmission of

data in accordance with the requirements of IEC 61508

3.1.1.22

safety connection

connection that utilizes the safety protocol for communications transactions

3.1.1.23

safety data

data transmitted across a safety network using a safety protocol

NOTE The Safety Communication Layer does not ensure safety of the data itself, only that the data is transmitted

safely.

3.1.1.24

safety device

device designed in accordance with IEC 61508 and which implements the functional safety

communication profile

3.1.1.25

safety extra-low-voltage (SELV)

electrical circuit in which the voltage cannot exceed a.c. 30 V r.m.s., 42,4 V peak or d.c. 60 V

in normal and single-fault condition, including earth faults in other circuits

NOTE An SELV circuit is not connected to protective earth.

[IEC 61131-2]

3.1.1.26

safety function

function to be implemented by an E/E/PE safety-related system or other risk reduction

measures, that is intended to achieve or maintain a safe state for the EUC, in respect of a

specific hazardous event

NOTE The definition in IEC 61508-4 is the same, with an additional example and reference.

[IEC 61508-4:2010, modified]

—————————

To be published.

61784-3-8 © IEC:2010(E) – 15 –

3.1.1.27

safety function response time

worst case elapsed time following an actuation of a safety sensor connected to a fieldbus,

before the corresponding safe state of its safety actuator(s) is achieved in the presence of

errors or failures in the safety function channel

NOTE This concept is introduced in IEC 61784-3:2010 , 5.2.4 and addressed by the functional safety

communication profiles defined in this part.

3.1.1.28

safety integrity level (SIL)

discrete level (one out of a possible four), corresponding to a range of safety integrity values,

where safety integrity level 4 has the highest level of safety integrity and safety integrity level

1 has the lowest

NOTE 1 The target failure measures (see IEC 61508-4:2010, 3.5.17) for the four safety integrity levels are

specified in Tables 2 and 3 of IEC 61508-1:2010 .

NOTE 2 Safety integrity levels are used for specifying the safety integrity requirements of the safety functions to

be allocated to the E/E/PE safety-related systems.

NOTE 3 A safety integrity level (SIL) is not a property of a system, subsystem, element or component. The correct

interpretation of the phrase “SILn safety-related system” (where n is 1, 2, 3 or 4) is that the system is potentially

capable of supporting safety functions with a safety integrity level up to n.

[IEC 61508-4:2010]

3.1.1.29

safety measure

measure to control possible communication errors that is designed and

implemented in compliance with the requirements of IEC 61508

NOTE 1 In practice, several safety measures are combined to achieve the required safety integrity level.

NOTE 2 Communication errors and related safety measures are detailed in IEC 61784-3:2010, 5.3 and 5.4.

3.1.1.30

safety-related application

programs designed in accordance with IEC 61508 to meet the SIL requirements of the

application

3.1.1.31

safety-related system

system performing safety functions according to IEC 61508

3.1.1.32

slave

passive communication entity able to receive messages and send them in response to

another communication entity which may be a master or a slave

3.1.1.33

time stamp

time information included in a message

—————————

In preparation.

To be published.

– 16 – 61784-3-8 © IEC:2010(E)

3.1.2 CPF 8: Additional terms and definitions

3.1.2.1

cycle

interval at which an activity is repetitively and continuously executed

3.1.2.2

safety application relationship (SAR)

application relationship between two or more safety related application relationship endpoints

3.1.2.3

safety application service element (SASE)

safety related application service element

3.1.2.4

safety data monitor timer

timer used by the time expectation function for safety data transmission

3.1.2.5

safety monitor timer

timer used by the time expectation function for safety connection management

3.1.2.6

safety PDU

synonym for safety-related DLPDU

3.1.2.7

slot

one quantum (granularity) of the position dependent mapping of the cyclic data fields

3.1.2.8

station

device and its corresponding SAREP associated with the transmission and reception of safety

data

NOTE The station number is used in the position dependent mapping of the cyclic data fields (a station occupies

one or more slots).

3.1.2.9

safety protocol transmission information

information distinguishing safety relevant messages

3.2 Symbols and abbreviated terms

3.2.1 Common symbols and abbreviated terms

CP Communication Profile [IEC 61784-1]

CPF Communication Profile Family [IEC 61784-1]

CRC Cyclic Redundancy Check

DLL Data Link Layer [ISO/IEC 7498-1]

DLPDU Data Link Protocol Data Unit

EMC Electromagnetic Compatibility

EUC Equipment Under Control [IEC 61508-4:2010]

E/E/PE Electrical/Electronic/Programmable Electronic [IEC 61508-4:2010]

FAL Fieldbus Application Layer [IEC 61158-5]

FS Functional Safety

FSCP Functional Safety Communication Profile

61784-3-8 © IEC:2010(E) – 17 –

MTBF Mean Time Between Failures

MTTF Mean Time To Failure

PDU Protocol Data Unit [ISO/IEC 7498-1]

PELV Protective Extra Low Voltage

PhL Physical Layer [ISO/IEC 7498-1]

PL Performance Level [ISO 13849-1]

PLC Programmable Logic Controller

SCL Safety Communication Layer

SELV Safety Extra Low Voltage

SIL Safety Integrity Level [IEC 61508-4:2010]

3.2.2 CPF 8: Additional symbols and abbreviated terms

AR Application Relationship

ASE Application Service Element

CMD Command Data

LED Light Emitting Diode

LID Link Identifier

PSD Protocol Support Data

RNO Running Number

SAR Safety Application Relationship

SAREP Safety Application Relationship Endpoint

SARPM Safety Application Relationship Protocol State Machine

SASE Safety Application Service Element

SRC Safety Relevant Controller

SRP Safety Relevant Peripheral

TPI Safety Transmission Packet Information

TPI-T Safety Transmission Packet Information from master

TPI-R Safety Transmission Packet Information from slave

3.3 Conventions

Conventions used in this document are defined in IEC 61158 Type 18 and IEC 61784-1 CPF 8.

4 Overview of FSCP 8/1 (CC-Link Safety™)

Communication Profile Family 8 (commonly known as CC-Link™ ) defines communication

profiles based on IEC 61158-2 Type 18, IEC 61158-3-18, IEC 61158-4-18, IEC 61158-5-18,

and IEC 61158-6-18.

The basic profiles CP 8/1, CP 8/2, and CP 8/3 are defined in IEC 61784-1. The CPF 8

functional safety communication profile FSCP 8/1 (CC-Link Safety™ ) is

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...