IEC 60335-2-40:2018

(Main)Household and similar electrical appliances - Safety - Part 2-40: Particular requirements for electrical heat pumps, air-conditioners and dehumidifiers

Household and similar electrical appliances - Safety - Part 2-40: Particular requirements for electrical heat pumps, air-conditioners and dehumidifiers

IEC 60335-2-40:2018 deals with the safety of electric heat pumps, including sanitary hot water heat pumps, air conditioners, and dehumidifiers incorporating motor-compressors and hydronic fan coils units, their maximum rated voltages being not more than 250 V for single phase appliances and 600 V for all other appliances. Partial units are within the scope of this International Standard.

Appliances not intended for normal household use but which nevertheless may be a source of danger to the public, such as appliances intended to be used by laymen in shops, in light industry and on farms, are within the scope of this standard. The appliances referenced above may consist of one or more factory-made assemblies. If provided in more than one assembly, the separate assemblies are to be used together, and the requirements are based on the use of matched assemblies. This standard does not take into account refrigerants other than group A1, A2L, A2 and A3 as defined by ISO 817 classification, A2L refrigerants are limited to those of a molar mass of more than or equal to 42 kg/kmol based on WCF – Worst Case Formulation as specified in ISO 817. This standard specifies particular requirements for the use of flammable refrigerants. Unless specifications are covered by this standard, including the annexes, requirements for refrigerating safety are covered by ISO 5149. Supplementary heaters, or a provision for their separate installation, are within the scope of this standard, but only heaters which are designed as a part of the appliance package, the controls being incorporated in the appliance. For appliances intended to be used in vehicles or on board ships or aircraft, additional requirements may be necessary; for appliances subjected to pressure, additional requirements may be necessary; This standard does not apply to: humidifiers intended for use with heating and cooling equipment (IEC 60335-2-88); appliances designed exclusively for industrial processing or appliances intended to be used in locations where special conditions prevail, such as the presence of a corrosive or explosive atmosphere (dust, vapour or gas). This sixth edition cancels and replaces the fifth edition published in 2013 and its Amendment 1:2016. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

- Clause 1 – limiting A2L refrigerants to those of a molar mass of more than or equal to 42 kg/kmol;

- Clause 7 – added requirements for A2L refrigerants,

- Clause 7 – added requirement for pre-charge pipe sets, detection systems, ventilation and the resulting charge;

- Clause 7 – added requirements for UV-C systems;

- Clause 7 – added requirements for transcritical refrigerating systems;

- Subclause 19.7 – amended text to match the intention of the subclause;

- Clause 21 – added requirements for transcritical refrigerating systems;

- Subclause 22 – added requirements for A2L refrigerants;

- Subclause 22– added detection systems;

- Subclause 22 – added new requirements for enhanced tightness refrigerating systems;

- Subclause 22 – added new requirements for UV-C;

- Clause 23 – added new requirements for UV-C;Clause

- Clause 24 – added requirements for transcritical refrigerating systems;

- Subclause 24 – added requirements for detection systems and airflow;

- Clause 32 added new requirements for UV-C;

- Annex BB – revised to add surface temperatures;

- Annex DD – added requirements for A2L refrigerants and amended requirements for flammable refrigerants to exempt A2L refrigerants;

- Annex GG – added requirements for A2L refrigerants;

- Annex GG.1 – amended Table GG.1 and related wording

- Annex GG.7 – added requirement to test;

- Annex GG.8 to GG.13 – new coverage for A2L refrigerants;

- Annex HH – revised to take into account A2L refrigerants;

- Annex JJ – new coverage of allowable opening of relays and similar components to prevent ignition of A2L r

Appareils électrodomestiques et analogues - Sécurité - Partie 2-40 : Exigences particulières pour les pompes à chaleur électriques, les climatiseurs et les déshumidificateurs

L'IEC 60335-2-40:2018 traite de la sécurité des pompes à chaleur électriques, notamment les pompes à chaleur pour production d'eau chaude sanitaire, les climatiseurs et les déshumidificateurs qui comportent des motocompresseurs et des ventiloconvecteurs hydroniques, dont la tension assignée maximale n'est pas supérieure à 250 V pour les appareils monophasés et à 600 V pour tous les autres appareils. Les unités partielles relèvent du domaine d'application de la présente Norme internationale.

Les appareils non destinés à un usage domestique normal, mais qui néanmoins peuvent constituer une source de danger pour le public, tels que les appareils destinés à être utilisés par des usagers non avertis dans des magasins, chez des artisans et dans des fermes, sont compris dans le domaine d'application de la présente norme.

Les appareils indiqués ci-dessus peuvent consister en un ou plusieurs ensembles fabriqués en usine. Si les appareils sont fournis en plusieurs ensembles, les ensembles doivent être utilisés conjointement et les exigences correspondantes dépendent de l'utilisation des ensembles assortis.

Les exigences relatives à la sécurité des systèmes frigorifiques sont spécifiées dans les normes ISO 5149-1, ISO 5149-2 et ISO 5149-3. En outre, l'IEC 60335-2-21 spécifie les exigences relatives aux cuves destinées au stockage de l'eau chauffée dans les pompes à chaleur pour production d'eau chaude sanitaire.

La présente norme ne couvre pas les fluides frigorigènes qui n'appartiennent pas aux groupes A1, A2L, A2 et A3 de la classification ISO 817. Les fluides frigorigènes A2L se limitent à ceux dont la masse molaire est supérieure ou égale à 42 kg/kmol d'après la formule "la plus défavorable" (WCF, Worst Case Formula) spécifiée dans l'ISO 817.

La présente norme spécifie les exigences particulières pour l'utilisation des fluides frigorigènes inflammables. Sauf spécification contraire dans la présente norme et ses annexes, les exigences relatives à la sécurité des systèmes frigorifiques sont spécifiées dans la série ISO 5149.

Les dispositifs de chauffage supplémentaires (ou les dispositions concernant leur installation) sont couverts par le domaine d'application de la présente norme, mais uniquement les dispositifs de chauffage qui sont conçus en tant que partie de l'appareil, les commandes étant incorporées à l'appareil.

L'attention est attirée sur le fait que:

- pour les appareils destinés à être utilisés dans des véhicules ou à bord de navires ou d'avions, des exigences supplémentaires peuvent être nécessaires;

- pour les appareils à pression, des exigences supplémentaires peuvent être nécessaires;

- dans de nombreux pays, des exigences supplémentaires sont spécifiées par exemple par les organismes nationaux de la santé publique responsables de la protection des travailleurs et par les organismes nationaux responsables du stockage, du transport, de la construction des bâtiments et des installations.

La présente norme ne s'applique pas:

- aux humidificateurs destinés à être utilisés avec des appareils de chauffage et de refroidissement (IEC 60335 2-88);

- aux appareils prévus exclusivement pour des usages industriels;

- aux appareils destinés à être utilisés dans des locaux présentant des conditions particulières, telles que la présence d'une atmosphère corrosive ou explosive (poussière, vapeur ou gaz).

Cette sixième édition annule et remplace la cinquième édition parue en 2013 et son Amendement 1:2016. Cette édition constitue une révision technique.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

– à l'Article 1, les fluides frigorigènes A2L se limitent à ceux dont la masse molaire est supérieure ou égale à 42 kg/kmol;

– à l'Article 7, des exigences ont été ajoutées pour les fluides frigorigènes A2L;

– à l'Article 7, une exigence a été ajoutée pour les ensembles de tuyaux de précharge, les systèmes de détection, la ventilation et la charge obtenue;

– à l'Art

General Information

- Status

- Published

- Publication Date

- 25-Jan-2018

- Technical Committee

- SC 61D - Appliances for air-conditioning for household and similar purposes

- Drafting Committee

- WG 9 - TC 61/SC 61D/WG 9

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 25-May-2022

- Completion Date

- 31-Mar-2020

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60335-2-40:2018 is the sixth-edition safety standard from the IEC for household and similar electrical appliances - specifically electrical heat pumps (including sanitary hot water heat pumps), air‑conditioners and dehumidifiers that incorporate motor‑compressors and hydronic fan coil units. It applies to appliances with maximum rated voltages of ≤ 250 V single‑phase and ≤ 600 V for other appliances, and covers partial units and multi‑assembly matched sets intended for use by laymen in homes, shops, light industry and farms.

This 2018 edition is a technical revision that adds and refines requirements for the use of flammable and mildly flammable refrigerants (A2, A2L, A3), transcritical systems, UV‑C systems, detection and ventilation measures, and enhanced tightness and testing aspects.

Key topics and technical requirements

- Scope & voltage limits: Single‑phase ≤250 V, other appliances ≤600 V; partial units included.

- Refrigerants: Limits and specific provisions for refrigerant groups A1, A2L, A2 and A3 per ISO 817; A2L refrigerants are limited to molar mass ≥ 42 kg/kmol (WCF basis). Particular requirements for use of flammable refrigerants are specified.

- Safety features added/updated: requirements for A2L refrigerants, pre‑charge pipe sets, refrigerant detection systems, ventilation and resulting charge limits, and enhanced tightness systems.

- Transcritical systems: New/expanded clauses addressing design, testing and safe operation.

- UV‑C systems: Requirements for appliances that include UV‑C sources (radiation conditioning, safety, testing).

- Testing & verification: New and revised annexes covering charge limits, ventilation (Annex GG), service and installation manual requirements for flammable refrigerants (Annex DD), leak simulation and pressure tests (Annexes FF, EE), detection sensor tests (Annex MM), and tests to prevent ignition of A2L refrigerants (Annex JJ, KK, NN, LL).

- Other safety aspects: motor protection, electrical insulation, mechanical strength, abnormal operation, and limits on relay/openings to avoid ignition sources.

Applications and who uses it

IEC 60335-2-40:2018 is used by:

- Appliance manufacturers and design engineers for compliant product design (heat pumps, AC units, dehumidifiers)

- Compliance and test laboratories for type testing and certification

- Certification bodies and national regulators assessing market access and safety compliance

- Installation and service organizations (installation, commissioning and servicing guidance)

- Safety managers specifying equipment for commercial/residential HVAC systems

Related standards

- ISO 817 - refrigerant classification (referenced for A1/A2/A2L/A3 groups)

- ISO 5149 - refrigerating safety (where refrigerant specifications are not covered by IEC 60335‑2‑40)

- IEC 60335‑2‑88 - humidifiers (appliances excluded from this standard)

Keywords: IEC 60335-2-40:2018, electrical heat pumps, air-conditioners, dehumidifiers, A2L refrigerants, flammable refrigerants, safety standard, refrigerant detection, transcritical systems, UV‑C.

Buy Documents

IEC 60335-2-40:2018 - Household and similar electrical appliances - Safety - Part 2-40: Particular requirements for electrical heat pumps, air-conditioners and dehumidifiers Released:1/26/2018

IEC 60335-2-40:2018 RLV - Household and similar electrical appliances - Safety - Part 2-40: Particular requirements for electrical heat pumps, air-conditioners and dehumidifiers Released:1/26/2018

IEC 60335-2-40:2018 - Household and similar electrical appliances - Safety - Part 2-40: Particular requirements for electrical heat pumps, air-conditioners and dehumidifiers Released:1/26/2018

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

IEC 60335-2-40:2018 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Household and similar electrical appliances - Safety - Part 2-40: Particular requirements for electrical heat pumps, air-conditioners and dehumidifiers". This standard covers: IEC 60335-2-40:2018 deals with the safety of electric heat pumps, including sanitary hot water heat pumps, air conditioners, and dehumidifiers incorporating motor-compressors and hydronic fan coils units, their maximum rated voltages being not more than 250 V for single phase appliances and 600 V for all other appliances. Partial units are within the scope of this International Standard. Appliances not intended for normal household use but which nevertheless may be a source of danger to the public, such as appliances intended to be used by laymen in shops, in light industry and on farms, are within the scope of this standard. The appliances referenced above may consist of one or more factory-made assemblies. If provided in more than one assembly, the separate assemblies are to be used together, and the requirements are based on the use of matched assemblies. This standard does not take into account refrigerants other than group A1, A2L, A2 and A3 as defined by ISO 817 classification, A2L refrigerants are limited to those of a molar mass of more than or equal to 42 kg/kmol based on WCF – Worst Case Formulation as specified in ISO 817. This standard specifies particular requirements for the use of flammable refrigerants. Unless specifications are covered by this standard, including the annexes, requirements for refrigerating safety are covered by ISO 5149. Supplementary heaters, or a provision for their separate installation, are within the scope of this standard, but only heaters which are designed as a part of the appliance package, the controls being incorporated in the appliance. For appliances intended to be used in vehicles or on board ships or aircraft, additional requirements may be necessary; for appliances subjected to pressure, additional requirements may be necessary; This standard does not apply to: humidifiers intended for use with heating and cooling equipment (IEC 60335-2-88); appliances designed exclusively for industrial processing or appliances intended to be used in locations where special conditions prevail, such as the presence of a corrosive or explosive atmosphere (dust, vapour or gas). This sixth edition cancels and replaces the fifth edition published in 2013 and its Amendment 1:2016. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - Clause 1 – limiting A2L refrigerants to those of a molar mass of more than or equal to 42 kg/kmol; - Clause 7 – added requirements for A2L refrigerants, - Clause 7 – added requirement for pre-charge pipe sets, detection systems, ventilation and the resulting charge; - Clause 7 – added requirements for UV-C systems; - Clause 7 – added requirements for transcritical refrigerating systems; - Subclause 19.7 – amended text to match the intention of the subclause; - Clause 21 – added requirements for transcritical refrigerating systems; - Subclause 22 – added requirements for A2L refrigerants; - Subclause 22– added detection systems; - Subclause 22 – added new requirements for enhanced tightness refrigerating systems; - Subclause 22 – added new requirements for UV-C; - Clause 23 – added new requirements for UV-C;Clause - Clause 24 – added requirements for transcritical refrigerating systems; - Subclause 24 – added requirements for detection systems and airflow; - Clause 32 added new requirements for UV-C; - Annex BB – revised to add surface temperatures; - Annex DD – added requirements for A2L refrigerants and amended requirements for flammable refrigerants to exempt A2L refrigerants; - Annex GG – added requirements for A2L refrigerants; - Annex GG.1 – amended Table GG.1 and related wording - Annex GG.7 – added requirement to test; - Annex GG.8 to GG.13 – new coverage for A2L refrigerants; - Annex HH – revised to take into account A2L refrigerants; - Annex JJ – new coverage of allowable opening of relays and similar components to prevent ignition of A2L r

IEC 60335-2-40:2018 deals with the safety of electric heat pumps, including sanitary hot water heat pumps, air conditioners, and dehumidifiers incorporating motor-compressors and hydronic fan coils units, their maximum rated voltages being not more than 250 V for single phase appliances and 600 V for all other appliances. Partial units are within the scope of this International Standard. Appliances not intended for normal household use but which nevertheless may be a source of danger to the public, such as appliances intended to be used by laymen in shops, in light industry and on farms, are within the scope of this standard. The appliances referenced above may consist of one or more factory-made assemblies. If provided in more than one assembly, the separate assemblies are to be used together, and the requirements are based on the use of matched assemblies. This standard does not take into account refrigerants other than group A1, A2L, A2 and A3 as defined by ISO 817 classification, A2L refrigerants are limited to those of a molar mass of more than or equal to 42 kg/kmol based on WCF – Worst Case Formulation as specified in ISO 817. This standard specifies particular requirements for the use of flammable refrigerants. Unless specifications are covered by this standard, including the annexes, requirements for refrigerating safety are covered by ISO 5149. Supplementary heaters, or a provision for their separate installation, are within the scope of this standard, but only heaters which are designed as a part of the appliance package, the controls being incorporated in the appliance. For appliances intended to be used in vehicles or on board ships or aircraft, additional requirements may be necessary; for appliances subjected to pressure, additional requirements may be necessary; This standard does not apply to: humidifiers intended for use with heating and cooling equipment (IEC 60335-2-88); appliances designed exclusively for industrial processing or appliances intended to be used in locations where special conditions prevail, such as the presence of a corrosive or explosive atmosphere (dust, vapour or gas). This sixth edition cancels and replaces the fifth edition published in 2013 and its Amendment 1:2016. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - Clause 1 – limiting A2L refrigerants to those of a molar mass of more than or equal to 42 kg/kmol; - Clause 7 – added requirements for A2L refrigerants, - Clause 7 – added requirement for pre-charge pipe sets, detection systems, ventilation and the resulting charge; - Clause 7 – added requirements for UV-C systems; - Clause 7 – added requirements for transcritical refrigerating systems; - Subclause 19.7 – amended text to match the intention of the subclause; - Clause 21 – added requirements for transcritical refrigerating systems; - Subclause 22 – added requirements for A2L refrigerants; - Subclause 22– added detection systems; - Subclause 22 – added new requirements for enhanced tightness refrigerating systems; - Subclause 22 – added new requirements for UV-C; - Clause 23 – added new requirements for UV-C;Clause - Clause 24 – added requirements for transcritical refrigerating systems; - Subclause 24 – added requirements for detection systems and airflow; - Clause 32 added new requirements for UV-C; - Annex BB – revised to add surface temperatures; - Annex DD – added requirements for A2L refrigerants and amended requirements for flammable refrigerants to exempt A2L refrigerants; - Annex GG – added requirements for A2L refrigerants; - Annex GG.1 – amended Table GG.1 and related wording - Annex GG.7 – added requirement to test; - Annex GG.8 to GG.13 – new coverage for A2L refrigerants; - Annex HH – revised to take into account A2L refrigerants; - Annex JJ – new coverage of allowable opening of relays and similar components to prevent ignition of A2L r

IEC 60335-2-40:2018 is classified under the following ICS (International Classification for Standards) categories: 23.120 - Ventilators. Fans. Air-conditioners. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60335-2-40:2018 has the following relationships with other standards: It is inter standard links to IEC 60335-2-40:2022, IEC 60335-2-40:2013/AMD1:2016, IEC 60335-2-40:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60335-2-40:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60335-2-40 ®

Edition 6.0 2018-01

INTERNATIONAL

STANDARD

colour

inside

Household and similar electrical appliances – Safety –

Part 2-40: Particular requirements for electrical heat pumps, air-conditioners and

dehumidifiers

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60335-2-40 ®

Edition 6.0 2018-01

INTERNATIONAL

STANDARD

colour

inside

Household and similar electrical appliances – Safety –

Part 2-40: Particular requirements for electrical heat pumps, air-conditioners

and dehumidifiers

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 23.120 ISBN 978-2-8322-5253-6

– 2 – IEC 60335-2-40:2018 IEC 2018

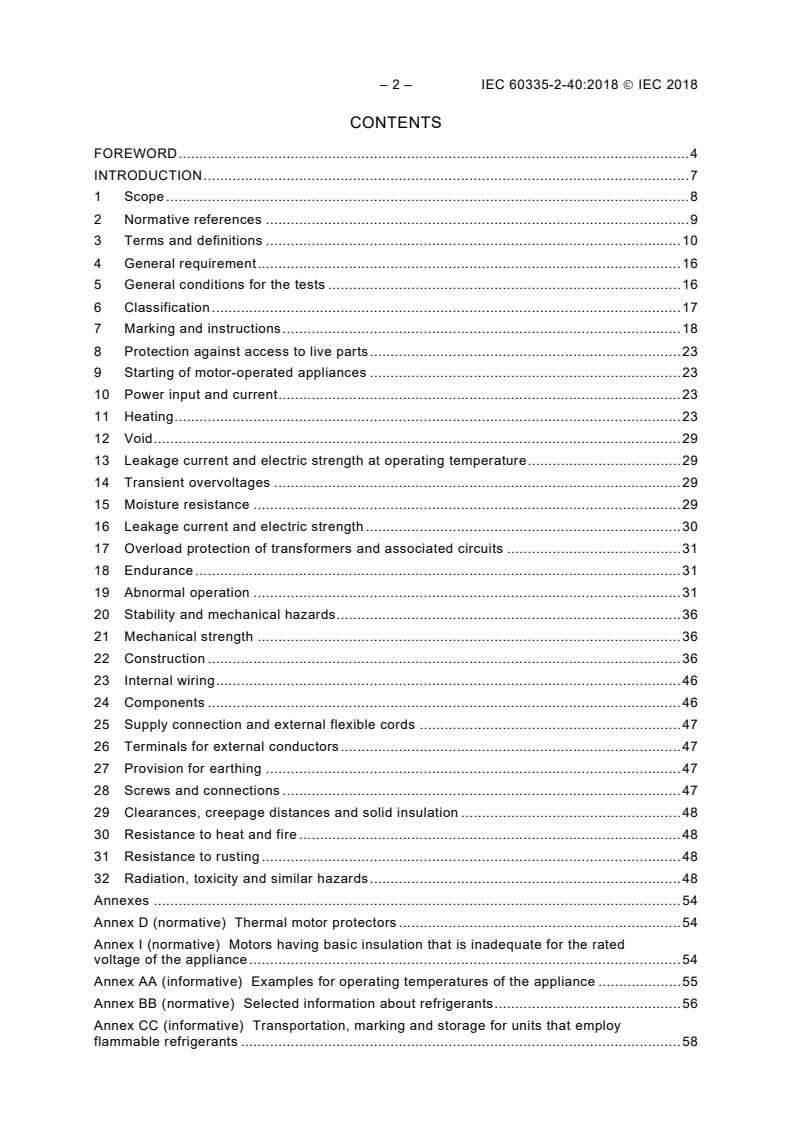

CONTENTS

FOREWORD . 4

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 9

3 Terms and definitions . 10

4 General requirement . 16

5 General conditions for the tests . 16

6 Classification . 17

7 Marking and instructions . 18

8 Protection against access to live parts . 23

9 Starting of motor-operated appliances . 23

10 Power input and current . 23

11 Heating . 23

12 Void . 29

13 Leakage current and electric strength at operating temperature . 29

14 Transient overvoltages . 29

15 Moisture resistance . 29

16 Leakage current and electric strength . 30

17 Overload protection of transformers and associated circuits . 31

18 Endurance . 31

19 Abnormal operation . 31

20 Stability and mechanical hazards . 36

21 Mechanical strength . 36

22 Construction . 36

23 Internal wiring . 46

24 Components . 46

25 Supply connection and external flexible cords . 47

26 Terminals for external conductors . 47

27 Provision for earthing . 47

28 Screws and connections . 47

29 Clearances, creepage distances and solid insulation . 48

30 Resistance to heat and fire . 48

31 Resistance to rusting . 48

32 Radiation, toxicity and similar hazards . 48

Annexes . 54

Annex D (normative) Thermal motor protectors . 54

Annex I (normative) Motors having basic insulation that is inadequate for the rated

voltage of the appliance . 54

Annex AA (informative) Examples for operating temperatures of the appliance . 55

Annex BB (normative) Selected information about refrigerants . 56

Annex CC (informative) Transportation, marking and storage for units that employ

flammable refrigerants . 58

Annex DD (normative) Requirements for operation, service and installation manuals of

appliances using flammable refrigerants . 59

Annex EE (normative) Pressure tests . 68

Annex FF (normative) Leak simulation tests . 71

Annex GG (normative) Charge limits, ventilation requirements and requirements for

secondary circuits . 73

Annex HH (informative) Competence of service personnel . 99

Annex II (Void) . 102

Annex JJ (normative) Allowable opening of relays and similar components to prevent

ignition of A2L refrigerants . 103

Annex KK (normative) Test method for hot surface ignition temperature for A2L . 105

Annex LL (normative) Refrigerant detection systems for A2L refrigerants . 109

Annex MM (normative) Refrigerant sensor location confirmation test . 111

Annex NN (normative) Flame arrest enclosure verification test for A2L refrigerants . 113

Annex OO (normative) UV radiation conditioning . 115

Bibliography . 116

Figure 101 – Example of label for field charged units . 50

Figure 102 – Arrangement for heating test of appliances with supplementary heater . 52

Figure 103 – Supply circuit for locked-rotor test of a motor of the single-phase type –

Revise as needed for three-phase test . 53

Figure GG.1 – Unventilated area. 95

Figure GG.2 – Mechanical ventilation . 96

Figure GG.3 – Isosceles triangle arrow test gauge . 96

Figure GG.4 – Measurement of vibration amplitude. 96

Figure GG.5 – Relevant heights h , h and h for calculation of A and m . 97

inst 0 rel min max

Figure GG.6 – Airflow direction . 98

Figure KK.1 – Front view of test apparatus labels . 105

Figure KK.2 – Test apparatus with dimensions . 106

Figure KK.3 – Top view of test apparatus . 107

Table 3 – Temperature limits . 27

Table 101 – UVC irradiance measurement location . 49

Table AA.1 – Examples for operating temperatures of the appliance . 55

Table BB.1 – Selected information about refrigerants. 56

Table DD.1 – Mandatory clauses in each manual . 59

Table GG.1 – Outline of Annex GG (informative). 74

Table GG.2 – Circulation airflow . 78

Table GG.3 – Appliance with packaging . 83

Table GG.4 – Appliance without packaging . 83

Table GG.5 – Minimum airflow . 94

– 4 – IEC 60335-2-40:2018 IEC 2018

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

HOUSEHOLD AND SIMILAR ELECTRICAL APPLIANCES – SAFETY –

Part 2-40: Particular requirements for electrical heat pumps,

air-conditioners and dehumidifiers

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60335-2-40 has been prepared by subcommittee 61D: Appliances

for air-conditioning for household and similar purposes, of IEC technical committee 61: Safety

of household and similar electrical appliances.

The text of this International Standard is based on the following documents:

FDIS Report on voting

61D/386/FDIS 61D/391/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This sixth edition cancels and replaces the fifth edition published in 2013 and its

Amendment 1:2016. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

– Clause 1 – limiting A2L refrigerants to those of a molar mass of more than or equal to

42 kg/kmol;

– Clause 7 – added requirements for A2L refrigerants,

– Clause 7 – added requirement for pre-charge pipe sets, detection systems, ventilation and

the resulting charge;

– Clause 7 – added requirements for UV-C systems;

– Clause 7 – added requirements for transcritical refrigerating systems;

– Subclause 19.7 – amended text to match the intention of the subclause;

– Clause 21 – added requirements for transcritical refrigerating systems;

– Subclause 22 – added requirements for A2L refrigerants;

– Subclause 22– added detection systems;

– Subclause 22 – added new requirements for enhanced tightness refrigerating systems;

– Subclause 22 – added new requirements for UV-C;

– Clause 23 – added new requirements for UV-C;Clause

– Clause 24 – added requirements for transcritical refrigerating systems;

– Subclause 24 – added requirements for detection systems and airflow;

– Clause 32 added new requirements for UV-C;

– Annex BB – revised to add surface temperatures;

– Annex DD – added requirements for A2L refrigerants and amended requirements for

flammable refrigerants to exempt A2L refrigerants;

– Annex GG – added requirements for A2L refrigerants;

– Annex GG.1 – amended Table GG.1 and related wording

– Annex GG.7 – added requirement to test;

– Annex GG.8 to GG.13 – new coverage for A2L refrigerants;

– Annex HH – revised to take into account A2L refrigerants;

– Annex JJ – new coverage of allowable opening of relays and similar components to

prevent ignition of A2L refrigerants;

– Annex KK – new coverage of test method for hot surface ignition temperature for A2L;

– Annex LL – new coverage of refrigerant detection systems for A2L Refrigerants;

– Annex MM – new coverage of refrigerant sensor location confirmation test;

– Annex NN – new coverage of flame arrest enclosure verification test for A2L refrigerants;

– Annex OO – new coverage of UV radiation conditioning

– Bibliography – added new references.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

This part 2-40 is to be used in conjunction with the latest edition of IEC 60335-1 and its

amendments. It was established on the basis of IEC 60335-1:2010, its Amendment 1:2013

and its Amendment 2:2016.

NOTE 1 When “Part 1” is mentioned in this standard, it refers to IEC 60335-1.

This part 2-40 supplements or modifies the corresponding clauses in IEC 60335-1, so as to

convert that publication into the IEC standard: Safety requirements for electrical heat pumps,

air-conditioners and dehumidifiers.

– 6 – IEC 60335-2-40:2018 IEC 2018

When a particular subclause of Part 1 is not mentioned in this part 2, that subclause applies

as far as is reasonable. When this standard states "addition", "modification" or "replacement",

the relevant text in Part 1 is to be adapted accordingly.

NOTE 2 The following numbering system is used:

• subclauses, tables and figures that are numbered starting from 101 are additional to those in Part 1;

• unless notes are in a new subclause or involve notes in Part 1, they are numbered starting from 101, including

those in a replaced clause or subclause;

• additional annexes are lettered AA, BB, etc.

NOTE 3 The following print types are used:

• requirements: in roman type;

• test specifications: in italic type;

• notes: in small roman type.

Words in bold in the text are defined in Clause 3. When a definition concerns an adjective, the adjective and

associated noun are also in bold.

The following differences exist in the countries indicated below:

• 6.1: Class 0I appliances are allowed (Japan).

• 11.8: The temperature of the wooden walls in the test casing is limited to 85 °C (Sweden).

A list of all parts of the IEC 60335 series, under the general title: Household and similar

electrical appliances – Safety, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

INTRODUCTION

It has been assumed in the drafting of this International Standard that the execution of its

provisions is entrusted to appropriately qualified and experienced persons.

This standard recognizes the internationally accepted level of protection against hazards such

as electrical, mechanical, thermal, fire and radiation of appliances when operated as in

normal use taking into account the instructions. It also covers abnormal situations that can be

expected in practice.

This standard takes into account the requirements of IEC 60364 as far as possible so that

there is compatibility with the wiring rules when the appliance is connected to the supply

mains. However, national wiring rules may differ.

If an appliance within the scope of this standard also incorporates functions that are covered

by another part 2 of IEC 60335, the relevant part 2 is applied to each function separately, as

far as is reasonable. If applicable, the influence of one function on the other is taken into

account.

When a part 2 standard does not include additional requirements to cover hazards dealt with

in Part 1, Part 1 applies.

NOTE 1 This means that the technical committees responsible for the part 2 standards have determined that it is

not necessary to specify particular requirements for the appliance in question over and above the general

requirements.

This standard is a product family standard dealing with the safety of appliances and takes

precedence over horizontal and generic standards covering the same subject.

NOTE 2 Horizontal and generic standards covering a hazard are not applicable since they have been taken into

consideration when developing the general and particular requirements for the IEC 60335 series of standards. For

example, in the case of temperature requirements for surfaces on many appliances, generic standards, such as

ISO 13732-1 for hot surfaces, are not applicable in addition to Part 1 or part 2 standards.

An appliance that complies with the text of this standard will not necessarily be considered to

comply with the safety principles of the standard if, when examined and tested, it is found to

have other features that impair the level of safety covered by these requirements.

An appliance employing materials or having forms of construction differing from those detailed

in the requirements of this standard may be examined and tested according to the intent of

the requirements and, if found to be substantially equivalent, may be considered to comply

with the standard.

– 8 – IEC 60335-2-40:2018 IEC 2018

HOUSEHOLD AND SIMILAR ELECTRICAL APPLIANCES – SAFETY –

Part 2-40: Particular requirements for electrical heat pumps,

air-conditioners and dehumidifiers

1 Scope

This clause of Part 1 is replaced by the following.

This part of IEC 60335 deals with the safety of electric heat pumps, including sanitary hot

water heat pumps, air conditioners, and dehumidifiers incorporating motor-compressors

and hydronic fan coils units, their maximum rated voltages being not more than 250 V for

single phase appliances and 600 V for all other appliances. Partial units are within the scope

of this International Standard.

Appliances not intended for normal household use but which nevertheless may be a source of

danger to the public, such as appliances intended to be used by laymen in shops, in light

industry and on farms, are within the scope of this standard.

The appliances referenced above may consist of one or more factory-made assemblies. If

provided in more than one assembly, the separate assemblies are to be used together, and

the requirements are based on the use of matched assemblies.

NOTE 101 A definition of ‘motor-compressor’ is given in IEC 60335-2-34, which includes the statement that the

term motor-compressor is used to designate either a hermetic motor-compressor or semi-hermetic motor-

compressor.

NOTE 102 Requirements for refrigerating safety are covered by ISO 5149-1, ISO 5149-2, and ISO 5149-3.

Requirements for containers intended for storage of the heated water included in sanitary hot water heat pumps

are, in addition, covered by IEC 60335-2-21.

This standard does not take into account refrigerants other than group A1, A2L, A2 and A3 as

defined by ISO 817 classification, A2L refrigerants are limited to those of a molar mass of

more than or equal to 42 kg/kmol based on WCF – Worst Case Formulation as specified in

ISO 817.

This standard specifies particular requirements for the use of flammable refrigerants. Unless

specifications are covered by this standard, including the annexes, requirements for

refrigerating safety are covered by ISO 5149.

The parts of ISO 5149 of particular concern to this standard are as follows:

• ISO 5149-1:2014, Refrigerating systems and heat pumps – Safety and environmental

requirements – Part 1: Definitions, classification and selection criteria.

• ISO 5149-2, Refrigerating systems and heat pumps – Safety and environmental

requirements – Part 2: Design, construction, testing, marking and documentation;

• ISO 5149-3:2014, Refrigerating systems and heat pumps – Safety and environmental

requirements – Part 3: Installation site.

Supplementary heaters, or a provision for their separate installation, are within the scope of

this standard, but only heaters which are designed as a part of the appliance package, the

controls being incorporated in the appliance.

NOTE 103 Attention is drawn to the fact that

• for appliances intended to be used in vehicles or on board ships or aircraft, additional requirements may be

necessary;

• for appliances subjected to pressure, additional requirements may be necessary;

• in many countries, additional requirements are specified, for example, by the national health authorities

responsible for the protection of labour and the national authorities responsible for storage, transportation,

building constructions and installations.

NOTE 104 This standard does not apply to

• humidifiers intended for use with heating and cooling equipment (IEC 60335-2-88);

• appliances designed exclusively for industrial processing;

• appliances intended to be used in locations where special conditions prevail, such as the presence of a

corrosive or explosive atmosphere (dust, vapour or gas).

2 Normative references

This clause of Part 1 is applicable except as follows.

Addition:

IEC 60068-2-52, Environmental testing – Part 2: Tests – Test Kb: Salt mist, cyclic (sodium,

chloride solution)

IEC 60079-14, Explosive atmospheres – Part 14: Electrical installations design, selection and

erection

IEC 60079-15:2010, Explosive atmospheres – Part 15: Equipment protection by type of

protection "n"

IEC 60335-2-34:2012, Household and similar electrical appliances – Safety – Part 2-34:

Particular requirements for motor-compressors

IEC 60335-2-51, Household and similar electrical appliances – Safety – Part 2-51: Particular

requirements for stationary circulation pumps for heating and service water installations

IEC 60730-2-6, Automatic electrical controls – Part 2-6: Particular requirements for automatic

electrical pressure sensing controls including mechanical requirements

IEC 61032, Protection of persons and equipment by enclosures – Probes for verification

IEC 62471:2006, Photobiological safety of lamps and lamp systems

ISO 817, Refrigerants – Designation and safety classification

ISO 1302, Geometrical Product Specifications (GPS) – Indication of surface texture in

technical product documentation

ISO 4892-2, Plastics – Methods of exposure to laboratory light sources – Part 2: Xenon-arc

lamps

ISO 4892-4, Plastics – Methods of exposure to laboratory light sources – Part 4: Open-flame

carbon-arc lamps

ISO 5149-1:2014, Refrigerating systems and heat pumps – Safety and environmental

requirements – Part 1: Definitions, classification and selection criteria

– 10 – IEC 60335-2-40:2018 IEC 2018

ISO 5149-2, Refrigerating systems and heat pumps – Safety and environmental requirements –

Part 2: Design, construction, testing, marking and documentation

ISO 5149-3:2014, Refrigerating systems and heat pumps – Safety and environmental

requirements – Part 3: Installation site

ISO 5151, Non-ducted air conditioners and heat pumps – Testing and rating for performance

ISO 7010:2011, Graphic symbols – Safety colours and safety signs – Registered safety signs

ISO 13253, Ducted air-conditioners and air-to-air heat pumps – Testing and rating for

performance

ISO 13256 (all parts), Water-source heat pumps – Testing and rating for performance

ISO 14903, Refrigerating systems and heat pumps – Qualification of tightness of components

and joints

ISO 15042, Multiple split-system air-conditioners and air-to-air heat pumps – Testing and

rating for performance

ASTM D4728-06:2012, Standard Test Method for Random Vibration Testing of Shipping

Containers

CAN/CSA-C22.2 No. 0.17, Evaluation of Properties of Polymeric Materials

UL 746A, Standard for Polymeric Materials – Short Term Property Evaluations

UL 746B, Standard for Polymeric Materials – Long Term Property Evaluations

3 Terms and definitions

This clause of Part 1 is applicable except as follows.

3.1.4 Addition:

Note 101 to entry: If the appliance comprises electrical accessories, including fans, the rated power input is

based upon the total maximum electrical power input with all accessories energized, when operating continuously

under the appropriate environmental conditions. If the heat pump can be operated in the heating or cooling mode,

the rated power input is based upon the input in the heating or in the cooling mode, whichever is the greater.

3.1.9 Replacement:

normal operation

conditions that apply when the appliance is mounted as in normal use and is operating under

the most severe operating conditions specified by the manufacturer

3.101

heat pump

appliance which takes up heat at a certain temperature and releases heat at a higher

temperature

Note 1 to entry: When operated to provide heat (e.g., for space heating or water heating), the appliance is said to

operate in the heating mode; when operated to remove heat (for example, for space cooling), it is said to operate in

the cooling mode.

Note 2 to entry: A heat pump can contain a combination of condensing unit or condenser unit and an

evaporating unit or evaporator unit and can be equipped to operate in a reverse cycle mode.

3.102

sanitary hot water heat pump

heat pump intended to transfer heat to water suitable for human consumption

3.103

air conditioner

encased assembly or assemblies designed as an appliance to provide delivery of conditioned

air to an enclosed space, room or zone

Note 1 to entry: It includes an electrically operated refrigerating system for cooling and possibly dehumidifying

the air.

Note 2 to entry: It may have means for heating, circulating, cleaning and humidifying the air.

Note 3 to entry: An air conditioner can contain a combination of condensing unit or condenser unit and an

evaporating unit or evaporator unit.

3.104

dehumidifier

encased assembly designed to remove moisture from its surrounding atmosphere

Note 1 to entry: It includes an electrically operated refrigerating system and the means to circulate air. It also

includes a drain arrangement for collecting and storing and/or disposing of the condensate.

3.108

wet-bulb temperature

WB

temperature indicated when the temperature-sensitive element in a wetted wick has reached a

state of constant temperature (evaporative equilibrium)

3.109

dry-bulb temperature

DB

temperature indicated by a dry, temperature-sensitive element shielded from the effects of

radiation

3.110

evaporator

heat exchanger in which refrigerant liquid is vaporized by absorption of heat

3.111

heat exchanger

device specifically designed to transfer heat between two physically separated fluids

3.112

indoor heat exchanger

heat exchanger designed to transfer heat to the indoor parts of the building or to the indoor

hot water supplies (e.g. sanitary water) or to remove heat therefrom

3.113

outdoor heat exchanger

heat exchanger designed to remove or release heat from the heat source (for example,

ground water, outdoor air, exhaust air, water or brine)

3.114

supplementary heater

electric heater provided as part of the appliance to supplement or replace the output of the

refrigerant circuit of the appliance by operation in conjunction with, or instead of, the

refrigerating circuit

– 12 – IEC 60335-2-40:2018 IEC 2018

3.115

pressure-limiting device

mechanism that automatically responds to a predetermined pressure by stopping the

operation of the pressure-imposing element

3.116

pressure-relief device

pressure actuated valve or rupture member which functions to relieve excessive pressure

automatically

3.117

appliances accessible to the general public

appliances intended to be located in residential buildings or in commercial buildings

3.118

appliances not accessible to the general public

appliances which are located either in a secured location with restricted access (e.g. machine

rooms, rooftop and the like) or at a level not less than 2,5 m or in secured rooftop areas

3.119

hydronic fan coil unit

factory-made assembly which provides the function of forced circulation of air for heating

and/or cooling, which may also include the function of dehumidification and/or filtering of air,

but which does not include the source of cooling or heating

Note 1 to entry: Hydronic fan coil units can include provision for electric resistance heating. Heat exchanger

coils are intended for hydronic heating and cooling only.

3.120

flammable refrigerant

refrigerant classified as class A2L, A2 or A3 according to ISO 817

3.121

refrigerating system

combination of interconnected refrigerant containing parts constituting one closed refrigerant

circuit in which refrigerant is circulated for the purpose of extracting heat at the low

temperature side to reject heat at the high temperature side by changing the state of the

refrigerant

3.122

maximum allowable pressure

limit to the refrigerating system operating pressure, generally the maximum pressure for

which the equipment is designed, as specified by the manufacturer

Note 1 to entry: Maximum allowable pressure constitutes a limit to the operating pressure whether the

equipment is working or not, see Clause 21.

3.123

low-pressure side

part(s) of a refrigerating system operating at the evaporator pressure

3.124

high-pressure side

part(s) of a refrigerating system operating at the condenser pressure

3.125

service port

means to access the refrigerant in a refrigerating system for the purpose of charging or

servicing the system, typically a valve, tube extension or entry location

3.126

factory sealed single package unit

factory assembly of components of refrigerating system fixed on a common mounting to

form a discrete unit in which all refrigerating system parts have been sealed tight by

welding, brazing or a similar permanent connection during the manufacturing process

3.127

pre-charged pipe sets

interconnecting refrigerant lines which are supplied with the unit and supplied with a

refrigerant charge for the purpose of completing the refrigerating system in the field for

appliances that are made up of more than one subassembly and are assembled in the field to

complete the refrigerating system

3.128

condenser

heat exchanger in which refrigerant vapour is condensed by removal of heat

3.129

condensing unit

factory-made assembly that includes one or more motor-compressors, condenser in cooling

mode and motor-driven fan, blower or pump to circulate the heat transfer fluid through the

condenser with associated operational controls in addition to the necessary wiring

Note 1 to entry: These units are intended for field connection to an evaporator unit. A condensing unit can also

be equipped to operate in the reverse cycle mode. A condensing unit can include expansion device(s).

3.130

condenser unit

factory-made assembly that includes one or more condensers in cooling mode and motor-

driven fan, blower or pump to circulate the heat transfer fluid through the condenser with

associated operational controls in addition to the necessary wiring

Note 1 to entry: These units are intended for field connection to an evaporating unit. A condenser unit can also

be equipped to operate in the reverse cycle mode.

Note 2 to entry: A condenser unit does not include a motor compressor or expansion device.

3.131

evaporating unit

factory-made assembly that includes one or more motor-compressors, evaporator in cooling

mode, expansion device(s), and motor-driven fan, blower or pump to circulate fluid through

the evaporator with associated operational controls in addition to the necessary wiring

Note 1 to entry: These units are intended for field connection to a condenser unit. An evaporating unit can also

be equipped to operate in the reverse cycle mode and can include provision for electric resistance heating or

similar sources of auxiliary heat.

3.132

evaporator unit

factory-made assembly that includes one or more evaporators in cooling mode, and may

include a motor-driven fan, blower or pump to circulate fluid through the evaporator with

associated operational controls in addition to the necessary wiring

Note 1 to entry: These units are intended for field connection to a condensing unit. An evaporator unit can also

be equipped to operate in the reverse cycle mode and can include provision for electric resistance heating or

similar sources of auxiliary heat. An evaporator unit can include expansion device(s).

Note 2 to entry: An evaporator unit does not include a motor compressor.

– 14 – IEC 60335-2-40:2018 IEC 2018

3.133

partial unit

condensing unit, evaporating unit, condenser unit, or evaporator unit which are part of a

total assembly of a heat pump, air-conditioner, or sanitary hot water heat pumps where not

all assemblies to create the complete refrigerating system are specified by the manufacturer

Note 1 to entry: Partial units are evaluated for safety as stand-alone.

3.134

installed height

h

inst

height of the bottom of the appliance relative to the floor of the room after installation

Note 1 to entry: The installed height is given in metres.

3.135

release offset

h

rel

distance from the bottom of the appliance to an opening where refrigerant can leave the

appliance in the event of a refrigerant leak

Note 1 to entry: The release offset is given in metres.

3.136

refrigerant charge

m

c

actual refrigerant charge of a single refrigerating system

Note 1 to entry: The refrigerant charge is expressed in kg.

3.137

maximum refrigerant charge

m

max

maximum refrigerant charge for a single refrigerating system as result from a calculation

for room area or similar

Note 1 to entry: The maximum refrigerant charge is expressed in kg.

3.138

refrigerant detection system

sensing system which responds to a pre-set concentration of refrigerant in the environment

Note 1 to entry: A refrigerant detection system may have multiple sensing elements.

3.139

auto ignition temperature

AIT

lowest temperature at or above which a chemical can spontaneously ignite in a normal

atmosphere, without an external source of ignition, such as a flame or spark

[SOURCE: ISO 5149-1:2014, definition 3.7.7]

3.140

hot surface ignition temperature

HSIT

highest temperature at which a refrigerant does not ignite when tested in accordance with

Annex KK

3.141

A2L refrigerant

refrigerant classed as A2L according to ISO 817

3.142

lower flammability limit

LFL

lower flammability limit according to ISO 817

3.143

enhanced tightness refrigerating system

refrigerating system in which the indoor units are designed and fabricated to ensure a high

level of confidence that large refrigerant leak rates will not occur in normal and abnormal

operation

3.144

refrigerant distribution assembly

separate refrigerant assembly which is installed in the interconnecting refrigerant lines for the

purpose of distributing refrigerant flow to one or more indoor units

3.145

potential ignition source

PIS

hot surfaces, flames and current carrying devices which can be the source of arcing or

sparking

Note 1 to entry: Examples of potential ignition sources are UV lights, electric heaters, pilot flames, brushed

motors and similar devices.

3.146

circulation airflow

mechanically induced airflow movement within the space or duct connected spaces

3.147

ultraviolet radiation

optical radiation for which the wavelengths are shorter than those for visible radiation

Note 1 to entry: For ultraviolet (UV) radiation, the range between 100 nm and 400 nm is commonly subdivided

into: UV-A, from 315 nm to 400 nm; UV-B, from 280 nm to 315 nm; and UV-C, from 100 nm to 280 nm.

[SOURCE: IEC 60050-845:1987, 845-01-05]

3.148

optica

...

IEC 60335-2-40 ®

Edition 6.0 2018-01

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Household and similar electrical appliances – Safety –

Part 2-40: Particular requirements for electrical heat pumps, air-conditioners

and dehumidifiers

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60335-2-40 ®

Edition 6.0 2018-01

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Household and similar electrical appliances – Safety –

Part 2-40: Particular requirements for electrical heat pumps, air-conditioners

and dehumidifiers

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 23.120 ISBN 978-2-8322-5333-5

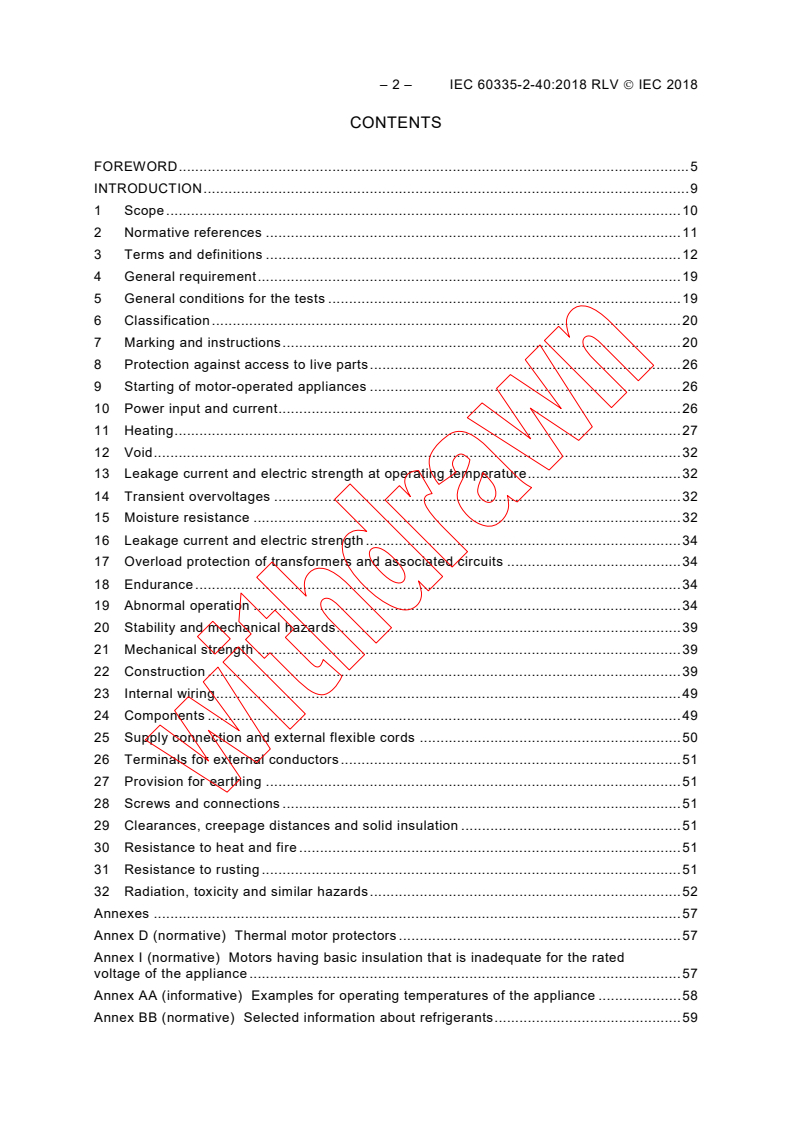

– 2 – IEC 60335-2-40:2018 RLV IEC 2018

CONTENTS

FOREWORD . 5

INTRODUCTION . 9

1 Scope . 10

2 Normative references . 11

3 Terms and definitions . 12

4 General requirement . 19

5 General conditions for the tests . 19

6 Classification . 20

7 Marking and instructions . 20

8 Protection against access to live parts . 26

9 Starting of motor-operated appliances . 26

10 Power input and current . 26

11 Heating . 27

12 Void . 32

13 Leakage current and electric strength at operating temperature . 32

14 Transient overvoltages . 32

15 Moisture resistance . 32

16 Leakage current and electric strength . 34

17 Overload protection of transformers and associated circuits . 34

18 Endurance . 34

19 Abnormal operation . 34

20 Stability and mechanical hazards . 39

21 Mechanical strength . 39

22 Construction . 39

23 Internal wiring . 49

24 Components . 49

25 Supply connection and external flexible cords . 50

26 Terminals for external conductors . 51

27 Provision for earthing . 51

28 Screws and connections . 51

29 Clearances, creepage distances and solid insulation . 51

30 Resistance to heat and fire . 51

31 Resistance to rusting . 51

32 Radiation, toxicity and similar hazards . 52

Annexes . 57

Annex D (normative) Thermal motor protectors . 57

Annex I (normative) Motors having basic insulation that is inadequate for the rated

voltage of the appliance . 57

Annex AA (informative) Examples for operating temperatures of the appliance . 58

Annex BB (normative) Selected information about refrigerants . 59

Annex CC (informative) Transportation, marking and storage for units that employ

flammable refrigerants . 62

Annex DD (normative) Instruction manual for servicing refrigerant containing

appliances Requirements for operation, service and installation manuals

of appliances using flammable refrigerants . 63

Annex EE (normative) Pressure tests . 72

Annex FF (normative) Leak simulation tests . 75

Annex GG (normative) Charge limits, ventilation requirements and requirements for

secondary circuits . 77

Annex HH (informative) Competence of service personnel . 106

Annex II (Void) . 109

Annex JJ (normative) Allowable opening of relays and similar components to prevent

ignition of A2L refrigerants . 110

Annex KK (normative) Test method for hot surface ignition temperature for A2L . 112

Annex LL (normative) Refrigerant detection systems for A2L refrigerants . 116

Annex MM (normative) Refrigerant sensor location confirmation test . 118

Annex NN (normative) Flame arrest enclosure verification test for A2L refrigerants . 120

Annex OO (normative) UV radiation conditioning . 122

Bibliography . 123

Figure 101 – Example of label for field charged units . 53

Figure 101 102 – Arrangement for heating test of appliances with supplementary

heater . 55

Figure 102 103 – Supply circuit for locked-rotor test of a motor of the single-phase

type – Revise as needed for three-phase test . 56

Figure GG.1 – Unventilated area. 102

Figure GG.2 – Mechanical ventilation . 103

Figure GG.3 – Isosceles triangle arrow test gauge . 103

Figure GG.4 – Measurement of vibration amplitude. 103

Figure GG.5 – Relevant heights h , h and h for calculation of A and m . 104

inst 0 rel min max

Figure GG.6 – Airflow direction . 105

Figure KK.1 – Front view of test apparatus labels . 112

Figure KK.2 – Test apparatus with dimensions . 113

Figure KK.3 – Top view of test apparatus . 114

Table – Minimum room area (m ) (see Note 2 of Clause GG.2) .

Table – Maximum charge (kg) (see Note 2 of Clause GG.2) .

Table – Mass of refrigerants .

Table 3 – Temperature limits . 30

Table 101 – UVC irradiance measurement location . 52

Table AA.1 – Examples for operating temperatures of the appliance . 58

Table BB.1 – Selected information about refrigerants. 59

Table DD.1 – Mandatory clauses in each manual . 63

Table GG.1 – Outline of Annex GG (informative). 78

Table GG.2 – Circulation airflow . 83

– 4 – IEC 60335-2-40:2018 RLV IEC 2018

Table GG.3 – Appliance with packaging . 88

Table GG.4 – Appliance without packaging . 89

Table GG.5 – Minimum airflow . 101

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

HOUSEHOLD AND SIMILAR ELECTRICAL APPLIANCES – SAFETY –

Part 2-40: Particular requirements for electrical heat pumps,

air-conditioners and dehumidifiers

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

– 6 – IEC 60335-2-40:2018 RLV IEC 2018

International Standard IEC 60335-2-40 has been prepared by subcommittee 61D: Appliances

for air-conditioning for household and similar purposes, of IEC technical committee 61: Safety

of household and similar electrical appliances.

The text of this International Standard is based on the following documents:

FDIS Report on voting

61D/386/FDIS 61D/391/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This sixth edition cancels and replaces the fifth edition published in 2013 and its

Amendment 1:2016. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

– Clause 1 – limiting A2L refrigerants to those of a molar mass of more than or equal to

42 kg/kmol;

– Clause 7 – added requirements for A2L refrigerants,

– Clause 7 – added requirement for pre-charge pipe sets, detection systems, ventilation and

the resulting charge;

– Clause 7 – added requirements for UV-C systems;

– Clause 7 – added requirements for transcritical refrigerating systems;

– Subclause 19.7 – amended text to match the intention of the subclause;

– Clause 21 – added requirements for transcritical refrigerating systems;

– Subclause 22 – added requirements for A2L refrigerants;

– Subclause 22– added detection systems;

– Subclause 22 – added new requirements for enhanced tightness refrigerating systems;

– Subclause 22 – added new requirements for UV-C;

– Clause 23 – added new requirements for UV-C;Clause

– Clause 24 – added requirements for transcritical refrigerating systems;

– Subclause 24 – added requirements for detection systems and airflow;

– Clause 32 added new requirements for UV-C;

– Annex BB – revised to add surface temperatures;

– Annex DD – added requirements for A2L refrigerants and amended requirements for

flammable refrigerants to exempt A2L refrigerants;

– Annex GG – added requirements for A2L refrigerants;

– Annex GG.1 – amended Table GG.1 and related wording

– Annex GG.7 – added requirement to test;

– Annex GG.8 to GG.13 – new coverage for A2L refrigerants;

– Annex HH – revised to take into account A2L refrigerants;

– Annex JJ – new coverage of allowable opening of relays and similar components to

prevent ignition of A2L refrigerants;

– Annex KK – new coverage of test method for hot surface ignition temperature for A2L;

– Annex LL – new coverage of refrigerant detection systems for A2L Refrigerants;

– Annex MM – new coverage of refrigerant sensor location confirmation test;

– Annex NN – new coverage of flame arrest enclosure verification test for A2L refrigerants;

– Annex OO – new coverage of UV radiation conditioning

– Bibliography – added new references.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

This part 2-40 is to be used in conjunction with the latest edition of IEC 60335-1 and its

amendments. It was established on the basis of IEC 60335-1:2010, its Amendment 1:2013

and its Amendment 2:2016.

NOTE 1 When “Part 1” is mentioned in this standard, it refers to IEC 60335-1.

This part 2-40 supplements or modifies the corresponding clauses in IEC 60335-1, so as to

convert that publication into the IEC standard: Safety requirements for electrical heat pumps,

air-conditioners and dehumidifiers.

When a particular subclause of Part 1 is not mentioned in this part 2, that subclause applies

as far as is reasonable. When this standard states "addition", "modification" or "replacement",

the relevant text in Part 1 is to be adapted accordingly.

NOTE 2 The following numbering system is used:

• subclauses, tables and figures that are numbered starting from 101 are additional to those in Part 1;

• unless notes are in a new subclause or involve notes in Part 1, they are numbered starting from 101, including

those in a replaced clause or subclause;

• additional annexes are lettered AA, BB, etc.

NOTE 3 The following print types are used:

• requirements: in roman type;

• test specifications: in italic type;

• notes: in small roman type.

Words in bold in the text are defined in Clause 3. When a definition concerns an adjective, the adjective and

associated noun are also in bold.

The following differences exist in the countries indicated below:

• 6.1: Class 0I appliances are allowed (Japan).

• 11.8: The temperature of the wooden walls in the test casing is limited to 85 °C (Sweden).

A list of all parts of the IEC 60335 series, under the general title: Household and similar

electrical appliances – Safety, can be found on the IEC website.

– 8 – IEC 60335-2-40:2018 RLV IEC 2018

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or